Zongshen 250cc Engine Repair Guide

Maintaining and restoring your two-wheeled companion can be a rewarding experience for any enthusiast. This section aims to provide crucial insights and detailed instructions for tackling various aspects of motorcycle upkeep and enhancement. From basic troubleshooting to advanced modifications, understanding the inner workings of your vehicle is essential for optimal performance and longevity.

Proper knowledge and techniques can help you diagnose issues effectively, enabling you to tackle problems head-on. This guide will cover a range of topics that will empower you to take control of your bike’s functionality. Whether you are a novice or a seasoned mechanic, the information presented here is designed to cater to all skill levels.

As you delve into the intricacies of your machine, you will discover the importance of each component and how they interact. With a focus on clarity and accessibility, this resource will equip you with the tools needed for a successful and satisfying overhaul, ensuring that your ride remains in peak condition for years to come.

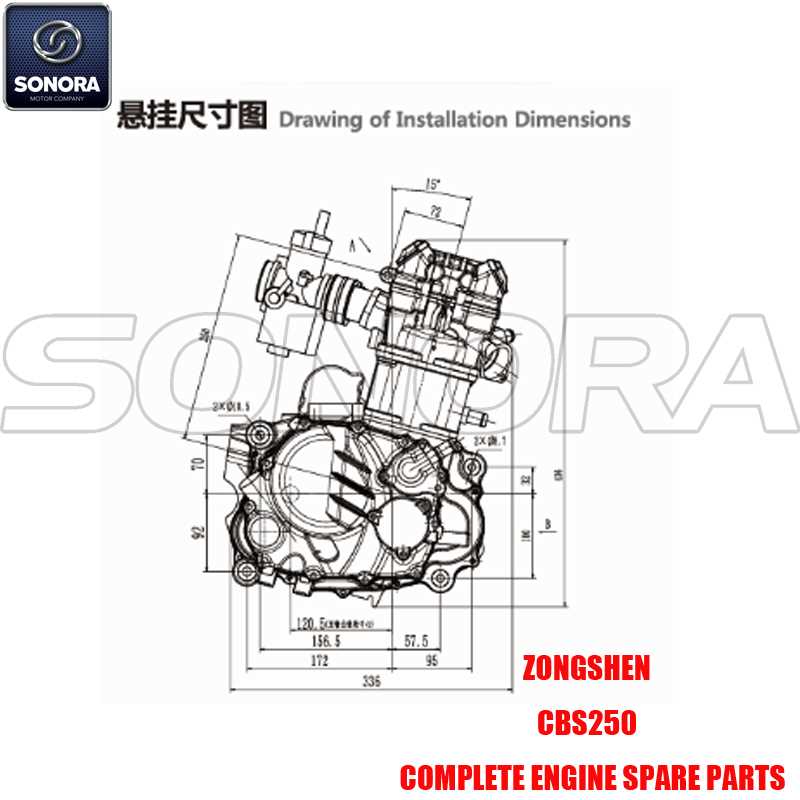

Zongshen 250cc Engine Overview

This section provides a comprehensive look at a popular power unit widely utilized in various two-wheeled vehicles. It highlights key features, performance characteristics, and maintenance insights that enthusiasts and technicians should be aware of.

- Design: This power source is known for its robust construction, ensuring durability and longevity in demanding conditions.

- Performance: It delivers impressive torque and horsepower, making it suitable for both urban commuting and off-road adventures.

- Fuel Efficiency: Designed to optimize fuel consumption, it strikes a balance between power and economy.

- Cooling System: The cooling mechanism employed ensures effective temperature management, preventing overheating during prolonged use.

Understanding the fundamental aspects of this power unit enables better maintenance practices and enhances overall performance. Regular check-ups and adherence to best practices will ensure optimal functionality and longevity.

Common Issues with Zongshen Engines

When it comes to small displacement power units, various challenges may arise during operation. Understanding these common complications can help in maintaining optimal performance and longevity. Frequent problems can stem from design flaws, poor maintenance, or external factors that affect functionality.

Overheating is a prevalent issue that can lead to severe damage if not addressed promptly. This often occurs due to insufficient coolant levels, clogged cooling passages, or a malfunctioning thermostat. Regular checks of the cooling system can help prevent this situation.

Another frequent concern is fuel delivery problems. Insufficient fuel flow can result from clogged filters, faulty pumps, or issues with the carburetor. Ensuring that the fuel system is clean and functioning properly is crucial for reliable performance.

Electrical malfunctions are also common and can affect starting and overall operation. Issues may arise from worn-out wiring, faulty connectors, or malfunctioning sensors. Routine inspections of the electrical components can mitigate these risks.

Lastly, leaks are a significant problem that can arise from various seals and gaskets. Regularly inspecting these areas for signs of fluid loss can help in early detection and prevent more serious issues down the line.

Tools Required for Repairs

For successful maintenance and restoration of your motorcycle’s performance, having the right instruments is essential. This section outlines the various tools that will facilitate the process, ensuring efficient and effective service.

Essential Hand Tools

- Wrenches (various sizes)

- Socket set

- Screwdrivers (flathead and Phillips)

- Allen keys

- Pliers (needle nose and regular)

Specialized Equipment

- Torque wrench

- Oil filter wrench

- Compression tester

- Multimeter

- Leak-down tester

Having these tools on hand will not only simplify tasks but also enhance the overall effectiveness of the maintenance process, leading to improved longevity and reliability of the vehicle.

Step-by-Step Disassembly Process

This section outlines a detailed procedure for carefully taking apart a power unit. Following these steps will ensure that each component is accessed safely and efficiently, facilitating thorough inspection and maintenance.

Before beginning the disassembly, it is crucial to prepare your workspace and gather the necessary tools. Ensure that you have a clean area, free of clutter, to avoid losing any small parts during the process.

| Step | Description |

|---|---|

| 1 | Disconnect the power source and remove any protective covers to expose the main components. |

| 2 | Carefully detach any electrical connectors and hoses, labeling them if necessary for reassembly. |

| 3 | Remove the mounting bolts and lift off the outer casing, taking care not to damage any gaskets. |

| 4 | Extract the internal components one by one, ensuring to document their arrangement for easier reinstallation. |

| 5 | Inspect each part for wear and damage, cleaning them thoroughly before proceeding with any repairs or replacements. |

Following this structured approach will help in maintaining the integrity of all components and simplify the overall process of reassembly.

Inspecting Engine Components

Thorough examination of the internal parts of a power unit is crucial for maintaining optimal performance and longevity. This process involves assessing various elements to ensure they function correctly and are free from wear and damage.

Begin with the cylinder head, checking for any signs of cracks or warping. Inspect the valves for proper sealing and movement. It is essential to ensure that the valve seats are intact, as any irregularities can lead to loss of compression.

Next, examine the piston and rings. Look for scoring on the piston surface and check the ring gaps for proper alignment. Worn or damaged rings can result in decreased efficiency and increased oil consumption.

The crankshaft should be inspected for straightness and signs of wear on the bearing surfaces. Ensure that all components rotate freely without any binding. This will help prevent premature failure of the crankshaft and associated parts.

Finally, assess the lubrication system. Ensure that oil passages are clear and that the oil pump functions correctly. Proper lubrication is vital for reducing friction and preventing overheating, which can lead to catastrophic failure.

Cleaning and Maintenance Tips

Regular upkeep and thorough cleaning are essential for ensuring optimal performance and longevity of your machinery. Adopting a consistent maintenance routine can prevent issues before they arise and enhance the efficiency of your equipment.

Here are some helpful suggestions to keep in mind:

| Task | Frequency | Details |

|---|---|---|

| Check Oil Levels | Every 50 hours | Ensure that the lubricant is at the appropriate level for smooth operation. |

| Clean Air Filter | Every 25 hours | Remove and clean the filter to prevent dust buildup, which can hinder performance. |

| Inspect Fuel System | Monthly | Look for any leaks or blockages and clean as necessary to ensure proper fuel flow. |

| Examine Spark Plug | Every 100 hours | Check for wear and replace if needed to maintain efficient ignition. |

| Check Cooling System | Every 50 hours | Ensure that the cooling components are free of debris to prevent overheating. |

Following these maintenance tips will help you maintain the functionality of your equipment and extend its lifespan, ensuring a smoother experience during operation.

Reassembly Guidelines for Zongshen

When it comes to putting components back together after maintenance, following a systematic approach is essential for optimal performance. Ensuring that each part is correctly aligned and securely fastened contributes significantly to the longevity and efficiency of the assembly.

Preparation Steps

Before starting the reassembly process, gather all necessary tools and components. Clean all parts thoroughly to remove any dirt or residue. Inspect each piece for wear and damage, replacing any that do not meet quality standards. A well-organized workspace can help streamline the reassembly process.

Reassembly Process

Begin reassembling by following the reverse order of disassembly. Pay attention to torque specifications for bolts and screws to avoid over-tightening, which can lead to damage. Use a thread-locking compound on critical fasteners to prevent loosening due to vibrations.

| Component | Torque Specification (Nm) |

|---|---|

| Cylinder Head | 20-25 |

| Crankcase Bolts | 15-20 |

| Connecting Rod Bolts | 30-35 |

| Oil Pan Screws | 10-15 |

After completing the reassembly, perform a thorough inspection to ensure everything is in place. Follow up with a testing phase to confirm that the assembly operates smoothly and efficiently.

Tuning and Adjusting the Engine

Tuning and optimizing performance is essential for achieving the best results from your two-wheeled vehicle. Proper adjustments can enhance throttle response, improve fuel efficiency, and ensure smooth operation. This section focuses on key areas that can be modified to achieve optimal performance.

Fuel Mixture Adjustment plays a crucial role in the overall functionality. The correct balance between air and fuel can significantly impact acceleration and responsiveness. It’s important to test different settings to find the ideal mixture that suits your riding style and conditions.

Ignition Timing is another vital aspect to consider. By fine-tuning the timing, you can enhance power output and efficiency. This involves adjusting the timing mechanism to ensure that the spark occurs at the right moment in the combustion cycle.

Finally, carburetor settings should not be overlooked. These settings influence the air and fuel delivery, which directly affects performance. Regular cleaning and calibration will help maintain the optimal functioning of this component.

Fuel System Troubleshooting

Effective diagnostics of the fuel delivery system is crucial for maintaining optimal performance. This section focuses on identifying common issues that can affect fuel supply and ensuring the system operates efficiently.

When encountering problems with fuel flow or combustion, several components should be evaluated. The table below outlines potential issues, symptoms, and recommended actions to address these challenges.

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Clogged Fuel Filter | Engine sputters or stalls | Replace the fuel filter |

| Faulty Fuel Pump | Difficulty starting or poor acceleration | Test and replace the pump if necessary |

| Leaking Fuel Lines | Fuel odor or visible leaks | Inspect and replace damaged lines |

| Dirty Fuel Injectors | Uneven idle or reduced power | Clean or replace the injectors |

| Incorrect Fuel Mixture | Black smoke from exhaust | Adjust the fuel mixture settings |

By systematically addressing these areas, one can significantly enhance the functionality of the fuel system and improve overall performance.

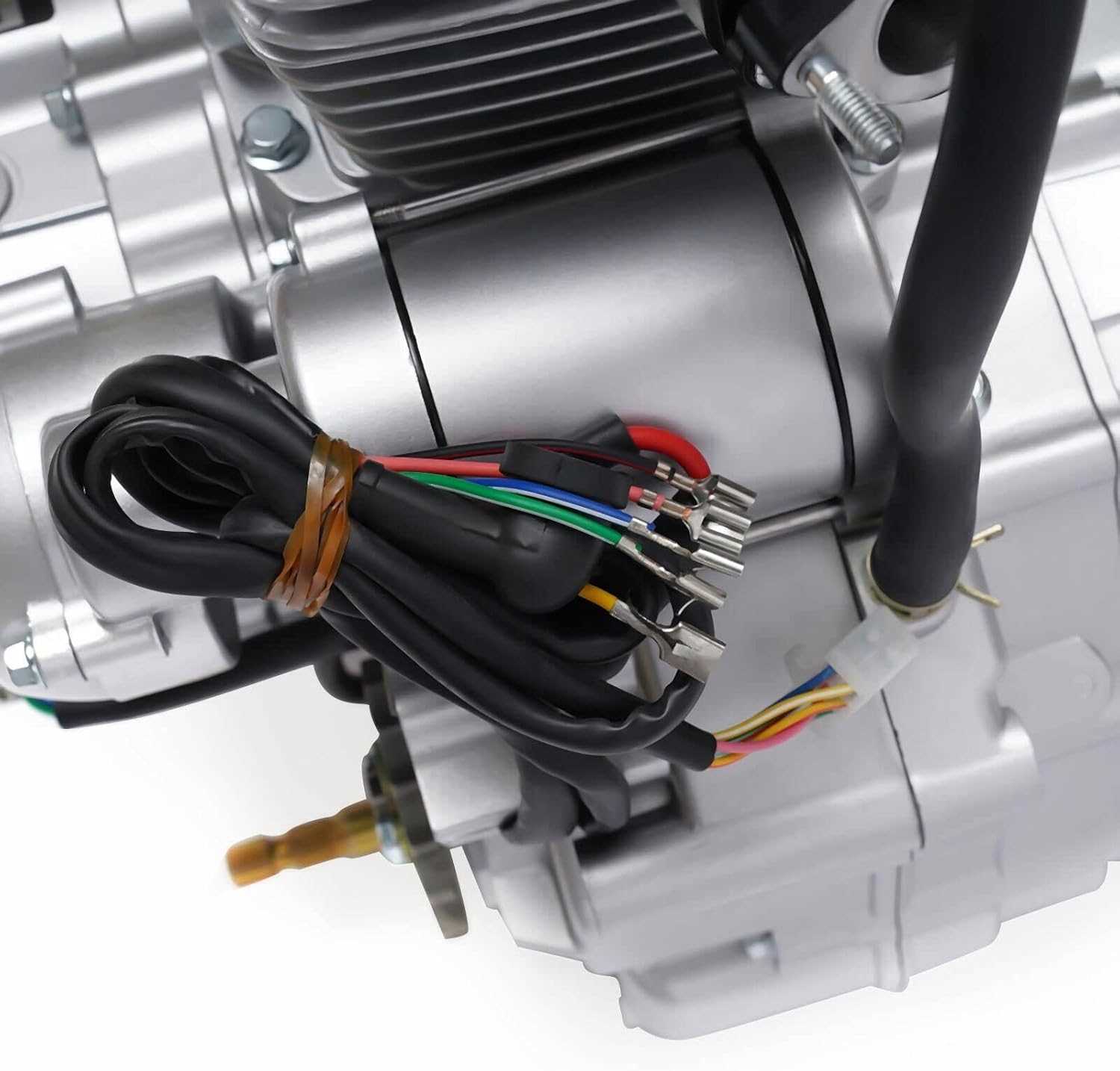

Electrical System Diagnosis

The functionality of any motorized vehicle heavily relies on its electrical components, which are essential for starting, running, and controlling various systems. Diagnosing electrical issues requires a systematic approach to identify faults and ensure optimal performance. This section provides guidance on assessing and troubleshooting the electrical circuitry to maintain operational efficiency.

Step 1: Initial Inspection

Begin by visually inspecting the wiring harness for any signs of wear, damage, or corrosion. Pay close attention to connectors and terminals, as poor connections can lead to malfunctions.

Step 2: Testing Voltage

Utilize a multimeter to measure voltage levels across different points in the system. Ensure that the readings align with manufacturer specifications, as deviations can indicate underlying problems.

Step 3: Continuity Checks

Conduct continuity tests to verify that circuits are complete and functioning properly. An open circuit may suggest a break in the wiring, necessitating further investigation.

Step 4: Component Evaluation

Assess individual components such as the battery, alternator, and starter motor. Each part plays a critical role, and testing them can pinpoint specific areas that require attention.

Conclusion

By following these diagnostic steps, one can effectively troubleshoot and resolve electrical issues, thereby ensuring the reliable operation of the vehicle’s systems.

Performance Upgrades and Modifications

Enhancing the capabilities of your motorcycle can significantly improve your riding experience. By making strategic modifications, you can increase power, improve handling, and optimize fuel efficiency. This section explores various upgrades that can elevate performance and offer a more thrilling ride.

- Exhaust System:

- Upgrading to a high-performance exhaust can enhance airflow, reducing back pressure and improving power output.

- Consider lightweight materials to reduce overall weight.

- Air Intake:

- Installing a high-flow air filter allows for better air circulation, contributing to improved combustion efficiency.

- Consider a performance air intake system for maximum airflow.

- Re-gearing:

- Changing the sprocket sizes can alter acceleration and top speed, tailoring the performance to your preference.

- Choose gearing that complements other modifications for balanced performance.

- ECU Tuning:

- Reprogramming the engine control unit can optimize fuel maps and ignition timing for enhanced performance.

- Consult a professional for custom tuning that suits your riding style.

- Suspension Upgrades:

- Investing in aftermarket suspension components can improve handling and ride comfort.

- Adjustable shocks allow for personalized tuning based on rider weight and terrain.

- Tires:

- Choosing high-performance tires can enhance grip and stability, especially in cornering.

- Consider the terrain you ride on to select the best tire type.

Each of these modifications can contribute to a more dynamic riding experience. It is essential to consider the intended use and personal preferences when planning upgrades to achieve optimal results.

Safety Precautions During Repairs

When working on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure a safe environment and promote efficient work practices. Below are key measures to follow while performing maintenance tasks.

- Personal Protective Equipment (PPE): Always wear appropriate safety gear, including gloves, goggles, and a helmet, to protect against potential hazards.

- Work Area Safety: Keep the workspace clean and organized to reduce the risk of slips, trips, and falls.

- Ventilation: Ensure adequate airflow in enclosed spaces to avoid inhalation of harmful fumes or gases.

- Tool Maintenance: Use tools that are in good condition. Regularly inspect them for any signs of wear or damage.

- Fire Safety: Have a fire extinguisher accessible, especially when working with flammable materials.

By adhering to these guidelines, individuals can create a safer atmosphere and minimize risks while engaging in maintenance activities.