Comprehensive Guide to Yamaha F70 Repair Manual

Owning a high-performance marine engine comes with the responsibility of ensuring its optimal functionality. Understanding the intricacies of your watercraft’s propulsion system is essential for maintaining peak performance and longevity. This section delves into the essential aspects of upkeep, providing insights into both routine checks and more complex issues that may arise over time.

Effective maintenance involves not only regular inspections but also the ability to diagnose and rectify common challenges. Whether you’re an experienced boater or a novice, having a thorough understanding of your engine’s workings will empower you to tackle problems confidently. Here, we will explore a range of procedures, from basic upkeep to more detailed interventions, all aimed at keeping your vessel in prime condition.

Equipped with the right knowledge and techniques, you can significantly enhance your engine’s reliability and performance. By following structured guidelines and recommendations, you will be better prepared to address any difficulties that may occur. This guide serves as a valuable resource, ensuring you can navigate through maintenance tasks with ease and expertise.

Overview of Yamaha F70 Engine

This section provides a comprehensive insight into a specific outboard engine model known for its performance and efficiency. Designed for various boating applications, it offers a blend of advanced technology and reliable mechanics, making it a popular choice among marine enthusiasts.

Engine Specifications

The powerplant features a robust design that delivers optimal output while maintaining fuel efficiency. With its lightweight construction, it ensures excellent maneuverability, making it suitable for a wide range of vessels. Key specifications include:

- Engine type: Four-stroke, inline

- Displacement: 1.0 liters

- Power output: Approximately 70 horsepower

- Weight: Around 113 kg

Performance Characteristics

This engine stands out for its smooth operation and reduced noise levels, contributing to an enjoyable boating experience. Its innovative fuel delivery system enhances performance, providing quick acceleration and consistent speed. Additionally, the incorporation of environmental considerations ensures lower emissions, aligning with modern sustainability standards.

In summary, this outboard engine model is engineered to meet the demands of both recreational and professional users, offering reliability and efficiency for diverse marine activities.

Common Issues with Yamaha F70

Every outboard motor may encounter specific challenges over time. Understanding these typical problems can help in maintaining optimal performance and prolonging the lifespan of the engine. Regular inspections and prompt attention to signs of malfunction are essential for ensuring reliability on the water.

Electrical Failures

One of the most frequent complications involves electrical components. Issues such as faulty wiring, blown fuses, or malfunctioning ignition systems can lead to starting difficulties or erratic performance. Regular checks of the electrical connections and components are crucial to prevent these failures from disrupting your activities.

Fuel System Problems

Another area of concern is the fuel system, where blockages or leaks can arise. Clogged filters, stale fuel, or issues with the fuel pump can significantly impact engine efficiency. Ensuring that the fuel system is clean and well-maintained can help avoid poor performance and potential damage to the engine.

Tools Needed for Repairs

When it comes to maintaining and fixing outboard engines, having the right equipment is essential for efficient and effective work. Proper tools not only simplify the process but also ensure that each task is completed with precision and care. Below, we outline the fundamental instruments that should be part of any maintenance kit.

Essential Hand Tools

A comprehensive set of hand tools is crucial for tackling various tasks. Common items include wrenches, pliers, and screwdrivers, which are necessary for loosening and tightening bolts or screws. Additionally, a torque wrench can help achieve the correct tightness, preventing damage to components. Keeping a set of sockets and a ratchet handy is also advisable for working on engine parts with greater ease.

Specialized Equipment

In addition to standard tools, certain specialized equipment is vital for specific repairs. A multimeter is invaluable for diagnosing electrical issues, while a compression tester can assess engine performance. Furthermore, having a quality set of pliers designed for fuel lines or hoses can streamline work significantly. Investing in these specialized tools will enhance the repair experience and contribute to better outcomes.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to effectively diagnosing and addressing issues with your outboard engine. By following a systematic approach, you can ensure that each problem is carefully evaluated and resolved, enhancing the longevity and performance of your equipment.

Begin by gathering all necessary tools and materials, ensuring that you have a clean workspace. Always start with a thorough inspection of the engine to identify visible signs of wear or damage. Pay attention to components such as the fuel system, ignition, and electrical connections.

Next, proceed with specific checks based on the symptoms observed. For instance, if the engine fails to start, examine the battery charge, wiring, and starter motor. For performance issues, inspect the fuel lines, filters, and carburetor settings.

Once you have pinpointed the area needing attention, disassemble the relevant components carefully. Keep track of screws and small parts to avoid losing them during the process. Clean each part thoroughly to remove dirt and debris that may hinder operation.

After cleaning, assess each component for damage or wear. Replace any parts that do not meet the required standards. Reassemble the engine systematically, following the reverse order of disassembly while ensuring all connections are secure.

Finally, conduct a series of tests to verify that the engine operates correctly. Monitor for any irregular sounds or performance issues, and make adjustments as necessary. Regular maintenance following these steps can significantly extend the life of your equipment.

Preventative Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By implementing a consistent maintenance routine, you can prevent unexpected breakdowns and enhance the overall efficiency of your machinery. These practices are designed to address potential issues before they escalate, allowing you to enjoy smooth operation for years to come.

Start with a thorough inspection of all components. Look for signs of wear or damage, and ensure that everything is properly secured. Pay close attention to fluid levels, as maintaining the correct amount is crucial for performance. Regularly check for leaks, and replace fluids according to the recommended schedule to keep the system running smoothly.

Cleaning is another vital aspect of maintenance. Accumulated dirt and debris can hinder functionality and lead to premature wear. Make it a habit to clean accessible parts regularly, ensuring that vents and filters are free from obstructions. This will not only improve efficiency but also help in identifying any potential issues early on.

Additionally, keep an eye on electrical connections. Corrosion can lead to poor performance and electrical failures. Inspect connectors and wiring periodically, and clean any corroded areas with appropriate solutions to maintain good conductivity. Lastly, consult the guidelines for any specific recommendations on maintenance intervals, as adhering to these can significantly reduce the likelihood of major repairs in the future.

Understanding Yamaha F70 Parts

This section aims to provide insight into the various components that make up a particular outboard engine. Familiarity with these elements is essential for effective maintenance and troubleshooting. Each part plays a critical role in the overall performance, and knowing their functions can significantly enhance the longevity and efficiency of the machinery.

Key Components

The primary elements include the powerhead, lower unit, and fuel system. The powerhead houses the engine and is responsible for converting fuel into mechanical energy. The lower unit contains the gears and propeller, playing a crucial role in thrust generation and maneuverability. The fuel system ensures that the engine receives the correct mixture for optimal performance, affecting speed and efficiency.

Maintenance Tips

Regular inspection and maintenance of these components are vital for ensuring smooth operation. Pay close attention to any signs of wear or damage, particularly in the powerhead and lower unit. Additionally, keeping the fuel system clean and properly adjusted will prevent issues that could lead to performance drops or engine failure.

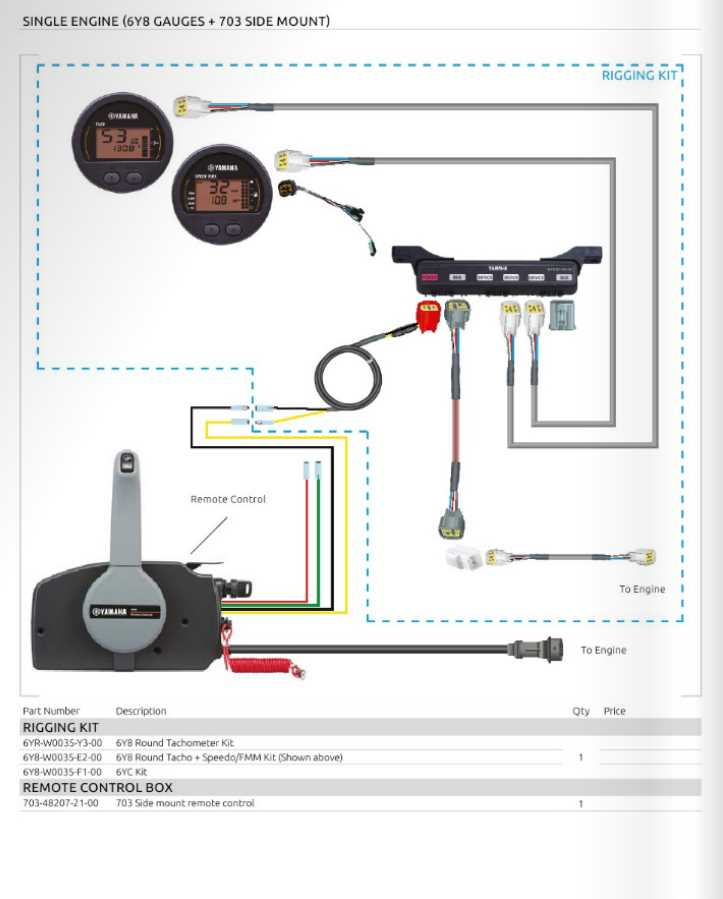

Wiring and Electrical System Guide

This section aims to provide a comprehensive overview of the wiring and electrical components essential for optimal performance and reliability. Understanding the intricacies of the electrical system is crucial for effective troubleshooting and maintenance.

Proper wiring ensures that all electrical elements function harmoniously. Familiarity with the layout and connections can prevent issues that may arise from wear or damage. Here are some key components to consider:

- Battery: The power source that initiates the electrical system.

- Starter motor: Responsible for starting the engine.

- Alternator: Charges the battery while the engine runs.

- Wiring harness: Connects various electrical parts and systems.

- Fuse box: Protects circuits by preventing overloads.

To maintain the integrity of the electrical system, follow these guidelines:

- Regularly inspect all wiring for signs of wear, fraying, or corrosion.

- Ensure connections are tight and free from oxidation.

- Replace fuses promptly if blown to avoid circuit damage.

- Keep the battery terminals clean and securely connected.

- Use proper gauge wires to prevent overheating and ensure efficient operation.

By adhering to these principles, one can ensure that the electrical system remains in peak condition, facilitating smooth operation and longevity.

Fuel System Troubleshooting Techniques

Addressing issues within the fuel system requires a systematic approach to identify and resolve potential malfunctions. By examining various components and understanding their interactions, one can effectively pinpoint the source of the problem and ensure optimal performance.

Common Symptoms and Causes

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Clogged fuel filter or empty tank |

| Rough idle | Dirty injectors or air leaks |

| Poor acceleration | Faulty fuel pump or pressure regulator |

Diagnostic Steps

To diagnose fuel-related issues, begin by inspecting the fuel tank and lines for blockages or leaks. Next, test the fuel pressure to ensure it meets manufacturer specifications. Checking the integrity of injectors and filters will also reveal if cleaning or replacement is necessary.

Cooling System Maintenance Advice

The efficiency of a watercraft’s cooling mechanism is vital for optimal performance and longevity. Regular upkeep ensures that the system operates smoothly, preventing overheating and potential damage. This section provides essential tips for maintaining the cooling system effectively.

Regular Inspection

Perform routine checks on all components of the cooling system, including hoses, clamps, and the water intake. Look for signs of wear, leaks, or blockages. Keeping these elements in good condition helps maintain proper water flow and prevents overheating.

Fluid Levels and Quality

Ensure that the coolant levels are adequate and the fluid is in good condition. Regularly change the coolant according to the manufacturer’s recommendations. Using the appropriate type of fluid will enhance cooling efficiency and protect against corrosion.

Emphasizing preventive maintenance will significantly extend the lifespan of your cooling system and improve overall performance. Stay proactive to enjoy a reliable and efficient operation on the water.

Testing and Adjusting Performance

This section focuses on the essential procedures for evaluating and fine-tuning the operational efficiency of your outboard engine. Regular assessments ensure that the unit operates at optimal levels, enhancing both performance and longevity. Understanding the various metrics and adjustments required can lead to a more enjoyable experience on the water.

Performance Evaluation

To begin the evaluation process, check key indicators such as throttle response, idle stability, and overall acceleration. Utilize diagnostic tools to monitor engine parameters and detect any anomalies. Pay attention to sounds and vibrations, as they can indicate underlying issues that may affect performance.

Adjusting Settings

After assessing performance, adjustments may be necessary. Start by calibrating the fuel-air mixture to ensure efficient combustion. Additionally, inspect and adjust the propeller pitch to optimize speed and torque. Regular maintenance of components such as the spark plugs and filters will also contribute to improved functionality.