Comprehensive Guide to Yamaha Golf Cart Engine Repair

When it comes to maintaining small transport vehicles, understanding their intricacies is essential for optimal performance and longevity. This guide delves into the essential practices for keeping these machines in top shape, ensuring smooth operation and enhancing overall functionality.

Whether you’re a seasoned enthusiast or a newcomer to the world of utility vehicles, having access to reliable information can make all the difference. The insights provided here will equip you with the knowledge needed to tackle common issues and conduct routine servicing effectively.

From troubleshooting typical malfunctions to exploring detailed procedures for enhancement, this resource aims to empower users. Armed with the right tools and information, you’ll be prepared to navigate the challenges of upkeep and maintenance with confidence.

Understanding Yamaha Golf Cart Engines

This section aims to provide insights into the inner workings of small utility vehicles commonly used in recreational settings. Knowledge of their power sources is essential for anyone looking to maintain or enhance performance.

These compact machines typically feature a few distinct types of propulsion systems:

- Electric systems, which rely on batteries for power.

- Gasoline-powered variants, utilizing combustion for operation.

Key components of these power units include:

- Fuel delivery systems, ensuring optimal mixture for combustion.

- Ignition mechanisms, crucial for starting and sustaining operation.

- Cooling systems, preventing overheating during use.

- Transmission systems, facilitating movement and speed adjustments.

Understanding the functionality of each element can greatly enhance one’s ability to troubleshoot issues and perform maintenance effectively.

In summary, gaining familiarity with these propulsion systems and their components can lead to improved performance and longevity of the vehicles, allowing for a better experience on the course or in other recreational activities.

Common Issues with Yamaha Engines

Many users encounter a variety of challenges with their small vehicles, which can lead to decreased performance and efficiency. Understanding these common problems can help in diagnosing issues early and maintaining optimal functionality.

Overheating is a frequent concern, often caused by insufficient coolant levels or a malfunctioning thermostat. This can lead to serious damage if not addressed promptly.

Fuel delivery problems can arise from clogged filters or failing pumps, resulting in poor acceleration or stalling. Regular checks of the fuel system can prevent these frustrating situations.

Starting difficulties are another common issue, typically linked to battery failures or starter motor malfunctions. Ensuring that the battery is charged and connections are clean can mitigate these problems.

Electrical system failures can disrupt overall functionality, often stemming from corroded wiring or faulty switches. Routine inspections of the electrical components can help identify and resolve issues before they escalate.

Being aware of these potential problems can empower users to take proactive measures, ensuring their vehicles remain in top condition for all their journeys.

Essential Tools for Engine Repair

When tackling the complexities of mechanical restoration, having the right instruments at your disposal is crucial. The appropriate gear not only streamlines the process but also enhances accuracy and safety. Below, we delve into the must-have items that will aid in any undertaking related to powertrain maintenance.

Basic Hand Tools

- Wrenches: A variety of sizes to accommodate different fasteners.

- Sockets and Ratchets: Essential for tightening and loosening bolts in hard-to-reach areas.

- Screwdrivers: Both flathead and Phillips varieties for various screws.

- Pliers: Useful for gripping and bending components.

Specialized Equipment

- Compression Tester: Measures the pressure within cylinders to assess performance.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Timing Light: Helps in adjusting the ignition timing for optimal operation.

- Multimeter: Essential for diagnosing electrical issues.

Having these tools readily available will greatly assist in achieving successful outcomes during mechanical work. A well-equipped workshop lays the foundation for effective maintenance and longevity of your machinery.

Step-by-Step Engine Troubleshooting Guide

This guide provides a systematic approach to diagnosing common issues that may arise in a motorized vehicle. By following these steps, you can identify problems and implement appropriate solutions, ensuring optimal performance.

Initial Checks

- Verify fuel levels and quality.

- Inspect battery condition and connections.

- Check for visible leaks or unusual odors.

Systematic Diagnosis

- Start-Up Issues:

- Listen for unusual sounds during ignition.

- Check the ignition switch and starter.

- Assess the electrical system for faults.

- Performance Problems:

- Monitor acceleration and deceleration.

- Evaluate throttle response.

- Inspect air filters for clogs.

- Overheating:

- Check coolant levels and condition.

- Inspect the cooling system for blockages.

- Evaluate the thermostat and radiator function.

By systematically addressing each area, you can effectively troubleshoot and resolve various challenges, ensuring a smoother operation.

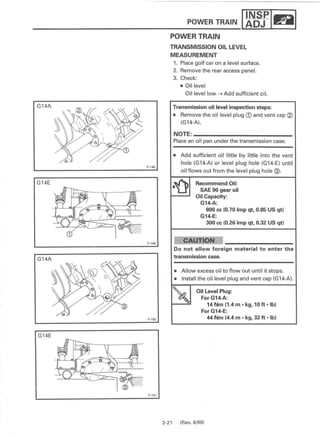

How to Change Engine Oil

Maintaining optimal performance requires regular fluid changes in your vehicle. Ensuring that the lubricant is clean and at the correct level not only prolongs the life of the machine but also enhances its efficiency. This guide will outline the necessary steps to effectively replace the lubricant, ensuring your vehicle runs smoothly.

Step 1: Gather Supplies

Step 2: Prepare the Vehicle

Park the machine on a level surface and turn off the ignition. It’s advisable to allow the unit to cool down for a while, as hot components can cause burns or other injuries. Once cooled, secure the vehicle to prevent any movement during the procedure.

Step 3: Drain the Old Fluid

Locate the drain plug, usually found at the bottom of the reservoir. Place the drain pan underneath and carefully remove the plug with your wrench. Allow the used lubricant to completely drain into the pan. Dispose of the old fluid responsibly according to local regulations.

Step 4: Replace the Filter

If your setup includes a filter, remove the old one. Apply a bit of new lubricant to the gasket of the new filter before installing it. This ensures a proper seal and prevents leaks.

Step 5: Add New Lubricant

Using a funnel, pour the new lubricant into the reservoir through the designated opening. Be sure to check the owner’s specifications for the correct type and amount needed. After filling, replace the cap securely.

Step 6: Check for Leaks

Start the unit and let it run for a few minutes. This allows the new fluid to circulate and fill the system. Afterward, inspect the area around the drain plug and filter for any signs of leaks. If everything is dry, you’ve successfully completed the task!

Step 7: Clean Up

Dispose of the used lubricant and filter in accordance with local environmental regulations. Clean your tools and the work area, ensuring everything is tidy before concluding your maintenance session.

Replacing Spark Plugs Effectively

Replacing ignition components is a vital maintenance task that can significantly enhance performance and efficiency. This section outlines essential steps to ensure a smooth and effective replacement process.

Before beginning, gather the necessary tools and materials:

- New ignition components

- Socket wrench

- Torque wrench

- Gap gauge

- Anti-seize compound (optional)

Follow these steps for a successful replacement:

- Preparation: Ensure the unit is turned off and cooled down. Disconnect the battery to prevent any electrical mishaps.

- Accessing the Components: Remove any covers or components that obstruct access to the ignition parts.

- Removing Old Components: Carefully unscrew the old pieces using a socket wrench. Avoid applying excessive force to prevent damage.

- Inspecting the Area: Check for any debris or damage in the socket before installing new parts.

- Installing New Components: Apply a small amount of anti-seize compound to the threads if desired. Install the new pieces and tighten them to the manufacturer’s specifications using a torque wrench.

- Reassembling: Replace any covers or components that were removed, ensuring everything is securely fastened.

- Final Check: Reconnect the battery and start the unit to verify proper function. Monitor for any unusual sounds or performance issues.

Regular maintenance of ignition components contributes to longevity and optimal functionality, making this task essential for any operator.

Cleaning the Carburetor Made Easy

Maintaining the optimal performance of your vehicle is essential, and one of the key components that often requires attention is the fuel delivery system. A clean carburetor ensures smooth operation and efficient fuel usage. This guide will simplify the process of cleaning, helping you restore functionality without unnecessary complications.

Gathering Your Supplies

Before starting, ensure you have all necessary tools and materials at hand. You will need a cleaning solution specifically designed for fuel systems, a soft brush, a set of screwdrivers, and some rags. Having these items ready will streamline your work and minimize downtime.

Step-by-Step Cleaning Process

Begin by disconnecting the fuel supply and removing the carburetor from its housing. Carefully take apart the components, noting their arrangement for reassembly. Submerge the removable parts in the cleaning solution and allow them to soak for a while. Use the soft brush to gently scrub away any buildup. Rinse thoroughly and dry completely before reassembling everything. Finally, reattach the unit, ensuring all connections are secure.

Diagnosing Electrical Problems in Carts

Identifying issues within the electrical systems of small vehicles can be a challenging yet essential task. These complications can manifest in various forms, from power failures to erratic behavior of components. Understanding the underlying causes is crucial for effective troubleshooting and ensuring optimal performance.

The following table summarizes common electrical issues, their symptoms, and possible solutions:

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Dead Battery | No power, dim lights | Charge or replace the battery |

| Loose Connections | Intermittent power, flickering lights | Tighten or clean connectors |

| Blown Fuses | No electrical function, dead circuit | Replace blown fuses |

| Faulty Switches | Components not responding | Inspect and replace faulty switches |

| Worn Wiring | Short circuits, sparks | Inspect and replace damaged wiring |

By systematically evaluating these factors, one can efficiently address and resolve electrical complications. Regular maintenance and inspections can help prevent issues before they escalate, ensuring a reliable and enjoyable experience.

Regular Maintenance Tips for Longevity

To ensure the extended lifespan of your vehicle, consistent upkeep is essential. Regular attention to various components not only enhances performance but also prevents unexpected failures. Following a structured maintenance routine will contribute to reliable operation over the years.

1. Routine Inspections: Regularly examine critical parts, such as the battery, brakes, and tires. Early detection of wear or damage can prevent more significant issues later.

2. Fluid Checks: Keep an eye on fluid levels, including oil and coolant. Maintaining appropriate levels ensures smooth functioning and reduces the risk of overheating or mechanical failure.

3. Tire Maintenance: Inspect tire pressure frequently. Properly inflated tires not only improve fuel efficiency but also enhance safety and handling.

4. Battery Care: Clean battery terminals and check connections. A well-maintained battery prolongs lifespan and reliability.

5. Cleaning: Regularly wash the exterior and clean the undercarriage. Removing dirt and debris helps prevent corrosion and keeps components in optimal condition.

6. Scheduled Servicing: Adhere to manufacturer-recommended service intervals. Professional maintenance can catch potential problems before they escalate.

7. Storage Practices: If your vehicle is not in use, store it in a dry, protected area. Using a cover can shield it from dust and environmental damage.

By implementing these practices, you can significantly enhance the durability and reliability of your vehicle, ensuring enjoyable and worry-free usage for years to come.

Upgrading Your Yamaha Golf Cart Engine

Enhancing the performance of your recreational vehicle can significantly improve its efficiency and enjoyment. Whether you seek increased speed, better torque, or improved fuel efficiency, various upgrades can be implemented to achieve these goals. This section will explore the options available to elevate your ride’s capabilities and ensure a smoother experience on the course or in the neighborhood.

Performance Enhancements

Consider installing a high-performance carburetor or fuel injection system to maximize fuel delivery. These upgrades can lead to improved acceleration and responsiveness, allowing for a more thrilling ride. Additionally, swapping out the stock exhaust for a performance variant can enhance airflow, resulting in better power output and a more robust sound.

Electrical System Improvements

Upgrading the electrical components can also yield significant benefits. Installing a higher-capacity battery and an advanced charging system can ensure that your vehicle operates efficiently under various conditions. Enhanced lighting systems not only improve visibility but can also add a custom aesthetic, making your vehicle stand out on any terrain.

Safety Precautions During Repairs

When engaging in maintenance tasks, ensuring safety is paramount. Adhering to proper guidelines not only protects the individual but also enhances the longevity and efficiency of the equipment. It is essential to take proactive measures to avoid accidents and injuries.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Work in a well-ventilated area to minimize exposure to harmful fumes.

- Keep the workspace clean and organized to prevent trips and falls.

- Ensure that tools and materials are in good condition and properly stored after use.

Specific Precautions

- Disconnect power sources before beginning any work to avoid electrical shock.

- Use proper lifting techniques when handling heavy components to prevent injuries.

- Be cautious of hot surfaces and allow adequate time for cooling.

- Follow manufacturer recommendations for specific tasks to ensure safety and effectiveness.

Finding Genuine Yamaha Replacement Parts

When it comes to maintaining performance and longevity, sourcing authentic components is crucial. Using original parts ensures that your vehicle operates efficiently and retains its value over time. This section will guide you through the process of identifying and acquiring these essential items.

Why Choose Authentic Components?

- Quality Assurance: Genuine parts are designed to meet specific standards, ensuring compatibility and durability.

- Optimal Performance: Original components are engineered to work seamlessly with your vehicle, enhancing overall functionality.

- Warranty Protection: Using authentic items often helps maintain any existing warranties, providing peace of mind.

Where to Find Original Parts

- Authorized Dealers: Always start with licensed dealerships that specialize in your vehicle’s brand.

- Official Websites: Many manufacturers offer online catalogs where you can browse and order parts directly.

- Trusted Retailers: Look for reputable stores that guarantee authenticity and have a good reputation in the industry.

- Online Marketplaces: Use well-known platforms, but ensure that the seller is verified and offers genuine products.

By choosing authentic components, you are investing in the reliability and efficiency of your vehicle, ensuring it remains in top condition for years to come.