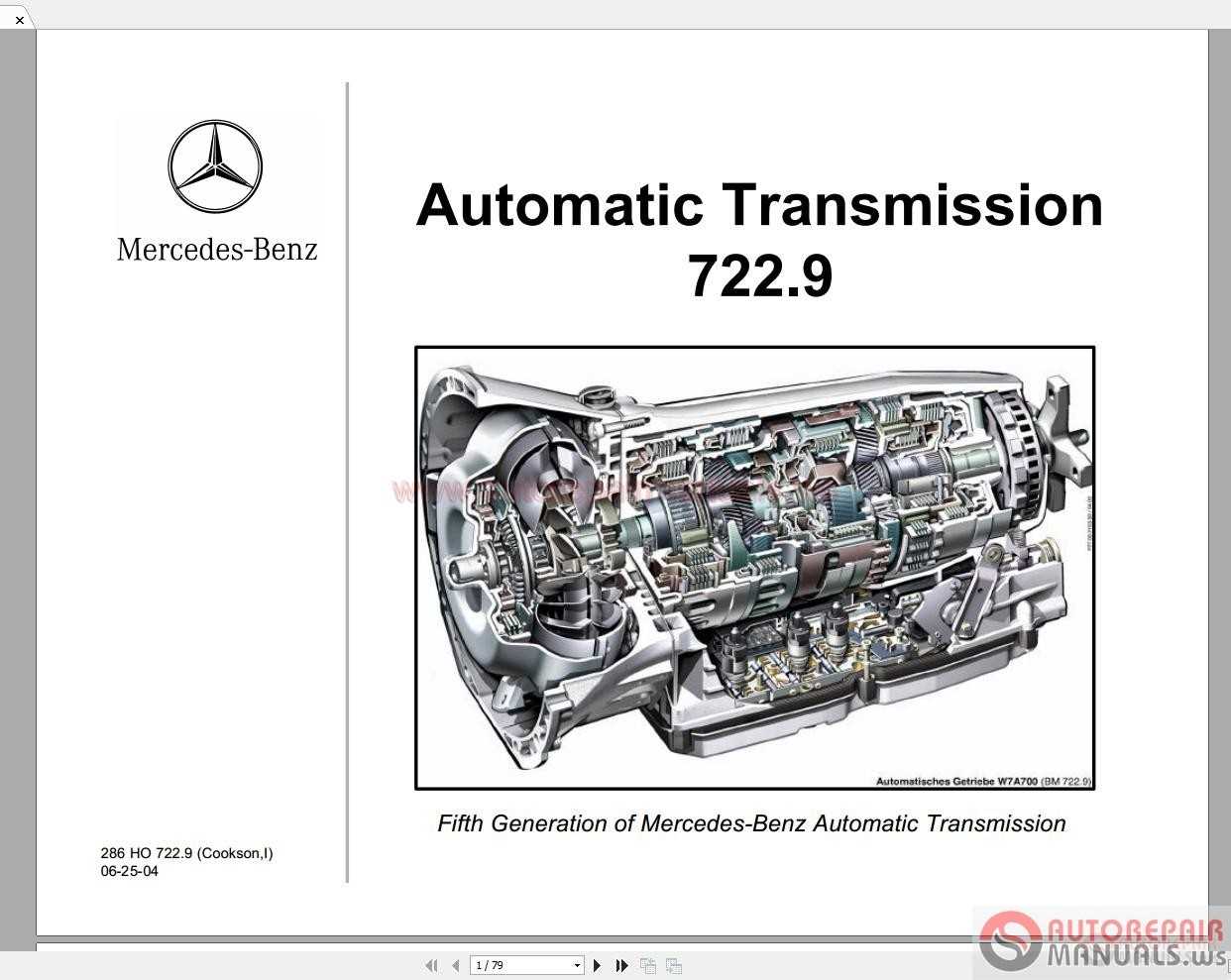

Comprehensive Guide to Repairing the 722.9 Transmission

This section aims to provide essential insights into the complexities involved in the upkeep of automotive gear systems. Understanding the intricacies of these components is crucial for ensuring optimal performance and longevity.

Proper maintenance plays a vital role in preventing common issues that can arise over time. By following detailed procedures and recommendations, vehicle owners can enhance the efficiency of their machinery and reduce the likelihood of unexpected failures.

Furthermore, it is important to familiarize oneself with the various components and their functions. Each element contributes to the overall operation, and knowledge of these parts empowers individuals to make informed decisions regarding their care and handling.

Understanding the 722.9 Transmission

This section provides insights into a specific type of automotive system designed to facilitate the smooth transfer of power from the engine to the wheels. Recognizing its intricate design and functionality is essential for anyone interested in vehicle performance and efficiency.

Crafted for optimal performance, this system employs a sophisticated arrangement of components that work in harmony. Its engineering incorporates advanced technology to ensure seamless gear shifts and enhanced driving experience. Understanding its workings can significantly contribute to effective maintenance and troubleshooting.

In addition to its performance capabilities, familiarity with the operational principles of this mechanism is crucial for diagnostics. Knowledge of potential issues and their symptoms allows for timely intervention, ensuring longevity and reliability. Engaging with this system’s design can lead to a deeper appreciation for modern automotive engineering.

Common Issues with 722.9 Models

In various automotive systems, certain patterns of malfunction frequently emerge, impacting performance and reliability. Understanding these prevalent complications can aid in effective troubleshooting and maintenance.

Transmission Overheating

One of the most widespread problems encountered involves excessive heat generation. This can lead to diminished efficiency and potential failure if not addressed promptly. Regular monitoring of operating temperatures is essential to avoid severe damage.

Shifting Difficulties

Another common challenge is the inconsistency in gear changes, which may manifest as hesitation or abrupt transitions. These issues can stem from various factors, including fluid quality and electronic control malfunctions. Timely diagnosis is crucial to restore proper functionality and ensure a smooth driving experience.

Tools Needed for Transmission Repair

When undertaking the complex task of overhauling a vehicle’s power transfer unit, having the right equipment is essential for a successful outcome. Proper tools not only enhance efficiency but also ensure the safety of the technician during the procedure.

Here is a list of essential tools you will need:

- Socket Set: A comprehensive socket set will allow you to access various fasteners with ease.

- Torque Wrench: This tool is crucial for applying the correct amount of force to bolts, ensuring they are securely fastened.

- Fluid Pump: A fluid pump is necessary for transferring lubricants and fluids into the unit.

- Snap Ring Pliers: These are essential for removing and installing retaining rings during disassembly.

- Gasket Scraper: A gasket scraper will help in cleaning surfaces to ensure a proper seal during reassembly.

In addition to these basic tools, specialized equipment may be required based on the specific design and features of the unit being serviced. Always refer to the guidelines for recommendations on additional implements that may enhance your workflow.

Step-by-Step Repair Procedures

This section outlines the essential processes involved in overhauling a specific type of vehicle component, ensuring proper functionality and longevity. Following these detailed instructions will help in effectively addressing common issues and restoring performance.

- Preparation

- Gather all necessary tools and equipment.

- Ensure a clean workspace to avoid contamination.

- Review safety protocols before starting.

- Disassembly

- Carefully remove the outer casing using appropriate tools.

- Document the placement of components for reassembly.

- Inspect each part for wear and damage.

- Inspection

- Check seals and gaskets for deterioration.

- Measure critical dimensions to ensure they meet specifications.

- Replace any damaged or worn components.

- Reassembly

- Follow the documented layout for proper component placement.

- Use new seals and gaskets to prevent leaks.

- Tighten fasteners to the recommended torque settings.

- Testing

- Reconnect all necessary connections.

- Run the system under controlled conditions to check for leaks.

- Monitor performance metrics to ensure proper operation.

By adhering to these systematic procedures, individuals can successfully enhance the reliability of their automotive systems.

Replacing Transmission Fluid Effectively

Changing the fluid within the vehicle’s power transfer system is a crucial maintenance task that helps ensure optimal performance and longevity. This process involves removing old fluid and introducing fresh fluid to maintain proper lubrication and functionality.

To carry out this procedure successfully, it’s essential to follow a systematic approach. Below is a step-by-step guide outlining the necessary actions:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and materials, including a fluid pump, collection container, and new fluid. |

| 2 | Locate the fill and drain plugs on the vehicle’s system. Ensure the engine is off and cool before proceeding. |

| 3 | Remove the drain plug and allow the old fluid to completely drain into the collection container. |

| 4 | Replace the drain plug securely to prevent leaks. |

| 5 | Use a pump to fill the system with the new fluid until it reaches the appropriate level. |

| 6 | Start the engine and allow it to run for a few minutes, then recheck the fluid level and add more if necessary. |

| 7 | Check for any leaks around the plugs and connections to ensure everything is secure. |

Regularly replacing the fluid not only enhances the system’s efficiency but also prevents potential issues down the line, ensuring a smooth driving experience.

Diagnosing Transmission Electrical Problems

Identifying issues related to the electrical components of vehicle gear systems requires a systematic approach. Accurate diagnosis is essential to ensure proper functionality and longevity of the system. Below are key steps to effectively troubleshoot electrical malfunctions.

- Check the Battery: Ensure the battery is fully charged and connections are secure. A weak battery can cause erratic behavior in electrical components.

- Inspect Wiring Harness: Look for any visible damage, corrosion, or loose connections in the wiring that could disrupt electrical flow.

- Test Sensors: Utilize diagnostic tools to assess the functionality of various sensors. Faulty sensors can lead to incorrect readings and operational issues.

- Examine Control Modules: Review error codes and inspect control modules for faults. Modules play a critical role in managing electronic functions.

- Conduct Voltage Tests: Measure voltage at key points in the circuit to identify any drops that may indicate resistance or short circuits.

Following these steps can help pinpoint the source of electrical complications, allowing for efficient troubleshooting and restoration of system performance.

Identifying Mechanical Failures in 722.9

Recognizing mechanical issues within complex automotive systems is crucial for ensuring optimal performance. Various signs and symptoms can indicate underlying problems, ranging from subtle changes in behavior to more pronounced malfunctions. A systematic approach to diagnosing these issues can significantly enhance repair efficiency and reliability.

Common Symptoms of Mechanical Issues

Drivers may notice unusual noises, erratic shifting patterns, or fluid leaks. These symptoms often serve as initial indicators of deeper mechanical troubles. Observing performance anomalies can guide technicians in pinpointing specific areas that require attention.

Diagnostic Techniques

Utilizing specialized diagnostic tools and methods is essential for accurately assessing mechanical integrity. Visual inspections, coupled with performance data analysis, can help identify potential failures early. Regular maintenance checks and fluid analyses further contribute to understanding the health of the system.

Importance of Regular Maintenance

Routine upkeep is crucial for ensuring the longevity and optimal performance of any mechanical system. By adhering to a consistent maintenance schedule, one can prevent potential issues and enhance the overall functionality of the equipment.

Regular attention can lead to various benefits:

- Increased Reliability: Frequent checks and services reduce the likelihood of unexpected failures.

- Cost Savings: Proactive measures often lead to lower repair costs by addressing minor problems before they escalate.

- Improved Performance: Well-maintained systems operate more efficiently, ensuring smoother operation.

- Extended Lifespan: Consistent care contributes to a longer life for the machinery, maximizing investment.

- Safety Assurance: Regular assessments help identify potential safety hazards, ensuring a safer environment for users.

In conclusion, prioritizing ongoing maintenance is essential for maximizing efficiency, safety, and longevity. Making it a habit can yield significant advantages for both performance and cost-effectiveness.

Cost Estimates for Repairs

Understanding the financial implications of vehicle maintenance is crucial for owners seeking to prolong the lifespan of their automobiles. Accurately estimating costs associated with component fixes can aid in budgeting and planning for necessary services.

Factors Influencing Repair Costs

- Parts Availability: The accessibility of components significantly impacts pricing. Rare parts may increase overall expenses due to sourcing challenges.

- Labor Rates: Regional variations in labor charges can lead to fluctuations in total costs. Urban areas often have higher hourly rates compared to rural locations.

- Vehicle Condition: The overall state of the automobile can affect the extent of necessary work. A vehicle in poor condition may require additional repairs.

- Service Complexity: The intricacy of the task at hand can determine labor duration and associated costs. More complicated issues will naturally lead to higher expenses.

Estimated Cost Ranges

While costs can vary widely, the following ranges provide a general idea:

- Basic Component Replacement: $500 – $1,500

- Comprehensive Overhaul: $1,500 – $4,000

- Labor Costs: $100 – $200 per hour

Consultation with professionals can provide more accurate estimates tailored to individual circumstances, ensuring informed decisions for vehicle care.

Choosing Quality Replacement Parts

When it comes to maintaining vehicle performance, selecting high-grade components is essential. Quality parts not only enhance reliability but also ensure longevity, minimizing the need for frequent replacements.

Factors to Consider

- Manufacturer Reputation: Choose parts from well-known manufacturers that have a history of producing durable products.

- Material Quality: Look for components made from high-quality materials that can withstand wear and tear.

- Compatibility: Ensure the parts are designed to fit your specific vehicle model for optimal performance.

- Warranty: A good warranty can provide peace of mind, indicating the manufacturer’s confidence in their product.

Where to Find Quality Parts

- Authorized dealerships often offer genuine components.

- Reputable auto parts stores usually stock a selection of reliable brands.

- Online marketplaces may provide access to a broader range, but verify seller ratings and reviews.

By carefully considering these factors and sourcing parts from trusted outlets, you can ensure the best outcomes for your vehicle’s functionality and safety.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly reduce risks associated with mechanical work. Adopting safety measures protects not only the technician but also the equipment and environment.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects and chemicals, and steel-toed boots to guard against heavy items falling. Wearing the right attire helps minimize the chances of injury during the process.

Work Environment Organization

Maintaining an organized workspace contributes to a safer environment. Keeping tools and materials neatly arranged reduces the risk of tripping hazards. Additionally, ensuring adequate lighting allows for better visibility, which is vital when handling intricate components. Regularly checking for any spills or loose parts further enhances safety during operations.

Resources for Further Assistance

For those seeking additional guidance and support, a variety of resources are available to enhance your understanding and facilitate effective solutions. These tools and references can be invaluable in navigating the complexities of automotive systems and ensuring optimal performance.

Online Communities and Forums

Engaging with online communities can provide a wealth of knowledge and shared experiences. These platforms often host discussions that cover troubleshooting, techniques, and innovative practices.

Professional Workshops and Training

Participating in workshops led by experts can deepen your practical skills and theoretical understanding. Such training sessions are designed to address both fundamental concepts and advanced strategies.

| Resource Type | Examples |

|---|---|

| Online Forums | Reddit, AutomotiveForums.com |

| Workshops | Local community colleges, Automotive training centers |

| Instructional Videos | YouTube, Vimeo |

| Technical Publications | Industry magazines, Online databases |