Comprehensive Guide to Yamaha Boat Motor Repair Manuals

Maintaining the performance and longevity of watercraft propulsion systems is essential for enthusiasts and professionals alike. Accessing comprehensive resources is key to understanding the intricacies of these vital components, ensuring they operate smoothly and efficiently. With the right guidance, owners can tackle common issues and enhance their vessel’s reliability on the water.

From troubleshooting techniques to detailed assembly instructions, a well-structured collection of information can empower users to perform necessary interventions with confidence. These resources cover a wide range of topics, including component specifications, assembly diagrams, and preventative maintenance tips, enabling individuals to address both minor adjustments and major overhauls.

Whether you are a seasoned sailor or a novice seeking to expand your knowledge, familiarizing yourself with these technical guides can significantly impact your experience on the water. Embracing the wealth of information available will not only save time and money but also deepen your connection to your craft and the joys of navigating the open waters.

Yamaha Boat Motor Overview

This section provides a comprehensive look at a renowned brand’s aquatic propulsion systems, focusing on their design, functionality, and maintenance considerations. These devices are crucial for enhancing the performance and efficiency of watercraft, ensuring smooth navigation and enjoyable experiences on the water.

Key Features

The innovative systems are engineered with precision, offering a range of features that cater to diverse user needs. Advanced technology ensures optimal fuel efficiency, while lightweight materials contribute to better handling and responsiveness. Many models include integrated controls that enhance user experience, making operation intuitive and seamless.

Maintenance Essentials

Proper upkeep is vital for longevity and reliable performance. Regular inspections and servicing help prevent issues, ensuring that these devices operate at peak efficiency. Utilizing detailed guides can simplify the maintenance process, allowing users to address potential problems proactively. Understanding the fundamentals of upkeep can greatly enhance the overall lifespan and performance of these essential components.

Common Yamaha Motor Issues

When operating a watercraft, various challenges can arise that affect performance and reliability. Understanding these frequent concerns can help owners maintain their equipment effectively and ensure a smooth experience on the water. Below are some of the typical problems encountered, along with their potential causes and solutions.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, faulty ignition, fuel blockage | Check battery connections, inspect ignition components, clear fuel lines |

| Overheating | Blocked cooling system, low coolant levels, faulty thermostat | Flush cooling system, top off coolant, replace thermostat |

| Unusual Noises | Loose parts, worn bearings, improper installation | Tighten components, replace bearings, check installation |

| Fuel Leaks | Worn gaskets, damaged fuel lines, loose connections | Replace gaskets, repair or replace lines, tighten connections |

| Power Loss | Clogged filters, incorrect propeller size, engine misfire | Clean or replace filters, assess propeller size, check ignition system |

Addressing these common challenges proactively can lead to enhanced longevity and performance. Regular maintenance checks and being aware of signs of distress will contribute to a better experience on the water.

Benefits of Repair Manuals

Access to comprehensive guides significantly enhances the ability to troubleshoot and maintain equipment. These resources provide valuable insights and step-by-step instructions, empowering users to address issues effectively. By leveraging such documents, individuals can save time and money while gaining a deeper understanding of their systems.

Cost Efficiency

Utilizing detailed instructions can lead to substantial savings. Instead of relying on professional services, users can perform maintenance and fix common problems independently. This approach not only reduces expenses but also promotes self-sufficiency.

Enhanced Knowledge

Studying these informative texts increases one’s technical knowledge and familiarity with the equipment. Understanding the intricacies of the system can prevent future malfunctions and extend the lifespan of the components.

| Benefit | Description |

|---|---|

| Cost Savings | Reduces the need for professional repairs, allowing for DIY solutions. |

| Time Efficiency | Streamlines the troubleshooting process with clear guidelines. |

| Improved Skills | Increases technical expertise and confidence in handling equipment. |

| Preventive Maintenance | Encourages regular upkeep to avoid major issues down the line. |

Essential Tools for Repairs

When tackling mechanical tasks, having the right instruments is crucial for success. A well-equipped workspace can significantly enhance efficiency and accuracy, making the process smoother and more effective. Understanding which items are indispensable can help streamline your efforts and ensure optimal results.

Basic Equipment

- Wrenches: Various sizes for loosening and tightening fasteners.

- Screwdrivers: Flathead and Phillips options for different screw types.

- Pliers: For gripping and manipulating small components.

- Socket set: Provides versatility for a range of bolts and nuts.

- Measuring tape: Essential for precise measurements.

Specialized Instruments

- Multimeter: Used for electrical diagnostics and troubleshooting.

- Torque wrench: Ensures fasteners are tightened to the correct specifications.

- Compression tester: Helps assess the condition of internal components.

- Fuel pressure gauge: Monitors the fuel system’s efficiency.

- Diagnostic scanner: Identifies issues and codes for troubleshooting.

Equipping yourself with these essential tools will not only aid in addressing common issues but will also prepare you for more complex tasks that may arise in the future.

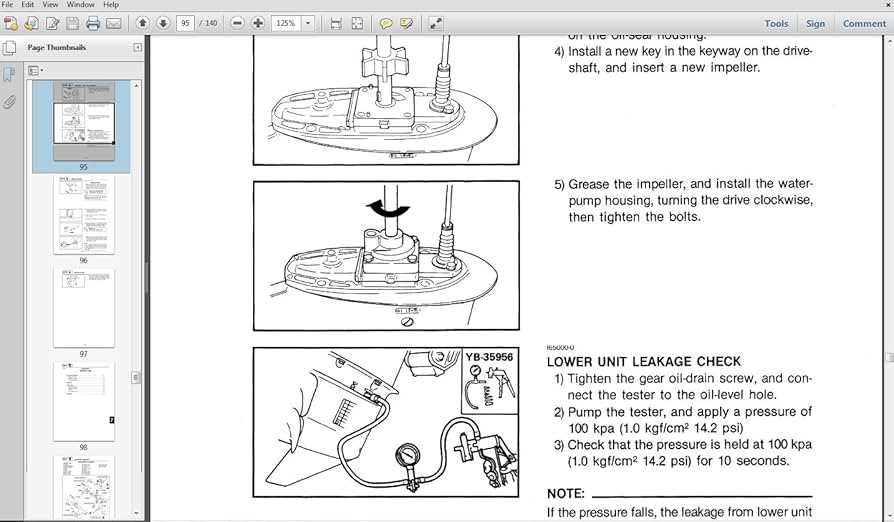

Step-by-Step Repair Techniques

This section provides a comprehensive guide for addressing common issues associated with aquatic propulsion systems. Following a systematic approach can significantly enhance efficiency and extend the lifespan of the equipment. By employing detailed methodologies, users can navigate through various challenges with confidence and clarity.

Essential Tools and Equipment

Before embarking on any maintenance task, it is crucial to gather the appropriate tools. Having the right equipment at hand not only facilitates the process but also ensures safety and accuracy during the procedure.

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Adjusting screws |

| Multimeter | Measuring electrical components |

| Pliers | Gripping and bending materials |

| Cleaning Supplies | Removing debris and buildup |

Basic Troubleshooting Steps

To effectively identify and rectify issues, follow these straightforward steps:

- Conduct a visual inspection for any obvious signs of wear or damage.

- Test all electrical connections for continuity.

- Verify fuel supply and ensure proper flow.

- Check for any leaks in the system.

- Consult technical resources to confirm specifications.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your investment. Here are essential practices to keep in mind.

- Regular Inspections: Conduct thorough checks to identify any wear or damage early.

- Cleaning: Remove dirt, salt, and debris after each use to prevent corrosion and buildup.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Fluid Checks: Monitor oil and coolant levels regularly to ensure optimal operation.

- Storage: Store equipment in a cool, dry place, especially during off-seasons, to prevent deterioration.

By following these guidelines, you can significantly enhance the efficiency and longevity of your gear. Consistent upkeep is key to avoiding costly repairs and ensuring reliable performance for years to come.

Finding Genuine Yamaha Parts

When it comes to maintaining your aquatic vessel’s performance, sourcing authentic components is essential. Using original parts ensures longevity and reliability, allowing for smooth operation and enhanced safety on the water.

Identifying genuine components can sometimes be challenging, especially with the availability of numerous aftermarket alternatives. To navigate this landscape effectively, always look for trusted suppliers and authorized dealers. They typically offer products that meet the rigorous standards set by the manufacturer.

One way to confirm authenticity is by examining packaging for specific identifiers such as serial numbers or holograms. These markings often indicate that the part is original and has undergone quality checks.

Additionally, engaging with online forums and communities dedicated to enthusiasts can provide insights and recommendations for where to purchase authentic items. Fellow users often share their experiences and can guide you toward reputable sources.

Lastly, consider contacting the manufacturer directly for assistance in locating authorized vendors. This proactive approach can save time and ensure that you invest in parts that will serve your needs effectively.

Safety Precautions During Repairs

Ensuring safety while undertaking maintenance tasks is essential for preventing accidents and injuries. Adhering to specific guidelines can significantly reduce risks and promote a secure working environment.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep your workspace organized and free from clutter to minimize hazards.

Additionally, being aware of potential dangers can help in preparing for safe handling of tools and components:

- Ensure all electrical connections are disconnected before beginning any work.

- Use tools that are suitable for the task and in good condition to prevent malfunctions.

- Be cautious of sharp edges and heavy parts that may cause injury if mishandled.

By following these precautions, you can create a safer atmosphere while performing essential tasks, ultimately leading to more effective outcomes and personal safety.

Understanding Motor Specifications

Grasping the characteristics of propulsion units is essential for ensuring optimal performance and longevity. Each unit comes with a set of specifications that outlines its capabilities, helping users make informed decisions regarding their selection and maintenance.

Key Specifications to Consider

- Power Output: Typically measured in horsepower, this indicates the strength of the engine.

- Displacement: Refers to the total volume of all the cylinders in the engine, influencing efficiency and torque.

- Fuel Type: Specifies whether the unit operates on gasoline, diesel, or alternative fuels.

- Weight: The overall mass of the unit can affect handling and stability.

- Dimensions: Size affects compatibility with various installations and overall performance.

Importance of Understanding Specifications

Comprehending these details aids in matching the propulsion unit to specific needs, ensuring that the selected engine aligns with both operational requirements and environmental considerations. Proper knowledge leads to enhanced efficiency and reduced wear over time.

- Identify your requirements.

- Review specifications carefully.

- Choose a unit that best fits your criteria.

When to Seek Professional Help

Determining the right moment to consult an expert can be crucial for maintaining the longevity and performance of your aquatic machinery. While many tasks can be handled independently, certain situations warrant professional intervention to ensure safety and efficiency.

Consider seeking assistance in the following circumstances:

- Complex Issues: If the problem involves intricate systems that you are unfamiliar with.

- Persistent Problems: When recurring issues do not resolve despite your efforts.

- Lack of Tools: If specialized equipment is required that you do not possess.

- Time Constraints: When you have limited time and need a quick, reliable solution.

- Safety Concerns: If there are any signs that could jeopardize safety, such as unusual noises or leaks.

In these scenarios, engaging a skilled technician can save you time, prevent further complications, and ultimately protect your investment.

Resources for Further Learning

Expanding your knowledge in the realm of mechanical devices can greatly enhance your skills and understanding. There are numerous avenues available for those looking to deepen their expertise and tackle various challenges effectively.

Online Courses and Tutorials

- Platforms like Coursera and Udemy offer specialized courses on engine maintenance and troubleshooting.

- YouTube has a wealth of video tutorials, providing visual guidance on common issues and solutions.

- Webinars and live sessions can provide real-time assistance and expert insights.

Books and Publications

- Technical manuals and reference books often contain detailed information and step-by-step instructions.

- Magazines focused on mechanical engineering frequently publish articles on innovations and best practices.

- Online forums and communities can be a source of shared experiences and recommendations for further reading.