Comprehensive Guide to Repairing the 1973 Ford F100

For enthusiasts and owners of vintage vehicles, understanding the intricacies of maintaining and restoring these iconic machines is essential. A thorough understanding of their mechanics not only enhances the driving experience but also preserves the vehicle’s value over time. This section delves into the various aspects of upkeep and troubleshooting for one of the most beloved trucks in automotive history.

Every classic vehicle has its unique characteristics and challenges, requiring specific knowledge to ensure optimal performance. From engine diagnostics to electrical systems, knowing how to address common issues can save time and money while enhancing the overall reliability of the truck. This guide offers insights into essential techniques and detailed procedures, tailored for those who appreciate the craftsmanship of bygone eras.

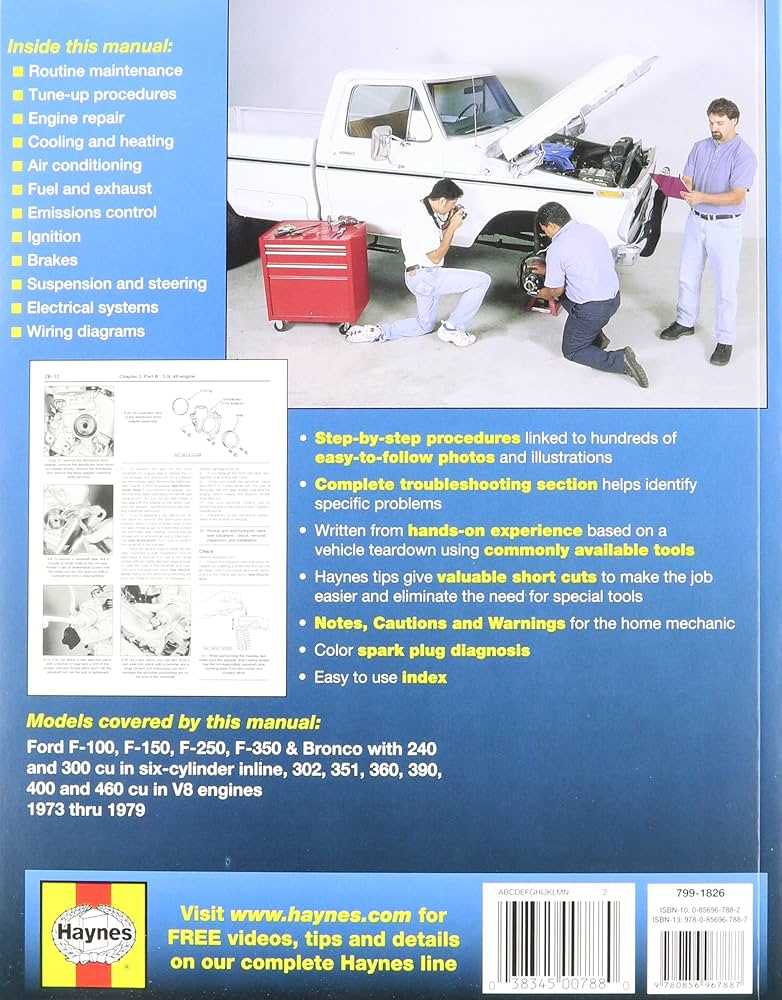

Moreover, this resource is designed to cater to both novice and experienced mechanics. Clear, step-by-step instructions, alongside valuable tips, empower individuals to tackle repairs and enhancements confidently. Whether restoring a cherished family heirloom or rejuvenating a classic truck for daily use, mastering these skills will provide a rewarding sense of accomplishment.

Overview of the 1973 Ford F100

This classic pickup model represents a pivotal moment in automotive history, embodying both robust design and functional versatility. Known for its durability and strong performance, this vehicle appeals to enthusiasts and collectors alike. Its production year marked a blend of tradition and innovation, making it a significant choice for various applications, from work to leisure.

The exterior design features a bold stance with a spacious cabin and a truck bed that accommodates both cargo and recreational activities. Under the hood, it showcases a range of powerful engine options that provide the necessary torque and horsepower, catering to a diverse set of driving needs.

| Feature | Description |

|---|---|

| Engine Options | Variety of engine configurations, ranging from V6 to V8, allowing for flexibility in performance and efficiency. |

| Transmission | Available in both manual and automatic, providing drivers with a choice based on preference and driving style. |

| Cab Configuration | Offered in styles such as regular and extended cab, enhancing comfort and utility for passengers and cargo. |

| Suspension | Sturdy suspension system designed for heavy loads, ensuring stability and control on various terrains. |

| Interior Features | Focus on practicality with straightforward controls and ample storage, reflecting the needs of its user base. |

Common Issues with the 1973 Model

This classic pickup has gained a reputation for durability, yet like any vintage vehicle, it is not without its challenges. Owners often encounter specific problems that can arise due to age, wear, and the inherent complexities of its design. Understanding these common issues can help enthusiasts and mechanics alike maintain performance and ensure longevity.

Engine Performance Concerns

One prevalent challenge involves the engine, particularly related to starting difficulties and rough idling. Many users report issues with fuel delivery systems, such as clogged filters and failing pumps, which can lead to inconsistent performance. Regular checks and maintenance of the ignition system, including spark plugs and wiring, are essential to mitigate these problems.

Electrical System Failures

The electrical components of this vehicle often show signs of deterioration over time. Common failures include malfunctioning alternators and battery issues. The wiring harness may also suffer from corrosion or shorts, affecting various systems such as lighting and instrumentation. Addressing these electrical issues promptly can prevent further complications and ensure reliable operation.

Essential Tools for Repairs

When it comes to maintaining and restoring classic vehicles, having the right set of instruments is crucial for achieving quality results. A well-equipped workspace not only enhances efficiency but also ensures that tasks are completed safely and effectively. This section outlines the fundamental implements that every enthusiast should consider for their automotive projects.

| Tool | Purpose |

|---|---|

| Socket Set | Used for tightening and loosening bolts and nuts in various sizes. |

| Wrenches | Essential for turning fasteners and making adjustments. |

| Screwdrivers | Helpful for fastening or loosening screws; both flathead and Phillips types are necessary. |

| Pliers | Useful for gripping, twisting, and cutting wire or other materials. |

| Jack and Stands | Important for lifting the vehicle to access the undercarriage safely. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Multimeter | Essential for diagnosing electrical issues and testing circuits. |

| Shop Manual | A reference guide providing specifications, diagrams, and repair procedures. |

Equipping oneself with these key instruments will facilitate various tasks, from simple maintenance to complex restorations. Investing in quality tools not only saves time but also enhances the overall experience of working on vehicles.

Step-by-Step Maintenance Guide

This section provides a comprehensive overview of essential upkeep practices to ensure your vehicle remains in optimal condition. By following a systematic approach, you can enhance its longevity and performance, making the experience more enjoyable and reliable. Regular attention to key components not only prevents potential issues but also contributes to safety and efficiency.

1. Engine Care: Begin with regular checks of the engine oil level and quality. Change the oil and filter according to the manufacturer’s recommendations to keep the engine running smoothly. Additionally, inspect belts and hoses for wear and tear, replacing them as necessary.

2. Brake System Inspection: Ensure that the braking system functions properly by checking the brake fluid level and the condition of brake pads and rotors. Replace any worn components promptly to maintain safety.

3. Tire Maintenance: Monitor tire pressure regularly and ensure they are properly inflated. Check tread depth and rotate tires every 5,000 to 7,500 miles to promote even wear. Alignment checks can also help improve handling and extend tire life.

4. Electrical System Check: Inspect the battery for corrosion and ensure connections are tight. Test headlights, turn signals, and brake lights to guarantee visibility and safety on the road. Consider replacing the battery every few years as part of regular upkeep.

5. Fluid Levels: Regularly check and top off essential fluids such as coolant, transmission fluid, and windshield washer fluid. Keeping these levels adequate will help avoid overheating and mechanical failures.

6. Exterior and Interior Maintenance: Keep the vehicle clean by washing it regularly to protect the paint from corrosion. Vacuum and clean the interior to preserve upholstery and overall aesthetics. Additionally, consider applying protective coatings to surfaces for added durability.

7. Seasonal Checks: As seasons change, so do maintenance needs. Prepare for winter by checking antifreeze levels and inspecting the heating system. In summer, ensure the air conditioning is functioning correctly for comfort.

By adhering to this systematic maintenance approach, you can ensure that your vehicle remains a reliable companion for years to come.

Engine Repair Procedures Explained

Understanding the intricacies of powertrain maintenance is crucial for optimal vehicle performance. This section delves into essential techniques and guidelines for diagnosing and addressing engine issues effectively. Mastering these procedures ensures longevity and reliability, enhancing the overall driving experience.

Common Diagnostic Techniques

Diagnosing problems requires a systematic approach. Begin by performing a thorough visual inspection to identify signs of wear, leaks, or corrosion. Utilizing tools such as compression gauges and diagnostic scanners can reveal underlying issues that may not be immediately visible. Regular monitoring of engine performance metrics is key to early detection of potential failures.

Maintenance and Component Replacement

After identifying the issue, the next step involves executing proper maintenance or component swaps. Adhering to manufacturer specifications during replacements is vital for ensuring compatibility and functionality. Whether it’s changing gaskets, belts, or even the entire power unit, following detailed instructions enhances the effectiveness of the service performed.

Transmission Troubleshooting Techniques

Diagnosing issues with a vehicle’s transmission system can be challenging yet essential for maintaining optimal performance. Understanding common problems and applying effective methods can significantly enhance the troubleshooting process. This section focuses on various techniques to identify and address transmission-related concerns.

Common Symptoms and Initial Checks

Before delving into complex diagnostics, it’s crucial to recognize the typical signs of transmission troubles. Issues such as slipping gears, unusual noises, or fluid leaks often indicate underlying problems. Initial checks should include examining the transmission fluid level and condition, as well as inspecting for visible leaks around the transmission housing. Ensure that the fluid is at the appropriate level and appears clean; discolored or burnt fluid may signal a need for further investigation.

Advanced Diagnostic Techniques

If preliminary checks do not reveal the cause, employing more advanced diagnostic techniques can provide deeper insights. Utilizing a scan tool to read error codes from the vehicle’s onboard diagnostic system can help pinpoint electronic issues affecting transmission performance. Additionally, performing a pressure test can identify problems with hydraulic functions within the system. Understanding these advanced methods is vital for effectively resolving transmission complications and ensuring the longevity of the vehicle.

Electrical System Diagnostics

The proper functioning of a vehicle’s electrical components is crucial for overall performance and reliability. Diagnosing electrical issues can be complex due to the interdependence of various systems. Understanding how to systematically approach these problems will enable effective troubleshooting and timely repairs.

Start with a basic understanding of the key components involved:

- Battery

- Alternator

- Starter motor

- Wiring harness

- Fuses and relays

To diagnose electrical faults, follow these steps:

- Visual Inspection: Check for obvious signs of damage, such as frayed wires or corroded terminals.

- Test the Battery: Use a multimeter to measure voltage. A healthy battery should read around 12.6 volts when fully charged.

- Check the Alternator: Ensure it is charging correctly by measuring the output while the engine is running. The voltage should be between 13.8 and 14.4 volts.

- Inspect the Starter Motor: Confirm that the motor is receiving adequate power when the ignition is engaged.

- Examine Fuses and Relays: Replace any blown fuses and check relays for proper operation.

Utilizing these diagnostic methods will facilitate identifying and resolving electrical system issues efficiently. Proper maintenance of the electrical system can prevent future complications and ensure reliable vehicle operation.

Suspension and Steering Adjustments

Properly tuning the suspension and steering components ensures a smoother, safer ride by enhancing vehicle stability and responsiveness. Regular adjustments can prevent uneven tire wear, reduce strain on the suspension system, and improve handling performance on different road surfaces. This section outlines key adjustments for maintaining optimal suspension balance and precise steering control.

Wheel Alignment and Camber Adjustment

Wheel alignment is crucial for achieving even tire wear and balanced vehicle handling. To maintain ideal wheel positioning, adjustments to camber, toe, and caster angles may be necessary. Camber adjustment, for instance, affects the angle at which tires contact the road, either positively or negatively, depending on specific driving conditions. Incorrect camber can lead to excessive outer or inner tire wear. Meanwhile, toe angle adjustments ensure that wheels are positioned correctly relative to each other, enhancing vehicle stability at various speeds.

Steering Mechanism Calibration

Accurate steering response is fundamental for safe driving and precise vehicle control. This requires attention to steering linkages, tie rods, and ball joints to maintain proper alignment and reduce slack in the system. Inspecting and adjusting these components helps prevent oversteering or understeering tendencies, providing a balanced, predictable driving experience. Regularly calibrated steering mechanisms also reduce vibration through the steering wheel, improving overall comfort and handling precision.

Routine checks and adjustments to both suspension and steering systems contribute to a well-balanced vehicle, ensuring both performance and longevity. For best results, perform these procedures according to recommended intervals and inspect for wear on components that may affect alignment or stability.

Bodywork and Rust Prevention Tips

Preserving the body of a classic vehicle involves more than just maintaining its appearance. Effective rust prevention and proper bodywork care are essential for long-term protection, helping keep the vehicle structurally sound and visually appealing. Here are some practical tips to safeguard your vehicle from rust and maintain the integrity of its bodywork.

1. Regular Cleaning and Inspection: Dirt, moisture, and salt can easily accumulate on the vehicle’s body, especially in hard-to-see areas like wheel wells and undercarriage parts. Regularly wash and dry the vehicle thoroughly, paying special attention to these hidden sections. Routine inspections will help you spot the first signs of rust or paint damage early, allowing for timely intervention.

2. Apply Protective Coatings: High-quality waxes and sealants create a barrier between the metal and environmental elements. Additionally, applying rust-inhibiting primers and undercoats to exposed metal surfaces can extend protection, especially in areas prone to moisture. These coatings should be reapplied as part of a seasonal maintenance routine.

3. Seal Seams and Gaps: Moisture often finds its way into the smallest gaps and seams, which can lead to rust in hard-to-reach areas. Use seam sealers to close off vulnerable joints and edges. Pay particular attention to areas around doors, trunks, and wheel wells, as they are often the most exposed to moisture infiltration.

4. Address Surface Rust Promptly: If minor rust spots are found, addressing them immediately will prevent the corrosion from spreading. Sand away rust spots and apply a rust-neutralizing primer to inhibit further oxidation. Finish by repainting the area to restore the protective layer.

5. Store in a Dry, Ventilated Space: Whenever possible, store the vehicle in a controlled environment to prevent prolonged exposure to humidity. Garages with good ventilation help reduce moisture levels, while using a car cover provides an extra layer of protection. Avoid parking on damp ground or grass, as these conditions can increase the risk of rust formation.

By incorporatin

Replacement Parts and Specifications

This section provides an overview of essential components and specifications for optimal vehicle maintenance and replacement. Selecting compatible and high-quality parts is critical to ensure reliable performance and longevity. The following details cover key replacement parts and their specifications, aiding in effective maintenance routines.

Essential Parts for Maintenance

Regular upkeep requires attention to several fundamental components. Critical parts such as brake assemblies, fuel system elements, and suspension components should be inspected frequently. Replacing these with quality parts maintains vehicle safety, enhances performance, and prevents unnecessary wear on related systems.

Engine Specifications and Parts

The engine setup involves various components, each contributing to overall power and efficiency. For optimal engine performance, maintaining specific parts, such as spark plugs, air filters, and carburetor jets, is essential. Replacement parts must meet original specifications to prevent malfunctions and ensure that power output remains consistent.

| Component | Specification | Replacement Interval |

|---|---|---|

| Spark Plugs | Gap: 0.032 inches | Every 15,000 miles |

| Air Filter | Dimensions: 10 x 2 inches | Every 12,000 miles |

| Oil Filter | Thread Size: 3/4-16 | With every oil change |

| Brake Pads | Thickness: Minimum 0.3 inches | Every 20,000 miles |

Regularly verifying and maintaining these parts according to the specified intervals ensures smooth operation and extends vehicle lifespan. Consulting with reputable suppliers for compatible and high-quality replacements is recommended.

Owner Testimonials and Experiences

Reading about real-life experiences from owners offers valuable insights into the performance and character of this classic pickup. Enthusiasts from different backgrounds have shared stories about reliability, unexpected challenges, and the rewarding journey of maintaining a vintage vehicle. Below are some of these firsthand accounts, highlighting both the joys and trials of ownership.

| Owner | Location | Experience Summary |

|---|---|---|

| John D. | California, USA | John describes his vehicle as “tough and trustworthy,” recounting several road trips that tested the truck’s endurance. He appreciates its rugged design but notes the challenges of sourcing rare parts. |

| Sarah K. | Ontario, Canada | For Sarah, owning her vintage truck has been a fulfilling hobby. She finds joy in restoration and says it brings a sense of nostalgia, though she admits it requires regular tuning for optimal performance. |

| Mark T. | Texas, USA | Mark values his truck for its simplicity and durability. He uses it for weekend projects and enjoys the straightforward mechanics, mentioning that with basic upkeep, the vehicle remains highly dependable. |

| Liam R. | Queensland, Australia | Liam shares that while his truck is not the fastest, it’s a head-turner wherever he goes. He appreciates the charm and functionality but acknowledges the need for occasional minor fixes. |

These testimonials reveal a shared admiration for the model’s resilience, charm, and classic appeal, coupled with a realistic understanding of