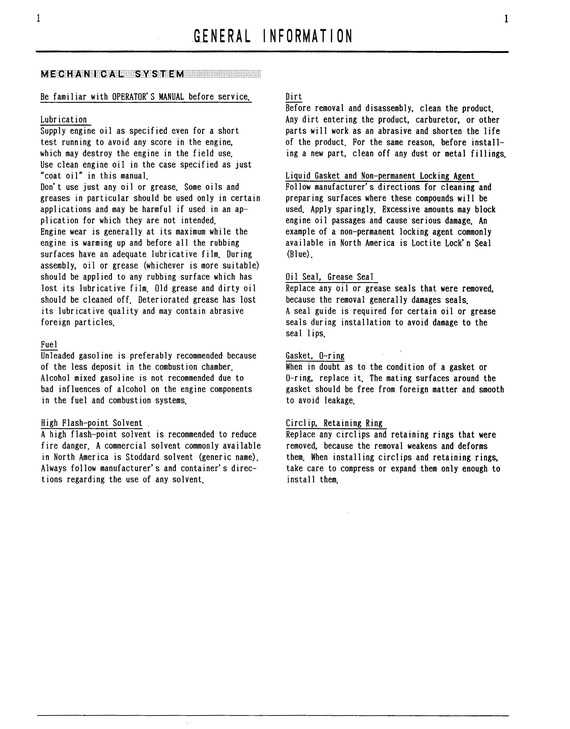

Kawasaki FC540V Repair Guide for Optimal Performance

In the realm of small engines, understanding the intricacies of their upkeep is vital for optimal performance and longevity. This guide delves into the essential practices and insights necessary for troubleshooting and enhancing the efficiency of various engine types. Whether you are a seasoned mechanic or a novice enthusiast, possessing the right knowledge can significantly impact your maintenance routine.

Understanding the Basics is crucial before embarking on any repair journey. Familiarity with the engine’s components and their functions will empower you to diagnose issues more effectively. This foundational knowledge serves as the bedrock for all subsequent maintenance activities, ensuring that each step taken is informed and purposeful.

Additionally, regular inspections play a pivotal role in preventing minor problems from escalating into major failures. By adhering to a systematic approach, you can identify wear and tear early, allowing for timely interventions. This not only saves time and resources but also enhances the overall reliability of the engine.

Engine Overview

This section provides an in-depth look at a specific type of small engine designed for efficiency and performance. The unit is known for its robust construction and reliable operation, making it a popular choice for various applications. Understanding its features and functionality is essential for anyone seeking to maximize its potential.

The powerplant is a four-stroke, air-cooled model that emphasizes durability and ease of maintenance. It operates with a horizontal shaft, which facilitates a wide range of attachments and machinery compatibility. With a focus on torque and fuel efficiency, this engine excels in delivering consistent performance under various conditions.

Equipped with a dual-element air filter, the unit ensures optimal airflow while protecting against debris, thus enhancing longevity. The ignition system is electronic, providing reliable starting and efficient operation. Users can expect a smooth power delivery, making it ideal for both residential and commercial applications.

Additionally, the design incorporates features aimed at reducing vibration and noise, contributing to a more pleasant user experience. This engine stands out in its category for its balance of power, efficiency, and ease of use, making it a favored choice for many operators.

Common Issues with Kawasaki FC540V

Engine problems can often arise with small power equipment, impacting performance and efficiency. Identifying and addressing these challenges is crucial for maintaining optimal functionality and extending the lifespan of the machine.

Frequent Problems

- Starting Difficulties: One of the most common complaints is trouble starting the engine. This can be caused by several factors, including fuel delivery issues, battery problems, or a faulty ignition system.

- Overheating: Overheating can occur due to inadequate cooling, debris clogging vents, or low oil levels. Monitoring the temperature during operation is essential.

- Fuel Consumption: Excessive fuel usage may indicate an improper air-fuel mixture, fuel leaks, or problems with the carburetor.

- Unusual Noises: Strange sounds from the engine can signal internal wear, loose components, or insufficient lubrication.

Maintenance Tips

- Regularly check and replace the air filter to ensure proper airflow.

- Inspect and clean the spark plug to maintain efficient ignition.

- Monitor oil levels and change oil according to the manufacturer’s schedule.

- Keep the cooling system free of debris to prevent overheating.

Essential Tools for Repairing FC540V

When maintaining and fixing machinery, having the right equipment is crucial for efficiency and effectiveness. This section outlines the key instruments that will aid in the service and upkeep of your engine, ensuring optimal performance and longevity.

Basic Hand Tools

- Wrenches: Both metric and standard sizes are essential for loosening and tightening bolts.

- Screwdrivers: A set including flathead and Phillips types will cover most fasteners.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating components.

- Socket Set: A versatile socket set will simplify the process of removing nuts and bolts.

Specialized Equipment

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Essential for diagnosing electrical issues and ensuring proper functionality of electrical components.

- Compression Tester: Useful for evaluating the health of the engine’s cylinders.

- Oil Filter Wrench: Specifically designed to facilitate the removal and installation of oil filters.

By equipping yourself with these essential tools, you can tackle maintenance tasks with confidence and ensure the machinery runs smoothly for years to come.

Step-by-Step Maintenance Procedures

Regular upkeep of your engine is crucial for optimal performance and longevity. Following a systematic approach can help identify issues early and ensure that all components function smoothly. This guide outlines essential maintenance tasks that can be performed to keep your machinery in top shape.

Essential Maintenance Tasks

Perform the following procedures regularly to maintain efficiency:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace the engine oil to prevent buildup and ensure smooth operation. |

| Air Filter Cleaning | Every 25 hours | Remove and clean the air filter to enhance airflow and improve combustion. |

| Spark Plug Inspection | Every 100 hours | Check for wear and replace to ensure reliable ignition and performance. |

| Fuel System Check | Every season | Inspect fuel lines and filter for clogs or leaks. |

Final Steps

After completing these tasks, always test the equipment to confirm that it operates correctly. Document any irregularities for future reference. A consistent maintenance routine will not only enhance performance but also extend the lifespan of your engine.

Replacing the Air Filter

Ensuring optimal engine performance requires regular maintenance, and one of the crucial tasks is the replacement of the air filter. A clean air filter allows for better airflow, enhancing efficiency and prolonging the lifespan of the engine. Over time, the filter accumulates dirt and debris, which can hinder performance. This guide outlines the steps needed to effectively replace the air filter in your equipment.

Tools Needed

| Tool | Purpose |

|---|---|

| Screwdriver | To remove screws or clips holding the filter cover |

| New Air Filter | To replace the old, clogged filter |

| Cleaning Brush | To clean the surrounding area before installation |

Steps for Replacement

1. Begin by turning off the engine and disconnecting the spark plug for safety. This will prevent any accidental starts during the process.

2. Locate the air filter compartment, which is usually covered by a protective cover. Use the screwdriver to remove the screws or clips securing the cover.

3. Once the cover is removed, gently take out the old air filter. Take note of its orientation for proper installation of the new filter.

4. Clean any debris from the compartment using a brush to ensure a secure fit for the new filter.

5. Insert the new air filter in the correct orientation and reattach the cover securely.

6. Finally, reconnect the spark plug and start the engine to ensure everything is functioning correctly.

Fuel System Troubleshooting Tips

Diagnosing issues within the fuel delivery system is essential for ensuring optimal performance and efficiency. A variety of factors can contribute to fuel-related problems, and understanding these can help in effectively addressing them.

- Check Fuel Quality: Always start by inspecting the fuel itself. Contaminated or old fuel can lead to engine performance issues.

- Inspect Fuel Lines: Look for cracks, leaks, or blockages in the fuel lines. Any damage can disrupt fuel flow.

- Examine Fuel Filter: A clogged filter can restrict fuel supply. Replace it if it’s dirty or hasn’t been changed in a while.

- Assess Fuel Pump: Ensure the pump is functioning correctly. Listen for unusual noises and check for proper pressure.

- Check Carburetor or Injector: Clean or rebuild the carburetor or check the injectors for clogs. Proper atomization is crucial for combustion.

By systematically evaluating each component, you can identify and resolve issues more effectively, leading to improved reliability and performance.

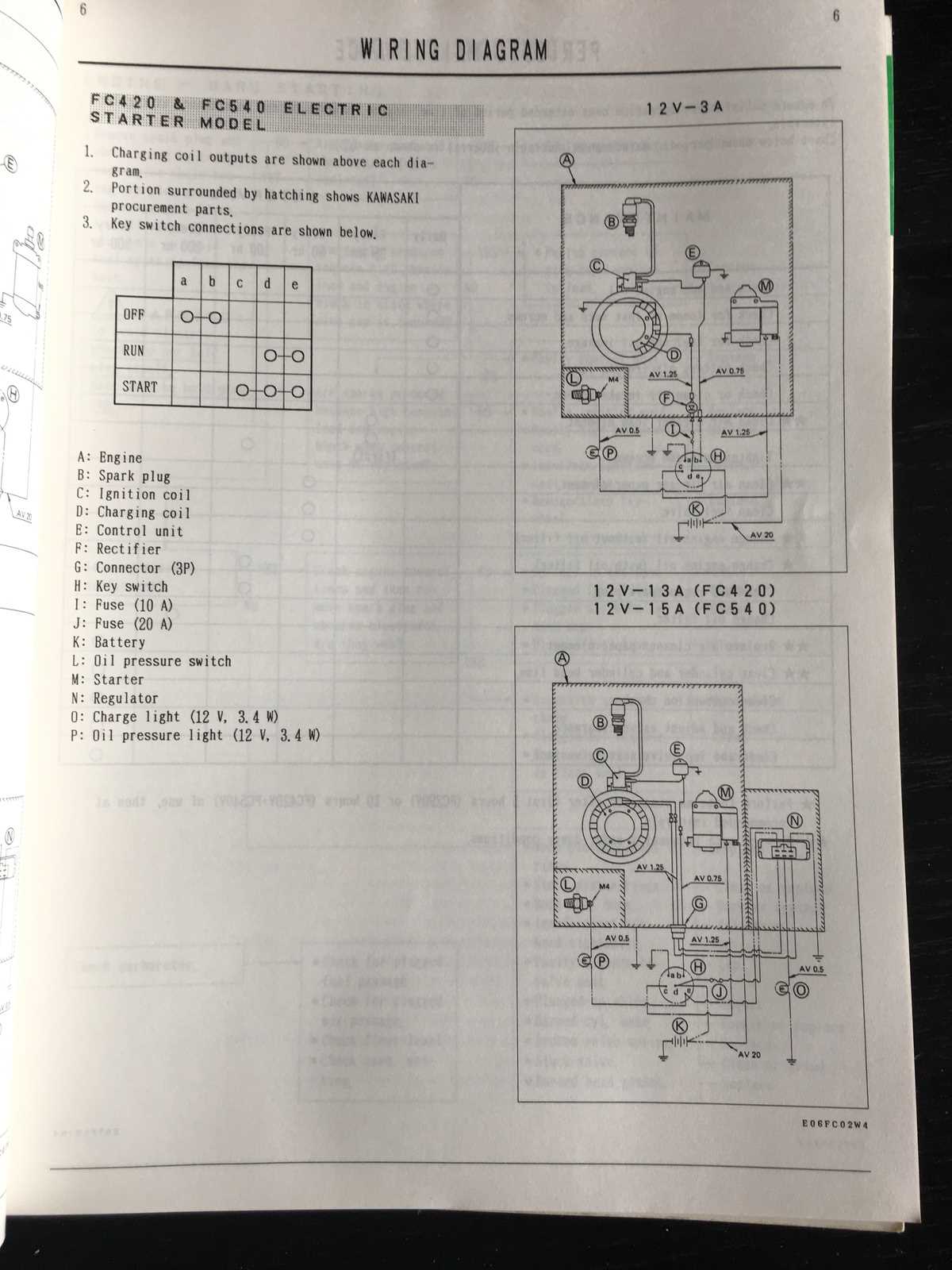

Electrical System Diagnostics

Diagnosing issues within the electrical framework of small engines is essential for optimal performance and longevity. A systematic approach to troubleshooting can help identify problems that may affect functionality, safety, or efficiency.

The following steps outline a comprehensive method for assessing electrical components:

- Visual Inspection:

- Check for damaged wiring, loose connections, or corrosion.

- Inspect connectors for signs of wear or dirt accumulation.

- Look for any burnt components or blown fuses.

- Testing Voltage:

- Use a multimeter to measure voltage at key points in the system.

- Ensure that voltage readings are within specified ranges for proper operation.

- Continuity Checks:

- Perform continuity tests on wires and connections to ensure there are no breaks.

- Identify any open circuits that may be causing issues.

- Component Testing:

- Evaluate individual components such as relays, switches, and sensors for functionality.

- Replace any faulty parts as needed.

- System Integration:

- After isolating issues, reassemble the system and recheck functionality.

- Verify that all components work in unison for effective performance.

By adhering to these steps, one can efficiently diagnose and rectify electrical issues, ensuring reliable operation of the equipment.

Servicing the Oil System

Maintaining the lubrication system is essential for optimal performance and longevity of the engine. Regular attention to the oil components ensures efficient operation and helps prevent potential issues that could arise from neglecting this critical system.

Checking Oil Levels

Start by regularly checking the oil level using the dipstick or oil gauge. Ensure the engine is on a level surface and has cooled down for accurate measurement. If the oil level is below the recommended mark, top it up with the appropriate type of lubricant. Regular checks help to avoid low oil conditions, which can lead to serious engine damage.

Changing the Oil and Filter

It’s important to replace the oil and filter at recommended intervals to maintain engine health. Begin by draining the old oil into a suitable container. Replace the oil filter using an oil filter wrench, ensuring a proper seal. After installing the new filter, refill with fresh oil, taking care to use the correct grade. Always dispose of the used oil and filter responsibly.

Note: Regular maintenance of the lubrication system not only enhances performance but also extends the life of the engine. Stay vigilant for any signs of leaks or unusual noises that may indicate a problem.

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance, efficiency, and longevity of a power unit. By delving into these parameters, users can better appreciate how their machinery operates, leading to informed decisions regarding maintenance and upgrades. This section will explore key aspects that define engine characteristics and their implications on functionality.

Key Performance Metrics

Among the most vital specifications are horsepower and torque. Horsepower reflects the engine’s ability to perform work over time, while torque indicates the twisting force available to perform tasks. Understanding the relationship between these two metrics can significantly influence how the engine is utilized in various applications, from gardening equipment to commercial machinery.

Operational Efficiency

Another critical area is fuel efficiency, which refers to the amount of fuel consumed relative to the power output. A higher efficiency rating suggests that the engine can produce more power with less fuel, reducing operational costs and environmental impact. Additionally, factors such as displacement and cooling systems contribute to an engine’s overall efficiency, highlighting the importance of each specification in achieving optimal performance.

Frequently Asked Questions about Repairs

This section addresses common inquiries related to maintenance and troubleshooting of small engines. Whether you are a seasoned technician or a beginner, understanding these key topics can greatly enhance your experience and efficiency in handling issues that may arise.

Common Issues and Solutions

- Engine Won’t Start: Check the fuel level, battery condition, and ensure that all connections are secure.

- Excessive Vibration: Inspect the blades and mounts for damage or misalignment.

- Strange Noises: Identify the source of the sound; it may indicate worn components or loose parts.

Maintenance Tips

- Regularly change the oil to maintain engine health.

- Clean the air filter to ensure optimal airflow.

- Inspect spark plugs and replace them as needed for efficient ignition.

Safety Precautions During Repair

When undertaking maintenance tasks on machinery, it is crucial to prioritize safety to prevent accidents and ensure efficient work. Following established guidelines and utilizing appropriate protective gear can significantly reduce risks associated with mechanical servicing.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and steel-toed boots to shield against injuries from flying debris or sharp edges. |

| Disconnect Power Sources | Before beginning any work, ensure that the power supply is disconnected to avoid accidental starts and electrical hazards. |

| Work in a Well-Ventilated Area | Ensure proper airflow to prevent inhalation of harmful fumes or dust generated during servicing. |

| Use Proper Tools | Utilize the right tools for each task to prevent damage to equipment and reduce the likelihood of injuries. |

| Follow Manufacturer Guidelines | Refer to the provided specifications and procedures to ensure correct and safe handling of all components. |

By adhering to these essential precautions, individuals can create a safer working environment and minimize the chances of accidents while handling machinery.