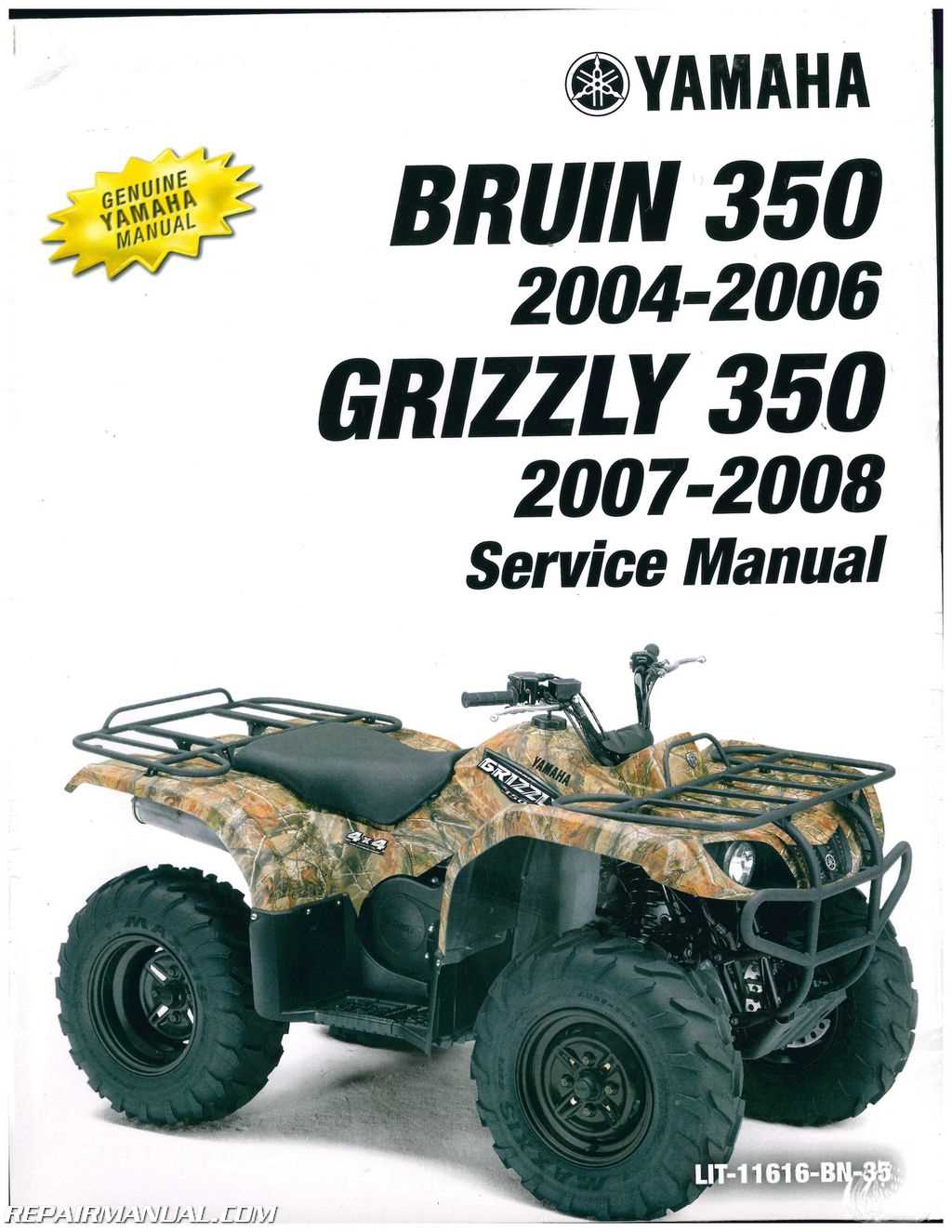

Comprehensive Repair Guide for the 2007 Yamaha Grizzly 350

When it comes to ensuring optimal performance of your all-terrain vehicle, having access to a comprehensive resource is invaluable. Such a guide provides essential insights into various aspects of upkeep, troubleshooting, and enhancement, catering to both novice and experienced riders. Whether you’re looking to conduct routine checks or tackle more complex issues, understanding the intricacies of your machine is crucial for longevity and efficiency.

In this section, we delve into the intricacies of maintaining a specific model renowned for its durability and versatility. We will explore common challenges owners face and offer solutions that empower users to take charge of their vehicle’s performance. With the right information at your fingertips, you can confidently navigate repairs and upgrades, ensuring your ride remains in peak condition.

By familiarizing yourself with vital maintenance practices, you not only extend the life of your machine but also enhance your riding experience. With a wealth of practical tips and insights, this guide aims to equip you with the knowledge needed to keep your off-road companion in prime condition. Embrace the adventure that lies ahead, armed with the expertise to tackle any challenge that comes your way.

Overview of the 2007 Yamaha Grizzly 350

This segment provides a comprehensive understanding of a popular all-terrain vehicle, renowned for its ruggedness and versatility. Designed to tackle various terrains, it is a favorite among outdoor enthusiasts who seek reliability and performance in challenging environments.

Key Features

The vehicle boasts a powerful engine, delivering impressive torque and acceleration. Its robust suspension system enhances stability, making it suitable for both recreational riding and heavy-duty tasks. With a user-friendly design, it appeals to both novice and experienced riders alike.

Performance and Handling

Equipped with advanced technology, this model ensures excellent maneuverability. The braking system provides responsive stopping power, while the overall build guarantees durability. Riders can expect a smooth experience whether navigating trails or transporting goods.

Common Issues with the Grizzly 350

All-terrain vehicles, while robust and reliable, can encounter a variety of challenges over time. Understanding these potential problems is essential for maintaining optimal performance and ensuring longevity. Below are some frequent concerns that users may face with this model.

- Starting Difficulties:

Issues with ignition can stem from various components, including:

- Weak battery

- Faulty starter motor

- Corroded electrical connections

- Overheating:

Excessive heat can lead to engine damage, often caused by:

- Low coolant levels

- Clogged radiator

- Faulty thermostat

- Transmission Issues:

Shifting difficulties can arise due to:

- Low fluid levels

- Worn out gears

- Faulty shift cable

- Brake Problems:

Inadequate braking performance may result from:

- Worn brake pads

- Leaking brake fluid

- Damaged rotors

Regular inspections and timely maintenance can help mitigate these issues, ensuring a smoother riding experience. Being proactive about repairs can save time and money in the long run.

Essential Tools for Repairs

When tackling maintenance tasks on your all-terrain vehicle, having the right set of instruments is crucial for ensuring efficiency and precision. A well-equipped workspace not only streamlines the process but also enhances the quality of the outcomes. Below is a compilation of vital tools that every enthusiast should consider for effective service and upkeep.

Basic Hand Tools

Starting with the fundamentals, a selection of hand tools is indispensable. This includes a variety of wrenches, screwdrivers, and pliers. These items enable you to tackle most fasteners and components easily. A torque wrench is particularly important for applying the correct amount of force to bolts, preventing damage and ensuring reliability.

Specialized Equipment

In addition to basic hand tools, having specialized equipment can greatly facilitate more complex tasks. A mechanic’s toolset often includes sockets, extensions, and ratchets, which are essential for reaching difficult areas. A multimeter is invaluable for diagnosing electrical issues, while a jack and stands are necessary for safely lifting the vehicle during inspection or repair. Investing in these tools can save time and prevent frustration during maintenance projects.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your all-terrain vehicle. Following a structured approach to maintenance can help prevent issues and enhance the overall riding experience. This section outlines a series of practical steps to keep your vehicle in top condition.

1. Routine Checks

Start with frequent inspections to identify any signs of wear or damage. Examine the tires for proper inflation and tread depth, and check the brakes for responsiveness. Additionally, inspect the lights and signals to ensure they are functioning correctly.

2. Fluid Maintenance

Maintaining proper fluid levels is critical for engine health. Regularly check the oil level and replace it according to the manufacturer’s recommendations. Similarly, monitor the coolant and transmission fluid levels, topping off as needed. Always use the specified fluids to maintain performance.

Note: Keeping a detailed log of maintenance activities can help track what has been done and when future services are due.

By adhering to these outlined steps, you will enhance the reliability and efficiency of your all-terrain vehicle, ensuring it remains ready for any adventure.

Engine Troubleshooting Tips

When experiencing issues with your vehicle’s powertrain, a systematic approach to diagnosis is essential. Identifying symptoms early can save time and prevent further damage. Below are some practical strategies to assist in diagnosing engine problems effectively.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Hard starting | Weak battery or faulty starter | Check battery charge and connections; test starter functionality. |

| Engine stalling | Fuel supply issues | Inspect fuel lines and filter; ensure the fuel pump is operational. |

| Unusual noises | Loose components or worn parts | Conduct a visual inspection; tighten or replace as needed. |

| Poor acceleration | Clogged air filter or exhaust | Clean or replace air filter; check exhaust for blockages. |

| Overheating | Coolant leaks or low fluid levels | Examine hoses and radiator; top off or repair coolant system. |

Utilizing these guidelines can streamline the diagnostic process, allowing for efficient repairs and maintenance. Always remember to consult specific guidelines tailored to your vehicle for optimal results.

Electrical System Diagnostics

This section focuses on the evaluation and troubleshooting of the electrical components within the vehicle. Proper functioning of the electrical system is crucial for overall performance, ensuring that all components operate effectively. By identifying issues early, you can avoid more significant problems and enhance the longevity of the machine.

Common Electrical Issues

- Battery failure

- Faulty wiring connections

- Defective switches

- Malfunctioning fuses

- Inoperative lights

Diagnostic Steps

- Inspect the battery for charge and corrosion.

- Check all wiring for signs of damage or loose connections.

- Test switches with a multimeter to ensure proper operation.

- Examine fuses and replace any that are blown.

- Verify that all lights function correctly and replace bulbs as needed.

Following these diagnostic steps can help pinpoint the source of electrical issues, allowing for timely repairs and ensuring reliable operation of the vehicle.

Suspension and Steering Adjustments

Proper maintenance of the suspension and steering systems is crucial for optimal performance and rider comfort. Adjustments in these areas can enhance stability, handling, and overall safety. Regular checks and calibrations ensure that your vehicle responds accurately to the terrain and riding conditions.

When considering adjustments, pay attention to the following components:

- Shock Absorbers: Ensure they are set to the appropriate preload for your weight and riding style.

- Front Forks: Adjust the compression and rebound settings to achieve the desired ride quality.

- Steering Alignment: Confirm that the wheels are aligned to prevent uneven tire wear and improve handling.

- Stabilizer Links: Check for wear and ensure they are properly tightened to maintain stability.

Follow these steps to make effective adjustments:

- Inspect all components for wear and damage before making changes.

- Adjust the preload on the shocks according to your weight and riding preferences.

- Set the compression and rebound damping on the front forks for improved handling.

- Check the steering alignment and adjust if necessary using proper tools.

- Test ride the vehicle to ensure the adjustments meet your expectations.

Regular adjustments will lead to a smoother ride and better control, ultimately enhancing your overall riding experience.

Brake System Inspection Guide

Ensuring the optimal performance of your vehicle’s braking mechanism is crucial for safety and reliability. This section provides a comprehensive overview of how to effectively assess the brake system, identifying potential issues and maintaining peak functionality.

Visual Inspection

Start with a thorough visual examination of the brake components. Look for any signs of wear, corrosion, or damage. Check the brake pads for thickness; they should not be worn down excessively. Inspect the rotors for scoring or uneven surfaces, which may indicate underlying problems. Pay special attention to the brake lines, ensuring there are no leaks or cracks that could compromise performance.

Functional Testing

After the visual check, it’s important to conduct a functional test. Engage the brake pedal and observe the response. The pedal should feel firm and responsive. If it sinks to the floor or feels spongy, there may be air in the hydraulic system or low brake fluid levels. Always ensure the vehicle is on a flat surface and securely positioned before performing this test. Regular checks will help maintain the effectiveness of the braking system and enhance overall safety.

Fluid Change Recommendations

Regular maintenance of various fluids is essential for optimal performance and longevity of your all-terrain vehicle. Ensuring that each fluid is replaced at the appropriate intervals helps prevent wear and tear on critical components, enhances efficiency, and contributes to overall safety. This section provides guidance on which fluids should be changed and the recommended frequencies for each type.

| Fluid Type | Recommended Change Interval | Notes |

|---|---|---|

| Engine Oil | Every 600 miles or every season | Use high-quality oil for better protection. |

| Transmission Fluid | Every 1,200 miles | Check for discoloration or burnt smell. |

| Coolant | Every 2 years | Ensure proper mixture to prevent overheating. |

| Brake Fluid | Every 2 years | Inspect for moisture contamination. |

| Fuel Filter | Every 1,500 miles | Replace for better fuel efficiency. |

Following these recommendations will help maintain the functionality of your vehicle and prevent potential issues in the future. Always refer to your owner’s guidelines for specific details related to your model.

Upgrading Your Grizzly’s Performance

Enhancing the capabilities of your all-terrain vehicle can significantly improve your riding experience, making it more enjoyable and efficient. By focusing on various aspects such as engine performance, suspension upgrades, and tire selection, you can achieve a noticeable boost in power and handling. This section will guide you through practical modifications that elevate your machine’s performance while ensuring reliability.

Engine Modifications

One of the most effective ways to increase power is by upgrading the engine components. Consider installing a high-performance air filter and an aftermarket exhaust system. These modifications can improve airflow and reduce back pressure, resulting in enhanced acceleration and throttle response. Additionally, tuning the fuel injection system can optimize fuel delivery for increased efficiency and power.

Suspension Enhancements

Improving your vehicle’s suspension system is crucial for better handling and comfort, especially when traversing rough terrain. Upgrading to adjustable shocks can allow for fine-tuning based on your riding style and the conditions you encounter. Stiffer springs can also help maintain stability under load, improving cornering and overall ride quality.

Tire Selection

The right tires play a significant role in performance. Choosing high-traction tires designed for specific terrain types can enhance grip and control. Whether you’re navigating muddy trails or rocky paths, selecting tires that match your riding environment can drastically improve your machine’s capabilities.

Regular Maintenance

Lastly, regular maintenance cannot be overlooked. Keeping your vehicle in top condition with routine checks on fluids, filters, and spark plugs will ensure that all upgrades perform optimally. Regular maintenance not only prolongs the life of your machine but also maximizes the benefits of any performance enhancements you’ve made.

Safety Practices During Repairs

Ensuring safety while conducting maintenance on machinery is crucial to prevent accidents and injuries. Adopting a careful approach not only protects the individual performing the work but also extends the lifespan of the equipment. Following established safety protocols can significantly reduce the risk of mishaps in the workshop.

Preparation and Equipment

Before beginning any maintenance tasks, it is essential to gather all necessary tools and materials. Wearing appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, minimizes exposure to hazards. Additionally, ensure that the workspace is clean and well-lit, and that any flammable materials are stored safely away from potential ignition sources.

Working Procedures

Always consult relevant documentation to familiarize yourself with the specific components being serviced. When handling heavy parts, use proper lifting techniques or tools designed for the task. Avoid wearing loose clothing that may get caught in moving parts, and keep your work area organized to prevent tripping hazards. Finally, remain focused and avoid distractions to maintain a high level of attention throughout the process.

Finding Replacement Parts and Accessories

When it comes to maintaining and enhancing your all-terrain vehicle, locating the right components and accessories is essential. Whether you are looking to replace worn-out parts or upgrade your machine for better performance, understanding where to source these items can save you time and money. This section will guide you through various avenues to explore for obtaining quality replacements and additional gear.

Online Marketplaces

One of the most convenient ways to find components is through online marketplaces. Websites specializing in vehicle parts often provide extensive catalogs, allowing you to compare prices and features. Make sure to check seller ratings and reviews to ensure the reliability of the components. Many platforms also offer warranties, which can provide peace of mind when making a purchase.

Local Dealers and Specialty Shops

Visiting local dealers and specialty shops can also be beneficial. These establishments often have knowledgeable staff who can help you find the right parts and provide valuable advice. Additionally, local shops may carry aftermarket accessories that can enhance your vehicle’s capabilities. Building a relationship with these businesses can lead to better service and access to exclusive products.