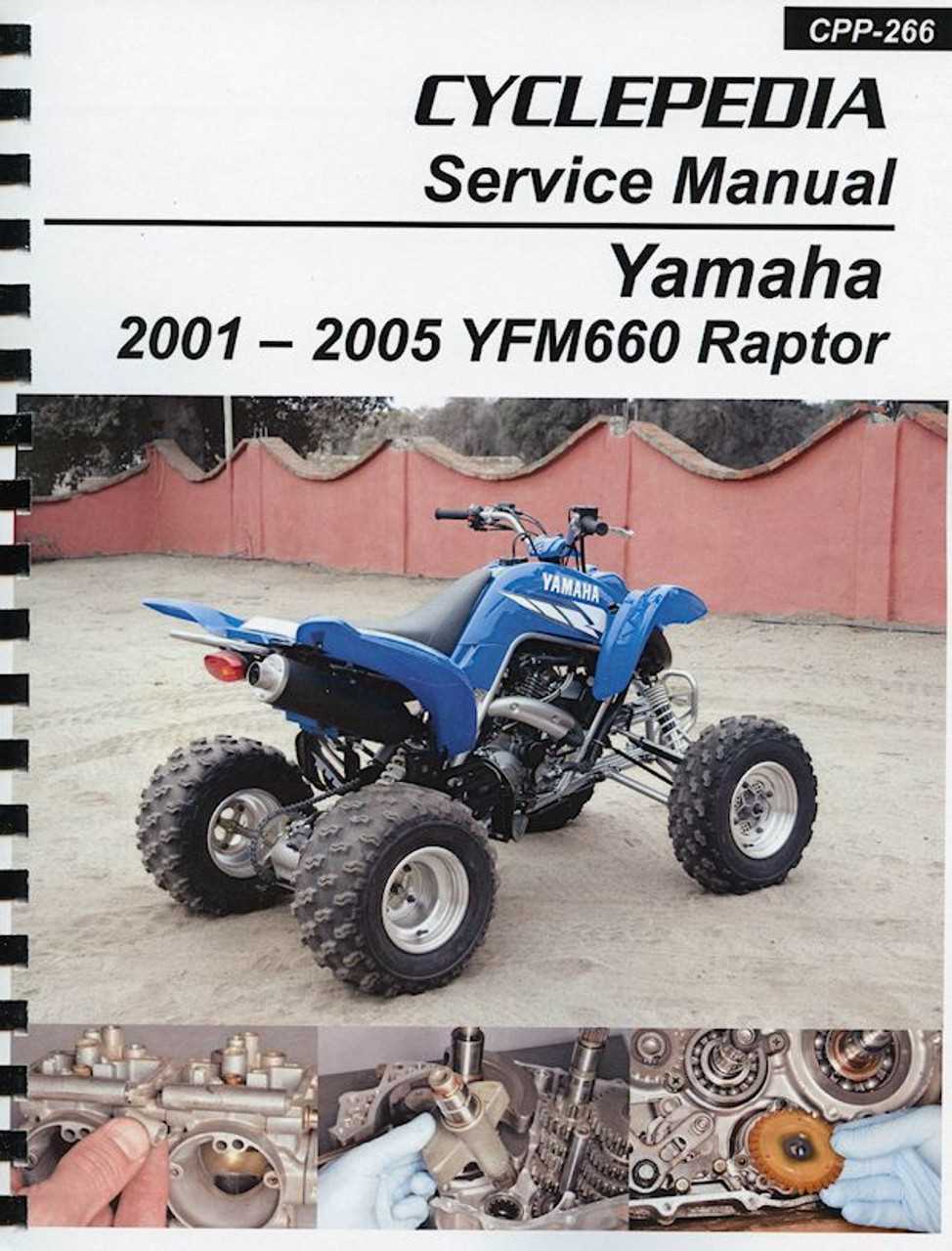

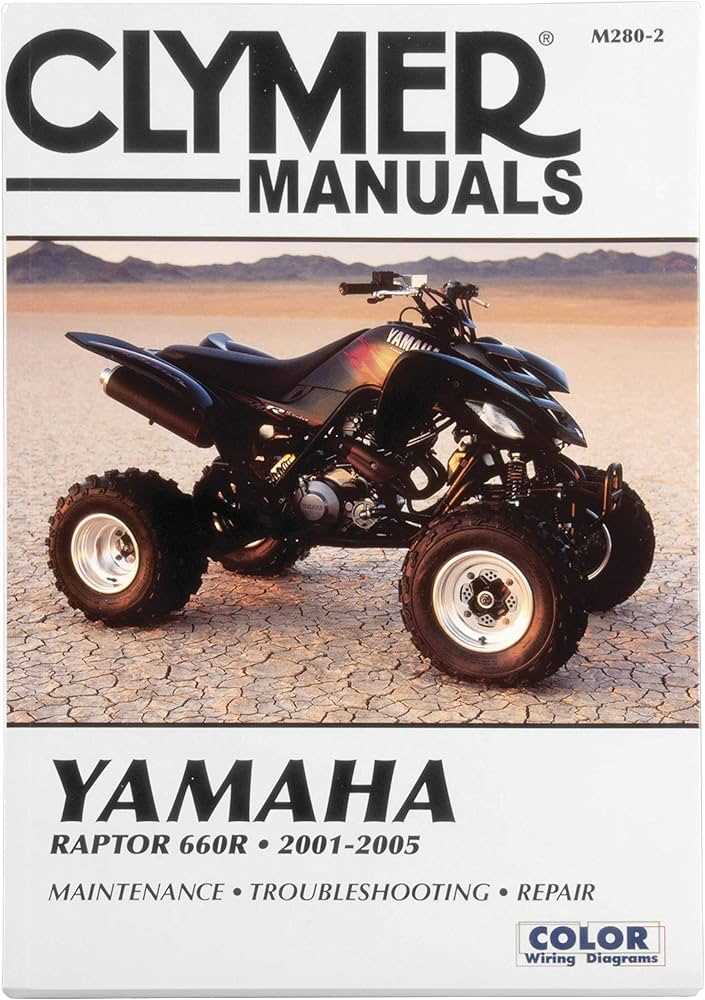

Yamaha Raptor Repair Manual Comprehensive Guide for Maintenance and Troubleshooting

Modern all-terrain vehicles are built for intense performance and rugged outdoor environments, providing unparalleled freedom for enthusiasts. However, as with any machine, regular maintenance and a keen understanding of potential technical issues are essential to keep these vehicles in optimal condition. Knowing where to start and which steps to follow can make a significant difference in prolonging the lifespan of your vehicle and enhancing safety on the trails.

Maintenance and diagnostic procedures for high-performance off-road machines can sometimes appear daunting, particularly for new riders. This guide aims to simplify these tasks by breaking down complex processes into straightforward steps. From initial assessments to more advanced repairs, every section is tailored to empower owners with the knowledge needed for a seamless upkeep experience.

Whether addressing minor tune-ups or investigating more intricate mechanical issues, understanding the essentials of engine management, suspension care, and electrical component upkeep will help maintain the vehicle’s peak performance. This resource provides all the necessary insights to ensure smooth operation and reliability, helping to maximize both safety and enjoyment on every ride.

Understanding Yamaha Raptor Mechanics

Grasping the core mechanical principles behind an all-terrain vehicle (ATV) enhances not only the rider’s experience but also empowers them to maintain and troubleshoot effectively. This section provides an overview of the key systems that govern an ATV’s performance, aiming to clarify how each component interacts within the broader framework of the vehicle.

Key Components and Their Functions

Every ATV relies on a robust set of components that include the engine, transmission, suspension, and braking systems. Each of these systems plays a distinct role in ensuring smooth operation across varied terrains. The engine provides power, the transmission transfers this power to the wheels, the suspension system absorbs shocks from uneven surfaces, and the braking system ensures safe deceleration. When understood as an interconnected network, these systems offer a foundation for both performance optimization and diagnostics.

Core Systems Breakdown

| System | Description | Key Components | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power Unit | Supplies energy to propel the vehicle forward; fuel combusts to create power. | Engine, Carburetor/Fuel Injection, Spark Plug | ||||||||||||||||||||||||||||||||||||

| Transmission | Transfers engine power to the wheels, adjusting speed and torque as needed. | Gearbox, Clutch, Drive Shaft | ||||||||||||||||||||||||||||||||||||

| Suspension | Abs

Essential Tools for Raptor MaintenanceRegular upkeep of your machine ensures it performs optimally and safely on any terrain. Having the right tools on hand can simplify routine adjustments, component checks, and part replacements, making at-home care both effective and efficient. Socket Set: A versatile socket set is indispensable for loosening and tightening a variety of bolts and nuts. Look for a set with metric and standard sizes to cover all bases and ensure compatibility with various fasteners. Torque Wrench: A torque wrench is essential for tightening bolts to specific specifications. Precise torque prevents over-tightening, which can damage parts, and under-tightening, which may lead to component failure during rides. Needle Nose Pliers and Cutters: These tools come in handy for tasks that require precision, such as manipulating small parts or cutting wires and zip ties. High-quality pliers ensure a strong grip and durability. Hex Key Set: Also known as Allen wrenches, these tools are needed for screws that have a hexagonal socket. Investing in a range of sizes, both metric and imperial, allows you to handle various bolts found on different parts. Oil Filter Wrench: For regular oil changes, an oil filter wrench simplifies the removal of the old filter. This tool provides grip without damaging the filter, making the job faster and cleaner. Chain Breaker Tool: A chain breaker is invaluable when it comes to adjusting or replacing the drive chain. It allows you to remove or add links easily, ensuring the correct chain length for optimal performance. Screwdriver Set: A good set of flathead and Phillips screwdrivers is a must-have. Quality screwdrivers reduce the Engine Troubleshooting and Diagnostics

Effective engine troubleshooting is essential for maintaining optimal performance and preventing long-term issues. This section offers step-by-step guidance on identifying common engine problems, providing key diagnostic techniques to assess potential malfunctions accurately. Understanding early symptoms and knowing how to pinpoint the root causes of engine issues can save time and resources, ensuring the machine runs smoothly. Common Engine Issues and SymptomsEngine issues often manifest through noticeable symptoms, each hinting at potential underlying problems. Below is a list of some frequent indicators, along with their possible causes, which will help in accurately diagnosing the issue:

Diagnostic Techniques

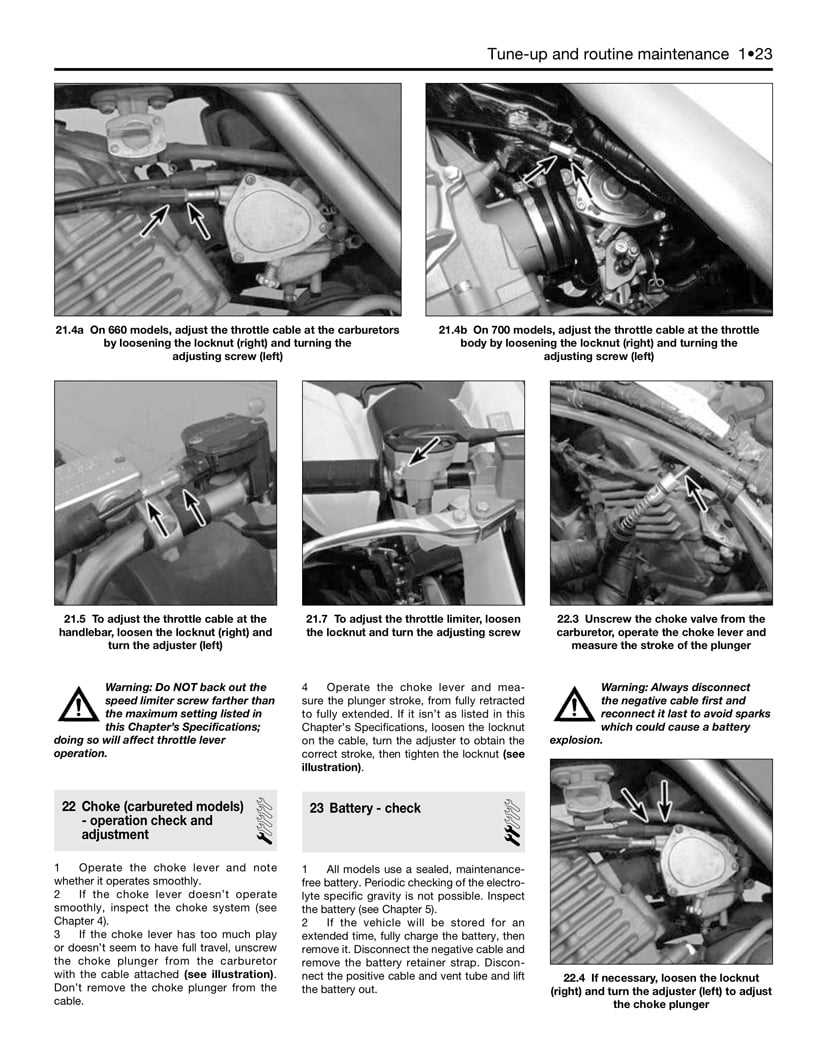

Diagnosing engine issues effectively requires both visual inspection and testing specific components. Start Replacing and Adjusting the Carburetor

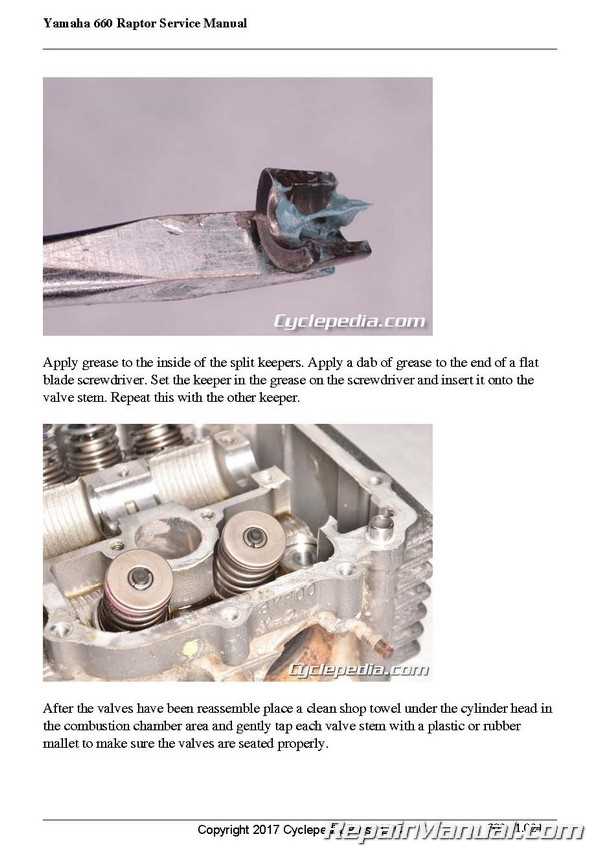

Replacing and fine-tuning the carburetor is essential for maintaining optimal engine performance, ensuring smooth fuel delivery, and preventing issues related to air-fuel imbalance. With time, the carburetor may require adjustments or a full replacement due to wear or contamination, affecting engine efficiency. Following the steps carefully can ensure that the fuel system functions reliably and prolongs the engine’s life. Step 1: Removing the Old Carburetor

Begin by disconnecting the fuel line, intake manifold, and throttle cables attached to the carburetor. Ensure that all fuel is drained from the system beforehand to avoid spills. Use a wrench to loosen the mounting bolts securing the carburetor, then gently detach it. Once removed, inspect the intake port for any buildup or damage that could affect performance after reinstallation. Clean surrounding components as necessary to prevent debris from contaminating the new carburetor. Step 2: Installing and Securing the New Carburetor

Position the new carburetor in place, aligning it with the intake manifold. Secure it with the mounting bolts, tightening them evenly to avoid air leaks. Reconnect the throttle cable and ensure it moves smoothly without any resistance. Attach the fuel line and confirm there are no leaks. Once the carburetor is installed, check all connections to ensure they are secure before proceeding to the adjustment phase. Adjusting the Carburetor for Optimal PerformanceAfter installation, adjust the air-fuel mixture screw to set the correct ratio. Start by turning the screw to the manufacturer’s recommended position, usually about one and a half turns out from fully closed. Start the engine and let it idle. Gradually adjust the screw while listening to the en Battery Care and Electrical System GuideMaintaining the power source and electrical framework of your vehicle is essential for optimal performance and longevity. Proper care not only ensures reliable starts and smooth operation but also protects the components from potential damage caused by neglect. This section offers insights into best practices for battery maintenance and understanding the electrical system’s functionalities. Battery Maintenance PracticesTo enhance the lifespan and efficiency of your vehicle’s battery, follow these essential practices:

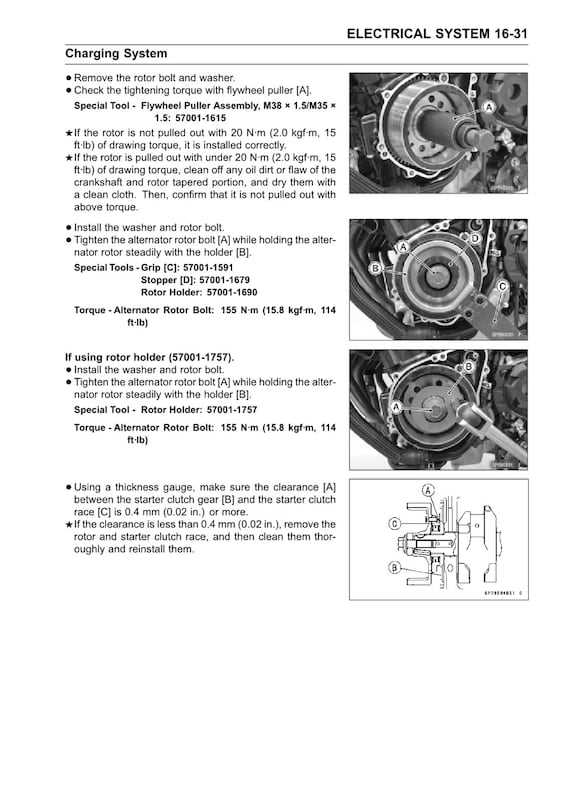

Understanding the Electrical SystemThe electrical system is critical for starting the engine, powering lights, and operating various electronic components. Familiarity with its main parts helps in troubleshooting and ensuring everything operates seamlessly:

Brake System Repairs and Safety TipsThe braking mechanism is crucial for the safe operation of any off-road vehicle. Proper maintenance and timely interventions can prevent failures that compromise safety. Understanding the components of the brake system and recognizing signs of wear can ensure optimal performance and longevity. Common Issues and SolutionsOne of the most frequent problems encountered is brake fluid leakage. Inspecting the lines for cracks or deterioration is essential, as even small leaks can significantly affect braking efficiency. Additionally, worn brake pads should be replaced regularly; ignoring this can lead to rotor damage, which is more costly to repair. Always ensure that the brake calipers function smoothly and that the pads are aligned correctly to avoid uneven wear. Safety Precautions

Before performing any maintenance on the braking system, always disconnect the battery to prevent accidental activation. Wear protective gear, including gloves and goggles, to shield against debris and fluid exposure. After any service, test the brakes in a safe area to ensure they function properly before resuming regular use. Regular inspections and attentive handling of any identified issues will contribute significantly to safe riding experiences. Suspension Tuning and Setup Guide

Tuning and configuring the suspension system of your all-terrain vehicle is essential for enhancing performance and comfort. Proper adjustment allows for optimal handling, improved stability, and a more enjoyable riding experience across various terrains. This guide provides insights into the key aspects of suspension tuning, including setup techniques, factors to consider, and common adjustments. Understanding Suspension Components

Before diving into tuning, it’s crucial to understand the primary components that make up the suspension system:

Key Tuning Techniques

Here are several important techniques to effectively tune your suspension:

Experimenting with these adjustments will help you find the ideal setup that matches your personal preferences and riding conditions. Regularly check and modify the suspension settings based on wear, terrain changes, and riding style to ensure optimal performance. Transmission Maintenance and Repair

Regular upkeep and troubleshooting of the transmission system are vital for ensuring optimal performance and longevity of the vehicle. Proper maintenance can prevent significant issues, enhance operational efficiency, and provide a smoother riding experience. Understanding the key components and their functions is essential for effective care and timely interventions. Key Components of the Transmission SystemThe transmission consists of several integral parts that work together to transfer power from the engine to the wheels. Familiarity with these components helps in diagnosing potential issues and performing necessary adjustments. Below is a summary of the main elements:

Maintenance Practices

Fuel System Cleaning and InspectionMaintaining optimal performance of the fuel delivery mechanism is essential for ensuring the longevity and efficiency of your vehicle. Regular cleaning and thorough examination of this system can prevent buildup, enhance fuel flow, and reduce the risk of engine complications. This section outlines the necessary steps to effectively clean and inspect the fuel system components, ensuring a smooth and reliable operation. Cleaning the Fuel Lines and Filters

The first step in maintaining the fuel delivery system involves cleaning the fuel lines and replacing any filters as needed. Over time, impurities and debris can accumulate, leading to restricted flow and potential damage. To initiate the cleaning process, detach the fuel lines carefully and use a suitable solvent to remove any buildup. It is advisable to inspect the filters regularly; if they appear clogged or damaged, replacing them promptly will help maintain efficient fuel delivery. Inspecting the Fuel Injectors

Another critical aspect of system maintenance is the inspection of the fuel injectors. These components play a vital role in atomizing fuel for efficient combustion. A thorough examination should include checking for leaks, blockages, or irregular spray patterns. Cleaning can be performed using specialized injector cleaners or ultrasonic cleaning methods. Ensuring that the injectors are functioning correctly not only improves performance but also enhances fuel efficiency and reduces emissions. Oil Change and Lubrication TipsMaintaining optimal performance and extending the lifespan of your vehicle requires regular oil changes and proper lubrication. This section provides essential tips and best practices to ensure your engine remains in top condition. Here are some crucial steps to follow during the oil change process:

Next, follow these steps for a successful oil change:

In addition to regular oil changes, proper lubrication of moving parts is vital. Consider the following tips:

By following these guidelines, you will ensure that your vehicle operates smoothly and efficiently, ultimately enhancing its performance and longevity. Chain and Sprocket Replacement TipsMaintaining the transmission system of your vehicle is crucial for optimal performance. Regular inspection and timely replacement of the chain and sprockets can significantly enhance your ride’s efficiency and longevity. This section provides essential guidance on effectively executing these replacements to ensure smooth operation. Preparation Steps

Replacement Process

Checklist for Routine Preventive CareMaintaining the optimal performance and longevity of your all-terrain vehicle requires consistent attention to preventive measures. By following a structured checklist, owners can identify potential issues before they escalate, ensuring safe and efficient operation. This proactive approach not only enhances the vehicle’s reliability but also reduces the likelihood of unexpected breakdowns. 1. Fluid Levels: Regularly check engine oil, coolant, and fuel levels. Top up or replace fluids as needed to ensure smooth operation. 2. Tire Inspection: Examine tires for wear and proper inflation. Rotate tires and replace them if tread depth is insufficient. 3. Brake Functionality: Test brakes for responsiveness. Inspect pads and discs for wear and replace them if necessary. 4. Battery Maintenance: Check battery terminals for corrosion and ensure the battery is charged. Clean connections and replace the battery if it shows signs of failure. 5. Air Filter Cleaning: Inspect the air filter for dirt and debris. Clean or replace it to maintain optimal air intake and engine performance. 6. Chain and Sprocket Condition: Examine the drive chain for tension and lubrication. Adjust tension as needed and lubricate to prevent wear. 7. Lighting Systems: Test headlights, taillights, and indicators to ensure they are functioning correctly. Replace any burnt-out bulbs. 8. General Framework Check: Inspect the frame and suspension components for signs of damage or wear. Tighten any loose bolts or connections. 9. Exhaust System: Check for leaks or damage in the exhaust system. Ensure all components are securely attached. 10. Seasonal Preparations: Depending on usage, perform seasonal checks, such as winterizing the vehicle or preparing it for summer use. |