Comprehensive Guide to Repairing Your Kenmore 90 Series Dryer

When household equipment malfunctions, it can lead to inconvenience and frustration. Understanding the intricacies of your laundry appliance can empower you to address common issues efficiently. This section aims to provide valuable insights and step-by-step guidance for those looking to restore functionality to their units.

Through practical advice and clear instructions, users will gain the confidence to tackle various challenges that may arise. Whether dealing with inconsistent performance or complete inoperability, our focus is on simplifying the troubleshooting process. This resource is designed for both novice and experienced individuals, ensuring that everyone can find useful information.

Equipped with the right knowledge, homeowners can save time and money by avoiding unnecessary service calls. Emphasizing the importance of regular maintenance and timely interventions, this guide serves as a vital tool for enhancing the longevity and efficiency of your equipment.

Understanding Kenmore 90 Series Dryers

This section aims to provide insight into a specific line of home appliances designed for efficient fabric drying. These machines are known for their reliability and various features that cater to different user needs, making them popular choices for households.

Key Features

- Durable construction for long-lasting performance.

- Multiple drying settings for various fabric types.

- Efficient energy use, helping to save on utility bills.

- Lint filtration systems that enhance safety and efficiency.

Common Issues and Solutions

- Inconsistent drying: Check the lint filter and venting system.

- No heat: Inspect heating elements and thermal fuses.

- Strange noises: Examine belts and drum support.

Understanding these aspects can greatly assist users in maintaining their appliances and troubleshooting common problems effectively.

Common Issues with Kenmore Dryers

Home appliances can experience various problems over time, leading to frustration for users. Understanding these frequent challenges can help in identifying solutions quickly. This section highlights some typical complications associated with these essential household machines.

One prevalent issue is insufficient drying, which may result from clogged vents or faulty heating elements. Users often notice that clothes remain damp after a complete cycle, prompting a closer inspection of the airflow and heating components.

Another common concern is excessive noise during operation. Unusual sounds can indicate worn-out belts, loose screws, or obstructions in the drum. Identifying the source of these noises is crucial for maintaining the appliance’s longevity.

Additionally, improper functioning of the control panel can lead to cycles not starting or stopping unexpectedly. This may stem from electrical issues or faulty buttons, requiring attention to restore normal operation.

Lastly, an appliance may exhibit signs of overheating, which can pose safety risks. Overheating can result from blocked vents or malfunctioning thermostats, making it essential to address these issues promptly to prevent further damage.

Tools Needed for Repairs

When tackling maintenance tasks on household appliances, having the right tools at hand is essential for a smooth and efficient process. Proper equipment not only ensures safety but also enhances the effectiveness of each procedure. A well-prepared toolkit can significantly reduce the time and effort required to address any issues that arise.

Basic hand tools such as screwdrivers, pliers, and wrenches are fundamental for disassembly and assembly. A multimeter is invaluable for diagnosing electrical problems, allowing for precise measurements of voltage and resistance. Additionally, a set of socket wrenches will be helpful for accessing hard-to-reach bolts and fasteners.

Don’t forget to include safety gear such as gloves and goggles to protect yourself from potential hazards. A flashlight or headlamp can illuminate dark areas, ensuring you can see what you’re working on clearly. Having these tools ready will empower you to effectively manage any challenges you encounter during the process.

Step-by-Step Troubleshooting Guide

This guide provides a structured approach to diagnosing and resolving common issues encountered with home appliances. By following systematic steps, users can identify the root causes of malfunctions and apply appropriate solutions effectively.

Begin by examining the device to gather initial insights. Check for any obvious signs of trouble, such as unusual noises or failure to operate. Next, consult the following table for common problems and their corresponding troubleshooting steps.

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| No power | Tripped circuit breaker, faulty outlet | Check circuit breaker and test outlet with another device. |

| Overheating | Blocked vents, faulty thermostat | Clear any obstructions and test the thermostat functionality. |

| Poor drying performance | Lint buildup, incorrect settings | Clean the lint filter and verify selected settings. |

| Strange noises | Loose components, worn parts | Inspect for loose screws or worn belts and replace as necessary. |

| Drum won’t spin | Faulty drive belt, malfunctioning motor | Check the drive belt for damage and test the motor for functionality. |

Following these steps will enhance the likelihood of identifying and rectifying issues efficiently, ensuring the appliance operates optimally.

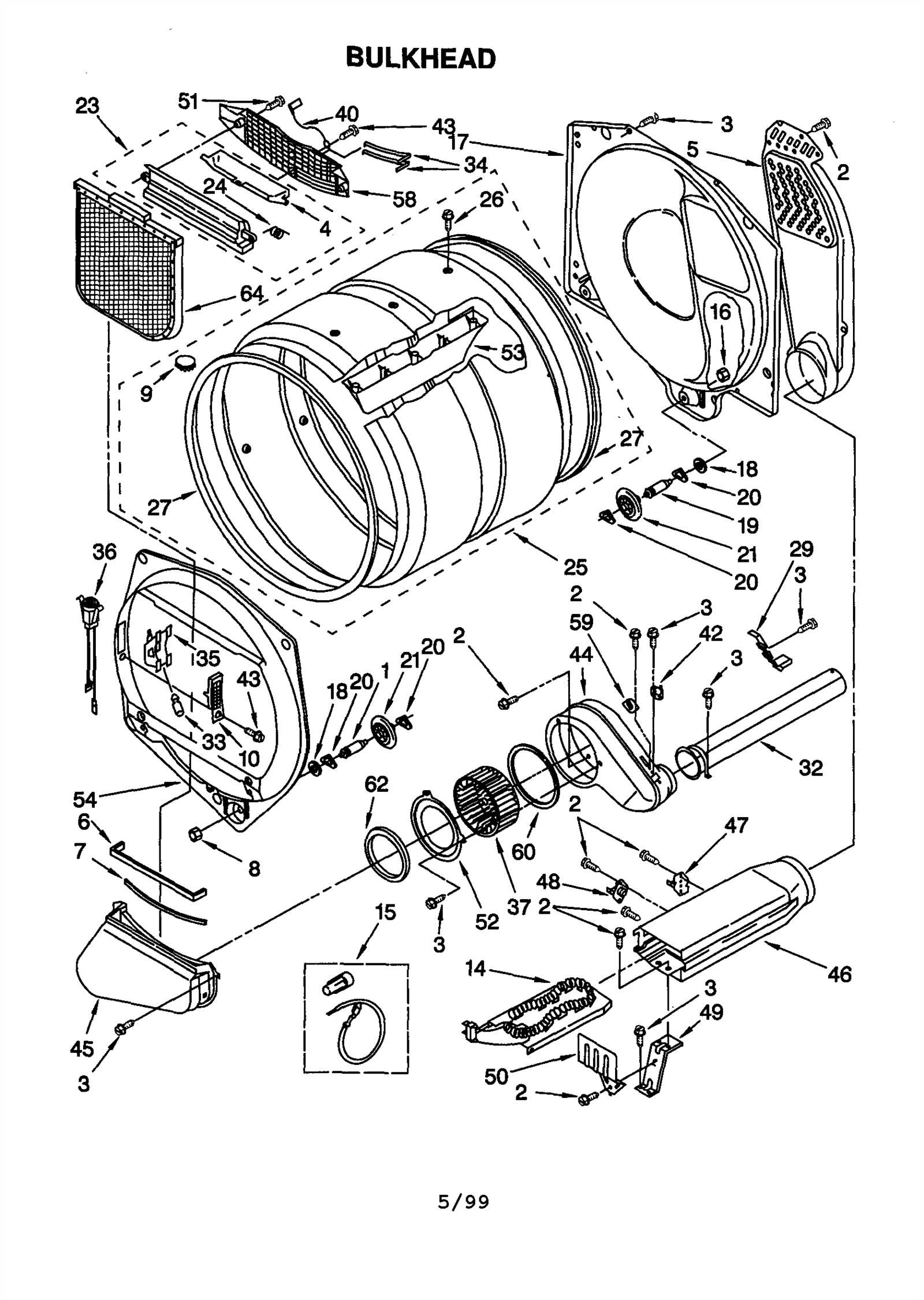

Replacing the Drum Belt

When the internal mechanism of your appliance begins to falter, one common issue might be a worn or broken belt. This component is essential for the rotation of the drum, ensuring that laundry dries effectively. Replacing this part can restore functionality and improve performance, making it a valuable maintenance task for any user.

Before proceeding, ensure you have the necessary tools and a replacement belt. The following table outlines the steps to follow during the replacement process:

| Step | Action |

|---|---|

| 1 | Unplug the appliance from the power source to ensure safety. |

| 2 | Remove the front panel or access door to gain entry to the drum area. |

| 3 | Take out the drum carefully, noting how the old belt is positioned. |

| 4 | Remove the worn belt from the motor and idler pulley. |

| 5 | Install the new belt, threading it around the motor and idler pulley as per the original configuration. |

| 6 | Reinsert the drum into its housing, ensuring the belt is properly aligned. |

| 7 | Reattach the front panel or access door securely. |

| 8 | Plug the appliance back in and test its functionality. |

By following these straightforward steps, you can effectively replace the drum belt and restore optimal operation to your appliance. Regular maintenance can prevent future issues, ensuring your laundry tasks are completed smoothly.

How to Fix Heating Problems

When your appliance fails to generate adequate warmth, it can lead to inefficient drying and prolonged laundry cycles. Addressing heating issues promptly is essential to restore functionality and ensure optimal performance. Here are some common causes and solutions to help you troubleshoot and resolve these concerns effectively.

Common Causes of Insufficient Heat

Understanding the underlying reasons for heating problems can assist you in pinpointing the issue. Here are a few frequent culprits:

| Cause | Description |

|---|---|

| Faulty Heating Element | The component responsible for generating heat may be damaged or burned out. |

| Thermostat Issues | A malfunctioning thermostat can lead to incorrect temperature readings, preventing the appliance from heating properly. |

| Blocked Ventilation | Clogged vents can restrict airflow, causing the heating element to overheat or fail to work efficiently. |

| Wiring Problems | Frayed or damaged wires can disrupt the electrical supply to heating components. |

Steps to Resolve Heating Issues

Once you identify the potential causes, follow these steps to address the heating problems:

1. Inspect the heating element for any visible damage and replace it if necessary.

2. Test the thermostat using a multimeter to check for continuity, replacing it if it’s faulty.

3. Clean out the ventilation system to ensure unobstructed airflow, checking ducts and lint traps.

4. Examine the wiring for any signs of wear or damage, and repair or replace as needed.

By methodically working through these steps, you can restore warmth and efficiency to your appliance, enhancing its overall performance.

Cleaning the Lint Trap and Ducts

Regular maintenance of lint accumulation is essential for optimal performance and safety. Keeping these components clean not only enhances efficiency but also helps prevent potential hazards, such as fires. A straightforward cleaning routine can significantly extend the lifespan of your appliance and improve its operation.

Steps to Clean the Lint Trap

Begin by removing the lint trap from its designated location. Carefully pull it out, ensuring no lint is left behind. Use your fingers or a soft brush to gather the collected fibers. It’s advisable to wash the trap with warm soapy water occasionally to eliminate any residue that may inhibit airflow. Make sure it is completely dry before reinserting it.

Cleaning the Ducts

After addressing the lint trap, focus on the ducts. Disconnect the vent from the appliance, taking care to avoid damaging any components. Use a vacuum with a long hose attachment to remove lint buildup within the ductwork. For a thorough clean, consider using a flexible brush designed for this purpose. Ensuring these pathways are free from obstructions promotes better airflow and efficiency.

Addressing Electrical Failures

When dealing with malfunctions related to power supply, it’s essential to understand common issues that can arise. Identifying these electrical problems early can save both time and money while ensuring safe operation. This section focuses on diagnosing and resolving typical electrical faults found in household appliances.

Start with Basic Checks: Before diving into more complex solutions, verify that the appliance is properly connected to a functioning outlet. Inspect the power cord for any visible damage and ensure that the circuit breaker hasn’t tripped. A simple reset may resolve the issue.

Testing Components: If basic checks don’t yield results, it may be necessary to examine internal components. Use a multimeter to test fuses and switches for continuity. A blown fuse or a malfunctioning switch can disrupt power flow, leading to operational failures.

Inspecting Wiring: Look for loose or frayed wiring connections inside the unit. Damaged wires can create shorts or open circuits, preventing the appliance from functioning correctly. Ensure all connections are secure and replace any damaged wiring as needed.

Professional Assistance: If the problem persists after troubleshooting, it may be time to consult a technician. Electrical systems can be complex, and attempting to repair intricate components without proper knowledge can be hazardous. Seeking expert help ensures that repairs are conducted safely and effectively.

Replacing Faulty Thermostats

Over time, temperature regulation components can fail, leading to issues with drying efficiency and appliance performance. Identifying and replacing these malfunctioning parts is crucial for restoring proper functionality. This section will guide you through the process of replacing defective thermostats, ensuring your equipment operates at optimal levels.

Before starting the replacement process, it is essential to gather the necessary tools and components. You will need a multimeter, screwdrivers, and a replacement thermostat suited for your model. Always ensure the appliance is unplugged before attempting any maintenance to prevent electrical hazards.

| Step | Description |

|---|---|

| 1 | Disconnect the power supply to the appliance for safety. |

| 2 | Access the thermostat by removing the back panel or cover, depending on your specific model. |

| 3 | Use a multimeter to test the existing thermostat for continuity, confirming whether it is indeed faulty. |

| 4 | Remove the defective thermostat by unscrewing it and disconnecting the wiring harness. |

| 5 | Install the new thermostat by connecting the wiring and securing it in place. |

| 6 | Replace the cover or panel and ensure everything is properly sealed. |

| 7 | Reconnect the power supply and run a test cycle to confirm proper operation. |

Following these steps will help you efficiently replace faulty temperature regulation components, ensuring your appliance runs smoothly and effectively. Regular maintenance checks can prevent future issues and prolong the life of your equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your appliance involves regular care and attention. By following a few essential practices, you can prevent common issues and enhance performance over time.

- Clean the lint filter after every use to improve airflow and efficiency.

- Inspect and clean the venting system periodically to avoid blockages that can lead to overheating.

- Check the seals and gaskets for wear and tear; replace them if necessary to maintain optimal performance.

In addition to routine cleaning, consider the following recommendations:

- Schedule professional maintenance annually to address potential problems before they escalate.

- Avoid overloading the appliance to ensure it operates within its designed capacity.

- Use appropriate settings for different types of fabrics to minimize wear and tear.

By implementing these tips, you can significantly enhance the durability of your appliance, ensuring it remains efficient and reliable for years to come.

When to Call a Professional

Understanding the right moments to seek expert assistance can save time and prevent further complications. While many issues can be tackled independently, there are instances when the involvement of a trained technician is essential for safe and effective resolution.

Signs That Indicate Professional Help is Needed

Certain symptoms may suggest a more serious underlying issue. It’s crucial to recognize these signs early to avoid potential hazards.

| Indicator | Description |

|---|---|

| No Power | If the unit fails to turn on despite checking the outlet and circuit breaker, it may signal a significant electrical problem. |

| Unusual Noises | Grinding, squeaking, or rattling sounds could indicate mechanical failure or loose components. |

| Excessive Heat | Overheating can pose a fire risk and typically requires immediate professional inspection. |

| Persistent Error Codes | Repeated error messages on the display often mean a malfunctioning sensor or system that needs expert diagnostics. |

Benefits of Seeking Professional Assistance

Engaging a specialist not only ensures the issue is addressed correctly but also provides peace of mind. Professionals possess the necessary tools and expertise to handle complex challenges, which can ultimately prolong the lifespan of your appliance.

Resources for Further Assistance

When facing challenges with your appliance, having access to reliable sources can make all the difference. Whether you’re looking for troubleshooting tips, part replacements, or expert guidance, numerous resources are available to help you resolve issues effectively. Below are some recommended avenues to explore for additional support.

Online Forums and Communities

Engaging with online platforms dedicated to appliance enthusiasts can provide valuable insights. Websites and forums often feature discussions where users share their experiences and solutions. Participating in these communities allows you to ask questions and receive advice from those who have faced similar problems.

Manufacturer Support and Documentation

Many manufacturers offer official support channels, including websites with downloadable documentation. These resources typically include troubleshooting guides and detailed diagrams. Additionally, reaching out to customer service representatives can connect you with knowledgeable individuals who can assist with specific inquiries.

Remember to always prioritize safety when addressing appliance concerns, and consult with professionals when necessary. Utilizing these resources can enhance your understanding and ensure your equipment operates smoothly.