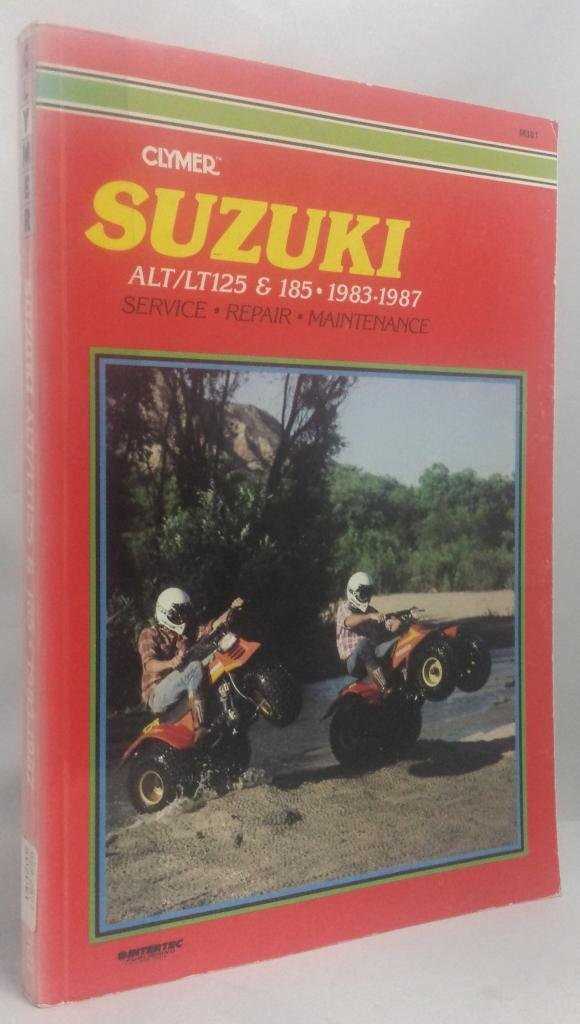

Repair Guide for 1985 Suzuki LT185 ATV

Owning a vintage all-terrain vehicle brings a unique experience, combining nostalgia with a strong sense of reliability. For enthusiasts and collectors alike, ensuring these machines remain in peak condition is both a rewarding challenge and an essential part of extending their longevity. This guide is dedicated to helping you understand every aspect of bringing an older model back to optimal performance.

Delving into the details, we cover the essential steps for upkeep, adjustments, and functional inspections. From essential maintenance practices to troubleshooting potential issues, you’ll find clear, step-by-step directions designed to keep your classic model running smoothly. Each section provides valuable insights and technical advice to assist in both preventative care and efficient repairs.

Whether you are an experienced mechanic or a passionate newcomer, this resource offers everything you need to enhance the performance and resilience of your trusted off-road companion. With the right approach and tools, the restoration and maintenance journey can be both accessible and deeply fulfilling.

1985 Suzuki LT185 Repair Guide

Maintaining and restoring your all-terrain vehicle requires attention to detail, understanding of essential mechanics, and familiarity with the unique specifications of the model. This guide provides practical steps for diagnosing and solving common issues, keeping your machine performing optimally.

From addressing engine concerns to ensuring smooth transmission operations, you’ll find essential tips for troubleshooting and performing essential fixes. The aim is to extend your vehicle’s longevity while making routine maintenance more approachable. With a systematic approach, even complex challenges can be managed effectively, ensuring a reliable and safe riding experience.

Understanding the LT185 Model Specifications

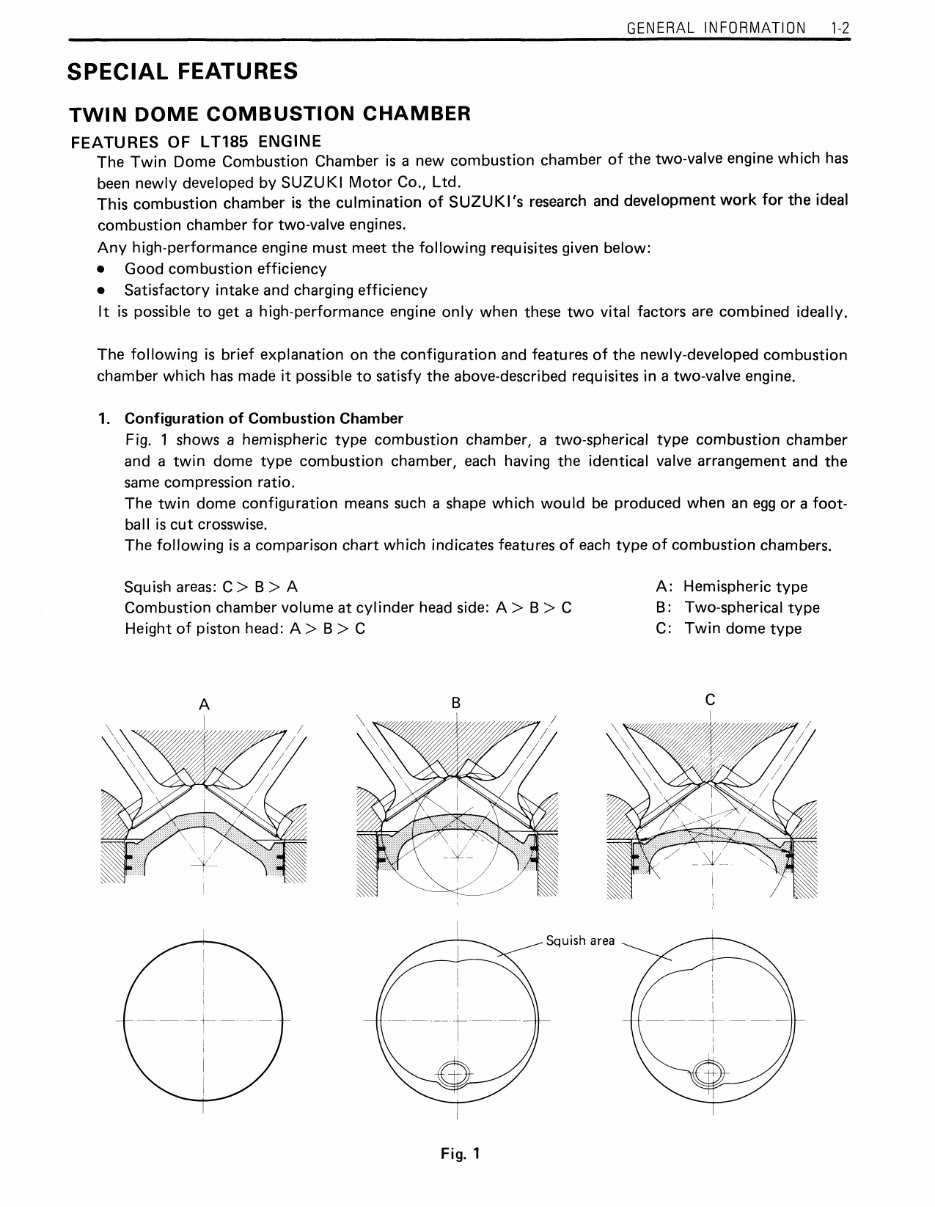

This section provides an overview of the essential features and technical details that define the LT model’s unique qualities. Known for its durable build and versatile functionality, this model stands out with a reliable design suited for a variety of terrains and usage needs. Understanding its specifications can help enhance performance, ensure proper care, and make adjustments where necessary.

The core of the LT model includes a sturdy engine, capable of handling various tasks with ease. Key elements such as frame construction, suspension design, and braking system combine to deliver a well-rounded and balanced experience for riders. Engine specifications and transmission capabilities also contribute to its adaptability, supporting both beginner and experienced operators.

Alongside its powertrain, this model features a thoughtfully engineered suspension system, offering stability and control over diverse surfaces. The braking setup is designed for reliable stopping power, further enhancing the safety and handling of the vehicle. With these technical details in mind, users can make informed decisions on operation, maintenance, and necessary adjustments to extend the model’s longevity.

Essential Tools for LT185 Maintenance

Keeping your vehicle in optimal condition involves not only regular check-ups but also the right set of tools to address various upkeep tasks. A proper toolkit allows for efficient handling of adjustments, inspections, and essential upkeep routines, making it easier to keep the machine running smoothly.

| Tool | Description | Purpose |

|---|---|---|

| Socket Wrench Set | Includes sockets in various sizes to fit different bolt heads | Useful for loosening and tightening nuts and bolts |

| Torque Wrench | Adjustable wrench that applies specific pressure | Ensures bolts and nuts are secured to the correct tightness |

| Oil Filter Wrench | Specialized tool for removing and installing oil filters | Essential for routine oil changes |

| Feeler Gauge | Set of calibrated metal strips or blades | Used to measure gaps in spark plugs and other components |

| Multimeter | Electronic tool to measure voltage, current, and resistance | Helps in diagnosing electrical issues |

A complete set of these tools will prepare any owner for essential maintenance tasks, supporting a more reliable and efficient operation.

Engine Troubleshooting and Repair Tips

Understanding the core issues that may affect the engine’s functionality is essential for maintaining optimal performance. This guide highlights frequent engine concerns and offers guidance on how to address them effectively. These suggestions are designed to assist with pinpointing problems and implementing practical solutions.

Common Engine Issues

When working on the engine, several common problems might arise, including starting difficulties, uneven idling, or unusual sounds. Often, these symptoms indicate underlying conditions such as fuel or air flow restrictions, ignition complications, or issues with essential components. By learning to identify these signs, you can take quick, targeted actions to maintain or restore performance.

Key Maintenance Tips

Regular upkeep, such as cleaning air filters and inspecting spark plugs, significantly contributes to engine efficiency and longevity. Attention to small details, like securing bolts and checking fluid levels, also prevents potential wear. With consistent checks and timely adjustments, the engine remains in optimal working order, enhancing reliability.

Inspecting and Replacing the LT185 Carburetor

Regular inspection and replacement of the carburetor are essential to maintain optimal engine performance and ensure smooth operation. By carefully examining the carburetor, you can identify potential issues early and address them before they impact the vehicle’s functionality. In this section, we will guide you through the process of checking and, if needed, replacing the carburetor.

Steps to Inspect the Carburetor

- First, ensure the engine is cool, and disconnect the fuel line to prevent spills.

- Detach the carburetor by loosening the mounting bolts and carefully remove it from the intake manifold.

- Examine the exterior for visible damage, wear, or build-up of dirt and deposits.

- Open the carburetor chamber to check the interior components for clogs, corrosion, or any accumulated debris that could restrict fuel flow.

Replacing a Worn Carburetor

- Prepare a compatible replacement carburetor and ensure all necessary tools are at hand.

- Securely mount the new carburetor, aligning it with the intake manifold and fastening the bolts carefully.

- Reconnect the fuel line, ensuring a tight seal to prevent leaks.

- Once installed, start the engine to verify that the carburetor functions correctly and adjust the settings as needed for smooth idling and acceleration.

Inspecting and, if needed, replacing the carburetor will contribute to the longevity and efficiency of the engine. Routine checks can also prevent more significant issues, ensuring that your vehicle performs reliably under various conditions.

LT185 Transmission Maintenance Techniques

Proper upkeep of the transmission system is crucial for ensuring optimal performance and longevity of your vehicle. Regular maintenance helps prevent premature wear and tear, enhances efficiency, and minimizes the risk of costly repairs. This section outlines essential techniques to maintain the transmission effectively.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Check | Every 500 miles | Inspect the transmission fluid level and condition. Low or dirty fluid can lead to overheating and damage. |

| Fluid Replacement | Every 2 years | Replace the transmission fluid to ensure proper lubrication and performance. Use the recommended type of fluid for best results. |

| Filter Inspection | Annually | Check the transmission filter for clogs and debris. A clean filter allows for better fluid circulation. |

| Seal Inspection | Every 1000 miles | Examine seals for leaks or wear. Replacing worn seals prevents fluid loss and potential damage. |

Electrical System Diagnosis and Solutions

The electrical system in any vehicle plays a critical role in its overall functionality. Understanding the common issues that can arise within this system is essential for effective troubleshooting. This section provides insights into diagnosing electrical malfunctions and offers solutions to address them.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Dead Battery | Vehicle won’t start, dim lights | Check battery connections, recharge or replace the battery |

| Faulty Wiring | Intermittent electrical failures | Inspect wiring for damage, repair or replace as needed |

| Defective Alternator | Warning light on, weak battery | Test alternator output, replace if necessary |

| Blown Fuse | No power to specific components | Identify blown fuses, replace with appropriate rating |

| Malfunctioning Starter | Clicking noise when starting | Inspect starter connections, test or replace starter |

Regular maintenance of the electrical system is vital for preventing these issues. By adhering to scheduled checks and promptly addressing any signs of malfunction, the longevity and performance of the vehicle can be significantly enhanced.

Repairing Suspension and Shock Absorbers

The effectiveness of a vehicle’s handling and comfort largely depends on its suspension system. Proper maintenance and timely adjustments are essential to ensure optimal performance. This section will explore the key aspects of addressing issues related to suspension and shock absorption components.

Identifying signs of wear or malfunction is crucial. Common indicators include:

- Unusual noises when driving over bumps

- Excessive bouncing or swaying during motion

- Uneven tire wear patterns

- Difficulty in steering or maintaining stability

To address these issues, follow these steps:

- Inspection: Begin by thoroughly examining the suspension system, including shock absorbers, springs, and mounting hardware.

- Testing: Conduct a bounce test by pushing down on the vehicle’s corners. If it bounces more than twice, the shock absorbers may need replacement.

- Replacement: If the components are damaged, consider replacing them with high-quality alternatives that meet or exceed original specifications.

- Reassembly: After replacing the necessary parts, reassemble the suspension system carefully, ensuring all bolts and nuts are tightened to the manufacturer’s torque specifications.

Regular maintenance checks can prevent potential issues from escalating. Keeping the suspension system in top condition enhances safety and comfort, ultimately leading to a better riding experience.

Brakes System Inspection and Adjustment

The braking system is a critical component of any vehicle, ensuring safety and control during operation. Regular inspection and proper adjustment of this system are essential to maintain optimal performance and prevent potential issues. This section will guide you through the necessary steps to evaluate and adjust the braking mechanisms effectively.

Begin by examining the brake pads and shoes for wear and damage. Check the thickness and look for any signs of cracking or glazing. Additionally, inspect the brake discs and drums for scoring or warping, which could impact braking efficiency. Ensure that all connections, such as hoses and lines, are secure and free from leaks.

| Component | Inspection Criteria | Adjustment Procedure |

|---|---|---|

| Brake Pads/Shoes | Check for wear and damage | Replace if below minimum thickness |

| Brake Discs/Drums | Look for scoring or warping | Machine or replace if damaged |

| Brake Fluid | Ensure proper level and condition | Top off or replace as necessary |

| Hoses/Lines | Inspect for leaks and wear | Replace if any damage is found |

Once the inspection is complete, adjustments may be necessary to ensure that the braking system operates effectively. Follow the manufacturer’s specifications for proper alignment and tensioning of components. Regular maintenance of the braking system not only enhances safety but also extends the lifespan of the vehicle.

Preventing Overheating in the LT185

Maintaining optimal operating temperatures is essential for the longevity and performance of your vehicle. Overheating can lead to serious damage, decreased efficiency, and costly repairs. Implementing effective strategies to manage temperature can enhance reliability and ensure smooth operation.

Regular Maintenance Practices

- Check coolant levels frequently to ensure adequate circulation.

- Inspect hoses and connections for leaks or wear that could hinder fluid flow.

- Clean the radiator to remove debris and dirt that obstruct airflow.

Monitoring Performance

Paying attention to how the vehicle behaves during operation can provide valuable insights into its health. Watch for signs of overheating, such as:

- Unusual temperature readings on the gauge.

- Steam or smoke from the engine compartment.

- Decreased power or sluggish acceleration.

By taking proactive measures and being vigilant, you can significantly reduce the risk of overheating, ensuring a smoother and more efficient riding experience.

Routine Care for Long-Lasting Performance

Regular maintenance is essential for ensuring optimal functionality and extending the lifespan of any vehicle. By adhering to a consistent care regimen, you can prevent potential issues, enhance performance, and promote reliability. This section outlines key practices that can contribute to the longevity of your machine.

Essential Maintenance Practices

Implementing routine checks and care can significantly improve your vehicle’s efficiency. Here are some vital practices to follow:

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil for optimal performance. |

| Air Filter Inspection | Monthly | Replace if dirty or clogged. |

| Brake System Check | Every 100 hours | Inspect pads and fluid levels. |

| Tire Pressure Check | Weekly | Maintain recommended pressure for safety. |

| Battery Condition Check | Every 30 hours | Clean terminals and check charge. |

Additional Tips for Optimal Care

In addition to regular tasks, consider these suggestions to maintain peak performance:

- Keep the vehicle clean to prevent rust and corrosion.

- Store in a dry, sheltered location to protect from weather elements.

- Use manufacturer-recommended parts for replacements.