Comprehensive Repair Guide for 2008 Yamaha R6

Maintaining a high-performance two-wheeled vehicle requires a thorough understanding of its components and systems. This guide aims to provide essential insights into keeping your machine in optimal condition. Whether you’re a seasoned enthusiast or a newcomer to the world of biking, knowing how to effectively care for your vehicle is crucial for enhancing its longevity and performance.

Every motorcycle has unique features that demand specific attention and care. From engine mechanics to electrical systems, having access to a detailed resource can significantly simplify the upkeep process. By following best practices, riders can ensure their machines operate smoothly and reliably, allowing for enjoyable rides without unexpected interruptions.

In this guide, you’ll find step-by-step instructions and useful tips that cover a range of maintenance tasks. Understanding these processes not only empowers you as a rider but also fosters a deeper connection with your vehicle. Equip yourself with the knowledge to handle routine inspections, troubleshooting, and repairs, ensuring your journey remains exhilarating.

2008 Yamaha R6 Maintenance Guide

Ensuring the longevity and optimal performance of a high-performance motorcycle requires diligent upkeep and regular attention to key components. This guide outlines essential practices for maintaining your vehicle, allowing for an enjoyable riding experience while minimizing the risk of unexpected issues.

Key aspects of routine maintenance include:

- Fluid Checks: Regularly inspect and replace engine oil, coolant, and brake fluid to keep systems running smoothly.

- Tire Maintenance: Monitor tire pressure and tread depth to ensure proper handling and safety on the road.

- Brake Inspection: Periodically check brake pads and rotors for wear to maintain effective stopping power.

- Chain and Sprocket Care: Clean and lubricate the chain to prevent wear and enhance performance.

Following a systematic approach to maintenance can significantly enhance the lifespan of your motorcycle. Regular inspections and prompt attention to any concerns will ensure that you can enjoy every ride with confidence.

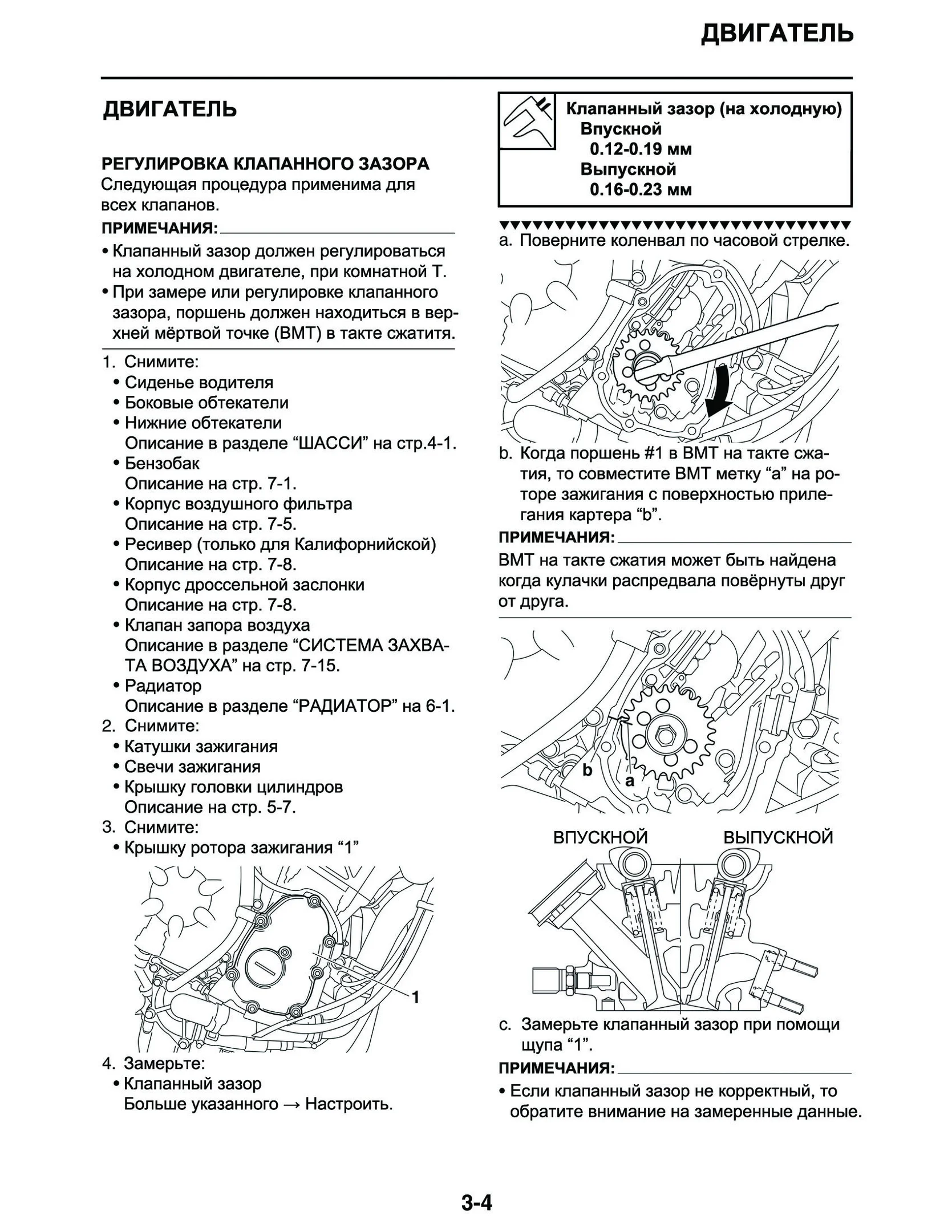

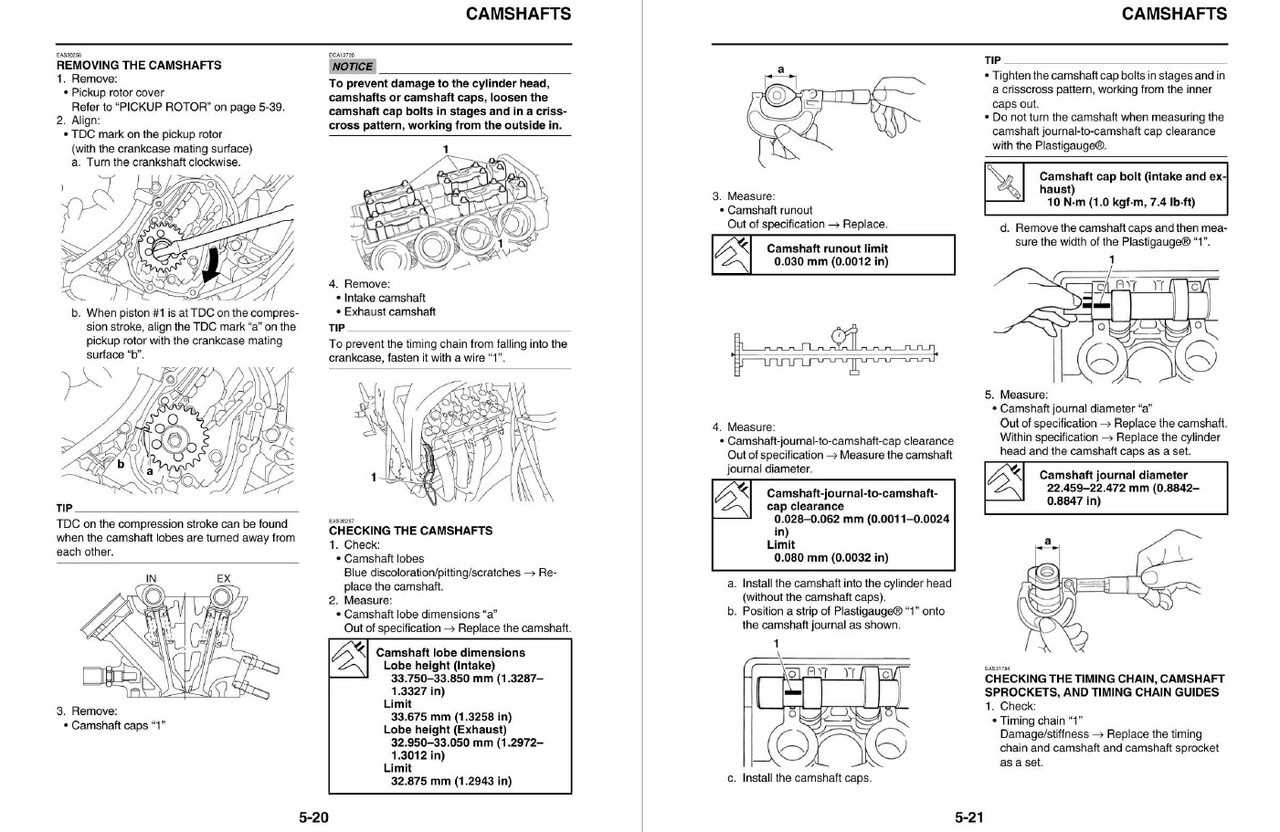

Understanding Engine Components

The heart of any vehicle lies within its power-generating system, where various elements work in unison to convert fuel into motion. This intricate assembly is designed to maximize performance and efficiency, making it crucial for enthusiasts and mechanics alike to grasp the function and interrelation of each part.

Key Parts of the Power System

Within this system, several critical components contribute to the overall operation:

- Pistons: These cylindrical parts move up and down within the cylinders, converting fuel combustion into mechanical energy.

- Cylinders: The chambers where pistons operate; they are essential for housing the fuel-air mixture.

- Cams: These components control the timing of valve openings and closings, ensuring optimal airflow.

- Crankshaft: A key element that converts the linear motion of the pistons into rotational motion.

- Valves: Critical for regulating the intake of air and fuel, as well as the expulsion of exhaust gases.

Importance of Maintenance

Regular upkeep of these components is vital for ensuring longevity and optimal performance. Neglecting any part can lead to significant issues that may affect the entire system. Proper attention to detail can enhance efficiency and reliability.

Routine Inspection Procedures

Regular assessments are essential for maintaining optimal performance and safety in any high-performance machine. These evaluations help identify potential issues before they escalate, ensuring longevity and reliability. Adhering to a systematic approach can significantly enhance the overall functionality and safety of the vehicle.

Visual Checks

Begin with a thorough visual inspection of key components. Look for any signs of wear, damage, or leaks that could affect operation. Pay attention to the frame, wheels, and exhaust system. Ensure that all fasteners are secure and that there are no loose parts. A keen eye for detail can prevent minor issues from developing into major concerns.

Fluid Levels and Condition

Regularly check the levels and condition of vital fluids. This includes engine oil, coolant, and brake fluid. Each fluid should be at the recommended level and free from contamination. Discolored or dirty fluids can indicate underlying problems that may require immediate attention. Keeping these fluids in optimal condition is crucial for smooth and safe operation.

Common Issues and Solutions

Maintaining a high-performance motorcycle can come with its share of challenges. Riders may encounter various complications that affect the overall functionality and safety of their machine. Understanding these common problems and their remedies is essential for ensuring optimal performance and longevity.

Electrical System Problems

One frequent issue involves the electrical system, where components such as the battery or wiring may fail. Signs of this can include difficulty starting or inconsistent lighting. Regularly checking connections and ensuring the battery is charged can prevent many of these complications. If issues persist, it may be necessary to inspect fuses and wiring for any signs of wear or damage.

Engine Performance Issues

Another common area of concern is engine performance, often manifested as stalling or reduced power. Such problems can stem from a variety of factors, including fuel quality or air intake restrictions. Regular maintenance, such as replacing filters and using high-quality fuel, can significantly mitigate these issues. In cases where performance remains inadequate, a thorough inspection of the fuel system may be required to identify underlying causes.

Step-by-Step Repair Techniques

This section provides a comprehensive overview of systematic approaches for addressing various mechanical issues. Each technique is designed to guide enthusiasts and technicians through the process, ensuring efficient and effective resolutions. By following these structured methods, one can enhance their skills while maintaining optimal performance of the vehicle.

Essential Tools and Equipment

Before commencing any procedure, it is crucial to gather the necessary tools and equipment. Having the right items on hand not only facilitates smoother operations but also minimizes the risk of damage. Common tools include wrenches, screwdrivers, and diagnostic devices, which play a vital role in the execution of tasks.

Diagnostic Steps for Common Issues

Identifying the root cause of a malfunction is key to successful intervention. Begin by observing symptoms, followed by a thorough inspection of the relevant components. Documentation of findings can assist in pinpointing areas requiring attention. This structured approach promotes a deeper understanding of the underlying mechanics.

Tools Required for Repairs

Having the right equipment is essential for effectively maintaining and fixing a high-performance motorcycle. Whether you are addressing minor adjustments or more complex issues, a well-equipped workspace enhances efficiency and ensures quality outcomes.

For basic tasks, a comprehensive set of hand tools, including wrenches, sockets, and screwdrivers, is indispensable. Additionally, specialized instruments such as torque wrenches are crucial for ensuring proper tightness and safety.

Furthermore, investing in diagnostic tools can greatly assist in identifying issues accurately. Equipment like multimeters and pressure gauges allow for precise measurements, aiding in effective troubleshooting.

Finally, safety gear should not be overlooked. Gloves, goggles, and protective clothing ensure that you remain safe while working, allowing you to focus on the task at hand without unnecessary risks.

Electrical System Troubleshooting

This section aims to guide users in identifying and resolving issues within the electrical framework of their vehicle. A comprehensive approach is essential to ensure all components are functioning optimally, providing a seamless experience during operation.

Common symptoms indicating electrical problems may include:

- Inconsistent power supply to accessories

- Dim or flickering lights

- Difficulty starting the engine

- Unusual sounds from the electrical system

To effectively troubleshoot, follow these systematic steps:

- Visual Inspection: Check for damaged wires, loose connections, or corrosion on terminals.

- Battery Check: Ensure the battery is charged and free of faults.

- Fuse Assessment: Examine fuses for breaks or malfunctions.

- Component Testing: Use a multimeter to test switches, relays, and other parts for functionality.

- Consult Documentation: Refer to electrical schematics for guidance on specific connections and components.

By following these steps, users can systematically identify and resolve electrical issues, ensuring their vehicle operates efficiently.

Brake System Maintenance Tips

Ensuring the longevity and reliability of your vehicle’s stopping mechanism is crucial for safety and performance. Regular attention to this vital component not only enhances overall functionality but also extends the lifespan of the system. Here are some essential maintenance suggestions to keep your braking apparatus in optimal condition.

Regular Inspection

Conducting frequent assessments can prevent minor issues from escalating into major problems. Focus on the following:

- Check brake pads for wear and replace them if they are thinner than recommended.

- Inspect brake fluid levels and look for any leaks in the system.

- Examine the condition of brake lines and hoses for cracks or deterioration.

Brake Fluid Maintenance

Maintaining clean and adequate brake fluid is vital for effective braking. Follow these guidelines:

- Replace brake fluid every two years or as recommended by the manufacturer.

- Use the appropriate type of brake fluid as specified in your vehicle’s specifications.

- Bleed the brake system periodically to remove air bubbles and contaminants.

Transmission Adjustments and Care

Proper maintenance and adjustments of the gear system are crucial for optimal performance and longevity of your vehicle. Regular checks can prevent issues that may arise from improper alignment or wear and tear. Understanding the intricacies of these components ensures a smooth riding experience.

Key aspects of maintaining the gear mechanism include:

- Regular Inspections: Check for any signs of wear, leaks, or damage.

- Fluid Levels: Ensure that the lubricant levels are appropriate and replace them as needed.

- Alignment Checks: Verify that all components are correctly aligned to prevent unnecessary strain.

In addition to routine checks, making adjustments when necessary is essential:

- Gear Cable Tension: Adjust the tension to ensure smooth shifting.

- Clutch Engagement: Properly set the clutch to allow for optimal performance.

- Shift Lever Position: Ensure the shift lever is positioned correctly for easy access.

By adhering to these maintenance practices, you can significantly enhance the efficiency and reliability of your vehicle’s gear system.

Suspension Setup and Repair

Ensuring optimal performance and comfort on two wheels involves understanding the nuances of the suspension system. This critical component plays a vital role in how a vehicle handles various terrains, absorbing shocks and providing stability. Proper adjustment and maintenance can significantly enhance both safety and riding experience.

Key Components of the Suspension System

The suspension system consists of several essential parts that work in harmony. Familiarizing yourself with these elements is crucial for effective tuning and troubleshooting:

- Forks: The front forks absorb shocks and maintain contact with the ground.

- Shock Absorbers: Located at the rear, these components control the rebound and compression of the rear wheel.

- Springs: These elements support the weight of the vehicle and determine ride height.

- Adjusters: These allow for fine-tuning of preload, compression, and rebound settings.

Adjustment Techniques

Fine-tuning the suspension requires attention to detail and a systematic approach. Here are some basic steps to achieve optimal setup:

- Check the current settings for preload, compression, and rebound.

- Adjust the preload to accommodate the rider’s weight and riding style.

- Tweak compression settings to manage how the suspension reacts to bumps.

- Set rebound adjustments to control how quickly the suspension returns after compression.

- Test the vehicle on varied surfaces and make incremental adjustments as needed.

Regular inspections and maintenance of the suspension system can prevent issues and prolong the life of these components. Keeping everything in optimal condition ensures a smooth and enjoyable ride.

Wiring Diagrams and Schematics

Understanding the intricate connections within a motorcycle is crucial for effective troubleshooting and maintenance. Clear illustrations and detailed diagrams serve as valuable tools for both novice and experienced mechanics. They provide a visual representation of the electrical pathways, helping to identify components and their interrelations.

Importance of Accurate Diagrams

Accurate schematics are essential for ensuring that all electrical elements function correctly. They outline the flow of current and signal pathways, allowing for quick diagnostics of potential issues. By following these diagrams, mechanics can avoid costly mistakes and ensure the longevity of the system.

Using Schematics Effectively

To maximize the utility of wiring diagrams, one should familiarize themselves with the symbols and notations used. Each element in the illustration represents specific components, making it easier to trace connections. A systematic approach to reviewing these schematics can greatly enhance repair efficiency and accuracy.

Safety Precautions During Repairs

When undertaking maintenance tasks on motor vehicles, it is essential to prioritize safety to ensure a smooth and secure working environment. Adhering to specific guidelines not only protects the individual performing the work but also preserves the integrity of the vehicle.

Here are some critical safety measures to consider:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Work in a well-ventilated area to prevent the buildup of harmful fumes and gases.

- Disconnect the battery before starting any electrical work to avoid shocks or shorts.

- Ensure the vehicle is securely elevated on jack stands, never just on a jack.

- Keep a fire extinguisher nearby and be aware of its location in case of emergencies.

By following these precautions, individuals can significantly reduce risks and create a safer environment during maintenance activities.

Performance Upgrades for R6

Enhancing the capabilities of your sportbike can significantly improve both handling and speed. This section explores various modifications that can elevate the overall performance of your motorcycle, ensuring a thrilling ride while maintaining reliability.

When considering upgrades, it’s essential to focus on key areas that impact performance:

- Engine Enhancements: Improving airflow and combustion can lead to noticeable power gains.

- Exhaust System: A high-performance exhaust can reduce weight and enhance exhaust flow, resulting in increased horsepower.

- Suspension Upgrades: Upgrading the suspension components can improve handling and stability during high-speed maneuvers.

- Brake Modifications: Enhanced braking systems provide better stopping power and improve safety during aggressive riding.

Each of these modifications can be tailored to suit individual riding styles and preferences. Whether you seek improved acceleration, better cornering, or enhanced braking, there are numerous options available to customize your machine.

Before proceeding with any upgrades, it’s crucial to conduct thorough research and consider the compatibility of parts. Consulting with experts can help ensure that the modifications align with your performance goals.