Comprehensive Guide to 2008 Cobalt Repairs

This section provides essential information for understanding the upkeep and troubleshooting of a specific automobile model. It aims to assist owners in navigating various maintenance tasks effectively, ensuring longevity and optimal performance.

Comprehensive insights into common issues and their solutions are included, allowing users to identify problems quickly. Furthermore, it emphasizes the importance of regular checks and timely interventions to prevent more significant challenges down the line.

By following the guidelines presented here, individuals can enhance their knowledge and confidence in handling vehicle care. This resource serves as a practical reference for both novice and experienced car enthusiasts alike.

2008 Cobalt Repair Manual Overview

This section provides a comprehensive look into the essential guidelines and recommendations for maintaining and troubleshooting a specific vehicle model. It aims to equip owners and technicians with the necessary knowledge to ensure optimal performance and longevity.

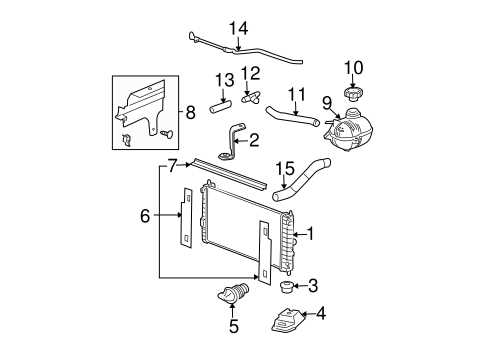

Key Features and Functions

Critical components of the vehicle’s system are highlighted, emphasizing the importance of regular checks and timely interventions. Understanding the various mechanisms will enhance the ability to diagnose issues effectively.

Maintenance Tips

Regular upkeep is crucial for sustaining the vehicle’s efficiency. This includes following recommended schedules for inspections and addressing minor issues before they escalate. Implementing these practices can significantly improve overall reliability.

Understanding Common Issues with Cobalt

This section explores prevalent challenges encountered with certain compact vehicles. By recognizing these problems, owners can better prepare for maintenance and troubleshooting, ensuring a smoother driving experience.

Frequent Mechanical Concerns

One of the main areas of concern involves the engine performance. Issues may arise from various sources, including fuel delivery and ignition systems. Regular checks can help identify these problems early, preventing further complications.

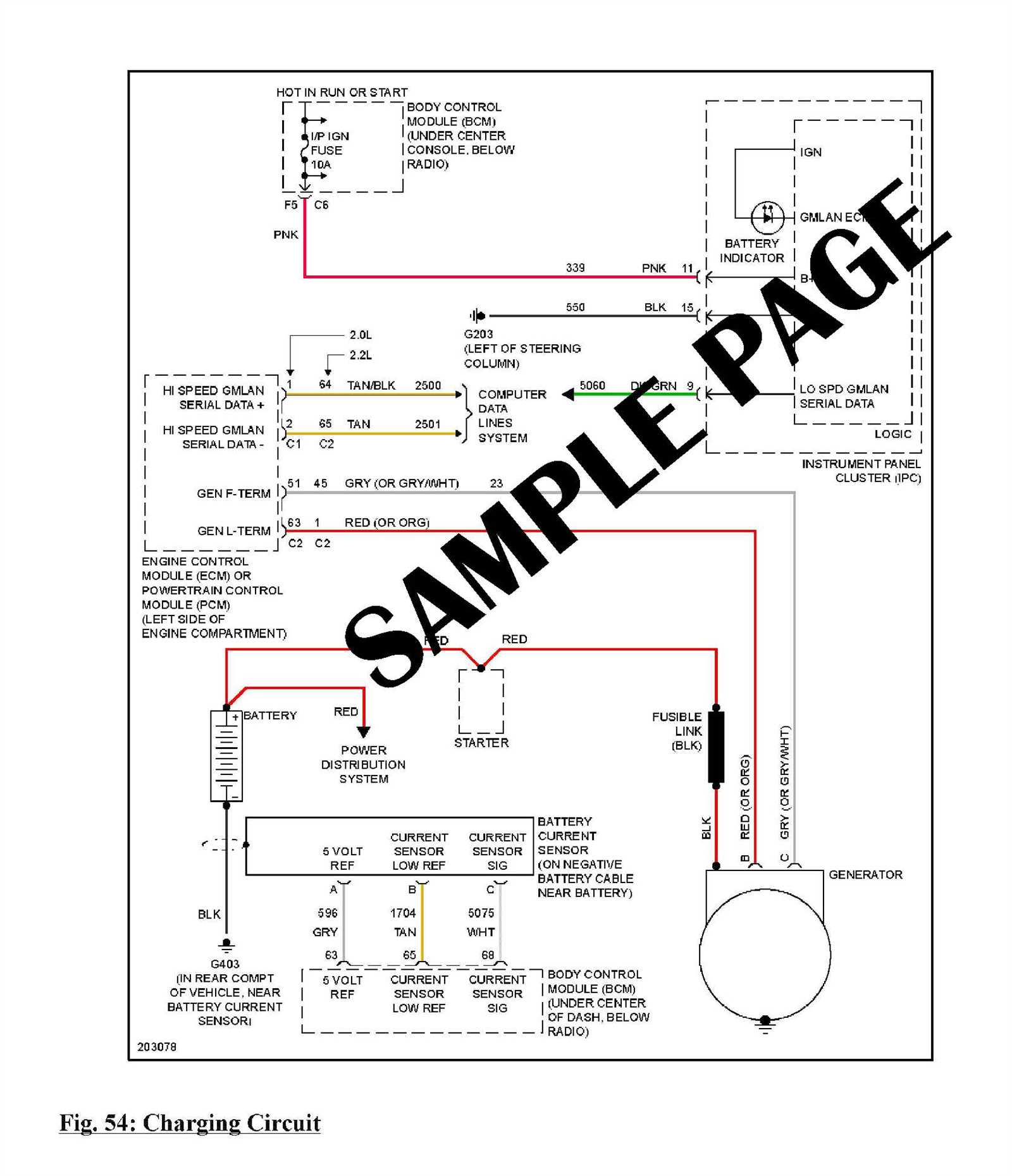

Electrical System Anomalies

Electrical components often present challenges, ranging from battery life to wiring faults. Monitoring the electrical system’s functionality is essential for reliable operation. Addressing any inconsistencies promptly can enhance vehicle safety and efficiency.

Essential Tools for Repairs

Having the right equipment is crucial for successfully addressing various vehicle issues. A well-equipped workspace ensures that tasks can be completed efficiently and effectively, leading to better outcomes and satisfaction.

Basic Equipment Needed

Every toolkit should include some fundamental items that serve multiple purposes:

- Socket Set: A variety of sizes for different fasteners.

- Wrenches: Both standard and metric for versatility.

- Screwdrivers: A selection of flathead and Phillips for various tasks.

- Pliers: Needle-nose and slip-joint types for gripping and bending.

- Jack and Stands: For safely lifting the vehicle during maintenance.

Specialized Tools for Advanced Tasks

For more complex repairs, additional instruments may be required:

- Diagnostic Scanner: For reading error codes and troubleshooting issues.

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Multimeter: Useful for electrical diagnostics and troubleshooting.

- Oil Filter Wrench: Helps in removing and installing oil filters.

- Brake Tool Set: Essential for brake system maintenance and repairs.

Investing in these tools can significantly enhance the ability to manage various automotive challenges, promoting a successful hands-on experience.

Step-by-Step Maintenance Procedures

This section provides a comprehensive overview of essential upkeep tasks designed to enhance the longevity and performance of your vehicle. By following these structured guidelines, you can ensure that your automobile remains in optimal condition.

Routine Checks

- Inspect fluid levels regularly, including oil, coolant, and brake fluid.

- Examine tire pressure and tread depth to maintain safety and efficiency.

- Check battery connections and clean terminals to prevent corrosion.

Periodic Maintenance Tasks

- Change the engine oil and replace the oil filter every 5,000 to 7,500 miles.

- Replace air filters and cabin filters to ensure clean airflow.

- Rotate tires every 6,000 to 8,000 miles to promote even wear.

Adhering to these procedures will help keep your vehicle running smoothly and effectively for years to come.

Engine Diagnostics and Troubleshooting

Effective engine diagnostics and troubleshooting are crucial for maintaining optimal performance in vehicles. Understanding potential issues can help identify symptoms early and prevent more significant problems down the line. This section focuses on essential techniques and methods to ensure the engine operates smoothly.

Common Symptoms and Indicators

Drivers may notice various signs that indicate engine troubles. Unusual noises, decreased power, or fluctuating RPMs can all signal underlying issues. Observing these symptoms is the first step in diagnosing the problem accurately.

Diagnostic Tools and Techniques

Utilizing diagnostic equipment is essential for identifying specific engine faults. Tools such as OBD-II scanners can provide valuable insights into error codes and sensor readings. Additionally, conducting visual inspections and performing compression tests can further pinpoint problems effectively.

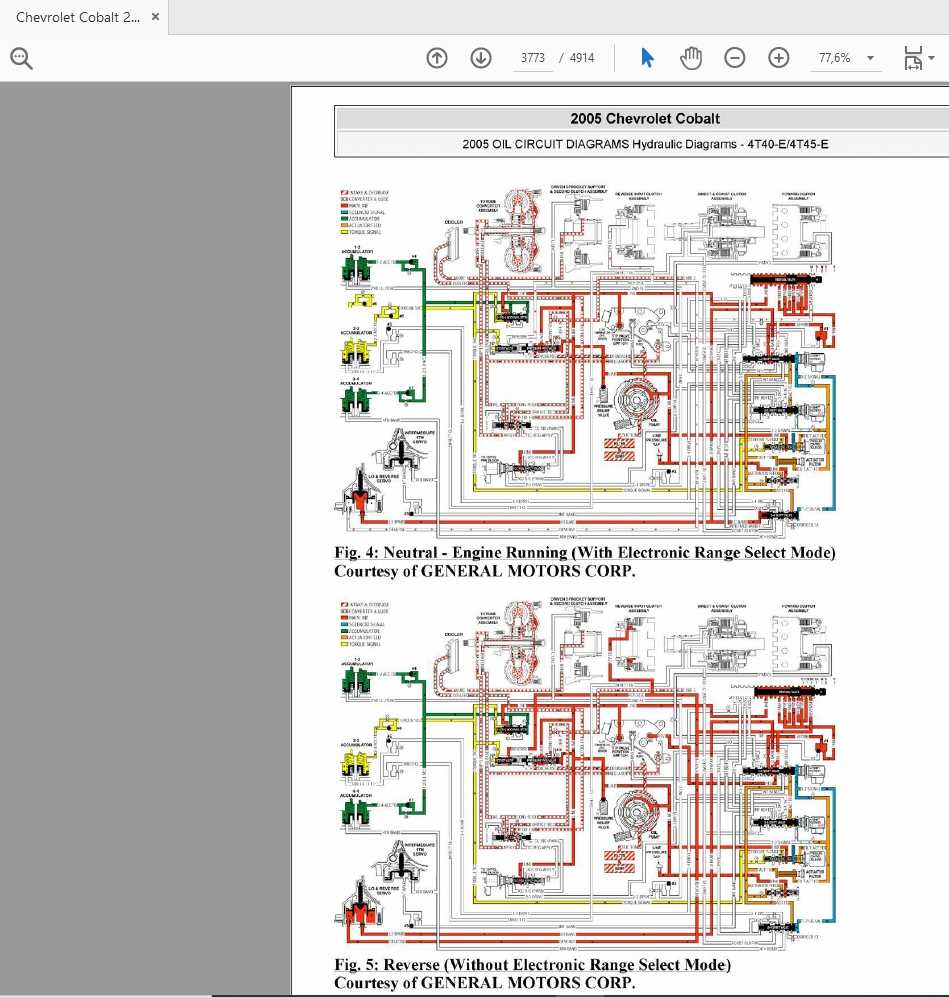

Transmission Problems and Solutions

This section addresses common issues related to gear systems and provides effective strategies for resolution. Understanding these challenges can help in maintaining optimal vehicle performance.

Typical issues may include:

- Slipping gears

- Unusual noises during shifting

- Fluid leaks

- Warning lights on the dashboard

To troubleshoot these problems, consider the following approaches:

- Check Fluid Levels: Ensure transmission fluid is at the correct level and in good condition.

- Inspect for Leaks: Examine the area under the vehicle for signs of fluid leakage.

- Listen for Noises: Pay attention to any abnormal sounds when changing gears, which may indicate internal issues.

- Consult a Professional: If problems persist, seek assistance from a qualified technician for a thorough diagnosis.

Implementing these solutions can enhance the longevity and reliability of the transmission system.

Electrical System Troubleshooting Guide

This section aims to assist in identifying and resolving issues related to the electrical components of your vehicle. Understanding the signs of malfunction can enhance safety and performance, ensuring a smoother driving experience.

Common Electrical Problems

Typical issues include battery failures, blown fuses, and faulty wiring. Recognizing symptoms such as dim lights or malfunctioning accessories can help pinpoint the source of the problem.

Troubleshooting Steps

Begin by inspecting the battery for corrosion or loose connections. Next, check fuses to confirm they are intact. Utilize a multimeter to assess voltage levels throughout the system. Follow these steps to ensure a thorough evaluation.

Brake System Inspection and Repair

The braking system is a crucial component of any vehicle, ensuring safety and control during operation. Regular examination and maintenance of this system are essential to prevent potential issues that could lead to decreased performance or failure. This section outlines the necessary steps for assessing and addressing any concerns related to the braking components.

Visual Inspection

Begin by performing a thorough visual check of the brake components. Look for signs of wear or damage on the brake pads, rotors, and calipers. Ensure that there are no leaks in the brake lines or fluid reservoirs, as these can significantly affect braking efficiency.

Brake Fluid Level and Quality

Check the brake fluid level and condition. The fluid should be clear and free of contaminants. If the fluid appears dark or murky, it may need to be replaced. Low fluid levels can indicate a leak in the system, requiring immediate attention.

Testing Brake Performance

Conduct a performance test by applying the brakes at various speeds. Listen for any unusual noises, such as grinding or squeaking, which may indicate worn components. Ensure that the vehicle stops smoothly and effectively, without pulling to one side.

Component Replacement

If any components are found to be faulty during the inspection, they should be replaced promptly. Use high-quality parts that meet or exceed manufacturer specifications to maintain optimal performance and safety. Follow proper installation procedures to ensure a secure fit.

Final Checks

After completing repairs or replacements, perform another inspection to confirm that everything is functioning correctly. Test drive the vehicle to ensure the brakes respond well and provide the expected stopping power.

Suspension and Steering Adjustments

The proper alignment and calibration of the suspension and steering systems are crucial for optimal handling and ride quality. Ensuring these components are adjusted correctly enhances vehicle stability and provides a comfortable driving experience.

Alignment Checks

Regular alignment checks are essential to maintain the correct angles of the wheels. Misalignment can lead to uneven tire wear and negatively impact steering response. It is advisable to have the alignment assessed periodically, especially after any suspension modifications or repairs.

Steering System Tuning

Tuning the steering mechanism is vital for achieving responsive handling. This includes inspecting components such as tie rods and bushings for wear and ensuring proper fluid levels. Adjustments should be made according to manufacturer specifications to enhance control and prevent potential issues.

Bodywork and Exterior Maintenance

Maintaining the exterior of your vehicle is essential for both aesthetic appeal and long-term durability. Regular attention to the bodywork not only enhances the overall appearance but also protects against rust and damage caused by environmental factors. Proper care ensures that your automobile remains in excellent condition over time.

Cleaning and Protecting Surfaces

Frequent washing with appropriate products helps remove dirt and grime. It is advisable to use a pH-balanced soap designed for vehicles to prevent any potential harm to the paint. Additionally, applying a wax or sealant can create a protective barrier against UV rays and contaminants, ensuring the surface remains shiny and well-preserved.

Inspecting and Repairing Damages

Regular inspections of the bodywork can help identify scratches, dents, or chips early on. Addressing these issues promptly can prevent further deterioration. For minor imperfections, touch-up paint may suffice, while more significant damages might require professional assistance to restore the original finish and integrity.

Interior Repairs and Upgrades

This section focuses on enhancing and fixing the internal components of your vehicle, ensuring both comfort and functionality. Upgrading the interior can greatly improve the driving experience and overall aesthetics.

Key areas to consider for enhancement include:

- Seats: Upgrading upholstery or adding seat covers can provide a fresh look and increased comfort.

- Dashboard: Consider replacing or customizing panels for a modern appearance.

- Audio System: Upgrading speakers and head units can significantly enhance sound quality.

- Lighting: Installing ambient or LED lights can create a more inviting atmosphere.

To ensure successful modifications, follow these tips:

- Research compatible components to avoid mismatches.

- Prioritize safety by ensuring all installations meet standards.

- Utilize quality tools and materials for durability.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines helps create a secure working environment, allowing individuals to focus on their tasks effectively.

Here are essential precautions to consider:

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Disconnect the battery before starting any electrical work to prevent shocks.

- Keep tools organized and within reach to minimize the risk of accidents.

- Use jack stands when lifting the vehicle to ensure stability.

- Stay informed about potential hazards associated with specific components.

By following these safety measures, individuals can minimize risks and promote a secure atmosphere during maintenance tasks.