Guide to Grasshopper Mower Repairs

In the realm of outdoor machinery, ensuring optimal performance is essential for achieving the best results. Regular upkeep not only prolongs the lifespan of your tools but also enhances their efficiency. This section delves into the various aspects of maintaining your equipment, providing insights and techniques to keep it in prime condition.

Understanding the components is crucial for effective management. By familiarizing yourself with the essential parts and their functions, you can identify potential issues before they escalate. This proactive approach minimizes downtime and ensures that your machinery operates smoothly.

Furthermore, learning to troubleshoot common problems empowers users to address minor issues independently. This knowledge not only saves time but also reduces the reliance on professional services, making maintenance a more manageable task for everyone.

This section aims to outline frequent challenges encountered by users of specific lawn maintenance equipment. Understanding these typical problems can help in effectively addressing them and ensuring optimal performance.

Frequent Problems Encountered

Users often face various issues that may affect the functionality and efficiency of their machines. Below are some common concerns:

| Issue | Description | Potential Solutions |

|---|---|---|

| Engine Stalling | Unexpected shutdown of the engine during operation. | Check fuel levels and ensure proper ignition system functioning. |

| Uneven Cutting | Inconsistent cutting height across the lawn. | Inspect blade sharpness and height adjustment mechanisms. |

| Electrical Failures | Malfunctions in the electrical system leading to operational failures. | Examine wiring and connections for any signs of damage or corrosion. |

| Excessive Vibrations | Abnormal vibrations during use that may indicate mechanical issues. | Check for loose components and ensure blades are balanced. |

By addressing these common issues, users can maintain their equipment more effectively and extend its lifespan.

Essential Tools for Repairs

To ensure effective maintenance and troubleshooting of equipment, having the right set of instruments is crucial. This selection not only facilitates the repair process but also enhances efficiency and safety during tasks.

Basic Hand Tools

Standard hand tools form the backbone of any maintenance kit. A combination of wrenches, screwdrivers, and pliers will allow for a wide range of adjustments and fixes. Investing in high-quality versions of these items can significantly improve longevity and ease of use.

Specialized Instruments

In addition to common tools, certain specialized instruments may be required for specific tasks. Items such as spark plug wrenches and compression testers can help diagnose issues accurately, making repairs more straightforward. Having these tools on hand ensures that any complications can be addressed promptly.

Step-by-Step Maintenance Procedures

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. This section outlines systematic tasks that can enhance efficiency and minimize issues over time.

Essential Maintenance Tasks

- Check and clean air filters to ensure proper airflow.

- Inspect and sharpen blades for effective cutting.

- Examine belts for wear and replace as needed.

- Change oil regularly to maintain engine health.

Seasonal Checks

- Before winter, prepare the unit for storage by draining fuel and cleaning.

- In spring, inspect all components for any damage that may have occurred during the off-season.

- Ensure tires are properly inflated and in good condition before use.

Troubleshooting Engine Performance Problems

Identifying issues with engine performance can be crucial for maintaining optimal functionality. Various factors may contribute to reduced power, unusual sounds, or difficulty in starting. This section provides a guide to diagnosing common performance-related concerns.

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Engine won’t start | Dead battery or faulty ignition | Check battery charge and connections; replace ignition components if necessary. |

| Loss of power | Clogged air filter | Inspect and clean or replace the air filter. |

| Excessive vibration | Worn-out components | Examine and replace damaged or worn parts. |

| Overheating | Insufficient cooling | Check coolant levels and ensure proper airflow. |

| Poor fuel efficiency | Incorrect fuel type | Verify the fuel specifications and replace if needed. |

Replacing Worn Blades Effectively

Maintaining sharp cutting implements is crucial for optimal performance and efficiency. Over time, these components can become dull or damaged, leading to subpar results. This section will guide you through the process of replacing worn cutting edges to ensure your equipment operates at its best.

Identifying Signs of Wear

Before proceeding with the replacement, it’s important to recognize when the cutting edges need attention. Look for visual indicators such as chips, excessive dullness, or uneven wear. Additionally, if you notice a decrease in cutting efficiency or a ragged finish, it’s time to consider a replacement.

Step-by-Step Replacement Process

To effectively replace the cutting edges, follow these steps:

- Gather necessary tools, including wrenches and safety gear.

- Carefully detach the worn components following the manufacturer’s guidelines.

- Align the new cutting edges properly and secure them tightly.

- Perform a final inspection to ensure everything is in place before usage.

By following these guidelines, you can maintain the efficiency and longevity of your equipment, ensuring it performs at its peak for years to come.

Checking and Adjusting Tire Pressure

Maintaining optimal tire pressure is essential for ensuring the smooth operation and longevity of your equipment. Proper inflation affects handling, fuel efficiency, and overall performance. Regularly monitoring and adjusting tire pressure can prevent unnecessary wear and improve safety during use.

To begin, gather a reliable tire pressure gauge and check the current pressure of each tire when they are cold. This means measuring before any usage, as heat generated during operation can lead to inaccurate readings. Consult the specifications provided for the recommended pressure levels to ensure you have the correct values for adjustment.

If the pressure is below the recommended level, use an air compressor to inflate the tires gradually. Take care not to overinflate, as this can lead to reduced traction and increased risk of damage. Conversely, if the tires are overinflated, release some air until the correct level is reached.

After adjustments, it is wise to recheck the pressure to confirm accuracy. Consistent monitoring of tire pressure will help maintain optimal performance and enhance the overall functionality of your machinery.

Electrical System Diagnostics Guide

This section provides a comprehensive approach to troubleshooting electrical systems, focusing on common issues and effective methods for diagnosis. Understanding the intricacies of electrical components is essential for ensuring optimal performance.

Common Electrical Issues

- Power interruptions

- Faulty connections

- Overheating components

- Blown fuses

Diagnostic Steps

- Check the power source for adequate voltage.

- Inspect all wiring for damage or corrosion.

- Test switches and relays for functionality.

- Evaluate components for signs of wear or failure.

Tools Needed

- Multimeter

- Wire strippers

- Insulation tester

- Screwdrivers

Maintaining the Fuel System Properly

Proper upkeep of the fuel system is essential for optimal performance and longevity of your equipment. Ensuring that the components are clean and functioning effectively can prevent issues that disrupt operation and efficiency. Regular maintenance routines can help identify potential problems early, saving time and resources in the long run.

Regular Cleaning of Fuel Filters

Keeping fuel filters clean is crucial for maintaining a steady flow of fuel to the engine. Over time, debris can accumulate, leading to clogs that hinder performance. Replace filters as recommended by the manufacturer to ensure uninterrupted operation. Regular checks can help you spot signs of wear and tear early.

Monitoring Fuel Quality

The quality of the fuel used directly affects the performance of your machinery. Always use fresh fuel and store it properly to avoid contamination. Check for any signs of water or debris in the tank, as these can cause significant operational issues. Keeping the fuel system well-maintained ensures your equipment runs smoothly and efficiently.

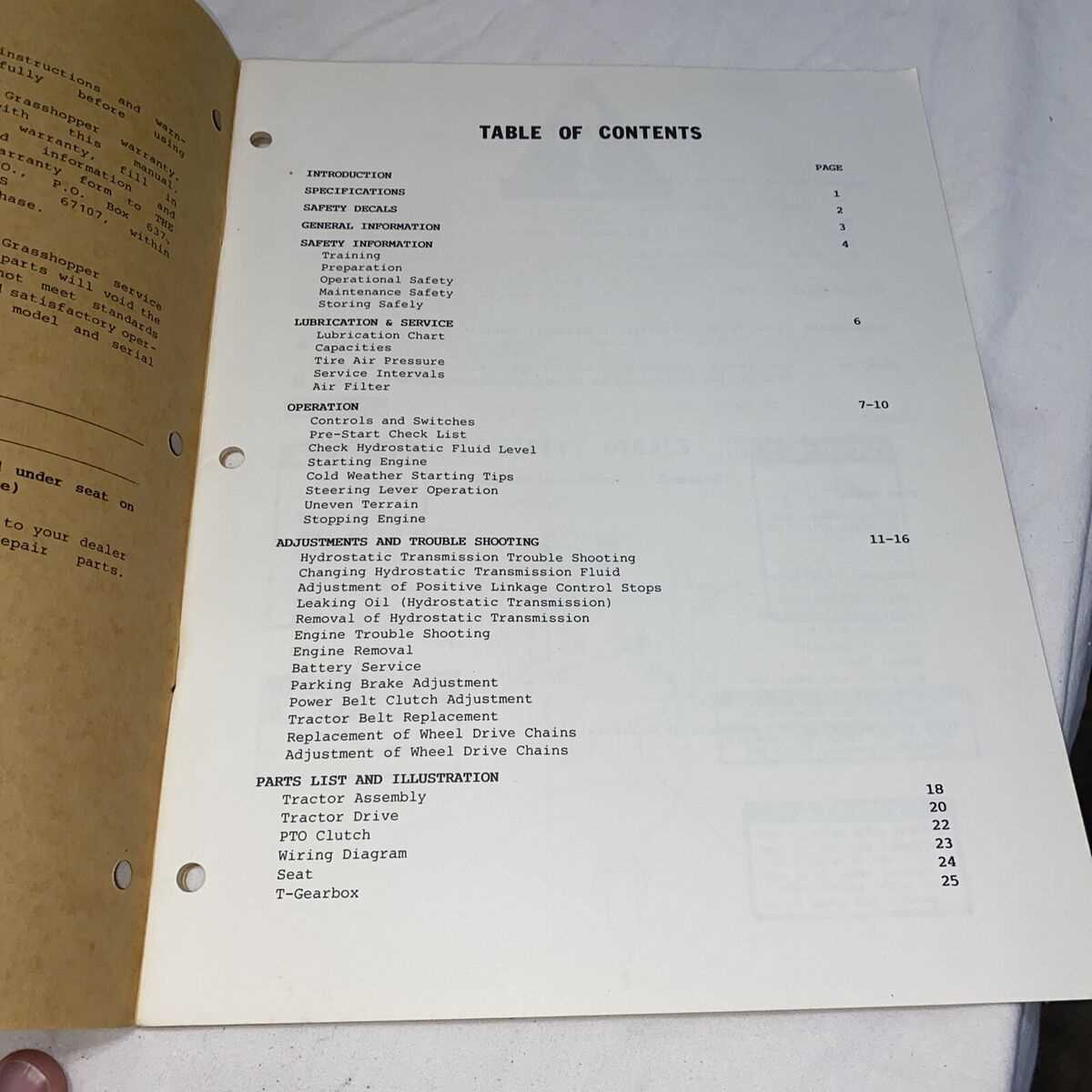

Understanding the Mower’s Manual

The guide for your cutting machine serves as a vital resource for both new and experienced users. It provides essential insights into the equipment’s features, operational instructions, and maintenance practices. Familiarizing yourself with this documentation can enhance your overall experience and ensure optimal performance.

Within the text, you will find detailed explanations of various components, safety precautions, and troubleshooting tips. Comprehending these elements is crucial for effective utilization and longevity of your device. Each section aims to empower you with knowledge, helping you navigate any challenges that may arise during use.

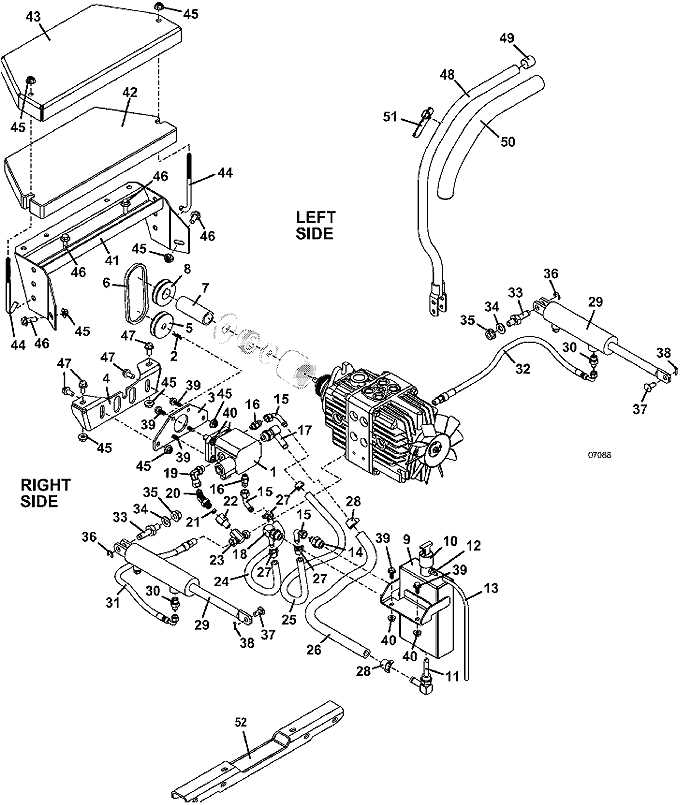

Additionally, the guide often includes illustrations and diagrams that visually represent the mechanisms at play. Utilizing these visuals alongside the written content can deepen your understanding and assist in executing tasks with confidence.

Safety Tips for Repair Work

Engaging in maintenance tasks requires a thorough understanding of safety protocols to ensure a secure environment. Implementing these guidelines not only protects the individual performing the work but also enhances the efficiency of the task at hand.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) when handling tools and machinery. This includes gloves, safety goggles, and sturdy footwear. Proper attire minimizes the risk of injury and safeguards against potential hazards.

Work Area Organization

Maintain a clean and organized workspace to prevent accidents. Ensure that tools are stored properly and that the area is free from clutter. This promotes focus and reduces the likelihood of mishaps during the task.

Parts Replacement: What to Know

Replacing components in your equipment is essential for maintaining optimal performance and longevity. Understanding the necessary steps and precautions can help ensure a smooth process. Here’s what you should keep in mind when it comes to substituting parts.

Essential Considerations

- Identify the Component: Ensure you know exactly which part needs replacement to avoid unnecessary purchases.

- Gather Tools: Collect the required tools before starting the replacement process for efficiency.

- Refer to Guidelines: Always consult any available documentation for specific instructions related to the part.

Steps for Replacement

- Turn off the equipment and disconnect from any power source to ensure safety.

- Carefully remove the damaged or worn part using the appropriate tools.

- Install the new component, ensuring it is securely fitted and aligned correctly.

- Recheck all connections and settings before powering on the equipment again.

Common Mistakes to Avoid

When maintaining outdoor equipment, it’s crucial to recognize frequent pitfalls that can hinder performance and lead to unnecessary complications. By being aware of these errors, operators can ensure smoother operations and extend the longevity of their machinery.

| Mistake | Consequence | Solution |

|---|---|---|

| Neglecting regular maintenance | Reduced efficiency and potential breakdowns | Establish a routine maintenance schedule |

| Using incorrect fuel types | Engine damage and poor performance | Refer to guidelines for fuel specifications |

| Ignoring warning signs | Minor issues becoming major problems | Address any unusual noises or vibrations immediately |

| Overlooking blade sharpness | Poor cutting results and increased strain on the engine | Regularly check and sharpen blades as needed |

| Improper storage | Damage from environmental factors and decreased lifespan | Store equipment in a dry, protected area |