Guide to Yamaha Hull Repair Techniques

This section provides essential insights into the upkeep and restoration of aquatic vessels. Understanding the structure and potential issues that can arise is crucial for ensuring longevity and performance on the water.

Whether you are dealing with minor imperfections or significant damages, having a thorough approach can make a substantial difference. This guide will walk you through various techniques and practices to enhance the integrity of your craft.

Emphasizing the importance of regular assessments and timely interventions, this resource aims to empower enthusiasts and professionals alike. By following the outlined procedures, you can maintain optimal functionality and aesthetic appeal for your watercraft.

This section aims to explore various types of watercraft structures, focusing on their characteristics and construction methods. Understanding these variations is essential for effective maintenance and restoration practices.

- Monohull Designs

Single-body vessels known for stability and ease of handling. Commonly used for recreational purposes, they offer straightforward construction and repair processes.

- Catamaran Structures

These multi-hull designs provide excellent buoyancy and stability, making them popular for leisure activities. Their unique configuration requires specific approaches to maintenance.

- Trimaran Models

Featuring three hulls, these boats offer exceptional speed and stability. Their complexity demands a thorough understanding of their structural integrity for any restoration efforts.

By examining these types, one can better appreciate the unique considerations involved in maintaining and restoring various vessel designs.

Common Issues with Hulls

Watercraft structures often encounter various challenges over time. Understanding these common problems is essential for ensuring the longevity and performance of your vessel. Below are some frequent issues that can arise, along with their potential causes and solutions.

Types of Problems

- Cracks and Damage: Structural cracks can occur due to impact or prolonged exposure to harsh conditions.

- Delamination: This issue arises when layers of the structure separate, often due to moisture infiltration.

- Corrosion: Metal components can suffer from rust, which weakens structural integrity over time.

Preventive Measures

- Regularly inspect the structure for any visible signs of wear or damage.

- Apply protective coatings to metal parts to prevent corrosion.

- Ensure proper storage conditions to minimize exposure to elements.

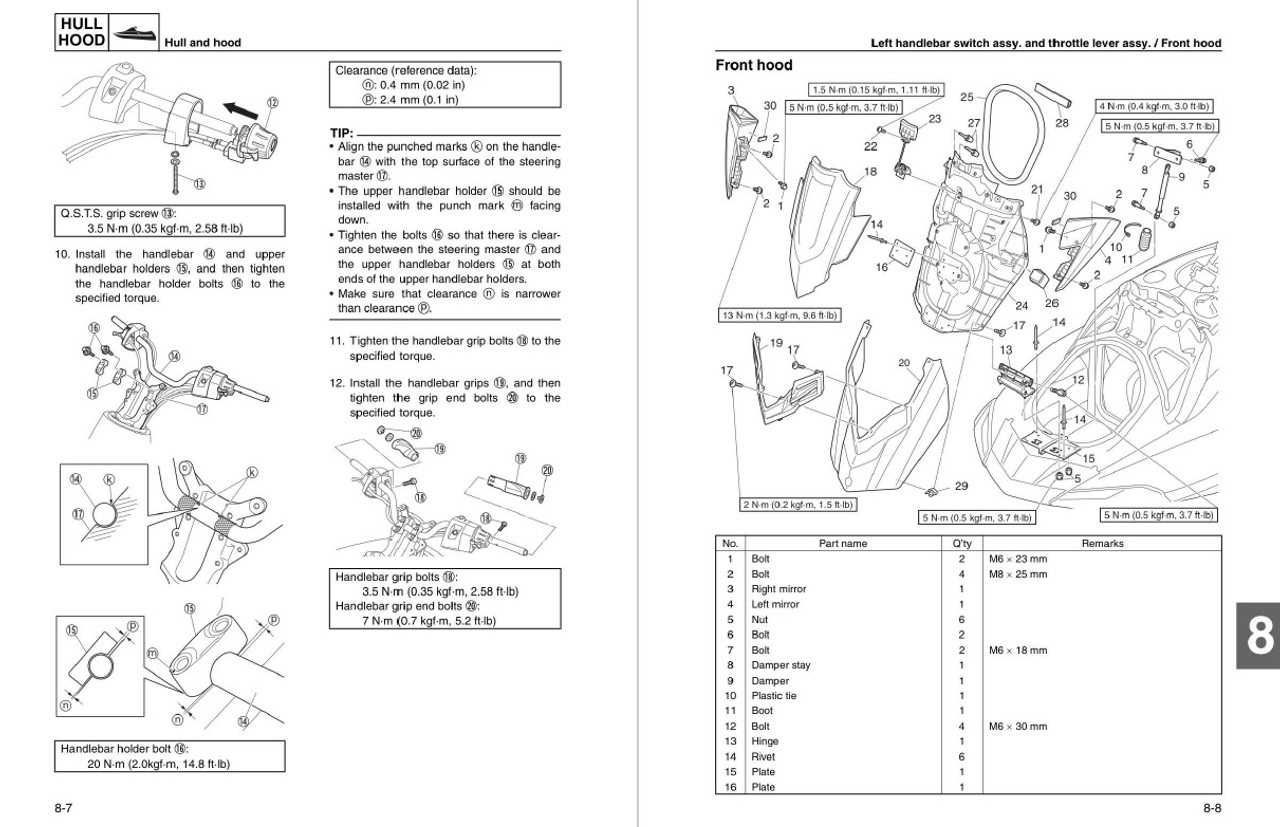

Essential Tools for Repairs

Having the right instruments is crucial for ensuring effective maintenance and restoration of any vessel. A well-equipped toolkit can significantly enhance the efficiency and quality of the work performed, making it easier to tackle various tasks.

Among the primary items to include are screwdrivers, which come in various sizes and types to accommodate different fasteners. Additionally, a reliable wrench set is essential for loosening or tightening bolts and nuts. For cutting tasks, an utility knife or a handsaw should be readily available.

Furthermore, a quality drill is indispensable for making holes or driving screws, while a measuring tape ensures precision in all dimensions. Lastly, safety gear such as gloves and goggles should always be on hand to protect against any potential hazards during the process.

Step-by-Step Repair Techniques

This section outlines effective methods for addressing common issues with watercraft structures. Following these techniques will help ensure longevity and optimal performance.

- Assessment of Damage:

Begin by examining the affected area carefully. Identify any cracks, dents, or punctures. Document your findings for reference.

- Preparation:

Clean the damaged section thoroughly. Remove any debris, dirt, or loose material to create a smooth surface for treatment.

- Material Selection:

Choose appropriate substances for the task, such as epoxy resin or fiberglass cloth. Ensure compatibility with the structure’s material.

- Application Process:

Apply the chosen material evenly over the damaged area. Use a brush or spatula to spread it, ensuring complete coverage.

- Curing Time:

Allow the applied material to cure according to the manufacturer’s instructions. This is crucial for achieving a strong bond.

- Finishing Touches:

Once cured, sand the area smoothly to match the surrounding surface. Optionally, paint or coat to blend with the original finish.

By following these systematic approaches, you can effectively restore the integrity of your watercraft, ensuring safe and enjoyable usage.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your watercraft. Regular attention to various components can significantly extend its lifespan and enhance your experience on the water.

Routine Inspection

- Check for any signs of wear and tear on the exterior.

- Inspect all seals and joints to prevent leaks.

- Examine the propulsion system for any loose or damaged parts.

Regular Cleaning

- Wash the surface after each outing to remove salt and grime.

- Use appropriate cleaners to maintain the finish and prevent corrosion.

- Store the vessel in a sheltered area to protect it from harsh weather conditions.

Identifying Damage Early

Recognizing issues at an early stage is crucial for maintaining the integrity and performance of your vessel. Prompt detection allows for timely intervention, which can prevent more extensive repairs and costs down the line.

Here are some common signs to watch for:

- Visible cracks or fractures in the exterior surface.

- Discoloration or unusual staining, which may indicate leaks.

- Soft spots that can be felt when applying pressure.

- Abnormal noises while navigating, suggesting structural problems.

Regular inspections should be conducted to ensure the structure remains in optimal condition. Following these steps can help identify potential issues early:

- Conduct routine visual assessments, especially after rough weather.

- Check for any changes in the vessel’s performance during use.

- Pay attention to feedback from crew members regarding any irregularities.

Taking these proactive measures will enhance the longevity and safety of your watercraft.

Choosing the Right Materials

When undertaking any restoration project, selecting appropriate components is crucial for achieving lasting results. The right choices not only ensure durability but also enhance overall performance. Understanding the various options available can significantly impact the success of the endeavor.

Durability is a key factor to consider when evaluating materials. Look for substances that can withstand environmental challenges, such as moisture and temperature fluctuations. Materials with high resistance to corrosion and wear will contribute to the longevity of the structure.

Another important aspect is weight. Lighter options may improve maneuverability, while heavier materials can provide greater stability. It is essential to balance these considerations based on the intended use and conditions of the vessel.

Lastly, consider the ease of application. Some materials require specialized skills or tools for installation, which can affect the overall timeline and cost of the project. Selecting user-friendly options can simplify the process and yield satisfactory results.

Professional vs. DIY Repairs

When it comes to addressing damage on watercraft, the choice between hiring an expert or tackling the task independently can significantly influence the outcome. Each approach carries its own set of advantages and challenges that must be carefully considered.

Professional assistance often ensures a high level of expertise and quality. Specialists bring a wealth of knowledge, experience, and the right tools to handle complex issues. This option is particularly beneficial for extensive damage, where meticulous attention to detail is crucial. Furthermore, professionals can offer warranties on their work, providing peace of mind for the owner.

On the other hand, DIY solutions can be appealing for those looking to save money or gain hands-on experience. Engaging in self-repair allows for a personalized approach and the satisfaction of completing the project independently. However, it is essential to consider the potential risks involved. Without proper skills and knowledge, the results may not meet the desired standards, leading to further complications down the line.

Ultimately, the decision between these two options should be based on the complexity of the situation, the owner’s skills, and the resources available. Weighing the pros and cons will help determine the most suitable path forward.

Preparing for a Repair Project

Before embarking on a restoration endeavor, it is crucial to gather the necessary knowledge and materials. A well-structured approach can significantly enhance the efficiency of the process and lead to successful outcomes.

Begin by assessing the condition of the item in question. Identifying specific issues will help in determining the tools and resources required. It is advisable to create a checklist that includes all necessary equipment, parts, and protective gear.

Next, ensure you have a suitable workspace. An organized and clean area will facilitate smoother operations and minimize the risk of accidents. Adequate lighting and ventilation are essential for maintaining focus and comfort during the project.

Finally, familiarize yourself with relevant techniques and safety precautions. Researching best practices will empower you to tackle challenges effectively and ensure a safer working environment.

Post-Repair Care and Inspection

After completing the restoration process, it is crucial to maintain and examine the surface to ensure longevity and optimal performance. Proper care and regular inspections help identify any issues early, prolonging the life of the structure.

Here are some essential practices to follow:

- Regular Cleaning: Remove dirt, salt, and debris using gentle cleaners to avoid damage.

- Visual Inspections: Frequently check for cracks, blisters, or other signs of wear.

- Moisture Checks: Inspect for any moisture accumulation, which could lead to deterioration.

- Hardware Examination: Ensure all fittings, seals, and attachments are secure and in good condition.

Incorporating these steps into a routine maintenance schedule will enhance the durability of the structure and improve safety during use.