Guide to Repairing Your Yamaha Blaster

Every enthusiast knows the importance of keeping their vehicles in optimal condition. This section offers valuable insights into the intricacies of maintaining a specific model designed for thrilling off-road experiences. Whether you are addressing common issues or enhancing performance, understanding the essential components is crucial.

In the realm of outdoor recreation, ensuring that your machinery runs smoothly can significantly impact your adventures. This guide delves into effective techniques for identifying problems and implementing solutions. By following these guidelines, you can prolong the life of your equipment while ensuring reliable functionality.

Ultimately, the goal is to empower users with the knowledge needed to handle various challenges. With detailed explanations and practical tips, you will be equipped to tackle maintenance tasks with confidence. Embrace the journey of keeping your vehicle at its best for every thrilling ride.

When undertaking maintenance or restoration of an all-terrain vehicle, having the right instruments is crucial. This section outlines the necessary equipment that ensures efficiency and effectiveness during the process, allowing enthusiasts to perform tasks with confidence.

Basic Equipment Overview

Essential tools include both handheld devices and specialized instruments designed to address various tasks. These tools not only facilitate repairs but also help in routine check-ups, making them indispensable for any vehicle owner.

Tool List and Their Functions

| Tool | Function |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for adjusting and securing components. |

| Torque Wrench | Ensures that bolts are tightened to the correct specifications. |

| Diagnostic Tool | Helps in identifying electrical and mechanical issues. |

| Oil Change Kit | Facilitates proper maintenance of the engine. |

Common Issues with Yamaha Blaster

This section addresses typical challenges encountered with a specific off-road vehicle. Understanding these common problems can aid in troubleshooting and maintenance, ensuring optimal performance and longevity.

Engine Performance Problems

One of the primary concerns with this type of vehicle is engine performance. Riders may notice issues such as reduced power output, difficulty starting, or irregular idling. These symptoms can often be traced back to fuel delivery issues, ignition system malfunctions, or air intake blockages.

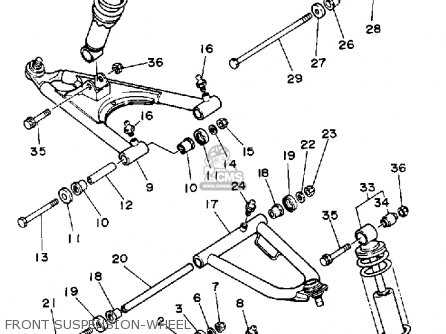

Suspension and Handling Difficulties

Another frequent issue relates to suspension and handling. A well-functioning suspension system is crucial for stability and control. Riders might experience a rough ride, excessive bouncing, or difficulty steering. These problems may stem from worn-out components, improper adjustments, or inadequate lubrication.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Power Loss | Poor fuel quality, faulty spark plug | Replace spark plug, use high-quality fuel |

| Rough Ride | Worn suspension parts | Inspect and replace worn components |

| Steering Problems | Incorrect tire pressure, alignment issues | Check tire pressure, adjust alignment |

Step-by-Step Engine Troubleshooting

Engine issues can arise for various reasons, and identifying the source of the problem is crucial for effective resolution. This section outlines a systematic approach to diagnosing common engine faults, ensuring a thorough evaluation of potential issues.

Follow these steps to troubleshoot engine problems:

-

Visual Inspection:

- Check for visible leaks, cracks, or damaged components.

- Inspect hoses and connections for wear and tear.

-

Fuel System Check:

- Ensure fuel is reaching the engine.

- Inspect fuel lines for blockages or leaks.

-

Electrical System Review:

- Examine wiring for frays or disconnections.

- Test the battery and ignition system for proper functionality.

-

Compression Test:

- Use a compression gauge to check cylinder pressure.

- Compare readings against manufacturer specifications.

-

Exhaust Inspection:

- Look for unusual smoke or odors.

- Check for blockages in the exhaust system.

By methodically following these steps, you can effectively identify and address engine-related issues, ensuring optimal performance.

Maintaining Your Yamaha Blaster

Regular upkeep of your all-terrain vehicle is essential for optimal performance and longevity. Proper care not only enhances reliability but also ensures a smoother ride. Implementing a consistent maintenance routine can prevent common issues and extend the lifespan of your machine.

Routine Inspections

Conducting periodic checks on key components, such as the engine and tires, is crucial. Look for any signs of wear or damage, and address them promptly. This proactive approach can save time and resources in the long run.

Fluid Changes

Ensuring that all fluids are at appropriate levels and changing them regularly is vital. Fresh oil and coolant help maintain efficient operation and prevent overheating. Regularly monitor these levels to avoid performance drops.

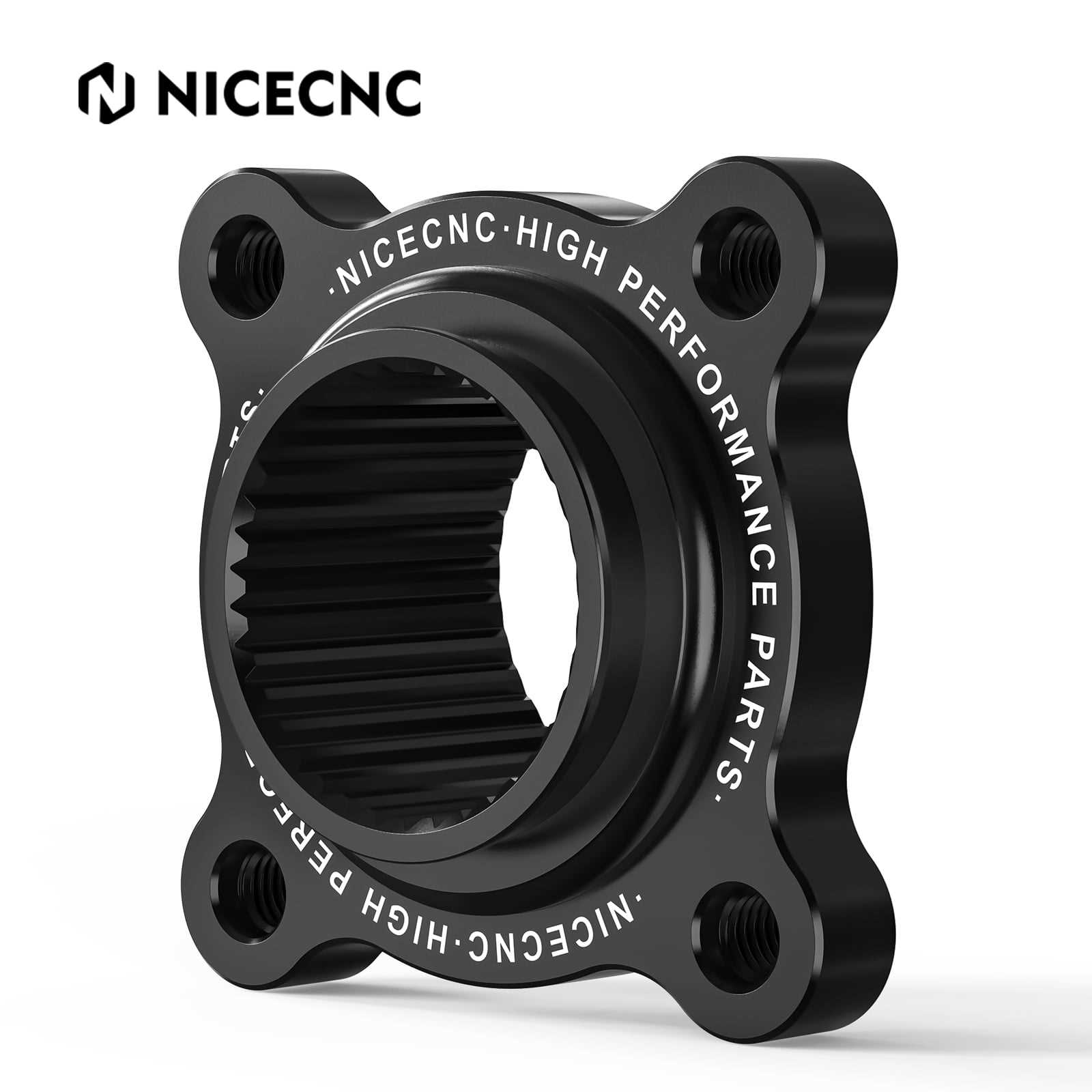

Parts Replacement Guidelines Explained

When it comes to maintaining your vehicle, understanding the process of substituting components is crucial for optimal performance and longevity. Properly executing this task not only enhances functionality but also prevents further damage and costly repairs.

Here are essential steps to consider during the replacement process:

- Assessment: Begin by thoroughly examining the part that needs replacement. Identify any signs of wear, damage, or malfunction.

- Selection of Parts: Choose high-quality components that match the specifications of the original equipment. Compatibility is key.

- Tools Required: Gather the necessary tools for the job. This may include wrenches, screwdrivers, and other specialized equipment.

- Preparation: Ensure the vehicle is in a stable position. Disconnect any power sources and follow safety protocols.

- Installation: Carefully follow the instructions for installing the new part. Ensure everything is aligned correctly and securely fastened.

- Testing: After installation, conduct a thorough check to ensure that the new component functions as intended. Look for any irregularities.

By adhering to these guidelines, you can effectively replace components and maintain the overall health of your vehicle.

Electrical System Diagnostics Process

The evaluation of the electrical components in a vehicle is crucial for ensuring optimal performance. This process involves a systematic approach to identifying issues within the circuitry, including both power supply and signal transmission.

Begin by inspecting the wiring harness for any visible signs of damage, such as frayed or corroded wires. Ensure all connections are secure and free of debris. Next, utilize a multimeter to measure voltage and continuity at various points in the system. This will help determine if power is reaching essential components.

Following the initial checks, focus on specific elements like the ignition system and lighting. Test switches, relays, and fuses to confirm their functionality. If discrepancies are noted, replace faulty components and retest the system to verify that the issues have been resolved.

Documentation of all findings and repairs is essential for future reference. By maintaining detailed records, you can streamline the diagnostics process for subsequent evaluations, ensuring the longevity and reliability of the electrical system.

Understanding Suspension Adjustments

Proper tuning of the suspension system is essential for achieving optimal performance and comfort during operation. Adjusting these settings can significantly enhance handling, stability, and overall ride quality.

Different terrains and riding styles necessitate various suspension configurations. By fine-tuning the suspension, riders can tailor their vehicle’s response to better suit their preferences and the conditions they encounter.

| Adjustment Type | Description | Impact on Performance |

|---|---|---|

| Preload | Determines the initial tension on the springs. | Affects ride height and overall firmness. |

| Compression | Controls how quickly the suspension compresses under load. | Influences stability during bumps and turns. |

| Rebound | Regulates how fast the suspension returns after compression. | Impacts control and comfort during recovery. |

Regularly reviewing and adjusting these settings can help maintain peak performance and extend the longevity of the system.

Fuel System Cleaning Techniques

Maintaining the cleanliness of the fuel system is essential for optimal engine performance. This section outlines effective methods to ensure the fuel delivery components are free from impurities, enhancing efficiency and longevity.

Here are some key techniques for cleaning the fuel system:

- Fuel Injector Cleaning: Utilize specialized cleaning solutions that can be introduced through the fuel line to dissolve deposits.

- Tank Cleaning: Empty the fuel tank and inspect for debris or rust. Rinse with a suitable solvent to eliminate contaminants.

- Fuel Filter Replacement: Regularly replace the fuel filter to prevent clogging and ensure smooth fuel flow.

- Carburetor Maintenance: Disassemble and clean the carburetor using a carburetor cleaner to remove varnish and residues.

- System Flush: Perform a complete system flush with a cleaning additive to clear out buildup in the fuel lines.

Implementing these techniques can significantly enhance fuel system efficiency, leading to improved overall engine functionality.

Wheel and Tire Maintenance Tips

Proper care for wheels and tires is essential for optimal performance and safety. Regular maintenance helps prolong their lifespan and enhances overall riding experience.

First, regularly inspect the tires for signs of wear, such as uneven tread or bulges. Maintaining correct air pressure is crucial; both under-inflation and over-inflation can lead to reduced traction and increased risk of blowouts.

Additionally, rotate the tires periodically to ensure even wear. Cleaning the wheels from dirt and debris not only improves appearance but also prevents corrosion and damage. Always ensure that lug nuts are tightened to the manufacturer’s specifications after any tire work.

Finally, consider seasonal changes. Different weather conditions may require switching to appropriate tires, such as all-terrain options for off-road activities. Following these guidelines will ensure better handling and safer rides.

Brake System Inspection Procedures

The examination of the braking system is crucial for ensuring safety and optimal performance. Regular checks help identify any potential issues before they escalate, ensuring reliable stopping power.

Visual Inspection

Begin by conducting a thorough visual assessment of the brake components. Look for any signs of wear or damage, such as cracked pads or leaking fluid. Ensure that the brake lines are intact and free from corrosion. Any irregularities should be addressed immediately to maintain effectiveness.

Functional Testing

After the visual inspection, perform a functional test of the braking system. Engage the brakes to check for responsiveness and consistency. Listen for any unusual sounds, such as grinding or squeaking, which may indicate a need for further investigation. Ensure that the braking mechanism engages smoothly and provides adequate stopping power.

Performance Upgrades for Better Efficiency

Enhancing the overall efficiency of your vehicle can significantly improve its performance and responsiveness. Various modifications can be implemented to optimize engine functionality, increase power output, and reduce fuel consumption.

Popular Upgrade Options

- Air Intake System: Upgrading the air intake can improve airflow to the engine, enhancing combustion efficiency.

- Exhaust System: A performance exhaust system can help expel gases more efficiently, leading to better engine performance.

- ECU Tuning: Modifying the engine control unit allows for optimized fuel maps and timing adjustments.

- Weight Reduction: Reducing excess weight can improve acceleration and handling.

Benefits of Upgrades

- Improved throttle response and acceleration.

- Enhanced fuel efficiency, leading to cost savings.

- Increased horsepower and torque.

- Better overall driving experience and enjoyment.

Final Checks Before Riding

Before embarking on your journey, it’s crucial to ensure that your vehicle is in optimal condition. Conducting a thorough inspection helps prevent potential issues that could arise while riding, ensuring both safety and performance.

Start by examining the tire pressure and tread for adequate grip. Low pressure or worn-out tires can lead to decreased stability and control. Next, inspect the braking system to confirm that it is functioning effectively. Check the fluid levels and look for any signs of leaks.

Additionally, verify that all lights are operational, including headlights and indicators. Proper visibility is essential for safe navigation, especially in low-light conditions. Finally, ensure that the fuel tank is sufficiently filled to avoid interruptions during your ride.