Comprehensive Guide to Battery Charger Repair

In the realm of electrical devices, ensuring longevity and optimal functionality is essential. This section delves into the intricacies of maintaining and troubleshooting essential power management tools. By understanding common issues and solutions, users can enhance the performance and lifespan of their equipment.

Comprehending the mechanisms behind these tools allows for informed decisions regarding their upkeep. Knowledge of potential problems and their resolutions empowers users to tackle challenges effectively, minimizing downtime and ensuring seamless operation.

Moreover, adopting regular maintenance practices can prevent minor issues from escalating into significant malfunctions. This proactive approach not only saves time but also contributes to the overall efficiency of the devices, making them reliable companions for various tasks.

Various problems can arise with devices designed to replenish energy storage units. Understanding these challenges can help users identify and resolve issues effectively.

Frequent Problems Encountered

- Overheating: Excessive heat can damage internal components.

- Inconsistent output: Fluctuating power levels may prevent proper functioning.

- Physical damage: Cracks or broken parts can impede operation.

- Connection issues: Worn or corroded connectors can lead to poor contact.

- Electrical faults: Short circuits may cause complete failure.

Troubleshooting Tips

- Check for visible damage on the unit and cables.

- Ensure that all connections are secure and clean.

- Monitor the temperature during use to prevent overheating.

- Test with a different energy source to rule out external factors.

- Consult technical documentation for specific guidelines.

Tools Required for Repair

To effectively address issues with electrical devices, certain essential instruments are necessary. These tools enable efficient diagnosis and troubleshooting, ensuring that every component can be inspected and adjusted as needed.

Essential Instruments

The following list includes the fundamental tools that are commonly utilized during the troubleshooting process:

| Tool | Purpose |

|---|---|

| Multimeter | Measures voltage, current, and resistance. |

| Screwdriver Set | Used for opening and securing enclosures. |

| Soldering Iron | Joins or repairs electrical connections. |

| Wire Strippers | Removes insulation from wires for connections. |

Additional Considerations

In addition to the primary tools listed above, having a clean workspace and appropriate safety gear can enhance the repair process. This ensures both efficiency and safety while working on electrical components.

Safety Precautions During Repair

Ensuring safety is paramount when working on electrical devices. By following specific guidelines, one can minimize risks and create a secure environment for maintenance tasks.

Essential Guidelines

- Always disconnect the device from the power source before starting any work.

- Use insulated tools to prevent accidental electric shocks.

- Wear safety goggles to protect your eyes from potential debris.

- Ensure the workspace is dry and free from clutter to avoid slip hazards.

Personal Protective Equipment

- Employ gloves made of rubber or other insulating materials.

- Consider using a face shield in addition to goggles for extra protection.

- Dress in non-static clothing to prevent damage to sensitive components.

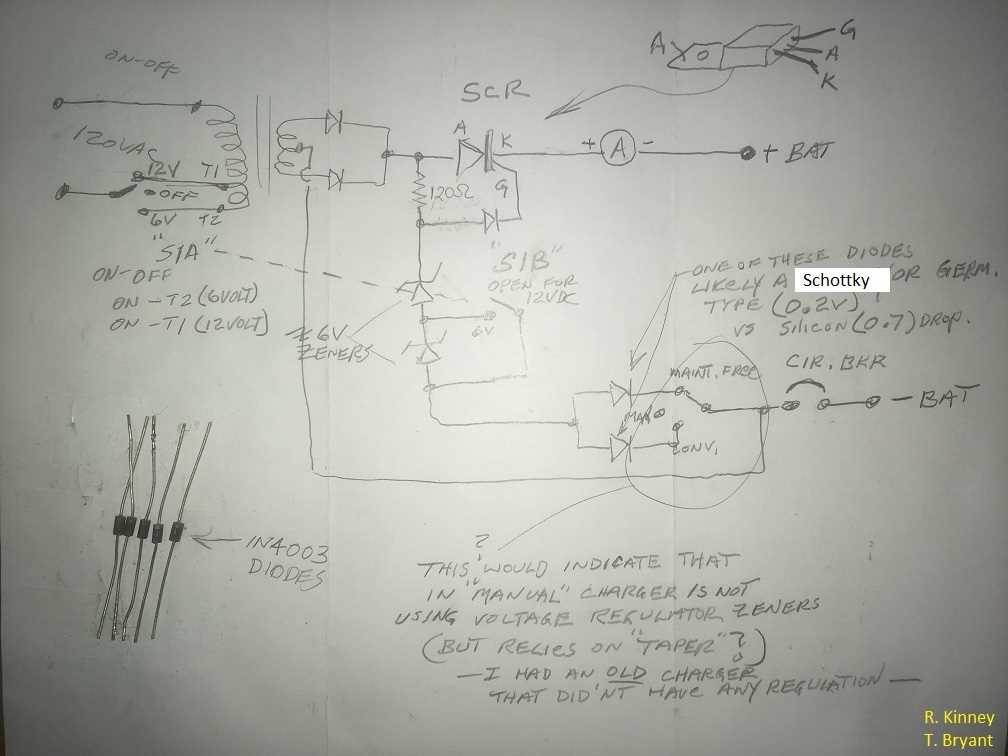

Identifying Charger Components

Understanding the various parts of a power replenishing device is essential for effective troubleshooting and maintenance. Each element plays a crucial role in the overall functionality, and recognizing them can aid in identifying potential issues and enhancing performance.

The primary elements include the energy input section, which is responsible for receiving electrical supply, and the regulation unit that controls the output. Additionally, there are safety mechanisms designed to prevent overloads, ensuring the unit operates within safe parameters. Each of these components contributes significantly to the device’s operation and reliability.

Furthermore, there are monitoring tools that provide feedback on the charging status, allowing users to assess the performance and efficiency of the system. Familiarizing oneself with these parts can lead to better maintenance practices and prolong the lifespan of the equipment.

Troubleshooting Electrical Connections

Ensuring optimal functionality of electrical devices often requires addressing issues related to their connections. A comprehensive understanding of how to identify and resolve these problems is essential for maintaining performance and safety.

Common Issues and Symptoms

Several symptoms may indicate connection problems, such as inconsistent power delivery or complete failure to operate. Visually inspecting connections for corrosion, fraying, or loose wires is crucial. Additionally, unusual noises or heat may suggest underlying issues that require immediate attention.

Steps to Diagnose and Fix

Begin by turning off the device and disconnecting it from any power source. Carefully examine all connections, ensuring that they are secure and free from damage. If necessary, clean contact points with a suitable solution to remove oxidation. For persistent issues, testing with a multimeter can help identify faulty connections, allowing for targeted repairs.

Testing Charger Functionality

Assessing the performance of a power source is crucial to ensure its efficiency and reliability. This process involves examining various components and conducting specific evaluations to verify that the unit operates correctly under different conditions.

Visual Inspection

Begin by conducting a thorough visual examination of the device. Look for any signs of wear, damage, or loose connections. Pay close attention to the cables and terminals, as these areas are often prone to faults.

Performance Testing

Utilize a multimeter to measure voltage output. Ensure that the readings align with the expected specifications. If the output is inconsistent or below the required levels, further investigation into the internal circuitry may be necessary. Additionally, monitor the temperature during operation, as excessive heat can indicate underlying issues.

Replacing Damaged Parts

Maintaining the functionality of electronic devices often requires the replacement of worn or defective components. Identifying and substituting these damaged elements is crucial for restoring proper operation and ensuring safety. This section will guide you through the essential steps for effectively replacing parts in such devices.

Assessing Damage: The first step involves thoroughly examining the unit to identify any faulty components. Look for visible signs of wear, such as corrosion, cracks, or discoloration. Testing the functionality of each part with a multimeter can help confirm which components need attention.

Choosing the Right Replacements: Once you have identified the damaged parts, sourcing appropriate replacements is vital. Always opt for high-quality components that match the specifications of the original parts. Using inferior substitutes can lead to further issues down the line.

Installation Process: Carefully remove the damaged components using suitable tools, ensuring you follow safety precautions. When installing new parts, pay attention to their orientation and connections. Securely fasten all components to prevent future malfunctions.

Final Checks: After the installation, it’s important to conduct a thorough inspection to confirm everything is correctly assembled. Testing the device before putting it back into regular use ensures that the new parts are functioning as intended and that no further issues are present.

Reassembling the Battery Charger

Putting the device back together requires careful attention to detail and methodical organization. This stage ensures that all components are securely in place and that the unit functions effectively after reassembly.

Begin by reviewing the layout of the internal parts. Arrange any screws or small pieces in a manner that will make them easy to locate during the process. Align the outer casing with the internal structure, ensuring that any connectors or cables are correctly positioned to avoid damage.

Once everything is aligned, gently press the casing together, making sure not to pinch any wires. Secure all screws in their designated locations, tightening them to the manufacturer’s specifications to maintain the integrity of the assembly. After completing these steps, the device should be ready for testing to confirm its operational status.

Performing Final Checks

Before concluding the maintenance process, it’s essential to ensure that all components are functioning correctly. This step guarantees optimal performance and safety during use. A systematic approach to verification will help identify any potential issues that may require attention.

| Check Item | Status | Action Required |

|---|---|---|

| Connections | Secure | None |

| Indicator Lights | Operational | None |

| Cooling System | Clear | Clean if necessary |

| Circuitry Inspection | Intact | Repair any damage |

By systematically reviewing these aspects, users can be confident in the reliability of the device. This diligence ensures a safe and efficient operation for future use.