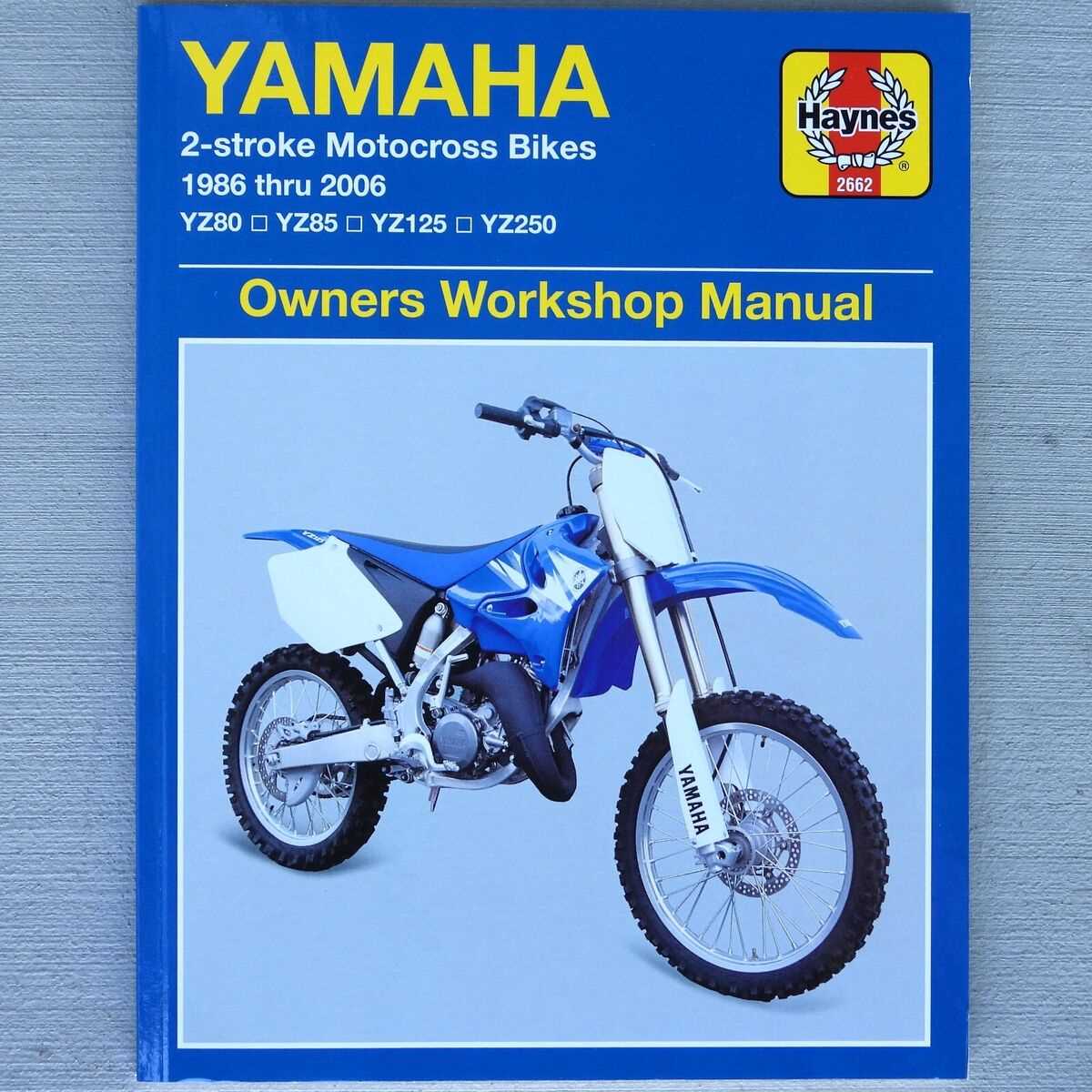

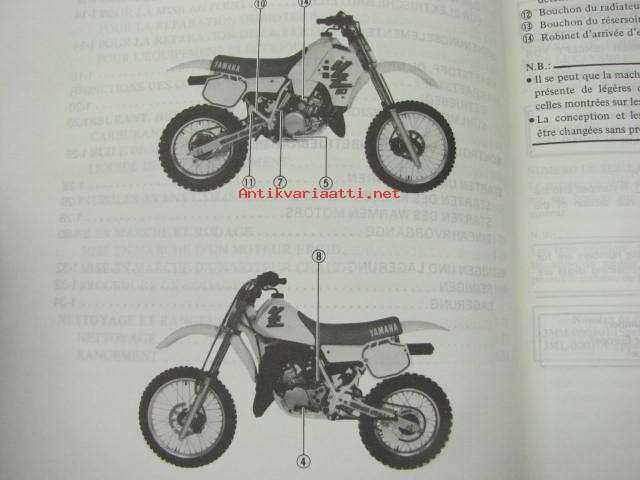

Yamaha YZ80 Repair Guide for Maintenance and Troubleshooting

The upkeep of a beloved two-stroke motorcycle is essential for ensuring its performance and longevity. This guide aims to provide enthusiasts and owners with valuable insights into the processes and techniques required to maintain and enhance the functionality of their cherished ride.

From troubleshooting common issues to performing routine inspections, this resource offers a comprehensive overview of essential practices. By understanding the intricacies of your machine, you can foster a deeper connection with it while maximizing its potential on and off the track.

Whether you are a novice looking to gain practical skills or an experienced rider seeking to refine your expertise, this guide will serve as a trusted companion. Equip yourself with the knowledge to navigate the complexities of maintenance, ensuring your motorcycle continues to deliver thrilling experiences for years to come.

Yamaha YZ80 Maintenance Overview

Regular upkeep of your two-wheeled machine is crucial for optimal performance and longevity. By following a structured maintenance routine, you can ensure that the vehicle operates smoothly, enhancing both safety and riding experience. This section provides an overview of essential practices that every owner should implement.

Routine Checks

Consistent inspections are vital for identifying potential issues before they escalate. Focus on key components such as the engine, brakes, and tires. Checking the oil levels, brake fluid, and tire pressure should be part of your regular assessment. Keeping these elements in check can prevent unexpected failures and improve overall functionality.

Periodic Services

In addition to routine checks, scheduled servicing should not be overlooked. Tasks like changing the oil, replacing air filters, and inspecting the chain are essential for maintaining peak performance. Following the recommended intervals for these services can significantly extend the lifespan of your vehicle and ensure it remains in top condition.

Essential Tools for Repairs

Maintaining and servicing a two-wheeled machine requires a variety of tools to ensure optimal performance and longevity. Having the right equipment not only simplifies the process but also enhances the quality of work completed. Here, we outline the fundamental instruments that every enthusiast should have on hand for effective maintenance tasks.

Basic Hand Tools

- Socket Set: Useful for loosening and tightening various fasteners.

- Wrenches: Adjustable and fixed wrenches are essential for a range of bolt sizes.

- Phillips and Flathead Screwdrivers: Necessary for accessing various components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Specialized Equipment

- Chain Tool: Helps with installation and removal of chains.

- Feeler Gauges: Essential for setting valve clearances accurately.

- Oil Filter Wrench: Makes it easier to replace the oil filter during maintenance.

- Brake Caliper Tool: Simplifies the process of servicing brake components.

Equipping your workspace with these tools will greatly facilitate the upkeep and adjustment of your machine, ensuring a smooth and enjoyable riding experience.

Common Issues with YZ80 Models

Various challenges can arise with certain two-stroke off-road motorcycles, often impacting performance and reliability. Understanding these frequent complications can aid owners in maintaining their machines and ensuring optimal function.

Engine Performance Problems

One of the most prevalent concerns involves engine performance, which may manifest as difficulty starting, rough idling, or stalling. These issues can stem from fuel delivery problems, such as clogged filters or faulty carburetors. Regular cleaning and maintenance of these components are essential to prevent performance degradation.

Transmission Difficulties

Transmission-related complications are also common, often indicated by issues with shifting gears smoothly. Problems may arise from worn clutch plates or misaligned cables. Regular inspections and adjustments can help maintain proper engagement and prolong the lifespan of the transmission system.

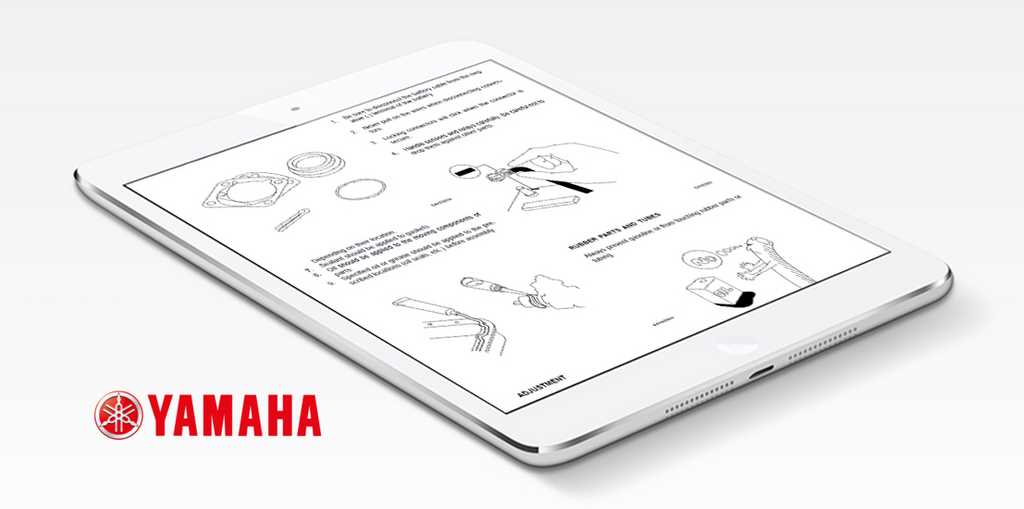

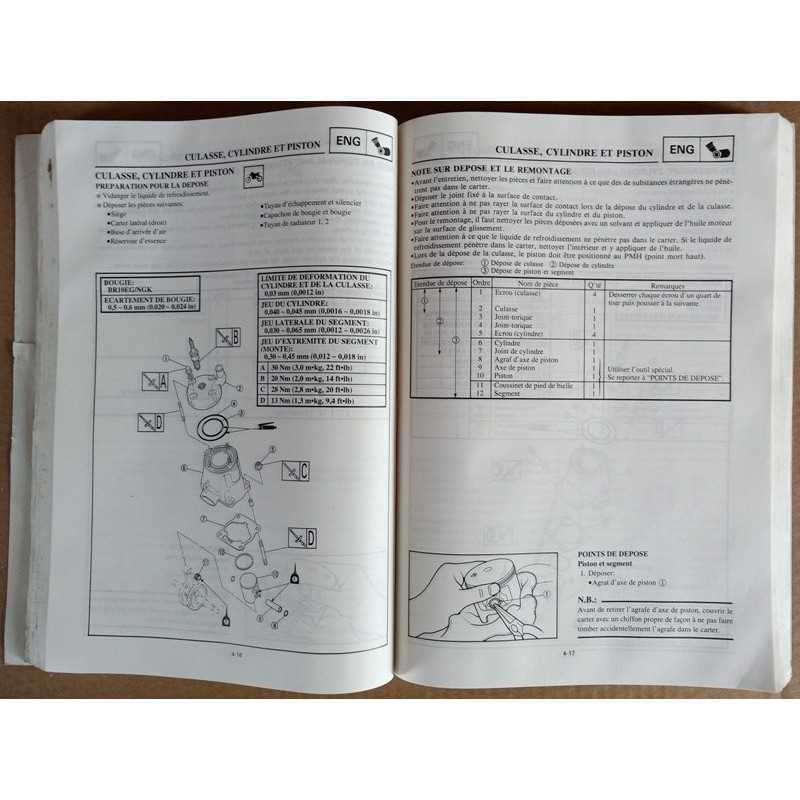

Step-by-Step Engine Disassembly

This section outlines a systematic approach to dismantling a small engine, ensuring that each component is handled with care. Proper disassembly is crucial for effective maintenance and troubleshooting. Follow the steps carefully to avoid damage and to facilitate reassembly.

-

Preparation: Gather all necessary tools, including wrenches, screwdrivers, and pliers. Ensure a clean workspace free from clutter.

-

Disconnect Power Sources: Remove the battery and any electrical connections to prevent accidental starts.

-

Drain Fluids: Safely drain oil and fuel to minimize spills and hazards.

-

Remove Outer Covers: Take off any protective covers or shrouds to access the engine components.

-

Detach Exhaust and Intake Components: Carefully unbolt and remove the exhaust system and intake manifold.

-

Disconnect Cooling System: If applicable, detach any hoses and components related to the cooling system.

-

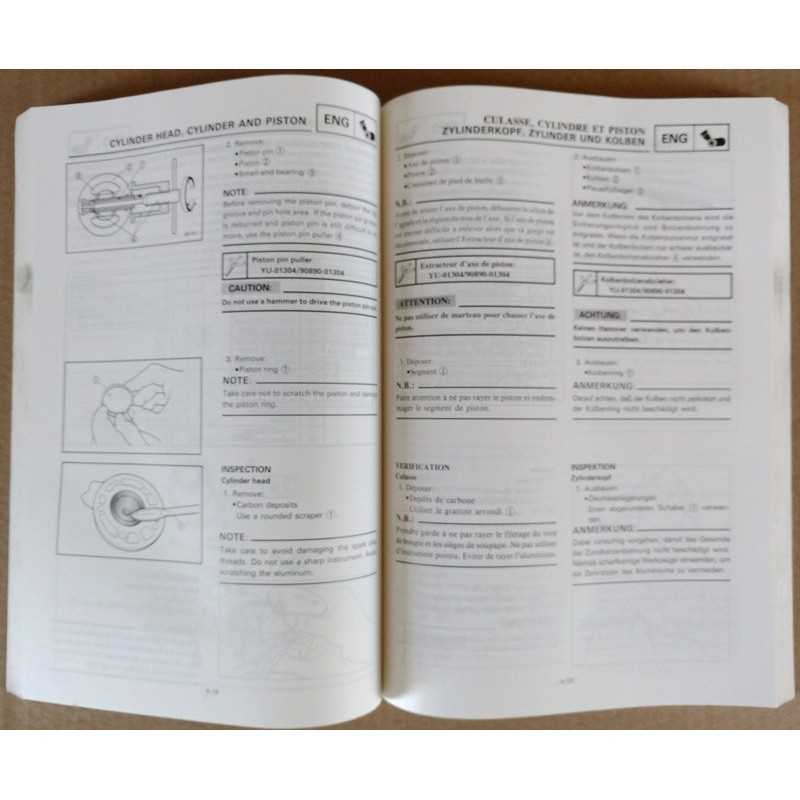

Remove Cylinder Head: Unscrew and lift the cylinder head to access the piston and cylinder.

-

Take Out Piston: Carefully remove the piston from the cylinder, taking care not to damage the rings.

-

Disassemble Crankcase: Finally, unscrew and separate the crankcase halves to expose the crankshaft and other internal parts.

Each step should be executed methodically, ensuring that all parts are stored in an organized manner for easy identification during reassembly. Keep track of all screws and bolts, as losing any component could complicate the process later on.

Reassembling the Yamaha YZ80

After completing the disassembly process, the next crucial step involves carefully putting all components back together. This phase requires attention to detail and a systematic approach to ensure every part is properly aligned and secured.

Begin with the engine assembly. Make sure all gaskets and seals are replaced to prevent leaks. Properly torque all bolts according to the specifications to maintain optimal performance and reliability. It’s important to follow the reverse order of disassembly to avoid missing any components.

Once the engine is in place, move on to reinstalling the suspension and wheels. Ensure that the suspension components are cleaned and lubricated before reassembly. Pay close attention to the alignment of the wheels; they should spin freely without obstruction.

Finally, reattach the electrical system, checking all connections for security and proper function. This will ensure that all lights, indicators, and ignition systems operate correctly.

By following these steps meticulously, you will ensure the successful reassembly of the vehicle, leading to improved performance and longevity.

Adjusting the Suspension Settings

Optimizing the performance of a two-wheeled vehicle requires careful attention to its suspension components. Proper adjustments can significantly enhance handling, comfort, and stability on various terrains. Understanding the nuances of suspension settings is essential for achieving a tailored riding experience that meets individual preferences and riding styles.

To begin, focus on spring preload. This setting determines how much weight the springs can support before compressing. Adjusting preload can help achieve the desired ride height and prevent bottoming out during aggressive maneuvers. A well-balanced preload will allow for smoother transitions and improved traction.

Next, consider compression damping. This controls how quickly the suspension compresses when encountering obstacles. Increasing compression damping can enhance stability on rough surfaces, while reducing it allows for a softer ride, ideal for smoother paths. Finding the right balance is crucial for maintaining control and comfort.

Finally, examine rebound damping. This setting influences how quickly the suspension returns to its original position after compression. Proper rebound adjustment prevents excessive bouncing, ensuring that the wheels remain in contact with the ground for better traction and control. Adjustments should be made gradually, testing the vehicle after each change to gauge the effects.

Regularly revisiting these settings is recommended, as changes in terrain and riding conditions may necessitate further fine-tuning. By taking the time to adjust these components, riders can greatly enhance their overall experience and performance.

Electrical System Troubleshooting

The effective functioning of the electrical components is crucial for optimal performance and reliability. When issues arise, it is essential to systematically identify and address potential problems within the circuitry and related systems.

Begin by ensuring that all connections are secure and free from corrosion. Inspecting wiring for wear or damage is vital, as frayed cables can disrupt the flow of electricity. If any connectors appear loose or corroded, they should be cleaned or replaced to restore proper connectivity.

Testing voltage levels at various points can help pinpoint areas where the electrical flow may be compromised. A multimeter can be used to check for continuity, ensuring that the circuit is complete. If low readings are detected, further investigation into the power source may be necessary.

In addition to inspecting the wiring and connectors, consider the integrity of the electrical components themselves. Components such as fuses and relays should be tested to confirm they are functioning correctly. If any parts are found to be defective, replacing them can often resolve the issue.

Finally, consult the specifications for any electrical devices to verify they are within operating parameters. Keeping a systematic approach to troubleshooting will facilitate the identification and resolution of electrical system issues, ensuring smooth operation.

Replacing the YZ80 Tires

Maintaining optimal performance on two wheels requires regular attention to the rubber that makes contact with the ground. Ensuring that the tires are in good condition is essential for both safety and handling. This section will guide you through the process of swapping out the worn-out tires for new ones, enhancing your vehicle’s overall functionality.

Preparation for Tire Replacement

Before beginning the replacement process, gather all necessary tools and equipment. You’ll need a tire lever, a wrench, and a suitable replacement tire. It’s advisable to perform this task in a well-lit area to ensure visibility. First, lift the vehicle securely using a stand to prevent any accidental movement during the procedure.

Removing and Installing the New Tires

Start by loosening the nuts on the wheel, ensuring they are not too tight. Once the nuts are removed, carefully take off the wheel from the frame. Next, use the tire lever to detach the old tire from the rim. Be cautious to avoid damaging the inner tube if applicable. After the old tire is removed, place the new tire onto the rim, ensuring proper alignment. Finally, reattach the wheel and tighten the nuts securely, ensuring everything is in place for your next ride.

Maintaining the Fuel System

Proper upkeep of the fuel delivery system is crucial for optimal performance and longevity of your two-wheeled machine. Regular inspection and maintenance help prevent issues such as clogging and poor fuel flow, ensuring that the engine receives the necessary fuel for efficient operation.

Routine Checks: Begin with frequent examinations of fuel lines and connections for any signs of wear, cracks, or leaks. Replacing damaged components promptly can prevent further complications and maintain fuel integrity.

Cleaning the Carburetor: Periodically, disassemble and clean the carburetor to remove deposits and ensure smooth fuel flow. Use a suitable cleaning solution and follow the manufacturer’s guidelines for reassembly.

Inspecting the Fuel Filter: A clean fuel filter is essential for protecting the engine from debris. Check and replace the filter according to the recommended schedule or if any blockages are noticed.

Fuel Quality: Always use high-quality fuel to minimize the risk of contamination. Avoid storing fuel for extended periods, as older fuel can degrade and affect performance.

By adhering to these maintenance practices, you can ensure the efficiency and reliability of your vehicle’s fuel system, contributing to a smoother ride and improved engine health.

Clutch and Transmission Care

Maintaining the components responsible for power transfer is crucial for optimal performance and longevity. Proper attention to these parts ensures smooth operation and can prevent costly repairs down the line. Regular maintenance helps identify potential issues before they escalate, contributing to a reliable riding experience.

Routine Inspection

Regular checks of the internal mechanisms are essential. Look for signs of wear or damage, and ensure that all parts are functioning correctly. Pay close attention to the following:

| Component | Inspection Tips |

|---|---|

| Clutch Plates | Check for warping or excessive wear. Replace if needed. |

| Springs | Inspect for signs of fatigue. Ensure they maintain proper tension. |

| Transmission Gears | Look for chipped or worn teeth. Smooth operation is key. |

| Fluid Levels | Ensure appropriate fluid levels for lubrication and cooling. |

Fluid Maintenance

Using the correct lubricants is vital for the health of these systems. Regularly changing the fluid not only maintains efficiency but also protects against overheating and wear. Follow the manufacturer’s guidelines for type and intervals to ensure the best performance.

Safety Tips for YZ80 Owners

Owning a high-performance two-wheeled vehicle comes with its own set of responsibilities. Ensuring safety not only protects the rider but also enhances the overall experience. Adhering to safety practices is essential for anyone looking to enjoy their machine while minimizing risks.

Pre-Ride Checks

- Inspect tires for proper inflation and wear.

- Check brakes for responsiveness and fluid levels.

- Ensure all lights and indicators are functioning.

- Verify that the chain is properly tensioned and lubricated.

- Look for any loose or damaged components before starting.

Protective Gear

- Always wear a certified helmet designed for motorcycle use.

- Use protective clothing, such as jackets and pants made of durable materials.

- Invest in gloves to improve grip and protect your hands.

- Wear boots that provide ankle support and grip.

- Consider additional gear like knee pads or chest protectors for added safety.