Comprehensive Guide to Repairing Your Yamaha Moto-4 250

Ensuring the longevity and optimal performance of your all-terrain vehicle is essential for a thrilling riding experience. This section aims to provide comprehensive insights and techniques that will aid enthusiasts in keeping their machines in peak condition. With the right approach, even minor issues can be addressed effectively, preventing costly repairs and extending the life of your vehicle.

In this guide, you will discover valuable information ranging from routine inspections to more complex troubleshooting. Understanding the intricacies of your vehicle’s components can empower you to tackle maintenance tasks with confidence. Each chapter is designed to equip you with the knowledge necessary to handle various challenges that may arise during your ownership journey.

Whether you’re a seasoned rider or a newcomer, having access to detailed guidance is crucial. The following sections will outline essential procedures, provide tips for enhancing performance, and highlight common pitfalls to avoid. Dive into the world of vehicle care and unlock the potential of your all-terrain machine.

Overview of Yamaha Moto-4 250

This section provides an insight into a notable all-terrain vehicle that has gained popularity for its reliability and versatility. Designed to navigate various landscapes, this model is equipped to handle both recreational and practical tasks, making it a preferred choice among enthusiasts and professionals alike.

Key Features

Among the standout attributes of this machine are its robust construction and efficient performance. With a powerful engine and well-designed suspension system, it offers a smooth ride even on challenging terrains. The user-friendly controls enhance the overall experience, making it accessible for riders of all skill levels.

| Feature | Description |

|---|---|

| Engine | Single-cylinder, air-cooled, delivering reliable power. |

| Transmission | Automatic transmission for effortless shifting. |

| Suspension | Independent front suspension for improved stability. |

| Weight | Lightweight design facilitating easier handling. |

Maintenance Considerations

Regular upkeep is essential for maintaining optimal performance. Basic tasks such as checking oil levels, inspecting the tires, and ensuring the brakes are functioning correctly can significantly prolong the lifespan of the vehicle. Familiarity with maintenance practices can enhance the overall ownership experience.

Common Issues and Solutions

Every all-terrain vehicle may encounter challenges during its lifecycle, requiring attention and care to maintain optimal performance. Understanding these frequent problems and their remedies can enhance the longevity and reliability of the machine, ensuring a smooth riding experience.

Engine Performance Problems

One of the most prevalent issues involves the engine not starting or stalling unexpectedly. This can stem from a variety of causes, including fuel blockage, battery failure, or ignition system faults. To address this, first, check the fuel lines for clogs and ensure that the fuel is fresh. If the battery appears weak, recharge or replace it as necessary. Lastly, inspect the spark plug for wear or deposits; replacing it can significantly improve performance.

Transmission Difficulties

Another common challenge is related to the transmission system, which may exhibit slipping or difficulty shifting gears. This often results from low fluid levels or contamination. To resolve this, begin by checking the transmission fluid level and topping it up if needed. If the fluid appears dirty or burnt, a complete fluid change may be required. Additionally, inspecting the linkage and adjusting it can help in restoring proper functionality.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of any vehicle. This section highlights the fundamental implements that every enthusiast should possess to ensure a smooth and successful experience when tackling mechanical challenges. From basic hand tools to specialized devices, understanding their use can significantly streamline the process.

Basic Hand Tools

Start with a solid set of hand tools, including wrenches, pliers, and screwdrivers. These essentials are necessary for loosening and tightening various components. A quality socket set can also be invaluable, allowing for quick access to hard-to-reach fasteners. Ensuring these tools are readily available will facilitate most routine tasks.

Specialized Equipment

In addition to standard tools, some specialized equipment can enhance your maintenance capabilities. A torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing potential damage. A multimeter is useful for diagnosing electrical issues, while a lift or stand provides better access to the undercarriage. Investing in these tools can make complex repairs more manageable and efficient.

Step-by-Step Maintenance Guide

Proper upkeep of your all-terrain vehicle ensures longevity and optimal performance. This guide outlines essential maintenance tasks that every owner should follow to keep their machine running smoothly and efficiently.

Regular Checks

- Fluid Levels: Regularly inspect oil, coolant, and brake fluid levels.

- Air Filter: Check and clean or replace the air filter to maintain airflow.

- Tires: Examine tire pressure and tread for wear and tear.

Scheduled Maintenance Tasks

- Change Engine Oil: Follow the manufacturer’s recommendation for intervals.

- Inspect the Battery: Ensure terminals are clean and connections are secure.

- Brake System: Examine brake pads and discs for signs of wear.

- Chain Lubrication: Clean and lubricate the drive chain to prevent rust.

- Spark Plug Replacement: Change spark plugs as needed for efficient combustion.

By adhering to these guidelines, you can enhance the reliability and performance of your vehicle, ensuring enjoyable rides for years to come.

Engine Troubleshooting Techniques

When it comes to diagnosing issues within an internal combustion unit, a systematic approach is essential. Identifying the root cause of performance problems can save time and resources, ensuring that repairs are effective and long-lasting. This section outlines key methods to troubleshoot engine difficulties, enabling users to effectively address and resolve common complications.

Initial Inspection

Begin by conducting a thorough visual examination of the engine components. Look for signs of wear, leaks, or damage. Pay attention to hoses, belts, and connections. Loose wires or corroded terminals can lead to electrical failures. Moreover, ensure that all fluids are at appropriate levels and free from contamination. An initial inspection can often reveal underlying issues that may not be immediately apparent.

Diagnostic Tests

Once the visual check is complete, implement diagnostic tests to gather more detailed information. Use a compression gauge to measure the pressure within the cylinders; low readings may indicate problems with valves or piston rings. Additionally, employing an O2 sensor can help assess fuel mixture efficiency. Analyzing exhaust emissions provides insight into combustion quality and can highlight issues with ignition timing or fuel delivery.

Replacing the Drive Chain

Maintaining optimal performance in any off-road vehicle often requires attention to the drive chain. This critical component connects the engine power to the wheels, enabling smooth acceleration and control. Over time, wear and tear can lead to diminished effectiveness, necessitating its replacement to ensure safety and efficiency during rides.

Before starting the replacement process, gather the necessary tools and materials. A clean workspace is also essential for a successful operation. Below is a list of items typically required:

| Tool/Material | Purpose |

|---|---|

| Socket Wrench | To remove bolts securing the chain. |

| Chain Breaker Tool | To disconnect the old chain. |

| New Drive Chain | Replacement for the worn-out chain. |

| Lubricant | To ensure smooth operation post-installation. |

| Safety Gear | Protective equipment for personal safety. |

Begin by elevating the vehicle securely, allowing easy access to the drive mechanism. Use the socket wrench to remove the necessary bolts, followed by utilizing the chain breaker tool to detach the old chain. Carefully inspect the sprockets for any signs of damage; replacing them may also be advisable if they show significant wear.

Once the old chain is removed, position the new one, ensuring it aligns correctly with the sprockets. Reattach all components and fasten the bolts securely. Finally, apply a suitable lubricant to the new chain to enhance its lifespan and performance. Regular checks and maintenance will prolong the life of your new drive chain and maintain the overall efficiency of your vehicle.

Brake System Inspection Tips

Ensuring optimal performance of the braking mechanism is crucial for safe operation. Regular evaluation of the components can prevent potential failures and enhance overall reliability. This section outlines effective methods to assess the braking system, focusing on critical areas that require attention.

1. Visual Inspection: Begin with a thorough visual examination of the brake components. Look for signs of wear, such as cracks or corrosion on the calipers, and inspect the brake pads for thickness. Uneven wear may indicate alignment issues or a need for replacement.

2. Check Brake Fluid: Ensure the brake fluid is at the recommended level. Low fluid can compromise braking efficiency. Additionally, examine the fluid’s clarity; contaminated fluid should be replaced promptly to maintain performance.

3. Test Brake Function: Engage the brakes at low speed to assess their responsiveness. Listen for unusual noises, such as grinding or squeaking, which may indicate problems. A spongy feeling in the brake lever or pedal may suggest air in the hydraulic system.

4. Inspect Hoses and Lines: Examine all hoses and lines for any signs of wear or leaks. Cracks or bulges can lead to brake failure. Ensure connections are secure and free from any fluid seepage.

5. Examine the Brake Disc: Inspect the brake discs for any grooves, warping, or discoloration. Uneven surfaces can affect braking efficiency and should be addressed by resurfacing or replacement.

6. Regular Maintenance: Establish a routine maintenance schedule to keep the braking system in optimal condition. Regular checks and timely replacements of worn components will help ensure safety and reliability on the road.

By following these tips, you can maintain a functional and effective braking system, contributing to safer rides and enhanced performance.

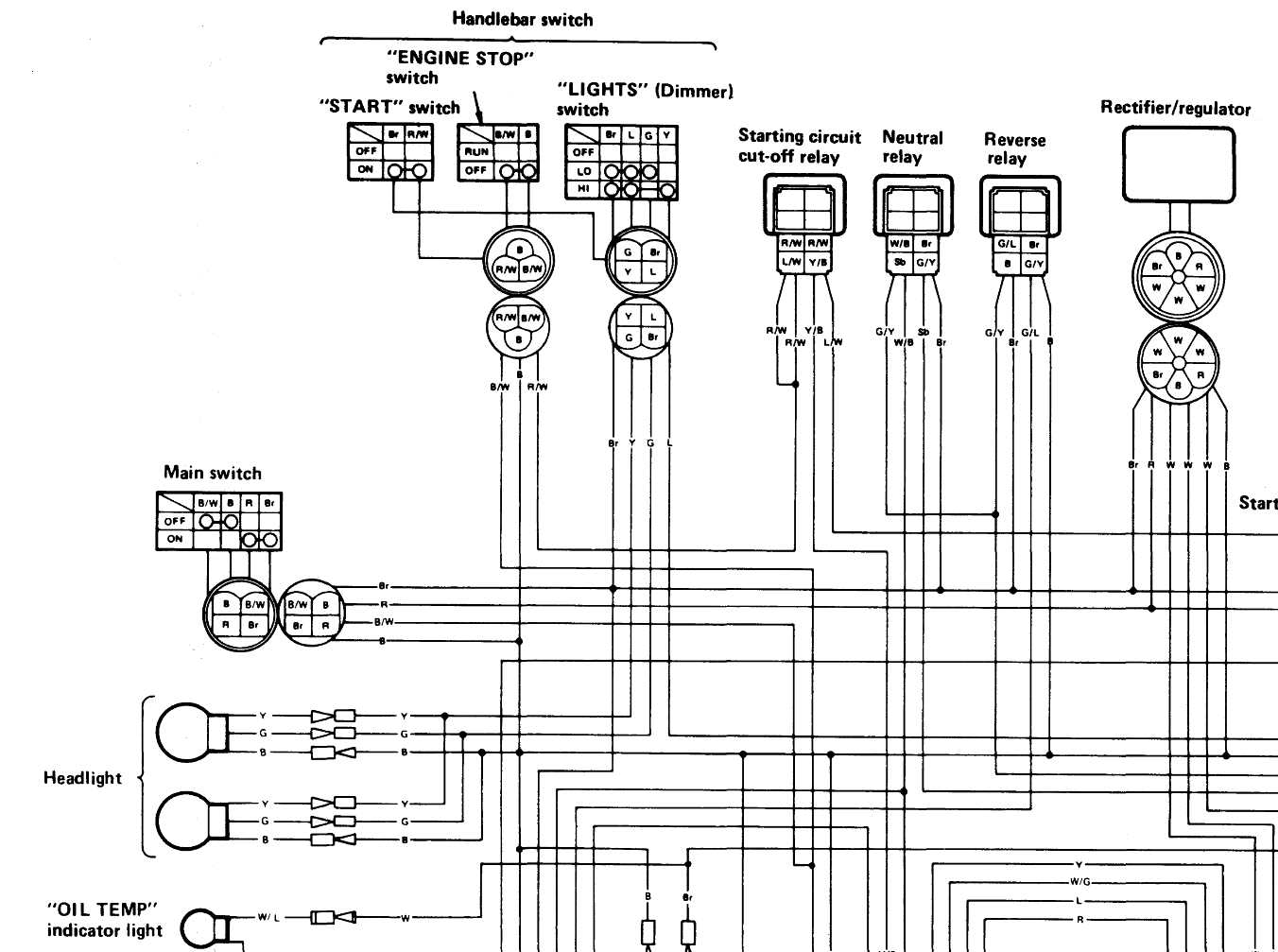

Electrical System Diagnostics

Diagnosing electrical systems is essential for ensuring optimal performance and longevity of any vehicle. This process involves identifying faults and malfunctions within the wiring, components, and circuitry, enabling efficient troubleshooting and repair.

Step-by-step diagnostics typically begins with a visual inspection of the wiring harnesses and connectors for any signs of wear or damage. Next, using a multimeter can help measure voltage, current, and resistance at various points, which is crucial for pinpointing issues.

Additionally, understanding schematics is vital, as they provide a clear representation of the electrical layout. By following the circuits, one can track down short circuits, open circuits, or faulty components that may disrupt normal functionality.

Finally, regular maintenance checks and keeping the system clean from corrosion and debris are important practices that contribute to preventing future electrical failures.

Fuel System Maintenance Advice

Proper upkeep of the fuel system is essential for ensuring optimal performance and longevity of your all-terrain vehicle. Regular maintenance can prevent issues such as poor fuel efficiency, hard starting, and engine misfires. By focusing on key components, you can enhance the reliability of your ride.

Regular Inspections

Frequent checks of the fuel lines, filters, and injectors can help identify potential problems before they escalate. Look for signs of wear, such as cracks in the hoses or debris in the filters. Keeping these components clean and free of obstructions will improve fuel flow and overall engine function.

Fuel Quality

Using high-quality fuel is vital for maintaining the health of the engine. Ensure that you select fuel that meets the manufacturer’s specifications. Additionally, consider using fuel stabilizers to prevent degradation, especially if the vehicle will remain unused for extended periods. This practice will help prevent varnish buildup and fuel-related issues.

Restoring the Suspension Components

Revitalizing the suspension system is essential for enhancing ride quality and overall performance. Over time, components can wear out or degrade, leading to a less stable and comfortable experience. This section focuses on the methods and techniques for refurbishing these critical parts, ensuring optimal function and safety.

Assessment and Disassembly

Begin by thoroughly inspecting each suspension element for signs of wear, such as leaks, cracks, or rust. Carefully disassemble the components, taking care to document the order of parts and any special configurations. This step is crucial for maintaining the integrity of the system during reassembly.

Cleaning and Reconditioning

Once disassembled, clean each part using appropriate solvents and brushes to remove dirt and debris. Inspect for damage and replace any worn components. Lubricate moving parts with high-quality grease to ensure smooth operation. After reconditioning, reassemble the suspension system, following the documented steps to maintain proper alignment and functionality.

Preparing for Seasonal Storage

When the time comes to store your vehicle for the off-season, proper preparation is essential to ensure it remains in optimal condition. Taking the right steps before putting your machine away can help prevent damage and ensure a smooth reawakening when it’s time to hit the road again.

Steps for Effective Preparation

To prepare your vehicle for storage, follow these crucial steps to protect its components and maintain performance:

| Task | Description |

|---|---|

| Clean Thoroughly | Remove dirt, mud, and debris to prevent corrosion and rust. |

| Fuel Stabilization | Add a fuel stabilizer to prevent the fuel from breaking down. |

| Oil Change | Replace old oil to remove contaminants and protect the engine. |

| Batter Maintenance | Disconnect the battery and store it in a cool, dry place. |

| Tire Care | Inflate tires to the recommended pressure and consider placing them on stands. |

Final Checks

Before closing the storage space, perform a final inspection. Ensure all fluids are topped off, and any necessary repairs are completed. Covering the vehicle with a breathable tarp can further protect it from dust and moisture. By following these guidelines, you can enjoy peace of mind knowing your machine will be ready for action when the season returns.

Finding OEM Parts and Accessories

Locating original equipment manufacturer components and supplementary items is essential for maintaining the longevity and performance of your vehicle. These authentic parts ensure that your machine operates as intended, preserving its reliability and efficiency. Whether you’re looking for replacements or enhancements, sourcing genuine items can significantly impact your overall experience.

To begin your search, consider visiting official dealerships or authorized retailers. They typically stock a wide range of products specifically designed for your model. Additionally, reputable online platforms offer convenient access to an extensive inventory of original parts, often accompanied by detailed descriptions and compatibility information.

Another effective strategy is to connect with dedicated forums or online communities where enthusiasts share their experiences. These groups often provide valuable insights and recommendations on where to find trustworthy suppliers. Furthermore, many members may have leads on hard-to-find components or can advise on potential alternatives that meet quality standards.

When purchasing, always verify the authenticity of the parts. Look for labels or markings that indicate the item is genuine. Investing in original components not only guarantees optimal functionality but also protects your investment in the long run.