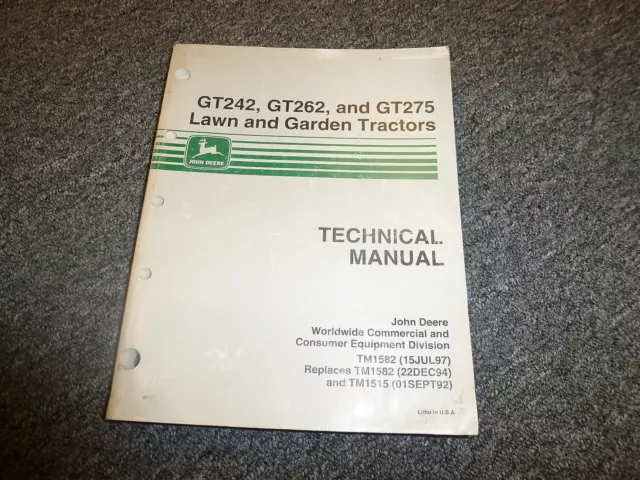

Complete Guide to John Deere GT262 Repair Manual

Effective upkeep of garden machinery is essential for optimal performance and longevity. Understanding the intricacies of your equipment not only enhances its functionality but also saves time and resources in the long run. This section provides invaluable insights into the common challenges faced by operators and offers practical solutions to ensure seamless operation.

Every machine has its unique characteristics and potential issues. Familiarizing yourself with the specifics of your device can empower you to tackle problems efficiently. From regular inspections to advanced troubleshooting techniques, mastering these skills will contribute to a smoother experience while utilizing your equipment.

In the following sections, we will explore detailed procedures and guidelines that will equip you with the knowledge necessary to maintain your machinery effectively. Whether you are a seasoned professional or a novice, this information aims to enhance your understanding and foster confidence in managing your tools.

Overview of John Deere GT262

This section provides a comprehensive examination of a specific model renowned for its efficiency and reliability in lawn care. Designed to meet the demands of both residential and commercial users, this machine combines robust features with user-friendly operation, making it a popular choice among enthusiasts.

Equipped with a powerful engine and advanced cutting technology, this model ensures optimal performance on various terrains. Its ergonomic design enhances comfort during extended use, while innovative features facilitate ease of maintenance and operation. This combination of power and practicality allows users to achieve exceptional results with minimal effort.

Additionally, this model supports a range of attachments and accessories, enhancing its versatility for different tasks. Whether tackling large lawns or navigating tight spaces, this machine adapts to various needs, making it an invaluable asset for outdoor maintenance.

Common Issues with GT262 Model

The GT262 model, like any piece of machinery, may encounter various challenges that can affect its performance and reliability. Understanding these common issues can aid in maintaining the equipment and ensuring its longevity. Below are some frequently observed problems along with suggestions for addressing them.

Electrical System Failures

One of the prevalent concerns is related to the electrical system. Symptoms may include difficulty starting the engine or flickering lights. These issues often stem from weak batteries, corroded connections, or faulty wiring. Regularly inspecting the battery and ensuring all connections are clean and secure can help mitigate these problems.

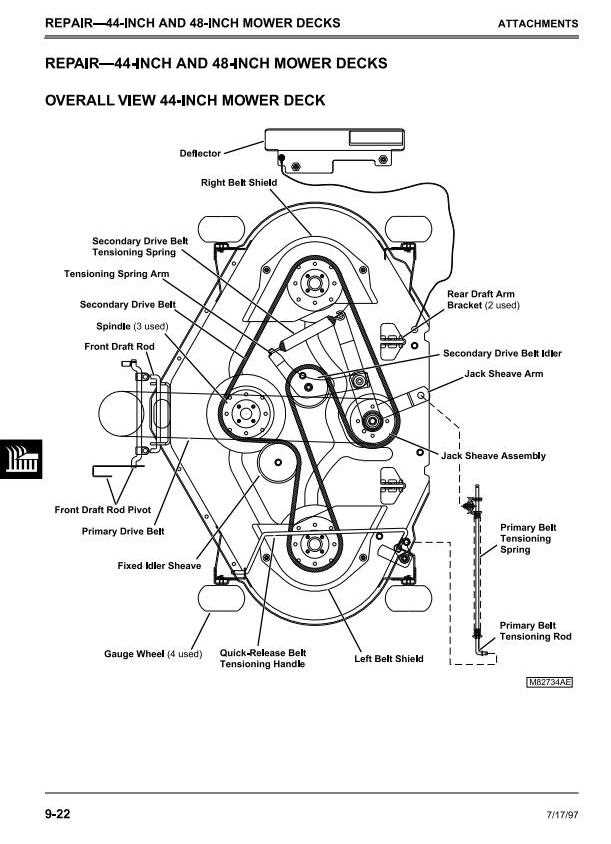

Cutting Deck Malfunctions

Another common problem involves the cutting deck. Users may notice uneven cuts or unusual noises while the mower is in operation. This can be attributed to dull blades, improper deck height settings, or debris buildup. It is essential to sharpen the blades regularly and clean the deck to maintain optimal performance.

Addressing these issues promptly can enhance the efficiency and functionality of the machinery, making it a valuable asset for years to come.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Proper upkeep not only extends the lifespan of the equipment but also enhances its performance and reliability. Following a few essential practices can lead to significant improvements in functionality and overall satisfaction.

Regular Cleaning: Keeping the exterior and engine components free of dirt and debris is crucial. Accumulated grime can lead to overheating and mechanical failures. Use a soft brush and a damp cloth to gently remove any buildup.

Fluid Checks: Frequently inspect all fluids, including oil, fuel, and coolant. Maintaining the appropriate levels and replacing fluids at recommended intervals is vital for optimal operation and preventing damage.

Tire Maintenance: Ensure tires are properly inflated and show no signs of wear or damage. Regularly checking tire pressure and rotating them can improve traction and extend their lifespan.

Inspection of Belts and Cables: Regularly examine belts and cables for fraying or wear. Replacing these components before they fail can prevent more extensive damage and costly repairs.

Storage Conditions: When not in use, store your equipment in a dry, sheltered environment. This helps protect it from the elements and reduces the risk of rust and corrosion.

Scheduled Servicing: Adhere to a regular maintenance schedule as outlined by the manufacturer. This can include professional inspections, tune-ups, and part replacements, which are essential for maintaining peak performance.

By implementing these practices, you can ensure that your machinery remains in excellent condition, ready to perform efficiently when needed.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is crucial for efficiency and effectiveness. Each project may require a unique set of instruments tailored to specific challenges, ensuring that all components are addressed properly.

Basic Hand Tools: A reliable set of hand tools forms the foundation of any maintenance endeavor. Essential items include wrenches, screwdrivers, and pliers. These tools facilitate the loosening and tightening of various parts, allowing for smooth disassembly and reassembly.

Specialized Equipment: For more intricate jobs, specialized devices may be necessary. Items such as torque wrenches and multimeters enable precise adjustments and diagnostics. Investing in high-quality, purpose-built tools can save time and enhance overall outcomes.

Safety Gear: Safety should never be overlooked. Appropriate protective gear, including gloves, goggles, and masks, helps prevent injuries and ensures a secure working environment. Prioritizing safety is as vital as the tools themselves.

Organizational Tools: Keeping tools organized can significantly streamline the process. Toolboxes, trays, and magnetic strips aid in maintaining an orderly workspace, minimizing the chances of losing essential instruments during a project.

In summary, preparing adequately with the right set of tools not only enhances productivity but also ensures that tasks are completed successfully and safely.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to troubleshooting and fixing various issues with your equipment. By following these detailed instructions, you can ensure optimal performance and extend the lifespan of your machine.

Initial Assessment

Before beginning any work, it’s crucial to evaluate the condition of your equipment. This includes:

- Inspecting for visible damage or wear.

- Checking fluid levels, such as oil and fuel.

- Listening for unusual noises during operation.

Basic Maintenance Steps

Regular upkeep can prevent many common problems. Follow these essential maintenance tasks:

- Clean the air filter regularly to ensure proper airflow.

- Change the oil and replace the oil filter as recommended.

- Sharpen or replace blades to maintain cutting efficiency.

- Inspect belts and cables for signs of fraying or damage.

By adhering to these procedures, you can maintain the functionality of your equipment and address any issues that arise effectively.

Understanding the Electrical System

The electrical system of any machinery plays a crucial role in its overall functionality. It encompasses various components that work together to ensure efficient operation, from powering essential systems to facilitating communication between different parts. A clear understanding of this system is vital for troubleshooting issues and maintaining optimal performance.

Key Components of the Electrical System

The primary elements of the electrical system include the battery, starter, alternator, and wiring harness. The battery stores electrical energy and provides the initial power needed to start the engine. Once the engine is running, the alternator generates electricity to recharge the battery and power the electrical accessories. The wiring harness connects these components, allowing for seamless communication and distribution of electrical energy throughout the machine.

Troubleshooting Electrical Issues

Identifying electrical problems requires a systematic approach. Common issues may stem from faulty connections, damaged wiring, or malfunctioning components. Regular inspection of the wiring harness and connectors can prevent potential failures. Using a multimeter to check voltage and continuity is essential for diagnosing problems effectively. By understanding how the electrical system operates, operators can address issues promptly and ensure reliable performance.

Safety Precautions During Repairs

When engaging in maintenance activities, ensuring safety should be a top priority. Proper precautions not only protect the individual performing the task but also safeguard the equipment and surrounding environment. By adhering to established safety guidelines, one can minimize the risk of accidents and injuries while maximizing efficiency.

Before starting any maintenance work, it is essential to equip yourself with the right protective gear. This includes gloves, goggles, and sturdy footwear to shield against potential hazards. Ensure that the workspace is well-lit and organized to prevent slips and falls.

Additionally, it is crucial to disconnect power sources before commencing any disassembly. This simple step can prevent electrical shocks and accidental starts. Familiarize yourself with the specific equipment’s components and follow recommended procedures to avoid mishaps.

Lastly, always keep a first-aid kit accessible and know how to use its contents. In the event of an emergency, prompt response can make a significant difference in outcomes. Remember, safety is an ongoing commitment that enhances not only personal well-being but also the integrity of the task at hand.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a daunting task. However, with the right approach and resources, this process can be streamlined significantly. The key lies in knowing where to search and how to identify quality items that will keep your equipment running smoothly.

Utilizing Online Resources

The internet is an invaluable tool for sourcing parts. Numerous websites specialize in providing extensive catalogs of various components. By entering the specific model or part number, users can quickly find what they need. Make sure to check reviews and ratings to ensure reliability and quality of the sellers.

Local Dealers and Salvage Yards

In addition to online options, local dealerships and salvage yards can be excellent resources. Authorized dealers often carry original components and can offer professional advice. Salvage yards, on the other hand, may have used parts at a fraction of the cost, which can be beneficial for budget-conscious repairs. Always verify the condition of the parts before making a purchase.

Service Schedule Recommendations

Maintaining equipment in optimal condition is crucial for performance and longevity. A well-structured service schedule helps ensure that all components operate smoothly and efficiently. Regular check-ups and maintenance tasks not only prevent unexpected breakdowns but also enhance the overall efficiency of the machine.

Here are key recommendations for an effective service schedule:

- Daily Inspections:

- Check fluid levels (oil, coolant, fuel).

- Inspect belts and hoses for wear.

- Ensure that all lights and signals are functional.

- Weekly Maintenance:

- Clean air filters to promote airflow.

- Lubricate moving parts to reduce friction.

- Inspect tires for proper pressure and wear.

- Monthly Checks:

- Change engine oil and replace the oil filter.

- Examine the battery and clean terminals.

- Inspect and tighten bolts and nuts.

- Seasonal Service:

- Perform a comprehensive inspection before heavy usage.

- Replace spark plugs and check ignition systems.

- Evaluate the condition of the fuel system.

Following these recommendations will help ensure the reliability and efficiency of your machinery, ultimately saving time and resources in the long run.

Upgrading Your GT262 Features

Enhancing your equipment can significantly improve its performance and functionality. By implementing a few strategic upgrades, you can tailor your machine to better suit your specific needs and tasks. This section explores various enhancements that can elevate your experience and productivity.

Consider the following upgrades:

- Engine Performance: Enhancing the engine can lead to better efficiency and power output. Look into performance kits or aftermarket parts that improve airflow and fuel delivery.

- Cutting Deck Modifications: Upgrading the cutting deck can improve grass cutting efficiency. Consider options such as high-lift blades or mulching kits for a cleaner cut.

- Suspension Improvements: Upgrading the suspension system can provide a smoother ride and better handling, especially on uneven terrain.

- Accessory Additions: Adding accessories like baggers, sprayers, or snow plows can extend the functionality of your machine, making it versatile for various tasks throughout the year.

Each upgrade can be tailored to your specific requirements, ensuring that your machine meets your expectations and enhances your overall experience. Before making any modifications, research the compatibility and potential benefits of each option to make informed decisions.