Comprehensive Guide to Yamaha OX66 Repairs

In the world of aquatic vehicles, proper upkeep is essential for optimal performance and longevity. Understanding the nuances of engine care can significantly enhance the reliability and efficiency of your vessel.

Comprehensive resources are invaluable for navigating the intricacies of engine maintenance. They provide crucial insights into troubleshooting common issues, ensuring that your machinery operates smoothly, regardless of the conditions faced on the water.

By familiarizing yourself with essential practices and guidelines, you can effectively address potential problems and extend the lifespan of your engine. This knowledge empowers you to tackle repairs with confidence and maintain peak performance throughout your journeys.

| Attribute | Details |

|---|---|

| Engine Type | Two-stroke |

| Cylinders | Six |

| Displacement | 3.1 L |

| Weight | 229 kg |

| Power Output | 200 hp |

Key Features

This engine boasts several innovative features designed to enhance performance and ease of use. Its design promotes efficient fuel consumption, while advanced technology ensures smooth operation even under challenging conditions. This model also includes user-friendly controls and diagnostics to facilitate maintenance and monitoring.

Common Issues Faced by Owners

Many users encounter a range of challenges with their outboard motors, impacting performance and reliability. Understanding these common problems can help in maintaining optimal functionality and ensuring a smoother experience on the water.

Engine Performance Problems

- Frequent stalling during operation

- Inconsistent acceleration and throttle response

- Difficulty starting, especially in cold weather

Electrical Issues

- Faulty ignition systems leading to misfiring

- Battery drainage and charging problems

- Issues with wiring connections causing intermittent failures

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise during operation. Following a systematic method can significantly enhance efficiency and ensure reliable performance.

1. Identify the Problem: Begin by observing any unusual behavior. Note specific symptoms, such as strange noises or irregular performance, as these details are crucial for diagnosis.

2. Check Connections: Ensure that all cables and connectors are secure. Loose connections can lead to intermittent issues that are often overlooked.

3. Inspect Components: Carefully examine all parts for signs of wear or damage. Look for corrosion, frayed wires, or any visible defects that may impede functionality.

4. Test with a Multimeter: Use a multimeter to check voltage and continuity in key circuits. This will help pinpoint areas where electrical failure may be occurring.

5. Consult Documentation: Reference specific technical guides to find troubleshooting tips tailored to the device. These resources can provide valuable insights into potential issues and their solutions.

6. Seek Professional Assistance: If the problem persists after following these steps, consider reaching out to a qualified technician for further evaluation and repair.

Implementing this structured approach can lead to effective resolution of issues and restore optimal performance.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. Various instruments not only streamline the process but also enhance the quality of the work performed. Understanding which tools are indispensable can significantly impact the efficiency and outcome of your projects.

Wrenches are fundamental for loosening and tightening various fasteners. A set of both metric and imperial sizes will ensure that you can handle a wide range of components. Screwdrivers, available in different types such as Phillips and flathead, are necessary for accessing screws in various locations.

Another vital tool is a multimeter, which is essential for diagnosing electrical issues. This device allows for accurate measurements of voltage, current, and resistance, aiding in troubleshooting problems effectively. Additionally, a toolbox or storage solution keeps all instruments organized, ensuring you can find what you need when you need it.

Lastly, consider investing in a workbench with ample space and proper lighting. A dedicated workspace promotes efficiency and safety while allowing you to focus on intricate tasks without distractions.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment involves a series of careful practices and routines. Regular attention to key components can significantly enhance performance and durability. This section outlines essential strategies that can be easily integrated into your maintenance schedule.

Regular Inspection

Conducting periodic assessments is crucial. Look for signs of wear, corrosion, or any irregularities in function. Timely detection of potential issues allows for early intervention, preventing more significant problems down the line.

Proper Storage

When not in use, ensure that your device is stored in a dry, climate-controlled environment. Protecting against moisture and extreme temperatures helps preserve critical components. Additionally, covering your equipment can shield it from dust and debris.

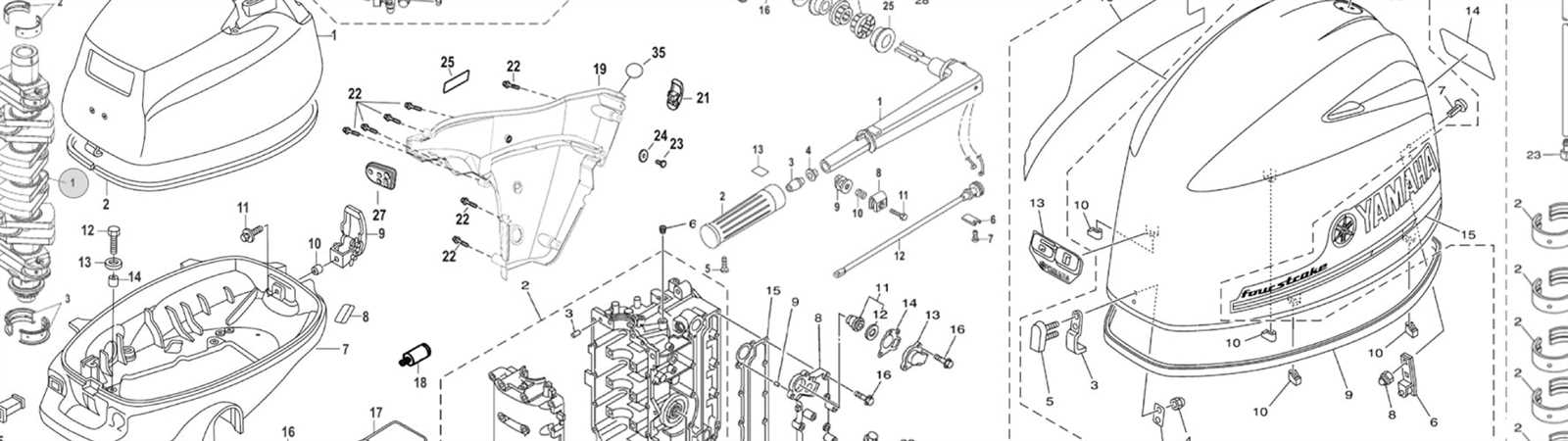

How to Replace Engine Components

Replacing engine parts is an essential task for maintaining optimal performance and extending the lifespan of your vessel’s power unit. This process can seem daunting, but with the right tools and a clear plan, you can successfully undertake this important maintenance work.

Preparation Steps

- Gather necessary tools, including wrenches, screwdrivers, and pliers.

- Ensure you have the replacement components ready and compatible with your specific engine model.

- Consult documentation for torque specifications and assembly instructions.

Replacement Process

- Begin by disconnecting the battery to prevent any electrical hazards.

- Remove the necessary panels to access the engine components that need replacement.

- Carefully detach the old parts, noting their orientation for accurate reinstallation.

- Install the new components, ensuring they are fitted securely and correctly aligned.

- Reassemble any removed panels and reconnect the battery.

Following these steps will help ensure a smooth replacement process and contribute to the overall efficiency of your engine.

Electrical System Diagnostics Explained

The functionality of an electrical system is crucial for optimal performance in various machinery. Understanding how to diagnose issues within this system can significantly enhance maintenance efficiency and longevity. This section delves into the fundamental principles of troubleshooting electrical components, providing a roadmap for effective diagnostics.

Key Components of the Electrical System

At the heart of any electrical system are key elements such as batteries, wiring, and various sensors. Each component plays a vital role in ensuring proper operation. For instance, batteries provide the necessary power, while sensors relay critical information about performance metrics. Familiarity with these components is essential for accurate diagnostics.

Diagnostic Techniques

Effective troubleshooting involves systematic approaches such as visual inspections, multimeter tests, and component isolation. A thorough visual check can reveal obvious signs of wear or damage. Utilizing a multimeter allows for precise measurements of voltage, current, and resistance, facilitating the identification of faults. Isolating components aids in determining whether the issue is localized or systemic.

By mastering these diagnostic techniques, one can ensure that the electrical system remains in peak condition, thereby preventing unnecessary failures and enhancing overall functionality.

Fuel System Maintenance Procedures

Proper upkeep of the fuel system is essential for optimal performance and longevity of the engine. Regular attention to this component can prevent issues such as poor fuel efficiency and engine misfires. Understanding the necessary steps to maintain the fuel system will ensure that it operates smoothly and efficiently.

Inspection of Fuel Lines

Begin by checking the fuel lines for any signs of wear, leaks, or blockages. Inspect all connections and fittings to ensure they are secure. If any damage is detected, replace the affected components promptly to avoid fuel loss and potential hazards.

Fuel Filter Replacement

Replacing the fuel filter at regular intervals is crucial to maintain fuel purity. A clogged filter can restrict fuel flow and lead to engine performance issues. Consult the guidelines for the appropriate replacement schedule and always use high-quality filters that meet the necessary specifications.

Cleaning the Fuel Injectors

Cleaning the injectors helps maintain optimal fuel atomization and combustion. Use a suitable cleaning solution or professional service to ensure the injectors are free from carbon deposits and other contaminants. This process can significantly improve engine responsiveness and efficiency.

Fuel Quality Check

Ensure that the fuel used meets the recommended standards for quality and type. Contaminated or low-quality fuel can lead to numerous performance problems. Regularly check for any sediment or water in the fuel tank and address these issues immediately.

Understanding Cooling System Functions

The cooling system plays a vital role in maintaining optimal operating temperatures for machinery. Its primary function is to dissipate excess heat generated during operation, ensuring that components remain within safe temperature limits. This is crucial for preventing overheating, which can lead to severe damage and decreased efficiency.

A well-functioning cooling system comprises various elements, including a heat exchanger, coolant, and circulation mechanisms. The heat exchanger transfers heat away from critical parts, while the coolant absorbs and transports this heat, allowing for effective temperature regulation. Regular maintenance of these components is essential for sustaining performance and prolonging the lifespan of the equipment.

Understanding how the cooling system operates can help identify potential issues before they escalate. Monitoring coolant levels and checking for leaks or blockages are important steps in ensuring that the system functions correctly. By recognizing the signs of cooling system failure, operators can take proactive measures to safeguard their machinery.

Recommended Lubricants and Fluids

Choosing the right lubricants and fluids is essential for maintaining optimal performance and longevity of your engine. Proper selection ensures smooth operation, reduces wear, and enhances efficiency.

| Type | Recommended Product | Purpose |

|---|---|---|

| Engine Oil | Synthetic 2-Stroke Oil | Provides lubrication and protects engine components |

| Gear Oil | High-Performance Gear Oil | Ensures smooth gear shifting and reduces friction |

| Coolant | Antifreeze/Water Mix | Regulates temperature and prevents overheating |

| Fuel Additive | Stabilizer | Enhances fuel stability and performance |

Using the appropriate products will contribute significantly to the efficiency and durability of your engine, making regular checks and timely replacements a key aspect of maintenance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to protect both the technician and the equipment. Adhering to specific guidelines minimizes risks and promotes a secure working environment.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and masks to shield against potential hazards. |

| Work Environment | Maintain a clean and organized workspace to prevent accidents and facilitate efficient workflows. |

| Electrical Safety | Disconnect power sources before beginning any maintenance to avoid electric shocks or shorts. |

| Tool Inspection | Regularly check tools for damage or wear to ensure they function correctly and safely. |

| Emergency Preparedness | Have emergency contacts and first-aid kits readily available in case of accidents. |

Where to Find Replacement Parts

Locating suitable components for maintenance or upgrades can significantly enhance the longevity and performance of your equipment. Various sources offer a wide range of options, making it easier to find what you need.

Here are some reliable avenues to explore:

- Authorized Dealers: Official dealers often stock original parts, ensuring compatibility and quality.

- Online Retailers: Numerous websites specialize in selling components, often providing user reviews and ratings.

- Local Marine Supply Stores: These shops may carry a selection of parts suitable for your needs and offer personal assistance.

- Second-Hand Markets: Platforms such as eBay or local classifieds can have pre-owned components at a lower cost.

- Forums and Community Groups: Engaging with fellow enthusiasts can lead to valuable recommendations and possible leads on where to buy.

Utilizing these resources will help ensure you find the necessary parts for effective upkeep.