Comprehensive Repair Guide for the 2012 Nissan Sentra

Maintaining a vehicle is essential for ensuring optimal performance and longevity. This section provides an extensive overview of essential techniques and insights that can assist car owners in understanding their automobiles better. Whether addressing minor issues or conducting more significant repairs, having access to detailed information can make the process smoother and more efficient.

From basic troubleshooting steps to more advanced procedures, this guide emphasizes the importance of familiarity with the vehicle’s components and systems. Equipped with the right knowledge, individuals can confidently tackle maintenance tasks, ultimately enhancing the driving experience. Additionally, having a well-structured reference can save both time and resources, allowing for informed decision-making during the upkeep of the vehicle.

Moreover, understanding the various functionalities and specifications of key parts can empower owners to make proactive choices. This not only prevents common problems but also contributes to a deeper appreciation of automotive engineering. Embracing these practices ensures that every journey remains safe and enjoyable.

Overview of 2012 Nissan Sentra

This section provides a comprehensive examination of a compact vehicle that combines practicality and efficiency. Designed for urban commuting and longer journeys, this model stands out with its blend of comfort, performance, and advanced features.

Key Features

- Spacious interior with ergonomic seating

- Fuel-efficient engine options

- Modern infotainment system

- Safety features including airbags and stability control

Performance and Handling

The vehicle is equipped with responsive handling characteristics, making it suitable for both city streets and highway travel. Its suspension system ensures a smooth ride, while the engine provides adequate power for various driving conditions.

Customer Satisfaction

- Reliability ratings are generally positive.

- Owners appreciate the balance of affordability and functionality.

- Many commend the low maintenance costs over time.

Common Issues with Nissan Sentra

Vehicles from this particular brand and model are known to exhibit a range of typical problems that owners may encounter over time. Understanding these issues can help in timely diagnosis and maintenance, ensuring a smoother driving experience.

Electrical Problems: Many users report difficulties with the electrical system, including malfunctioning lights and issues with the battery. These problems can lead to unexpected breakdowns if not addressed promptly.

Transmission Troubles: Drivers often experience shifting issues, which may manifest as delayed or rough transitions between gears. Regular checks and maintenance can help alleviate these concerns.

Suspension Wear: The suspension system may show signs of wear and tear, resulting in a rough ride. Common indicators include unusual noises or a noticeable decline in handling performance.

Brake System Issues: Frequent complaints involve the brake system, particularly regarding squeaking sounds or diminished responsiveness. Regular inspections are crucial for maintaining safety.

Engine Performance: Owners sometimes notice a decrease in engine efficiency, which can stem from various factors such as fuel delivery problems or sensor malfunctions. Monitoring engine performance can prevent more serious complications.

Awareness of these potential issues can empower owners to take proactive measures, ensuring their vehicle remains reliable and enjoyable to drive.

Essential Tools for Repairs

When tackling automotive maintenance and troubleshooting, having the right equipment is crucial for achieving successful outcomes. A well-equipped workspace can significantly enhance efficiency and precision, allowing for smoother operations whether you are performing minor adjustments or extensive overhauls.

Basic Hand Tools: A set of quality hand tools, including wrenches, screwdrivers, and pliers, forms the foundation of any mechanical toolkit. These essentials are indispensable for loosening and tightening various components.

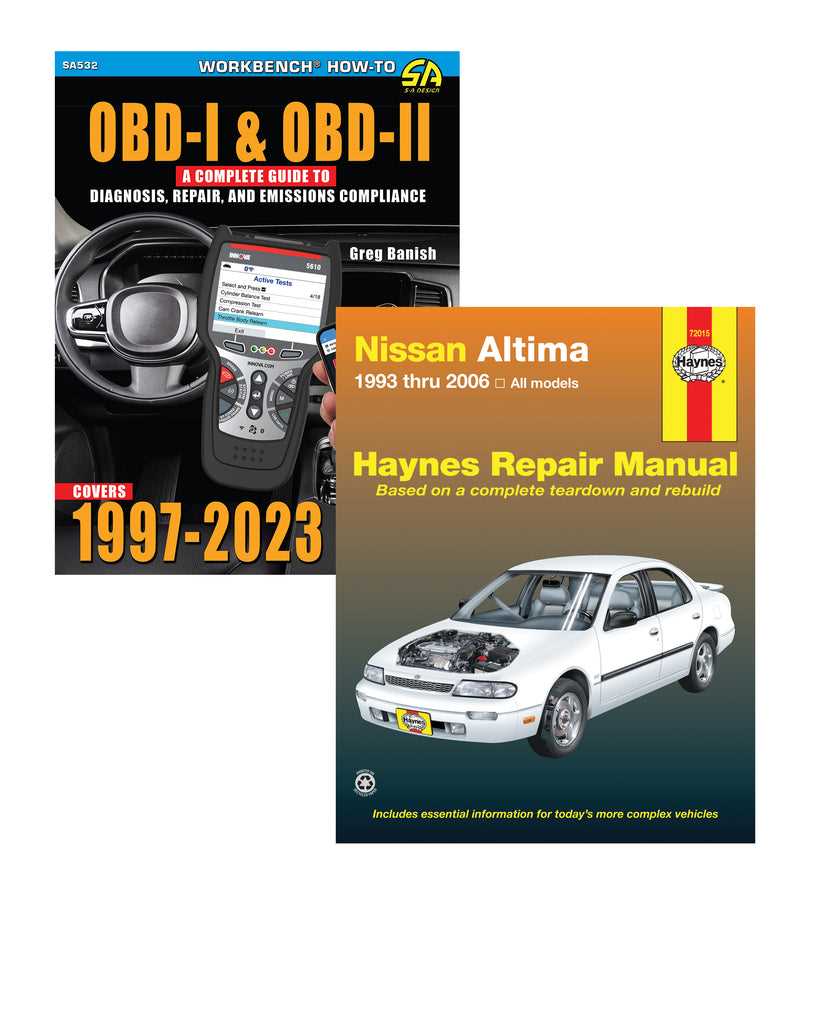

Diagnostic Equipment: Utilizing diagnostic tools such as OBD-II scanners can help identify issues quickly. These devices provide valuable insights into the vehicle’s performance and can save time during troubleshooting.

Specialty Tools: Depending on the specific tasks at hand, specialty tools may be required. Items like torque wrenches and pullers ensure that components are handled with care, maintaining integrity and safety.

Safety Gear: Don’t overlook the importance of safety equipment. Gloves, goggles, and appropriate clothing are essential to protect against potential hazards while working on vehicles.

In summary, having a comprehensive set of tools not only streamlines the process but also enhances the quality of work performed on vehicles.

Step-by-Step Maintenance Guide

Ensuring optimal performance and longevity of your vehicle involves regular upkeep and attention to detail. This guide provides a comprehensive approach to maintaining essential components, helping you avoid potential issues and enhancing the overall driving experience.

Essential Checks

- Inspect fluid levels regularly, including engine oil, coolant, brake fluid, and transmission fluid.

- Examine belts and hoses for signs of wear, cracking, or fraying.

- Check tire pressure and tread depth to promote safety and fuel efficiency.

- Ensure that all lights, signals, and indicators are functioning properly.

Routine Maintenance Tasks

- Change the engine oil and filter every 5,000 to 7,500 miles, depending on usage.

- Replace the air filter annually or as needed to maintain air quality and performance.

- Rotate tires every 6,000 to 8,000 miles to promote even wear.

- Flush and replace coolant every two years to prevent overheating.

- Inspect and replace brake pads and rotors as necessary for optimal stopping power.

Following these steps will help maintain vehicle reliability and performance, ultimately providing peace of mind during your travels.

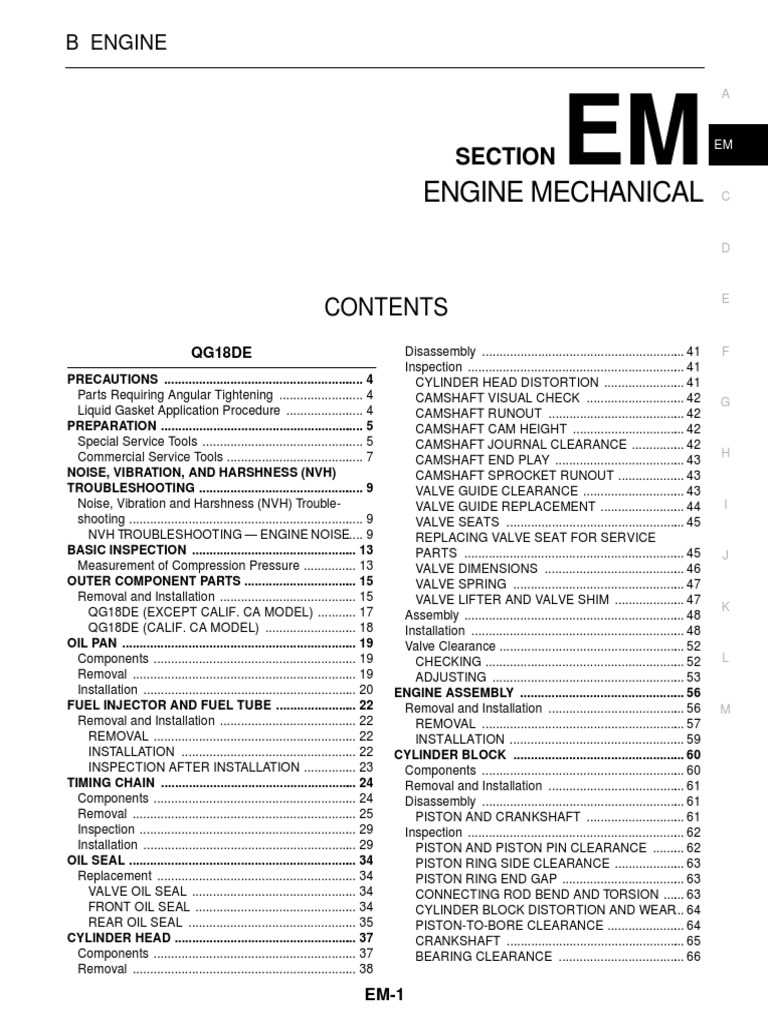

Engine Troubleshooting Techniques

Identifying issues within an engine requires systematic approaches that can help diagnose problems effectively. By employing specific techniques, one can pinpoint malfunctions and enhance performance. The following strategies serve as a guide for troubleshooting engine-related concerns.

- Visual Inspection: Start with a thorough examination of the engine bay. Look for signs of leaks, worn hoses, or loose connections.

- Listening for Noises: Unusual sounds such as knocking, grinding, or hissing can indicate specific issues. Pay attention to the origin of these sounds.

- Check Engine Light: If the warning light is illuminated, use a diagnostic tool to retrieve trouble codes, which can provide insight into potential problems.

- Fluid Levels: Ensure that oil, coolant, and other fluids are at appropriate levels. Low fluids can lead to overheating or insufficient lubrication.

Implementing these techniques systematically can lead to a better understanding of engine health and facilitate timely repairs.

- Test Drive: Conduct a test drive to observe performance under different conditions. Note any fluctuations in power, unusual vibrations, or responsiveness.

- Compression Test: Perform a compression test to assess the integrity of the cylinders. Low compression may indicate valve issues or gasket failures.

- Fuel System Check: Inspect fuel delivery components, including the pump and injectors. A malfunctioning fuel system can cause performance issues.

- Electrical Systems: Evaluate the ignition system and sensors. Faulty sensors can affect engine timing and efficiency.

By applying these techniques and maintaining a methodical approach, one can effectively troubleshoot engine issues and ensure optimal operation.

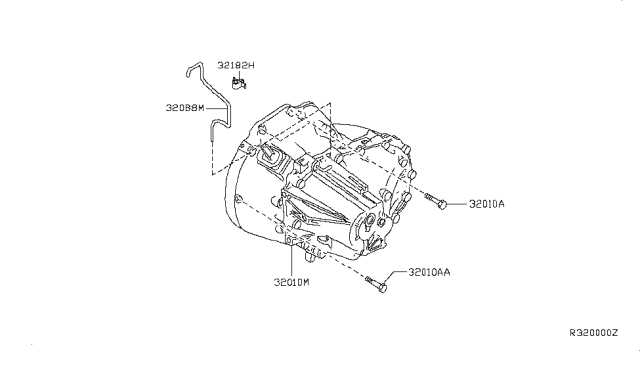

Transmission Repair Procedures

This section provides detailed guidance on the methods and techniques necessary for addressing issues related to the power transmission system. Understanding these procedures is essential for achieving optimal functionality and ensuring long-lasting performance.

To effectively troubleshoot and repair transmission concerns, follow these outlined steps:

| Step | Description |

|---|---|

| 1 | Begin by performing a thorough inspection of the transmission components, looking for signs of wear or damage. |

| 2 | Drain the transmission fluid and replace the filter to prevent contamination and maintain fluid integrity. |

| 3 | Check the fluid levels and adjust as necessary to ensure proper lubrication and cooling. |

| 4 | Examine the linkage and cables for any misalignments or breaks that could affect shifting performance. |

| 5 | If issues persist, consider disassembling the transmission for a more in-depth inspection of internal components. |

| 6 | Reassemble the system, ensuring all components are properly aligned and secured. |

| 7 | Conduct a test drive to verify that the transmission operates smoothly under various conditions. |

By adhering to these protocols, one can effectively restore transmission functionality and enhance overall vehicle performance.

Electrical System Diagnostics

The effective evaluation of an automobile’s electrical framework is essential for ensuring optimal performance and reliability. This section explores the various methods and tools necessary for assessing the electrical components and connections within a vehicle.

First, it’s crucial to understand the common issues that can arise within the electrical network. Problems such as inconsistent voltage, blown fuses, or malfunctioning sensors can lead to operational failures. Utilizing a multimeter is fundamental for measuring voltage, current, and resistance, allowing for precise identification of faults.

Visual Inspection should be the first step in any diagnostic process. Look for damaged wires, loose connections, and signs of corrosion. A thorough examination can often reveal underlying issues that may not be immediately apparent through testing.

Once potential issues are identified, troubleshooting techniques can be employed. Start by checking the power supply to critical components, such as the starter motor and electronic control units. Following a systematic approach can help isolate the root cause of electrical malfunctions.

Moreover, utilizing scan tools can significantly enhance diagnostic accuracy. These devices communicate with the vehicle’s onboard computer to retrieve error codes and provide insights into the functioning of various electrical systems. Interpreting these codes is vital for making informed decisions regarding repairs.

In conclusion, a comprehensive understanding of electrical system diagnostics is indispensable for maintaining vehicle efficiency. Regular assessments and prompt interventions can prevent minor issues from escalating into major repairs, ultimately prolonging the lifespan of the automobile.

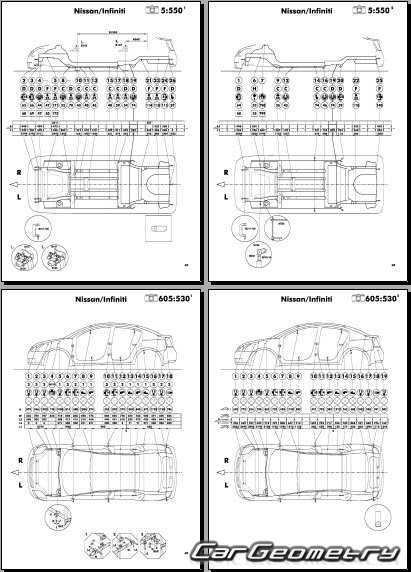

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are crucial for optimal vehicle handling and comfort. These adjustments ensure that the wheels maintain correct angles, enhancing stability and minimizing tire wear. Regular checks can significantly improve driving experience and prolong the lifespan of components.

Key Components to Inspect

- Shock absorbers and struts

- Control arms and bushings

- Steering rack and tie rods

- Wheel alignment settings

Adjustment Procedures

- Begin with a visual inspection of suspension parts for wear and damage.

- Check tire pressure and tread condition, ensuring even wear.

- Adjust the camber, caster, and toe angles according to manufacturer specifications.

- Test drive the vehicle to assess handling and make further adjustments if necessary.

Brake System Maintenance Tips

Maintaining the braking mechanism is crucial for ensuring safety and performance in any vehicle. Regular attention to this system not only extends its lifespan but also enhances overall driving experience. Proper upkeep can prevent costly repairs and unexpected failures, providing peace of mind for drivers.

Regular Inspections

Conducting periodic inspections of the braking components is essential. Look for signs of wear on pads and rotors, as well as fluid leaks. Checking the brake lines and connections can help identify potential issues before they escalate. Emphasizing early detection can save time and resources in the long run.

Fluid Maintenance

Maintaining the brake fluid is equally important. This fluid absorbs moisture over time, which can lead to decreased performance. Changing the fluid according to the manufacturer’s recommendations ensures optimal function and responsiveness of the braking system. Keeping the reservoir clean and topped up is a simple yet effective way to support braking efficiency.

Cooling System Inspections

The effective functioning of the engine’s thermal management system is crucial for optimal performance. Regular evaluations help identify potential issues before they escalate into major problems. This section outlines essential steps for conducting thorough assessments of the cooling mechanisms within the vehicle.

Visual Examination: Begin with a comprehensive visual inspection of the cooling components. Check for signs of leaks around hoses, connections, and the radiator. Any discoloration or wetness could indicate a failure that requires immediate attention.

Fluid Levels: Ensure that the coolant levels are within the recommended range. Low fluid levels can lead to overheating, compromising engine integrity. If the levels are low, top them up with the appropriate mixture and monitor for any irregularities.

Temperature Check: Utilize a thermometer or diagnostic tool to assess the operating temperature of the engine. The readings should align with the manufacturer’s specifications. Anomalies in temperature can signal underlying issues, such as a malfunctioning thermostat.

Pressure Testing: Conduct a pressure test on the system to verify its integrity. This process helps identify leaks that may not be immediately visible. A drop in pressure over time could indicate a failing component.

Hose Condition: Inspect all hoses for signs of wear, cracks, or bulges. Deteriorated hoses can lead to coolant loss and system failure. Replace any compromised hoses to maintain system efficiency.

Regular inspections of the thermal management system are vital for the longevity of the vehicle. Adhering to these practices not only prevents breakdowns but also enhances overall driving experience.

Fuel System Cleaning Methods

Maintaining the cleanliness of the fuel delivery system is essential for optimal performance and longevity of any vehicle. Various techniques exist to remove deposits and contaminants that can impede fuel flow and affect engine efficiency. Implementing these cleaning methods can restore the system’s functionality and improve overall vehicle operation.

Chemical Cleaning Solutions

Chemical treatments are widely used to cleanse the fuel system. These products are designed to dissolve carbon buildup and other impurities within the injectors and combustion chamber. Adding a fuel additive to the tank during a fill-up can help keep the system clean by regularly combating deposits as fuel is consumed.

Mechanical Cleaning Techniques

For more severe contamination, mechanical cleaning methods may be necessary. This approach often involves removing the injectors or other components for thorough cleaning. Ultrasonic cleaners are effective in this regard, as they use high-frequency sound waves to create microscopic bubbles that implode, dislodging stubborn grime from surfaces.

Safety Precautions During Repairs

When undertaking maintenance tasks on vehicles, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the potential hazards associated with mechanical work can significantly reduce risks and ensure a secure working environment.

Always wear appropriate personal protective equipment, such as gloves and safety glasses, to shield against harmful substances and flying debris. Additionally, working in a well-ventilated area can help minimize exposure to fumes and other hazardous materials.

Before starting any task, make sure to disconnect the battery to avoid electrical shocks and short circuits. It is also advisable to use jack stands or wheel chocks when elevating the vehicle to prevent unintended movement.

Keep your workspace organized and free from clutter to reduce the chances of trips and falls. Ensure all tools are in good condition and stored properly after use. Familiarizing yourself with the vehicle’s components and systems will also enhance your ability to work safely and efficiently.

Finally, consult relevant resources for specific guidelines related to the task at hand. Staying informed and following recommended practices will help maintain safety throughout the maintenance process.