Briggs and Stratton Single Cylinder OHV Repair Guide

Understanding the intricacies of small engine operation is essential for anyone looking to ensure optimal performance and longevity. This section delves into essential techniques and practices that can aid in the upkeep of your machinery, making it a valuable resource for both novice and experienced users alike.

By familiarizing yourself with the components and functions of these engines, you can tackle common issues that may arise during usage. Through a series of straightforward instructions and expert tips, you will gain the confidence needed to address various challenges and enhance the efficiency of your equipment.

Whether you’re dealing with routine maintenance or unexpected malfunctions, this guide aims to empower you with the knowledge necessary to keep your engine running smoothly. Embrace the opportunity to enhance your skills and ensure your equipment remains in peak condition.

Understanding Single Cylinder OHV Design

This section provides an overview of the design principles and functionalities of a specific engine configuration. These mechanisms are widely recognized for their efficiency and performance in various applications.

- Design Efficiency: The layout of these engines is optimized for power delivery and fuel consumption, making them suitable for both residential and commercial use.

- Compact Structure: Their compact nature allows for easier integration into a variety of machines, enhancing versatility.

- Maintenance Accessibility: The design facilitates straightforward access to critical components, simplifying upkeep tasks for users.

Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring that the engine operates at its best throughout its lifespan.

Common Issues with OHV Engines

Overhead valve engines are known for their efficiency and performance, but like any machinery, they can encounter various challenges. Understanding these common problems can help in maintaining optimal functionality and extending the engine’s lifespan.

One frequent issue is starting difficulties, often caused by fuel system blockages or ignition failures. Ensuring that the fuel is clean and the spark plug is in good condition can resolve many of these problems.

Another common concern is excessive noise, which may indicate issues such as worn components or inadequate lubrication. Regular maintenance, including oil changes and inspections, is essential to prevent these noises from escalating into more significant damage.

Additionally, overheating is a critical issue that can arise from insufficient cooling or debris clogging the cooling fins. Keeping the engine clean and ensuring proper airflow is vital to prevent overheating and potential engine failure.

Lastly, fuel leaks can pose both a safety hazard and a performance problem. Regularly checking fuel lines and connections can help identify and rectify leaks before they lead to more severe complications.

Tools Needed for Repair Tasks

When undertaking maintenance or troubleshooting activities, having the right instruments is essential for achieving optimal results. These tools facilitate efficient work and ensure that tasks are completed safely and effectively.

Basic Hand Tools: A set of standard hand tools, including wrenches, screwdrivers, and pliers, is crucial for most projects. These items allow for the tightening and loosening of various components with ease.

Diagnostic Equipment: Utilizing diagnostic devices can significantly aid in identifying issues. A multimeter, for example, helps assess electrical systems, providing insights into potential malfunctions.

Specialized Instruments: Depending on the specific requirements of the task, certain specialized tools may be necessary. Items like torque wrenches and feeler gauges are important for ensuring components meet required specifications.

Safety Gear: Always prioritize safety by wearing appropriate protective equipment. Safety glasses and gloves can prevent injuries while working with machinery.

Step-by-Step Repair Process

This section outlines a comprehensive approach to fixing issues related to the engine in question. By following a systematic method, you can ensure that each aspect of the engine is thoroughly examined and addressed effectively.

1. Preparation

Begin by gathering all necessary tools and parts. Ensure the workspace is clean and organized, allowing for efficient access to items as needed.

2. Disassembly

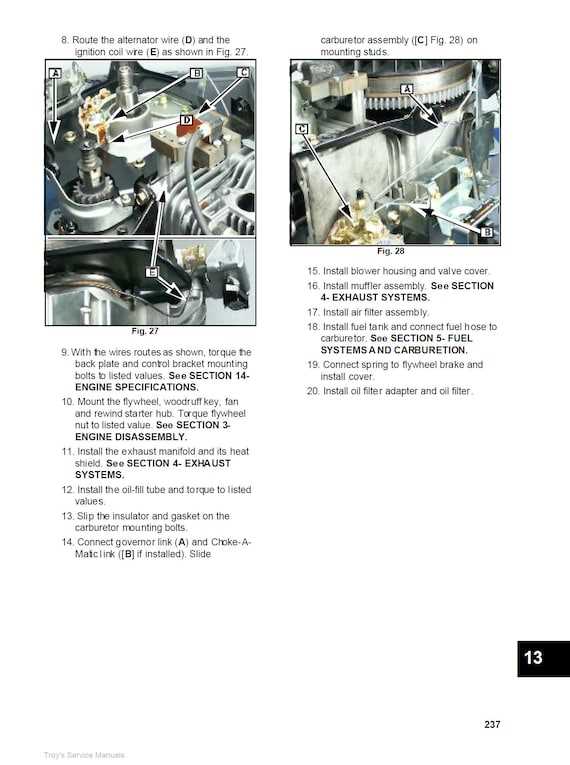

Carefully take apart the engine components, noting the order of removal. This will facilitate reassembly later on. Use proper techniques to avoid damaging any parts.

3. Inspection

Examine each component for wear and damage. Pay close attention to critical areas such as gaskets, seals, and valves. Make a list of items that need replacement or repair.

4. Cleaning

Clean all parts using appropriate solvents and brushes. Removing dirt and debris will help ensure optimal performance once reassembled.

5. Replacement

Install new components as necessary, ensuring they match the specifications required. Follow guidelines to guarantee proper fit and function.

6. Reassembly

Carefully reassemble the engine, retracing the steps taken during disassembly. Ensure all fasteners are tightened to the correct torque specifications.

7. Testing

After reassembly, conduct thorough tests to verify that the engine operates smoothly. Monitor for any unusual sounds or issues during the testing phase.

Maintenance Tips for Longevity

Ensuring the prolonged lifespan of your engine requires regular care and attention. By implementing a consistent maintenance routine, you can prevent premature wear and enhance performance. Simple practices can go a long way in keeping your equipment in optimal condition.

Regular Oil Changes

Changing the oil at recommended intervals is crucial for engine health. Fresh oil reduces friction and helps to maintain optimal operating temperatures. Always use the appropriate type of lubricant for your specific machinery.

Air Filter Inspection

Periodically checking the air filter is essential for maintaining airflow and preventing dirt from entering the engine. A clean air filter improves efficiency and helps the engine breathe properly. Replace or clean the filter as needed to ensure peak performance.

Diagnosing Engine Performance Problems

Identifying issues with engine functionality is crucial for optimal performance. Various symptoms may indicate underlying problems that need addressing. Understanding these signs can help in restoring efficiency and reliability.

Common Symptoms to Look For

Typical indicators of engine trouble include difficulty starting, irregular idling, and decreased power output. These signs may stem from various sources, such as fuel delivery issues, ignition failures, or mechanical wear. Observing any unusual behavior can be the first step toward effective troubleshooting.

Step-by-Step Diagnostic Approach

To accurately assess performance issues, begin with a systematic inspection. Start by examining the fuel system for clogs or leaks. Next, inspect the ignition components for wear or failure. Finally, consider checking the compression levels to determine the engine’s internal condition. Thorough diagnostics will lead to informed solutions and improved operation.

Replacing Key Engine Components

When maintaining an engine, it is crucial to recognize the importance of certain vital parts. Understanding how to replace these components can significantly enhance the performance and longevity of your machinery. This section will guide you through the essential steps and considerations involved in component replacement.

Identifying Components for Replacement

Before proceeding with the replacement, it is important to identify which parts require attention. Here are common components that may need to be replaced:

- Piston and Rings

- Crankshaft

- Connecting Rod

- Valves

- Gaskets

Steps for Replacing Engine Components

Follow these general steps to ensure a successful replacement process:

- Gather necessary tools and replacement parts.

- Carefully disassemble the engine to access the components.

- Remove the old parts, taking note of their arrangement.

- Install the new components, ensuring proper alignment and fit.

- Reassemble the engine and perform tests to confirm functionality.

Safety Precautions During Repairs

When conducting maintenance on any engine, it is crucial to prioritize safety. Understanding the potential hazards and taking appropriate measures can prevent accidents and injuries. Proper preparation and adherence to safety guidelines ensure a secure working environment for both the technician and the equipment.

Personal Protective Equipment (PPE)

Utilizing the right personal protective equipment is essential for safeguarding yourself during maintenance tasks. This includes items such as gloves, goggles, and sturdy footwear. Each piece of equipment serves a specific purpose in protecting against injuries.

| PPE Item | Purpose |

|---|---|

| Gloves | Protects hands from sharp edges and chemicals |

| Safety Goggles | Prevents eye injuries from debris and liquids |

| Steel-Toed Boots | Offers foot protection against heavy objects |

Work Area Organization

Maintaining an orderly workspace is vital to ensure efficiency and safety. A cluttered environment can lead to accidents and hinder your ability to perform tasks effectively. Ensure that tools are organized and that the area is free of any unnecessary materials.

Resources for Further Assistance

When dealing with engine maintenance and troubleshooting, having access to additional resources can be invaluable. Various platforms offer expert guidance, community support, and instructional materials that can enhance your understanding and help resolve issues effectively.

| Resource Type | Description | Website |

|---|---|---|

| Online Forums | Engage with fellow enthusiasts and mechanics for tips and solutions. | engineforum.com |

| Video Tutorials | Step-by-step guides for various maintenance tasks and repairs. | youtube.com |

| Technical Support | Contact professionals for expert advice and troubleshooting assistance. | enginesupport.com |

| Parts Suppliers | Find replacement components and accessories for your engine. | partsstore.com |