Comprehensive Guide to Yamaha DT 175 Repair Manual

When it comes to ensuring the longevity and performance of a two-wheeled vehicle, understanding its intricacies is essential. This section offers insights into the various aspects of maintenance, troubleshooting, and enhancements that every enthusiast should be familiar with. Whether you’re a novice looking to gain basic knowledge or an experienced rider aiming to refine your skills, this guide serves as a valuable resource.

Key Components of any motorized cycle are vital to its smooth operation. Regular upkeep not only enhances performance but also ensures safety during rides. By delving into the specifics of parts, systems, and functionality, owners can develop a comprehensive understanding that will enable them to tackle common issues with confidence.

In addition to routine checks and adjustments, knowing how to diagnose problems effectively is a crucial skill. With a focus on troubleshooting techniques and common pitfalls, readers will learn how to address various challenges that may arise. This knowledge empowers individuals to take proactive measures, preventing minor concerns from escalating into major repairs.

Overview of Yamaha DT 175

This section provides a comprehensive look at a notable off-road motorcycle model known for its reliability and performance. The machine is designed for both novices and experienced riders, offering a blend of versatility and user-friendliness that makes it suitable for various terrains. Its robust construction and efficient mechanics contribute to its status as a popular choice among enthusiasts.

Key Features

- Lightweight frame for easy maneuverability

- Powerful engine delivering impressive torque

- Advanced suspension system for enhanced comfort

- Durable tires suitable for off-road conditions

- Efficient braking system ensuring safety

Specifications

- Engine Type: Two-stroke, air-cooled

- Displacement: Moderate capacity for city and trail use

- Transmission: Manual with a multi-speed setup

- Fuel System: Carbureted for optimal performance

- Weight: Lightweight, aiding in agility

Overall, this motorcycle stands out in the realm of two-wheelers, appealing to riders who seek adventure and reliable performance on varied landscapes.

Common Issues and Solutions

This section addresses frequent challenges encountered by users of two-wheeled vehicles, providing effective solutions to enhance performance and longevity. Understanding these common problems can aid in timely interventions, ensuring a smooth riding experience.

- Starting Difficulties:

Problems with starting can stem from various sources, including fuel delivery or electrical issues. To resolve this:

- Check the fuel level and quality.

- Inspect the battery for charge and connections.

- Examine spark plugs for wear or deposits.

- Engine Overheating:

Overheating may lead to significant damage if not addressed promptly. Solutions include:

- Ensure the cooling system is functioning properly.

- Check for coolant leaks.

- Clean the radiator to improve airflow.

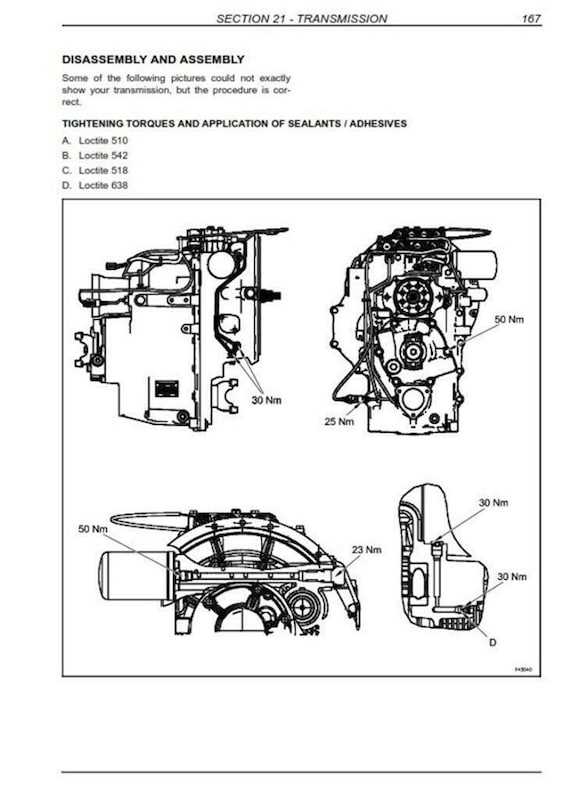

- Transmission Issues:

Shifting difficulties can arise from worn components or improper adjustments. To fix these:

- Inspect the clutch for proper engagement.

- Adjust the gear shifter if necessary.

- Replace any damaged cables or levers.

- Brake Performance:

Compromised braking can endanger safety. Consider these troubleshooting tips:

- Examine brake pads for wear and replace if needed.

- Check brake fluid levels and top up if low.

- Inspect brake lines for leaks or damage.

- Electrical Failures:

Electrical issues can affect lighting and ignition systems. Address these problems by:

- Testing the battery and replacing it if defective.

- Inspecting wiring for frays or corrosion.

- Checking fuses and replacing any that are blown.

By following these guidelines, users can troubleshoot and resolve common issues, ensuring their two-wheeled vehicle remains in optimal condition.

Tools Required for Repairs

When undertaking maintenance or troubleshooting tasks on a two-wheeled vehicle, having the right instruments is crucial. A well-equipped workspace not only facilitates efficient work but also ensures safety and accuracy throughout the process. Below is a comprehensive list of essential items that will aid in various maintenance procedures.

Essential Hand Tools

- Socket Wrench Set

- Combination Wrenches

- Torque Wrench

- Phillips and Flathead Screwdrivers

- Pliers (including Needle-Nose)

- Adjustable Wrench

- Hex Key Set

Specialized Equipment

- Feel Gauge

- Compression Tester

- Multimeter

- Carburetor Cleaning Kit

- Oil Filter Wrench

- Chain Breaker Tool

These tools will provide a solid foundation for conducting effective maintenance tasks. Ensuring that you have these instruments on hand will help streamline the process and enhance the overall outcome of your efforts.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing mechanical issues effectively. By following a systematic method, individuals can ensure that every aspect of the task is handled thoroughly, leading to optimal performance and longevity.

- Preparation:

- Gather necessary tools and equipment.

- Review specifications and guidelines related to the task.

- Set up a clean and organized workspace to enhance efficiency.

- Inspection:

- Conduct a visual examination to identify any visible signs of wear or damage.

- Check fluid levels and assess their condition.

- Perform a diagnostic test if applicable to pinpoint specific issues.

- Disassembly:

- Carefully remove components in a logical order to avoid confusion.

- Label parts as they are taken off to facilitate reassembly.

- Take photographs to document the setup for reference.

- Component Evaluation:

- Assess each part for functionality and integrity.

- Replace or repair any components that do not meet the required standards.

- Clean components thoroughly to ensure proper operation.

- Reassembly:

- Reattach parts in the reverse order of disassembly.

- Ensure all fasteners are tightened to the manufacturer’s specifications.

- Double-check alignment and connection of all components.

- Testing:

- Start the engine and listen for unusual noises.

- Conduct a performance test to ensure everything functions correctly.

- Monitor for leaks or other issues during initial operation.

- Final Checks:

- Perform a final inspection to verify all parts are secure.

- Dispose of any waste materials properly.

- Document the work completed for future reference.

Following this structured approach helps maintain efficiency and promotes successful outcomes in mechanical tasks.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your two-wheeled companion. By following a consistent maintenance routine, you can enhance performance, reduce the likelihood of breakdowns, and ultimately enjoy many rides without unexpected interruptions. Here are some vital tips to keep your vehicle in prime condition.

Regular Inspections

- Check the oil levels frequently to ensure smooth engine operation.

- Inspect the tires for wear and proper inflation; replace them as needed.

- Examine brake pads for thickness and functionality to ensure safety.

- Look over electrical connections and lights for any signs of damage or corrosion.

Routine Maintenance Tasks

- Change the oil and filter at recommended intervals to promote engine health.

- Clean or replace the air filter to improve airflow and engine efficiency.

- Keep the chain lubricated and adjusted to prevent wear and maintain performance.

- Flush the cooling system and replace the coolant as specified to prevent overheating.

By adhering to these guidelines, you can maximize the lifespan of your vehicle, ensuring that it remains reliable and enjoyable for years to come.

Understanding Engine Components

Engines are intricate systems comprised of various elements that work in harmony to convert fuel into mechanical energy. A comprehensive understanding of these components is essential for anyone looking to delve into the world of motor maintenance or enhancement. Each part plays a critical role in the engine’s overall functionality, and recognizing their interconnections can lead to more effective troubleshooting and performance optimization.

Key Parts of the Engine

The core components of an engine typically include the cylinder block, crankshaft, and piston. The cylinder block serves as the foundation of the engine, housing the cylinders where combustion occurs. The crankshaft transforms the linear motion of the pistons into rotational motion, while the piston moves within the cylinder, compressing the fuel-air mixture for ignition.

Supporting Systems

In addition to the primary components, various supporting systems are vital for optimal engine operation. The fuel system ensures a proper mix of air and fuel for combustion, while the cooling system prevents overheating by regulating the engine’s temperature. Understanding these supporting mechanisms is crucial, as they directly influence performance and longevity.

Electrical System Troubleshooting

The electrical system is crucial for the overall functionality of your vehicle. Identifying and resolving issues within this system can enhance performance and ensure safe operation. This section provides a comprehensive guide to diagnosing common electrical problems, allowing you to restore proper functionality effectively.

Identifying Common Issues

Electrical malfunctions can manifest in various ways, such as flickering lights, difficulty starting, or unexpected shutdowns. Begin by inspecting the battery and connections for signs of corrosion or loose wiring. Ensure that fuses are intact and check for any frayed wires that may cause shorts. By systematically examining these components, you can often pinpoint the root cause of the problem.

Testing Components

Once you’ve identified potential issues, the next step is to test individual components. Utilize a multimeter to measure voltage levels at various points within the system. This can help determine if the battery is delivering adequate power or if any parts, such as the starter or alternator, are malfunctioning. By following a logical testing procedure, you can efficiently isolate and address electrical faults.

Carburetor Adjustment Guidelines

Ensuring optimal performance of your two-wheeled vehicle requires careful attention to the fuel delivery system. Proper tuning of the carburetor is essential for achieving peak efficiency, smooth operation, and reliable starting. This section outlines essential steps and considerations for fine-tuning this critical component.

Before proceeding with adjustments, gather the necessary tools and materials:

- Flathead and Phillips screwdrivers

- Wrench set

- Fuel line clamps

- Carburetor cleaner

- Vacuum gauge (optional)

Follow these steps to achieve accurate settings:

- Inspect the Carburetor: Ensure that the carburetor is clean and free from debris. Remove any accumulated dirt using carburetor cleaner.

- Check Fuel Flow: Verify that fuel is flowing freely to the carburetor. Address any blockages in the fuel line.

- Adjust Idle Speed: Locate the idle speed screw and turn it clockwise to increase RPM or counterclockwise to decrease. Aim for a smooth, stable idle.

- Set Air-Fuel Mixture: Identify the mixture screw. Start with the recommended baseline setting, then fine-tune by adjusting it in small increments while observing engine response.

- Test Ride: Take your vehicle for a short ride to assess performance. Pay attention to acceleration, responsiveness, and idle stability.

- Readjust as Necessary: Based on the test ride, make further adjustments to the idle speed and air-fuel mixture as needed to achieve optimal performance.

Regular maintenance and precise tuning of the carburetor will enhance the longevity and reliability of your machine. Always refer to your specific vehicle’s guidelines for detailed specifications.

Transmission and Clutch Care

Proper maintenance of the transmission and clutch system is essential for ensuring the smooth operation and longevity of your vehicle. Regular attention to these components not only enhances performance but also prevents costly repairs in the long run. Understanding the significance of lubrication, adjustment, and inspection will help you maintain these critical parts effectively.

To ensure optimal function, follow a systematic approach to care for the transmission and clutch. Regular checks and timely interventions can help identify potential issues before they escalate. Here are some important aspects to consider:

| Aspect | Action | Frequency |

|---|---|---|

| Fluid Level | Check and top off as necessary | Every month |

| Fluid Condition | Inspect for discoloration or contamination | Every month |

| Clutch Adjustment | Ensure proper engagement and disengagement | Every 2-3 months |

| Leak Inspection | Look for signs of fluid leaks | Monthly |

| Component Wear | Check for signs of wear or damage | Every season |

By following these guidelines, you can ensure that the transmission and clutch remain in excellent condition, allowing for a smoother and safer riding experience. Timely maintenance is key to avoiding unforeseen complications and maintaining the overall performance of your vehicle.

Suspension and Brake Checks

Ensuring the proper functioning of the suspension and braking systems is crucial for safe and efficient operation. Regular inspections help identify potential issues, contributing to a smoother ride and improved handling. This section outlines essential steps for evaluating these systems, promoting both safety and performance.

Suspension Inspection

A well-maintained suspension system enhances comfort and stability. Follow these steps for a thorough assessment:

- Check for leaks: Inspect shock absorbers for any signs of fluid leakage.

- Assess bushings: Examine all rubber bushings for wear or damage.

- Inspect springs: Look for signs of corrosion or fatigue on coil and leaf springs.

- Evaluate alignment: Ensure that wheels are properly aligned to prevent uneven tire wear.

- Test rebound: Push down on the handlebars and observe how the suspension returns to its original position.

Brake System Evaluation

A reliable braking system is vital for safety. Conduct the following checks:

- Examine brake pads: Look for wear indicators and replace pads if they are worn down.

- Check fluid levels: Ensure brake fluid is at the recommended level and free of contaminants.

- Inspect lines and hoses: Look for cracks, leaks, or any signs of deterioration in brake lines.

- Test brake performance: Perform a gentle test to assess responsiveness and effectiveness.

- Evaluate rotor condition: Check for warping or excessive wear on brake rotors.

Maintaining the suspension and braking systems not only ensures a comfortable ride but also plays a significant role in overall safety. Regular inspections and prompt repairs when necessary are key to enjoying a reliable and safe experience.

Upgrading Yamaha DT 175 Parts

Enhancing the performance and functionality of a motorcycle can significantly improve the riding experience. This section discusses various components that can be upgraded to achieve better efficiency, increased power, and improved aesthetics.

When considering enhancements, it is essential to focus on parts that directly influence the machine’s performance. Upgrading the exhaust system, fuel intake, and suspension can lead to noticeable improvements. Below are some key components that riders might consider upgrading:

| Part | Benefits | Suggestions |

|---|---|---|

| Exhaust System | Improves exhaust flow and enhances sound | Aftermarket pipes, performance mufflers |

| Carburetor | Increases fuel efficiency and throttle response | High-performance carb kits |

| Suspension | Enhances ride comfort and handling | Upgraded shock absorbers, fork springs |

| Brakes | Improves stopping power and safety | Performance brake pads, upgraded rotors |

| Air Filter | Increases airflow for better combustion | High-flow air filters |

Choosing the right upgrades can significantly impact the overall performance and longevity of the motorcycle. Riders should conduct thorough research and select components that align with their riding style and preferences.

Resources for Further Reading

This section aims to provide valuable resources for individuals seeking to expand their knowledge on motorcycle maintenance and troubleshooting. Whether you are a novice or an experienced enthusiast, these references will offer insights, tips, and techniques to enhance your skills and understanding.

Books

- The Essential Guide to Motorcycle Maintenance – A comprehensive resource covering fundamental concepts and practices.

- Two-Wheel Troubleshooting – Focuses on common issues faced by riders and how to address them effectively.

- Advanced Mechanics for Bikes – Offers in-depth discussions on complex systems and repair methodologies.

Online Forums and Communities

Engaging with fellow riders can provide invaluable support and knowledge sharing. Consider participating in:

- Motorcycle Mechanics Forum – A vibrant community where enthusiasts share experiences and solutions.

- Rider’s Repair Network – A platform for discussing maintenance techniques and asking questions.

- Classic Bike Enthusiasts Group – Focuses on vintage models and their restoration processes.

Videos and Tutorials

Visual learning can be incredibly helpful for hands-on tasks. Here are some channels that offer practical demonstrations:

- Motorcycle Maintenance Academy – Offers a range of tutorials on various aspects of bike care.

- Two-Wheel Tinkering – Features DIY repair projects and maintenance tips.