Comprehensive Guide to Briggs Stratton Small Engine Repair

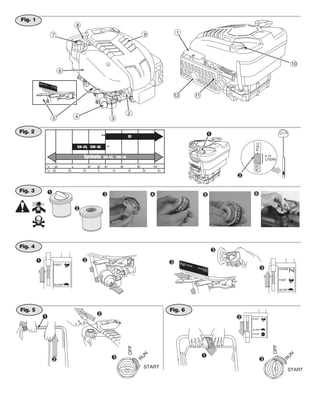

When it comes to ensuring optimal performance and longevity of your mechanical units, understanding the nuances of maintenance is crucial. This section delves into essential techniques and practices that can significantly enhance the functionality of your power units. Whether you’re a novice or a seasoned technician, the knowledge shared here aims to empower you with the skills necessary for effective oversight.

Detailed instructions will be provided to facilitate a thorough understanding of various components and their interrelations. From troubleshooting common issues to performing regular upkeep, this resource serves as a valuable reference point. Emphasis will be placed on practical approaches, enabling you to tackle challenges confidently and efficiently.

In addition to routine procedures, you will discover tips for addressing specific complications that may arise during operation. Mastering these skills not only aids in immediate problem-solving but also fosters a deeper appreciation for the intricate workings of your mechanical systems. Prepare to engage with a wealth of information that transforms maintenance into a straightforward and rewarding endeavor.

Essential Tools for Engine Repair

To successfully undertake maintenance and restoration tasks for various power units, having the right instruments is crucial. A well-equipped workspace not only enhances efficiency but also ensures safety during the process. This section outlines the fundamental implements that every technician should have on hand to facilitate effective troubleshooting and enhancement of mechanical performance.

Basic Hand Tools

Start with a set of standard hand tools, including wrenches, screwdrivers, and pliers. These are vital for loosening and tightening fasteners, allowing easy access to internal components. A reliable torque wrench is also necessary for applying the correct force to prevent damage during reassembly.

Diagnostic Equipment

Incorporating diagnostic devices, such as compression testers and multimeters, aids in identifying issues accurately. These tools help assess the health of the system and ensure optimal functionality, making them indispensable for anyone involved in mechanical upkeep.

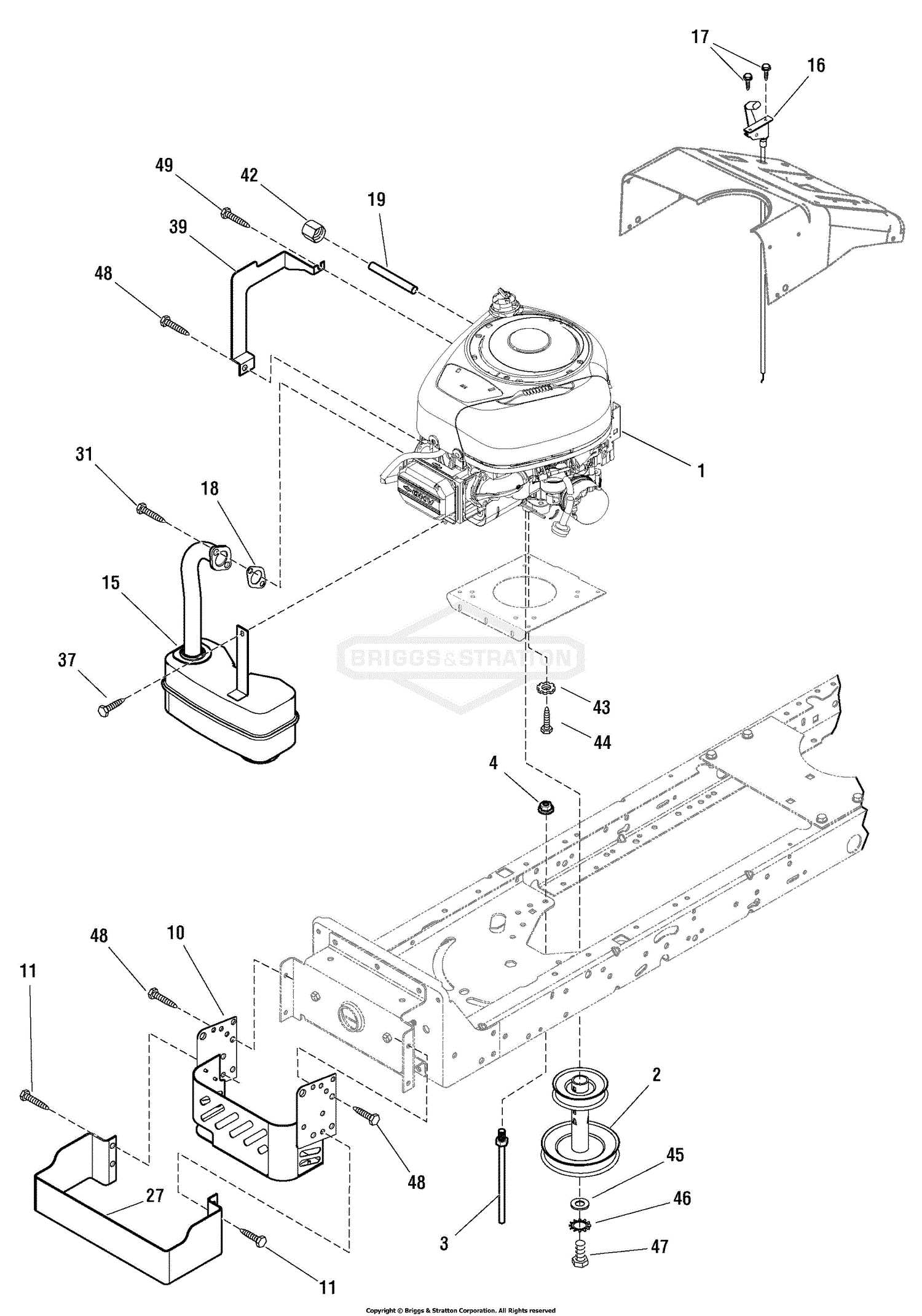

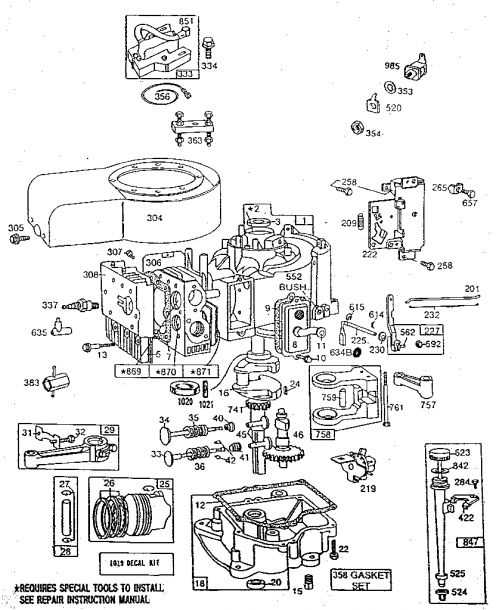

Understanding Engine Components and Functions

This section delves into the essential elements and their respective roles within a power unit. Recognizing how these parts interact is vital for efficient operation and maintenance. Each component contributes to the overall performance and reliability, making knowledge of their functions crucial for optimal use.

Combustion Chamber: This area is where the fuel-air mixture ignites, producing the force needed for movement. Understanding its design and functionality helps diagnose power issues.

Piston: The piston moves within the cylinder, converting combustion energy into mechanical motion. Its integrity is key to maintaining pressure and efficiency in the system.

Crankshaft: This rotating shaft translates the linear motion of the piston into rotational energy, driving the machinery. Recognizing wear or misalignment can prevent significant failures.

Valves: These components control the flow of gases in and out of the combustion chamber. Proper operation is essential for maintaining the cycle of intake and exhaust, directly impacting performance.

Ignition System: Responsible for initiating combustion, this system must function correctly to ensure reliable starts and efficient operation. Understanding its components can aid in troubleshooting starting issues.

Fuel System: This system delivers the necessary fuel for combustion. Knowing its components helps ensure the right mixture and flow, critical for performance and efficiency.

Overall, familiarity with these vital parts enhances maintenance practices and improves the longevity of the unit.

Common Issues in Small Engines

Various mechanical power sources often encounter similar challenges that can hinder their performance and efficiency. Understanding these prevalent concerns is essential for effective troubleshooting and maintenance.

| Issue | Symptoms | Possible Causes | Solutions |

|---|---|---|---|

| Starting Difficulties | Engine does not start or cranks slowly | Weak battery, fuel blockage, faulty spark plug | Check battery charge, clear fuel lines, replace spark plug |

| Overheating | Excessive heat output, smoke emission | Low oil levels, blocked cooling fins, dirty air filter | Top up oil, clean cooling components, replace air filter |

| Poor Performance | Loss of power, irregular running | Clogged fuel filter, worn-out parts, improper tuning | Replace fuel filter, inspect components, adjust settings |

| Fuel Leaks | Puddles of fuel, strong smell | Damaged fuel lines, loose connections, faulty seals | Inspect and replace fuel lines, tighten connections, change seals |

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing issues with power equipment. By following these structured steps, users can identify problems and apply solutions effectively, enhancing performance and extending the lifespan of their machines.

Initial Assessment

Begin by evaluating the overall condition of the unit. Look for visible signs of damage or wear. Follow these steps:

- Check for leaks or unusual odors.

- Inspect all connections and components for integrity.

- Ensure that the fuel supply is adequate and free from contaminants.

Operational Tests

After the initial assessment, conduct operational tests to further narrow down potential issues. Follow these steps:

- Attempt to start the unit. Note any irregular sounds or failure to ignite.

- Monitor the operation for unusual vibrations or smoke.

- Evaluate performance under load to identify any power loss.

Document all findings during the assessment and testing phases for future reference. This will assist in pinpointing the problem and determining the best course of action.

Maintenance Practices for Longevity

Ensuring the durability and optimal performance of your machinery requires a commitment to consistent upkeep. Implementing effective maintenance routines can significantly extend the lifespan of your equipment and enhance its efficiency.

Regular Inspection and Cleaning

Conducting routine checks and cleaning is essential to identify wear and tear early. Remove debris, dust, and other contaminants from all components. Pay special attention to air filters and cooling systems, as clogs can lead to overheating and operational issues. Keeping parts clean promotes better airflow and overall performance.

Scheduled Fluid Changes

Changing fluids at regular intervals is vital for maintaining optimal functionality. Ensure that all lubricants and fuels are fresh and meet the specified requirements. Regularly replace oil and check for leaks to prevent damage and ensure smooth operation. Adhering to a strict schedule for fluid changes can prevent unnecessary breakdowns and costly repairs.

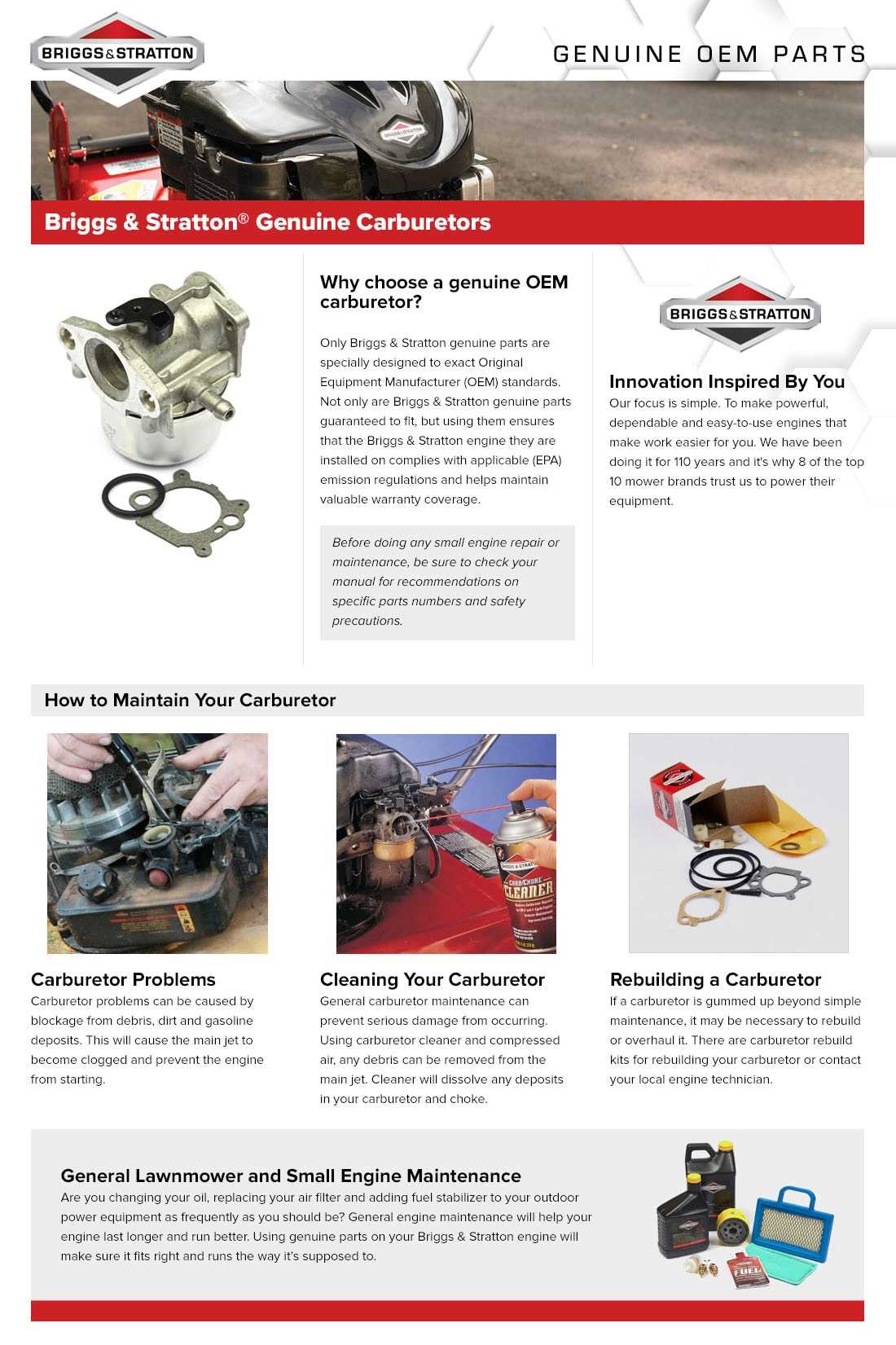

Fuel System Cleaning and Care

Maintaining a clean fuel system is essential for optimal performance and longevity of outdoor power equipment. Regular attention to this area ensures smooth operation and prevents issues related to fuel delivery.

Here are key steps to effectively clean and care for the fuel system:

- Inspect the fuel tank for debris or contamination.

- Drain old fuel and replace it with fresh fuel to prevent varnishing.

- Clean the fuel filter to ensure unobstructed fuel flow.

- Check fuel lines for cracks or leaks, replacing as necessary.

- Examine the carburetor for buildup and clean it thoroughly.

Using quality fuel and additives can enhance performance and help prevent issues. Always refer to specific guidelines for your equipment to ensure proper maintenance practices.

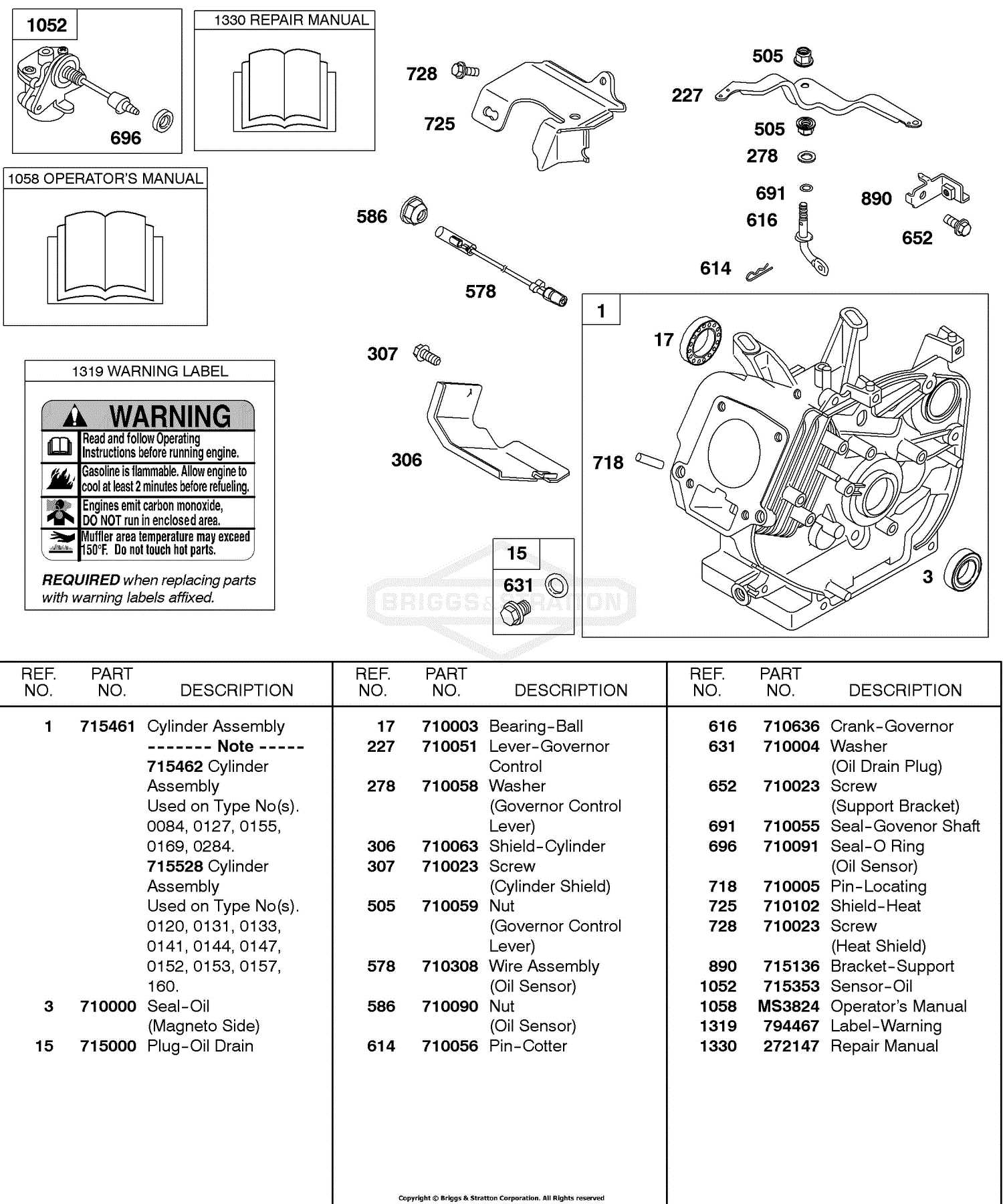

Rebuilding vs. Replacing Engine Parts

When faced with issues in mechanical systems, enthusiasts often grapple with the decision to either refurbish existing components or install new ones. Each approach carries distinct advantages and considerations that can impact performance, longevity, and overall costs.

Advantages of Rebuilding

Refurbishing parts can be a cost-effective solution, especially when original components are still in good condition. By restoring functionality, it may extend the life of machinery significantly. This method often involves less waste, aligning with environmentally conscious practices.

Benefits of Replacement

On the other hand, installing new parts can provide enhanced reliability and performance. New components often come with warranties, ensuring peace of mind. This approach can also eliminate the risk of potential failures associated with older, refurbished parts.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial for both personal well-being and the longevity of the equipment. By adhering to specific guidelines, one can minimize risks and enhance the overall experience of servicing machinery.

- Always wear appropriate protective gear, including gloves, safety goggles, and sturdy footwear.

- Work in a well-ventilated area to prevent the buildup of harmful fumes.

- Ensure that all tools are in good condition and suitable for the task at hand.

Following these steps will help create a safer environment while attending to mechanical tasks.

- Disconnect power sources before starting any work.

- Keep flammable materials away from the work area.

- Be aware of your surroundings to avoid potential hazards.

By maintaining focus and prioritizing safety, one can efficiently perform maintenance activities without unnecessary risks.

Repair Techniques for Common Problems

This section outlines effective methods for addressing frequent issues encountered during maintenance tasks. Understanding these techniques can significantly enhance performance and longevity, ensuring optimal operation of various machinery.

Identifying and Troubleshooting Issues

Before initiating any corrective actions, it is crucial to accurately diagnose the problem. Here are steps to follow:

- Observe the symptoms carefully.

- Consult relevant documentation for potential causes.

- Perform basic tests to confirm your suspicions.

Common Fixes and Adjustments

Once the issue has been identified, several common solutions can be implemented:

- Replace worn-out components with high-quality alternatives.

- Clean filters and intake systems to improve airflow.

- Adjust settings to ensure proper operation of moving parts.

- Lubricate joints and bearings to minimize friction.

- Inspect and tighten all connections to prevent leaks.

When to Seek Professional Help

Determining when to consult an expert can significantly impact the longevity and performance of your machinery. While many issues can be tackled with basic knowledge and tools, certain situations may require specialized skills and equipment. Understanding these instances can help ensure your device operates efficiently and safely.

Signs of Complex Issues

If you encounter persistent problems that do not resolve with standard troubleshooting methods, it may be time to reach out for professional assistance. Unusual noises, erratic behavior, or visible damage often indicate underlying complications that necessitate expert intervention.

Safety Concerns

When safety becomes a concern, seeking help is crucial. If you notice leaks, excessive vibrations, or any signs that could pose a risk to yourself or others, it’s advisable to consult a trained technician. Prioritizing safety will prevent accidents and ensure proper functioning.

Resources for Further Learning

Enhancing your knowledge in mechanical maintenance and troubleshooting can greatly improve your skills. Various materials are available to support your journey, providing both foundational concepts and advanced techniques. Utilizing diverse resources will empower you to tackle a wide range of challenges effectively.

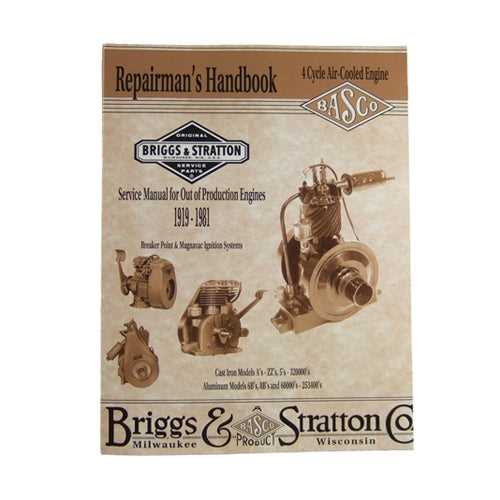

Books and Manuals

Comprehensive guides offer in-depth insights into various components and operational principles. Look for literature that covers the fundamentals of maintenance, as well as specific topics related to your interests. Reference materials can serve as valuable tools for hands-on projects and diagnostics.

Online Courses and Videos

The internet is rich with educational content, including video tutorials and online classes. Many platforms offer courses tailored to specific skill levels, allowing you to learn at your own pace. Engaging with interactive content can facilitate a deeper understanding of practical applications and troubleshooting methods.