Comprehensive Guide to Repairing Your Kenmore 70 Series Washing Machine

Every household appliance has its quirks and challenges, often leading to unexpected hiccups in daily routines. Understanding how to address these issues not only extends the lifespan of the equipment but also enhances efficiency and performance. This guide aims to provide essential insights for users who wish to tackle common problems with their laundry equipment effectively.

By familiarizing yourself with the operational intricacies and potential pitfalls, you can cultivate a proactive approach to maintenance. Whether it’s dealing with unusual sounds, water drainage problems, or cycles that don’t seem to function as intended, having a clear reference can make all the difference. The information presented here is designed to empower users, enabling them to confidently resolve issues and ensure their devices remain in optimal condition.

Additionally, understanding the inner workings of these household essentials can save time and money, eliminating the need for frequent professional interventions. With this knowledge at your fingertips, you’ll be equipped to identify symptoms and apply appropriate solutions, turning challenges into manageable tasks.

Understanding the Kenmore 70 Series

This section delves into the intricacies of a popular household appliance renowned for its reliability and efficiency. By exploring its components and functionality, users can gain insight into its operational mechanisms, ensuring optimal performance and longevity.

Key Features

The appliance boasts a range of functionalities designed to cater to various laundry needs. With multiple settings and cycles, it accommodates different fabric types and load sizes, making it a versatile choice for any home. Additionally, features like energy efficiency and user-friendly controls enhance the overall experience.

Troubleshooting Tips

Understanding common issues can empower users to address minor problems independently. Simple tasks such as checking connections, ensuring proper loading, and maintaining cleanliness can significantly improve functionality. When faced with more complex challenges, referring to resources can provide valuable guidance.

Common Issues with Kenmore Washers

When dealing with household appliances, certain problems frequently arise that can disrupt daily routines. Understanding these common challenges can aid users in troubleshooting and maintaining optimal performance.

Frequent Problems

Several issues tend to occur with these devices, ranging from mechanical failures to performance inconsistencies. Recognizing the symptoms can help in addressing the root causes effectively.

| Issue | Description |

|---|---|

| Unusual Noises | Grinding or squeaking sounds may indicate a problem with the drum bearings or motor. |

| Water Leaks | Puddles around the unit could stem from loose hoses or worn-out seals. |

| Failure to Spin | A lack of spinning might be due to an unbalanced load or malfunctioning motor. |

| Drainage Issues | Water not draining properly can be caused by clogs in the drain hose or pump. |

Tips for Prevention

Regular maintenance can help prevent many of these issues. Cleaning filters, checking hoses, and ensuring proper loading techniques are essential steps to prolong the life of the appliance.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues encountered with household laundry appliances. Following these steps can help identify problems efficiently, allowing for effective solutions.

1. Check Power Supply

Ensure that the unit is properly plugged in and that the outlet is functioning. A quick test can be done by plugging in another device.

2. Inspect Water Supply

Verify that the water valves are turned on and that there are no kinks in the hoses. Low water pressure can also be a culprit.

3. Examine the Door Lock

If the lid or door won’t open, it may be due to a malfunctioning lock. Ensure it engages properly when closed.

4. Listen for Unusual Noises

Peculiar sounds during operation can indicate issues. Take note of any grinding or clunking noises, which may suggest a foreign object is trapped.

5. Review Error Codes

If the appliance displays error codes, consult the user guide for specific meanings and recommended actions for each code.

6. Assess Drum Movement

Check if the drum is spinning freely. If it’s stuck, inspect for blockages or mechanical failures that could be causing the issue.

7. Clean Filters and Hoses

Regular maintenance is crucial. Clean lint filters and hoses to prevent clogs that can disrupt performance.

8. Seek Professional Help

If the problem persists after following these steps, it may be time to contact a qualified technician for a thorough evaluation.

How to Access the Repair Manual

Finding the necessary documentation for troubleshooting and fixing your appliance is crucial for ensuring its longevity and efficiency. This guide provides clear steps to locate and utilize the appropriate resources to assist you in the process.

Online Resources

- Visit the official website of the manufacturer.

- Use search engines to find specific guides by entering the model number.

- Explore forums and community sites where users share their insights and links to documents.

Physical Copies

- Check the interior of the appliance for a printed guide.

- Visit local appliance retailers or service centers for additional resources.

- Consult your user manual if available, as it often contains references to repair guides.

By utilizing these methods, you can easily access the necessary documentation to help you address any issues effectively.

Replacing the Drive Belt Explained

When it comes to maintaining your appliance, one critical component that often requires attention is the drive belt. This part is essential for transferring power from the motor to the drum, enabling it to function smoothly. Over time, wear and tear can lead to issues such as slipping or complete failure, necessitating a replacement.

Identifying the Need for Replacement

Signs that the belt may need changing include unusual noises, such as squeaking or grinding, or if the drum fails to spin altogether. Regularly checking for fraying or cracking can help catch problems early, allowing for a timely fix. Neglecting these symptoms can result in more significant issues down the line.

Step-by-Step Replacement Process

To replace the drive belt, first, ensure the appliance is unplugged for safety. Access the inner compartment by removing the necessary panels. Carefully detach the old belt from the pulleys and replace it with a new one, ensuring it is properly aligned. Finally, reassemble the components and plug the unit back in to test its functionality. Proper installation is crucial for optimal performance.

Fixing Water Drain Problems

Addressing issues related to water drainage is crucial for ensuring optimal performance of your appliance. When drainage problems arise, it can lead to various complications, including inefficient cleaning and potential damage. Understanding common causes and solutions can help you troubleshoot effectively.

Here are some frequent reasons for water drainage difficulties:

- Clogged Hoses: Accumulation of debris or lint can obstruct hoses, preventing proper water flow.

- Blocked Filter: The filter may become filled with dirt or small objects, disrupting drainage.

- Faulty Pump: A malfunctioning pump may not expel water as needed, leading to stagnant water.

- Improper Installation: Incorrect positioning of hoses can impede drainage, especially if they are kinked or bent.

To resolve these issues, consider the following steps:

- Inspect and Clean Hoses: Check for blockages in the hoses and clean them thoroughly.

- Examine the Filter: Remove and clean the filter to ensure it is free from any obstructions.

- Test the Pump: Listen for unusual noises when the appliance attempts to drain; replace the pump if it is not functioning correctly.

- Check Hose Positioning: Ensure hoses are correctly installed and not kinked to allow for proper drainage.

By following these steps, you can effectively address water drainage issues and enhance the performance of your appliance.

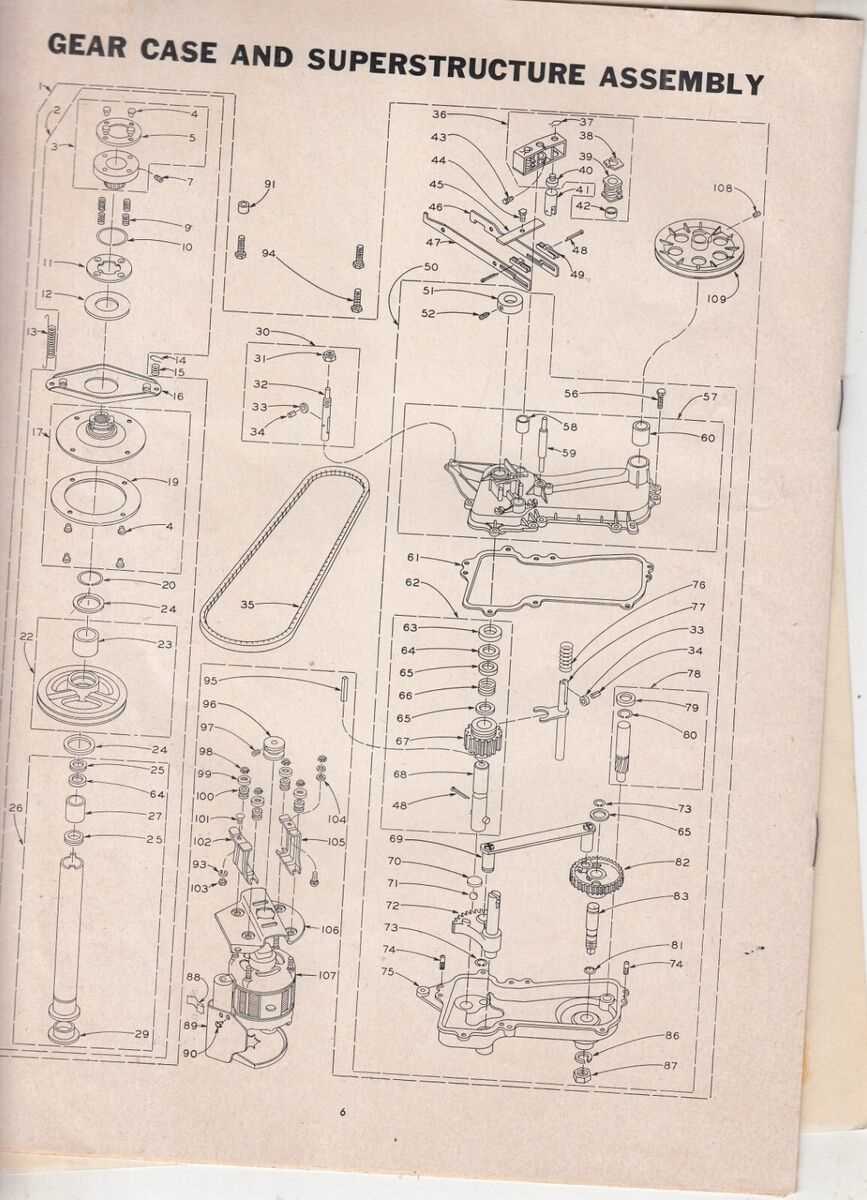

Addressing Agitator Malfunctions

Understanding the common issues that can arise with the central component responsible for the agitation process is crucial for effective troubleshooting. This section outlines potential problems and their solutions to ensure optimal performance.

- Insufficient Agitation:

If the central device is not moving properly, it may fail to clean clothes effectively. Check for:

- Wear and tear on the drive belt

- Obstructions in the gear assembly

- Issues with the motor coupling

- Unusual Noises:

Strange sounds during operation can indicate a malfunction. Investigate:

- Loose or damaged components

- Foreign objects caught in the mechanism

- Worn bearings

- Agitator Not Engaging:

If the component fails to start, consider checking:

- Electrical connections and wiring

- The timer or control board

- The lid switch for proper function

By systematically diagnosing these issues, users can maintain the efficiency of their unit and prolong its lifespan.

Electrical Components and Their Functions

This section delves into the various electrical elements that play crucial roles in the operation of household appliances. Understanding these components helps in diagnosing issues and maintaining efficient performance.

Main Components

- Power Supply: Provides the necessary voltage for the unit to operate.

- Control Board: Acts as the brain, managing all functions and user inputs.

- Motor: Drives the movement of various parts, crucial for operational tasks.

- Heating Element: Responsible for raising the temperature of water for cleaning processes.

Sensor Functions

- Water Level Sensor: Monitors the amount of water in the reservoir to prevent overflow.

- Temperature Sensor: Ensures water reaches the desired temperature for optimal cleaning.

- Door Lock Switch: Prevents operation when the access door is open for safety.

Each component is integral to the overall functionality, ensuring that the appliance operates smoothly and effectively. Regular inspection and understanding of these parts can lead to improved performance and longevity.

Cleaning the Filter and Hoses

Maintaining optimal performance in your appliance requires regular attention to certain components. Ensuring that filters and hoses are clean is essential for preventing blockages and enhancing efficiency. This section will guide you through the steps necessary to keep these parts in top condition.

Start by locating the filter, which is typically situated near the inlet valve or at the bottom of the unit. Carefully remove it according to the guidelines provided in your device’s documentation. Rinse the filter under warm water to eliminate any accumulated debris or residue, and allow it to dry completely before reinstallation.

Next, turn your attention to the hoses. Inspect them for any signs of wear or damage, such as cracks or bulges. Disconnect the hoses from their connections, using caution to avoid spills. Clean the interior of the hoses by flushing them with warm water. A gentle scrub with a soft brush can help dislodge stubborn buildup. After cleaning, ensure that both the hoses and the filter are securely reattached, checking for leaks.

Regular maintenance of these components not only prolongs the lifespan of your appliance but also ensures it operates smoothly, providing you with the best possible performance.

Adjusting Spin Cycle Settings

Properly calibrating the spin cycle is crucial for achieving optimal performance and fabric care. Adjusting these settings allows users to manage moisture levels in garments, reducing drying time and energy consumption. This section will guide you through the steps to customize the spin speed for various fabric types and load sizes.

Different fabrics require specific spin settings to prevent damage and ensure thorough cleaning. The table below outlines recommended spin speeds based on common material types.

| Fabric Type | Recommended Spin Speed (RPM) |

|---|---|

| Delicates | 400 – 600 |

| Cotton | 800 – 1000 |

| Synthetics | 600 – 800 |

| Towels | 1000 – 1200 |

By following these guidelines, users can effectively adjust the spin cycle settings to match their specific laundry needs, ensuring garments are properly cared for while optimizing energy use.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring that your household appliance remains efficient and functional over the years. By following a few straightforward guidelines, you can significantly extend its lifespan and maintain optimal performance. Regular attention to specific components can help prevent common issues and reduce the need for extensive interventions.

Regular Cleaning

Keep it clean to prevent buildup of dirt and grime. Regularly wipe down surfaces and clean the interior to avoid any unpleasant odors or mold growth. Ensure that all filters and compartments are free of debris. This simple act can greatly enhance efficiency and performance.

Check Hoses and Connections

Inspect hoses and connections periodically for any signs of wear or damage. Replace any frayed or leaking hoses to avoid water damage or inefficiency. Tightening connections can also prevent leaks, which can lead to more serious issues if left unaddressed.

By implementing these tips, you can enjoy a reliable and effective appliance for years to come. Remember that proactive measures often prevent costly repairs down the line.

Identifying Noise Issues in Washers

Understanding the origin of unusual sounds during operation is crucial for maintaining the longevity and efficiency of laundry appliances. Various factors can contribute to audible disturbances, ranging from minor issues to significant mechanical failures. This section aims to provide insights into diagnosing these noise-related concerns, enabling users to take appropriate actions.

Common Types of Noises

Familiarizing yourself with the typical sounds can help pinpoint the source of the problem. For instance, thumping or banging may indicate an unbalanced load, while grinding noises could suggest worn-out components. Squealing may arise from a misaligned belt or other moving parts, highlighting the need for immediate attention.

Steps for Troubleshooting

Begin by observing the appliance during various cycles to determine when the noise occurs. Check for any foreign objects that may have become lodged within the drum. Additionally, ensure that the unit is level and securely positioned. If the issue persists, examining internal components or seeking professional assistance might be necessary to avoid further damage.

When to Call a Professional Repairman

There are times when tackling issues on your own may not be the best approach. Recognizing the limits of your skills and the complexity of a situation is crucial for ensuring safety and efficiency. Certain signs indicate that it might be time to seek the expertise of a trained technician to avoid further complications.

Signs of Serious Malfunction

If you encounter persistent problems that don’t resolve with basic troubleshooting, it’s wise to consult a specialist. Unusual noises, leaks, or error codes that reappear despite resets can suggest underlying issues that require professional insight. Ignoring these signals can lead to more severe damage and higher costs in the long run.

Safety Concerns

When dealing with electrical components or complex mechanical failures, safety should be your top priority. If you notice frayed wires, burning smells, or other hazardous conditions, refrain from attempting repairs yourself. In such cases, enlisting the help of an expert is essential to ensure both your safety and the proper functioning of your equipment.