Comprehensive Guide to Repairing Yamaha 25 HP 2 Stroke Outboard Motors

Ensuring the longevity and optimal performance of a small marine engine requires a comprehensive understanding of its mechanics and regular upkeep. This guide aims to provide essential insights into the common issues faced by enthusiasts and operators, helping them navigate the complexities of their vessels. With the right knowledge, maintaining these powerful machines can be a straightforward process.

Every engine experiences wear and tear over time, making it crucial for users to familiarize themselves with its components and functionality. Addressing minor malfunctions promptly not only enhances performance but also prevents more significant problems down the line. This resource highlights key aspects of maintenance, offering practical advice tailored for those who wish to extend the life of their equipment.

From troubleshooting common concerns to performing routine checks, understanding the intricacies of engine care can transform the boating experience. Empowering users with the right techniques and tips ensures that they can confidently manage their marine engines, enjoying smooth and reliable outings on the water.

Understanding Yamaha 25 HP Outboard Engines

This section aims to provide a comprehensive overview of a specific type of marine propulsion system designed for small to medium-sized watercraft. These engines are known for their reliability and efficiency, making them a popular choice among boating enthusiasts. Understanding their design and functionality is crucial for anyone looking to maintain or troubleshoot these powerful machines.

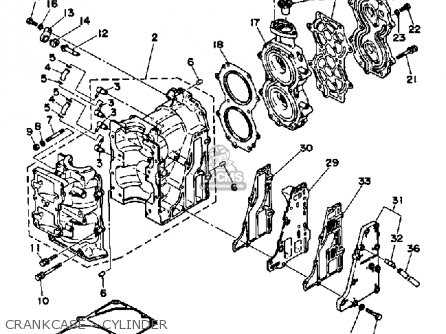

The engine in question typically features a lightweight structure, facilitating ease of handling and installation. Its two-cylinder configuration allows for a balance of power and fuel economy, which is essential for recreational use as well as commercial applications. The simplicity of the mechanical layout contributes to its robust performance under various conditions.

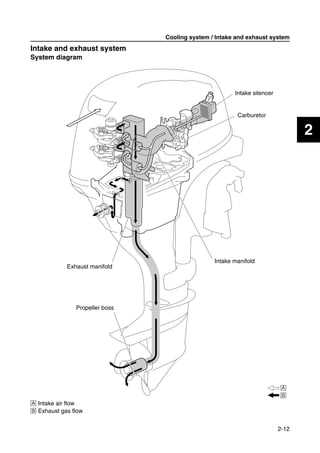

Regular maintenance is vital to ensure optimal functioning. Key components such as the fuel system, ignition system, and cooling mechanisms require periodic checks to prevent potential issues. Knowledge of these elements not only enhances the lifespan of the engine but also improves overall boating experiences.

In addition to maintenance, understanding troubleshooting techniques can empower users to address common problems that may arise. Familiarity with symptoms and potential solutions can save time and reduce costs associated with professional servicing. Mastering these concepts equips boaters with the confidence to navigate the complexities of engine care.

Common Issues with Two-Stroke Engines

Two-stroke engines are widely appreciated for their simplicity and power, but they are not without their challenges. Understanding common problems can help users maintain optimal performance and longevity. This section outlines typical issues encountered with these engines and offers insight into their causes and potential solutions.

Frequent Problems

- Overheating: Insufficient cooling can lead to elevated temperatures, resulting in damage to components.

- Fuel Issues: Incorrect fuel mixtures or stale fuel can cause poor combustion and operational inefficiencies.

- Exhaust Blockages: Carbon buildup can restrict exhaust flow, impacting performance and emissions.

- Piston Wear: Inadequate lubrication may lead to excessive wear on the piston and cylinder walls.

- Starting Difficulties: Problems with ignition systems or fuel delivery can make starting challenging.

Preventive Measures

- Regularly check and clean the cooling system to prevent overheating.

- Use the correct fuel mixture and replace old fuel to ensure proper combustion.

- Inspect exhaust systems for carbon buildup and clean as necessary.

- Maintain appropriate lubrication levels to reduce wear on internal components.

- Test ignition and fuel systems periodically to ensure reliable starting.

Essential Tools for Outboard Repair

Having the right set of instruments is crucial for maintaining and fixing marine engines. These tools not only facilitate the process but also ensure that tasks are performed safely and effectively. Below are some essential implements that every enthusiast should have on hand.

- Wrenches: A variety of sizes will help tackle different fasteners.

- Screwdrivers: Both flathead and Phillips types are necessary for various screws.

- Socket Set: A comprehensive socket set allows for quick adjustments and repairs.

- Pliers: Needle-nose and slip-joint pliers are versatile for gripping and twisting.

- Torque Wrench: Essential for applying precise force to fasteners.

In addition to the basic tools, consider the following specialized equipment:

- Fuel Line Pliers: Designed for working with fuel lines safely.

- Compression Tester: Helps assess engine performance and identify issues.

- Multimeter: Essential for electrical diagnostics and troubleshooting.

- Feeler Gauges: Useful for checking clearances in engine components.

- Service Manual: While not a tool in the traditional sense, it provides invaluable guidance.

Having these tools at your disposal can make a significant difference in the efficiency and quality of your maintenance tasks, ensuring your marine equipment operates smoothly and reliably.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your marine engine in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of the equipment. Following a systematic routine ensures that potential issues are identified early, allowing for timely interventions.

Begin with a thorough inspection of all external components. Look for any signs of wear, corrosion, or damage that could affect functionality. Pay close attention to the fuel lines and connections, as these are critical for safe operation.

Next, check the lubrication levels. Proper oiling is essential for reducing friction and preventing overheating. Change the lubricant as recommended by the manufacturer, ensuring that you use the appropriate type for your engine.

Inspect the cooling system. Ensure that the water intake is clear of debris and that the thermostat functions properly. This step is crucial for preventing overheating during use.

Examine the propeller for any dings or bends. A damaged prop can lead to decreased efficiency and potential further damage. If necessary, remove and repair or replace it.

Finally, conduct a thorough cleaning of the unit. Regularly removing dirt and salt buildup helps to maintain its appearance and functionality. A clean engine is not only more efficient but also easier to inspect for any emerging issues.

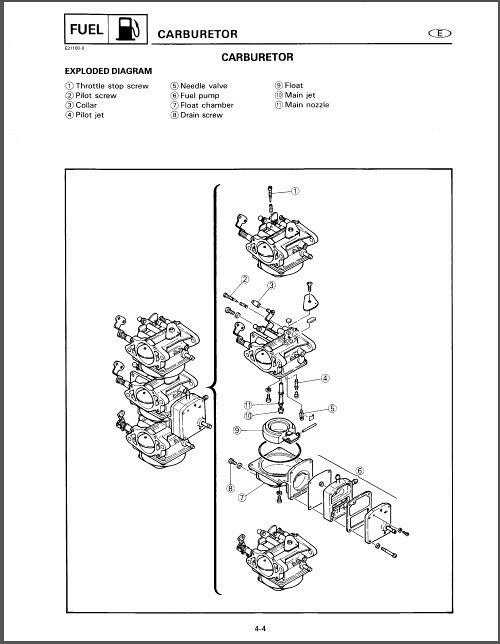

Diagnosing Fuel System Problems

Identifying issues within the fuel delivery mechanism is essential for optimal engine performance. Various symptoms can indicate that the system is not functioning correctly, affecting overall efficiency and reliability. Understanding these symptoms and the underlying causes can help streamline troubleshooting and restore proper operation.

Common indicators of fuel system malfunctions include inconsistent starting, poor acceleration, and reduced power output. To effectively diagnose these problems, one should follow a systematic approach that includes visual inspections and performance tests.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Clogged fuel filter | Replace filter and check fuel lines |

| Rough idling | Dirty carburetor | Clean or rebuild carburetor |

| Poor acceleration | Insufficient fuel pressure | Check fuel pump operation |

| Black smoke from exhaust | Rich fuel mixture | Adjust mixture settings |

| Overheating | Blocked fuel lines | Inspect and clear obstructions |

Each of these symptoms requires careful evaluation to pinpoint the exact issue. Regular maintenance and monitoring can prevent many of these problems from occurring, ensuring a smoother and more reliable experience.

Electrical Components Troubleshooting Tips

When dealing with marine propulsion systems, ensuring the functionality of electrical components is essential for optimal performance. Identifying and addressing issues can prevent further complications and enhance reliability. Below are effective strategies for diagnosing common electrical problems.

| Symptom | Possible Cause | Troubleshooting Steps |

|---|---|---|

| No power to the system | Blown fuse or faulty wiring | Check and replace any blown fuses; inspect wiring for damage or loose connections. |

| Intermittent electrical failure | Corroded terminals | Examine and clean all electrical connections; apply a corrosion inhibitor as needed. |

| Starter motor not engaging | Defective solenoid | Test the solenoid with a multimeter; replace if it fails to operate correctly. |

| Overheating | Short circuit or overloaded circuit | Inspect wiring for shorts; ensure that all components are within the recommended load specifications. |

| Battery not charging | Faulty alternator | Check voltage output from the alternator; replace if it does not meet specifications. |

By systematically approaching these potential issues, one can effectively maintain and enhance the performance of the electrical systems in marine vessels.

Replacing the Water Pump Effectively

Maintaining optimal performance in marine engines often hinges on the functionality of the water circulation system. A critical component of this system is the water pump, which requires periodic inspection and replacement to ensure proper cooling. This section outlines the steps necessary for effectively substituting this vital part, enhancing longevity and reliability.

Preparation and Tools

Before initiating the replacement process, gather essential tools such as screwdrivers, pliers, a wrench set, and a replacement water pump kit. Ensure the engine is turned off and cooled down to prevent any injuries. Additionally, have a clean workspace ready to keep all components organized, making the procedure smoother.

Step-by-Step Replacement Process

Start by removing the cover to access the pump. Detach the existing unit by loosening screws and carefully lifting it away from its housing. Clean any debris or old gasket material from the mounting surface. Next, install the new pump by aligning it properly and securing it with screws. Finally, reconnect any hoses and check for leaks before sealing everything up. Testing the system after installation ensures that cooling efficiency is restored and the engine operates at peak performance.

Gearcase and Propeller Maintenance

Proper care of the gearcase and propeller is essential for ensuring optimal performance and longevity of your marine engine. Regular maintenance not only enhances efficiency but also prevents costly damages. This section outlines key practices to keep these components in excellent condition.

Inspection and Cleaning

Begin with a thorough inspection of the gearcase for any signs of wear, corrosion, or leaks. Look for damage around the seals and ensure that the oil level is adequate. Cleaning the exterior with fresh water after each use helps remove salt and debris that can cause deterioration. For the propeller, check for dings or bends, as even minor imperfections can affect performance. A clean and well-maintained propeller contributes significantly to fuel efficiency.

Lubrication and Replacement

Regular lubrication is vital for the gearcase to function smoothly. Use high-quality gear oil and replace it according to the manufacturer’s recommendations. If you notice any unusual noises or vibrations, it may indicate that the internal components require attention. Similarly, if the propeller shows significant damage or deterioration, replacing it is crucial for maintaining optimal thrust and handling. Always ensure that the replacement propeller is compatible with your engine specifications.

Conducting Compression Tests Safely

Performing compression evaluations is crucial for assessing engine health and performance. Ensuring safety during this process is paramount to avoid accidents and damage to equipment. Proper preparation and attention to detail can lead to effective diagnostics without compromising personal safety or the integrity of the engine.

Here are essential safety steps to follow when conducting compression tests:

- Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses, to protect against potential debris and high-pressure situations.

- Ensure the workspace is well-ventilated to prevent the buildup of harmful gases and fumes.

- Disconnect the ignition system to prevent accidental starting during the testing process.

- Be cautious of hot surfaces; allow the engine to cool if it has been running prior to testing.

- Utilize proper tools, such as a compression gauge, and ensure they are in good condition to prevent malfunction.

By adhering to these guidelines, you can effectively and safely perform compression evaluations, leading to accurate assessments of engine performance and condition.

Preventive Measures for Longevity

Maintaining equipment in optimal condition is essential for ensuring its durability and efficiency. By adopting a proactive approach, users can significantly extend the lifespan of their machines while enhancing performance. This section outlines key strategies that can be implemented to prevent issues before they arise.

Regular Maintenance Practices

- Conduct routine inspections to identify any signs of wear and tear.

- Clean the components regularly to prevent buildup of debris and salt.

- Check fluid levels frequently and replace them as necessary.

- Inspect and replace filters to ensure proper function and efficiency.

Proper Usage Techniques

- Follow operational guidelines to avoid overloading the system.

- Avoid prolonged idling, which can lead to carbon buildup.

- Use the appropriate fuel type to prevent engine damage.

- Be mindful of the environment, such as weather conditions, to prevent unnecessary strain on the equipment.

Implementing these preventive measures not only enhances reliability but also contributes to long-term savings by reducing repair costs and downtime.

Upgrading Yamaha Outboard Performance

Enhancing the efficiency and capability of your marine engine can lead to a more enjoyable experience on the water. By focusing on several key areas, you can significantly improve speed, fuel efficiency, and overall responsiveness. Whether you’re an avid fisherman or a recreational boater, these modifications can elevate your time spent on the water.

Engine Tuning and Maintenance

Regular maintenance is essential for optimal performance. Ensure that all components are functioning properly and replace worn parts as needed. Additionally, tuning the engine can improve its responsiveness. Adjusting the carburetor settings and ensuring the fuel mixture is correct can lead to better acceleration and smoother operation. Checking spark plugs for wear and replacing them can also enhance ignition efficiency.

Propeller Selection

The choice of propeller can greatly influence your vessel’s performance. Selecting a propeller with the appropriate pitch and diameter can improve speed and fuel consumption. A propeller that matches the engine’s power band will optimize thrust and reduce strain, ultimately providing a more efficient ride. Experimenting with different propellers can help you find the best fit for your specific needs.

Resources for Further Learning

Enhancing your understanding of marine engines can significantly improve your maintenance skills and overall boating experience. This section provides a curated list of valuable resources that can help deepen your knowledge and equip you with practical skills.

- Online Forums: Engage with communities of enthusiasts and experts who share insights and troubleshooting tips.

- Video Tutorials: Platforms like YouTube offer a plethora of visual guides covering everything from basic upkeep to complex repairs.

- Books and E-books: Look for comprehensive literature that covers various aspects of engine mechanics and maintenance practices.

- Workshops and Classes: Local boating clubs or community colleges may offer hands-on learning experiences.

Consider these resources as stepping stones toward mastering the intricacies of engine care and operation. Each option provides unique perspectives and techniques to enhance your capabilities.