Comprehensive Guide to Repairing Yamaha 25 HP Outboard Motors

When it comes to ensuring the longevity and optimal performance of your 25 HP marine engine, understanding its intricate workings is essential. Proper care and attention can prevent unexpected breakdowns and enhance your boating experience. This section serves as a comprehensive resource, equipping you with the knowledge needed to tackle common issues and perform essential upkeep tasks.

Familiarity with the engine’s components and how they interact is crucial. From the fuel system to the ignition components, each part plays a significant role in the overall functionality. By mastering these elements, you can confidently address any concerns that arise during your outings on the water.

Additionally, having access to detailed instructions for maintenance tasks empowers you to handle repairs independently. This not only saves time but also fosters a deeper connection with your vessel. Ultimately, being proactive about maintenance will lead to more enjoyable and worry-free boating adventures.

Understanding Yamaha 25 HP Outboard Engines

This section delves into the intricacies of a specific class of marine propulsion systems known for their reliability and performance. These units are commonly used in various watercraft, making them essential for both recreational and professional activities on the water. Understanding their components and functionality can enhance the overall boating experience and ensure optimal operation.

Key Components

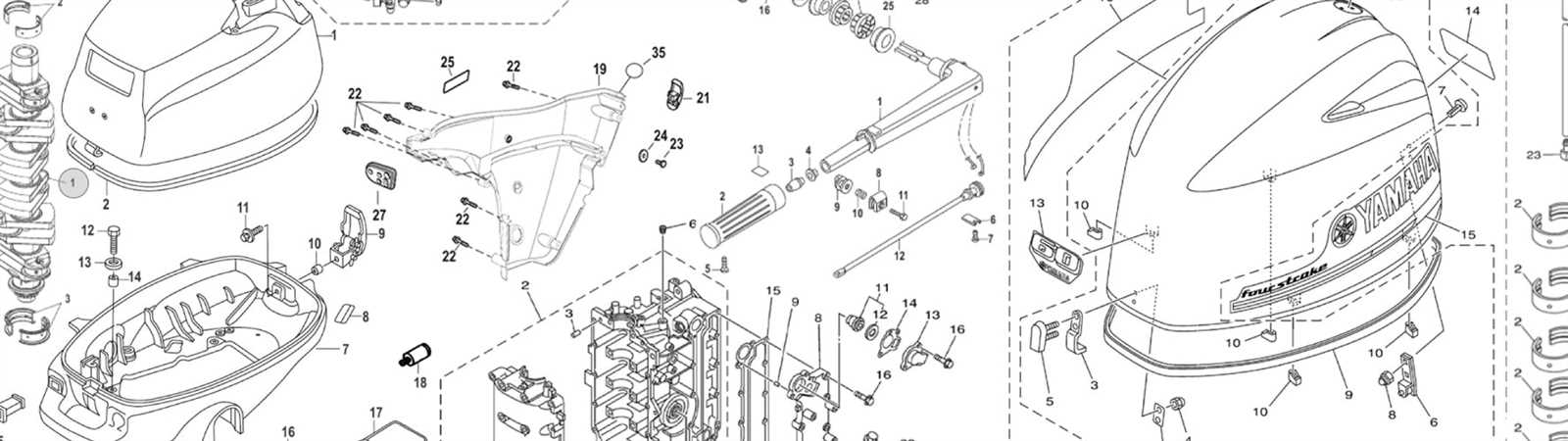

The propulsion systems feature several critical elements, including the powerhead, lower unit, and fuel delivery system. The powerhead houses the engine, which generates thrust through combustion. The lower unit is responsible for directing the thrust and facilitating steering, while the fuel system ensures efficient combustion for optimal performance.

Maintenance Tips

Common Issues with Yamaha 25 HP Motors

This section explores frequent challenges faced by users of this specific motor model. Understanding these issues can enhance maintenance and performance, ultimately leading to a more enjoyable boating experience.

Typical Problems

- Overheating due to cooling system failures.

- Fuel delivery issues, often linked to clogged filters.

- Starting difficulties, which may arise from electrical malfunctions.

- Strange noises indicating potential mechanical wear.

Preventive Measures

- Regularly check and clean the cooling system.

- Replace fuel filters according to the maintenance schedule.

- Inspect wiring and connections frequently.

- Listen for unusual sounds during operation to catch issues early.

Essential Tools for Outboard Repair

Having the right instruments at your disposal is crucial for maintaining and fixing marine engines. Proper equipment not only streamlines the process but also enhances safety and efficiency. Below is a curated list of must-have tools for anyone looking to ensure their engine remains in peak condition.

Basic Hand Tools

- Screwdrivers: A set of various sizes and types (flathead and Phillips) is essential for handling different fasteners.

- Wrenches: Both adjustable and socket wrenches are necessary for loosening and tightening bolts and nuts.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating wires and small components.

Specialized Instruments

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Essential for diagnosing electrical issues and ensuring proper voltage levels.

- Fuel Pressure Gauge: Allows for the monitoring of fuel system performance.

By investing in these essential tools, you can effectively tackle any maintenance task and extend the lifespan of your marine machinery.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of marine engines. This section outlines a systematic approach to maintenance tasks, focusing on crucial areas that require attention. By following these procedures, users can enhance reliability and reduce the likelihood of malfunctions during operation.

1. Engine Inspection

Begin by visually inspecting the engine for any signs of wear or damage. Check for loose connections, frayed wires, and signs of corrosion. Ensure that all components are securely fastened. A thorough inspection helps in identifying potential issues before they escalate into serious problems.

2. Fluid Checks and Changes

Regularly monitor and change essential fluids. This includes checking oil levels, fuel quality, and coolant conditions. Replace old oil and filters to ensure the engine operates smoothly. Keeping these fluids at optimal levels is crucial for maintaining performance and preventing overheating.

Identifying Engine Symptoms and Solutions

Understanding the signs of engine issues is crucial for maintaining optimal performance and ensuring longevity. Recognizing these symptoms early allows for timely interventions, preventing further complications and costly repairs. This section will explore common indicators of malfunction and provide practical solutions to address them effectively.

One of the most frequent symptoms is unusual noise coming from the engine. This could manifest as knocking, grinding, or excessive rattling. Such sounds often indicate issues with internal components, suggesting a need for immediate inspection to identify the source and prevent severe damage.

Another common sign is a decrease in power or acceleration. If the vessel struggles to reach its normal speed, it may be due to fuel delivery problems, air intake blockages, or malfunctioning ignition systems. Investigating these areas can help restore performance and efficiency.

Overheating is also a critical issue that should not be ignored. Elevated temperatures can result from insufficient coolant flow, a malfunctioning thermostat, or a blocked water intake. Regular checks of the cooling system can mitigate the risk of overheating and potential engine failure.

Finally, observing excessive smoke or exhaust emissions can indicate various problems, ranging from fuel mixture issues to internal damage. Monitoring these emissions closely can provide insights into the engine’s health and highlight the need for adjustments or repairs.

How to Troubleshoot Fuel Systems

Ensuring optimal performance of a propulsion system often hinges on the effective functioning of its fuel delivery mechanisms. Identifying issues within this system can prevent operational failures and enhance overall efficiency. This section outlines key steps for diagnosing common problems related to fuel supply and quality.

Identifying Fuel Supply Issues

Begin by examining the fuel lines for blockages or leaks. A thorough inspection can reveal cracks or kinks that may impede the flow. Additionally, verify that the fuel filter is clean; a clogged filter can restrict fuel delivery, leading to performance issues. If any part of the fuel line is compromised, it is essential to replace it promptly to maintain proper flow.

Assessing Fuel Quality

Next, evaluate the quality of the fuel itself. Contaminated fuel can cause various operational problems. Check for water or debris in the fuel tank; using a clear container to inspect fuel can be beneficial. If contamination is present, draining and replacing the fuel may be necessary. Furthermore, ensure that the fuel meets the required specifications for optimal performance.

Electrical Components: Repair and Replacement

This section focuses on the essential electrical elements of marine engines, highlighting their significance and common issues that may arise. Understanding how to maintain and replace these components is crucial for optimal performance and longevity.

Key electrical components include:

- Ignition system

- Starter motor

- Wiring harness

- Battery

- Voltage regulator

Here are some common problems and solutions:

- Ignition System: Symptoms like difficulty starting or misfiring may indicate faulty spark plugs or ignition coils. Regular inspection and timely replacement are essential.

- Starter Motor: If the engine fails to crank, it could be a result of a defective starter motor. Check connections and consider replacement if necessary.

- Wiring Harness: Damaged wires can lead to shorts or erratic behavior. Inspect for frays and corrosion, and replace any compromised sections.

- Battery: Ensure the battery is charged and connections are clean. A weak battery may need replacing to ensure reliable starts.

- Voltage Regulator: If electrical components appear to be underperforming, the voltage regulator might be failing. Testing and replacement should be considered.

Proper care and proactive management of these elements will enhance overall functionality and reliability, ensuring a smoother experience on the water.

Importance of Regular Oil Changes

Maintaining the health of any mechanical system is crucial for its longevity and efficiency. One of the simplest yet most impactful tasks that can be performed is the regular replacement of lubricating fluids. This practice not only enhances performance but also prevents potential damage that could arise from neglecting such a fundamental aspect of maintenance.

Enhancing Performance

Frequent fluid changes ensure that the internal components operate smoothly. Over time, oils can become contaminated with debris and lose their effectiveness. Fresh lubricants help reduce friction, allowing the engine to run more efficiently. This improved functionality often translates to better fuel economy and overall performance, making the machine more responsive and reliable.

Preventing Damage

Regularly changing the lubricating fluid is essential for preventing wear and tear on critical engine parts. Old oil can lead to sludge buildup, which may obstruct vital pathways and cause overheating. By adhering to a routine change schedule, owners can significantly extend the life of their equipment, minimizing the risk of costly repairs and downtime.

In summary, prioritizing timely fluid replacements is a key practice that supports both performance and durability, ensuring that any mechanical system remains in optimal condition for years to come.

Gearbox Maintenance and Adjustments

Proper care and fine-tuning of the gearbox are essential for ensuring smooth operation and longevity of the marine propulsion system. Regular attention to this component helps prevent wear and tear, ultimately enhancing performance and reliability. This section outlines critical procedures for maintaining and adjusting the gearbox to achieve optimal function.

Regular Inspection is the first step in gearbox care. Inspecting for leaks, unusual noises, and signs of wear can help identify potential issues before they escalate. Check seals and gaskets for any signs of damage, and ensure that all mounting bolts are secure.

Another vital aspect is Lubrication. The gearbox relies on proper lubrication to minimize friction and heat buildup. Regularly check the oil level and condition, replacing it according to the manufacturer’s recommendations. Use the specified type of lubricant to ensure compatibility and performance.

Alignment and Adjustments play a crucial role in gearbox efficiency. Misalignment can lead to premature failure and increased wear. Regularly verify the alignment of the drive shaft and adjust as necessary to maintain proper operation. Consult technical guidelines to determine the appropriate alignment specifications.

Lastly, Gear Ratio Check is essential for optimal performance. Verify that the gearbox is set to the correct gear ratio for your specific application. Adjustments may be needed if you notice any discrepancies in performance or response. This will ensure that the system operates at its best, providing the power and efficiency required.

Safety Tips During Outboard Repairs

Ensuring safety while conducting maintenance tasks on marine engines is crucial for both the technician and the equipment. Proper precautions can prevent accidents, injuries, and damage. Here are some essential guidelines to follow when performing service work on your motorized vessel.

Preparation and Environment

- Choose a well-ventilated area to work on the engine to avoid inhaling harmful fumes.

- Ensure that the workspace is organized and free of clutter to minimize the risk of accidents.

- Keep a fire extinguisher nearby, especially when working with flammable substances.

Personal Protective Equipment

- Wear safety goggles to protect your eyes from debris and fluids.

- Use gloves to safeguard your hands from sharp objects and chemicals.

- Consider wearing steel-toed boots to protect your feet from heavy equipment.

By adhering to these safety tips, you can help ensure a secure working environment while maintaining your marine engine effectively.

Resources for Further Learning and Support

Expanding your knowledge and skills in engine maintenance and troubleshooting can greatly enhance your experience. A variety of resources are available to help you gain a deeper understanding of various systems, improve your abilities, and connect with others in the field.

Online Forums and Communities

Engaging with online communities can provide valuable insights and support. Here are some platforms to consider:

- Specialized Forums: Websites dedicated to boating and engine maintenance often feature discussions, troubleshooting tips, and user experiences.

- Social Media Groups: Facebook and Reddit host groups where enthusiasts share knowledge, ask questions, and post advice.

- Video Tutorials: Platforms like YouTube have countless tutorials covering various maintenance tasks and common issues.

Books and Publications

Books and printed resources offer in-depth information and detailed instructions. Consider the following:

- Technical Manuals: Comprehensive guides that explain systems, maintenance schedules, and common repairs.

- How-to Books: These provide step-by-step processes for specific tasks, catering to various skill levels.

- Industry Magazines: Regular publications that include articles, reviews, and tips related to engines and maintenance practices.

Utilizing these resources can empower you to enhance your knowledge and confidently tackle any challenges that may arise.