Ultimate Guide to Repairing Manual Transmissions

The intricate system that allows for smooth shifting and optimal performance is crucial for any vehicle. Understanding its components and functionality can empower owners to tackle issues effectively. A proactive approach to addressing malfunctions not only enhances driving experience but also prolongs the life of the vehicle.

Through a series of systematic steps, individuals can gain insights into the intricacies of the gear system. This process involves careful examination, assessment of any complications, and the implementation of effective solutions. Emphasizing attention to detail, one can navigate the complexities of this vital mechanism.

Equipped with the right tools and knowledge, enthusiasts can confidently delve into the nuances of their vehicle’s performance. The journey of restoring functionality opens the door to a deeper appreciation of automotive engineering, fostering a sense of accomplishment and connection with the vehicle.

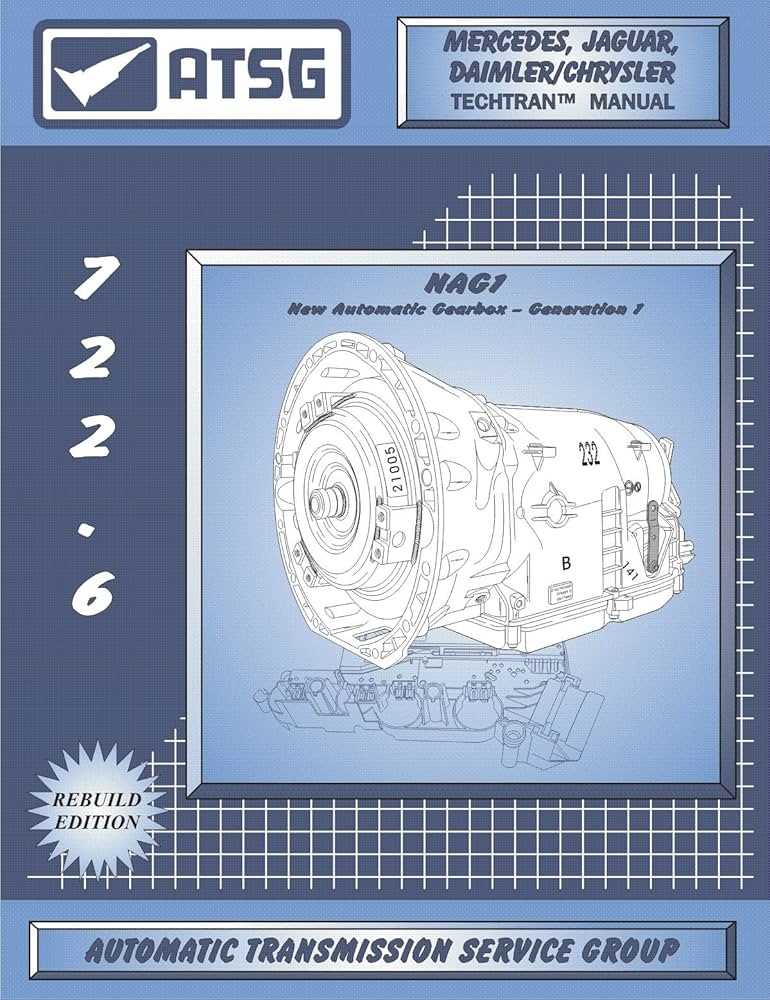

How to Repair Manual Transmission

This section outlines the essential steps for addressing issues with a specific vehicle component that facilitates gear shifting. Understanding the underlying mechanics and identifying common problems are crucial for effective resolution.

Common Issues and Diagnosis

Many individuals encounter challenges such as difficulty in shifting gears, unusual noises, or fluid leaks. Proper diagnosis begins with a thorough examination of symptoms and understanding the potential causes. Observing the performance and gathering information about the driving experience can help pinpoint the issue.

Steps for Restoration

Once the problem is identified, the process involves disassembling the relevant parts, inspecting for wear or damage, and replacing any faulty components. Reassembly should be carried out meticulously, ensuring all connections are secure. Finally, testing the functionality ensures that the issue has been successfully addressed.

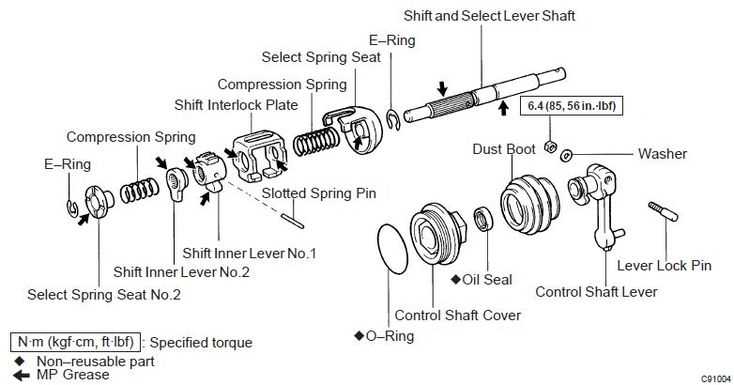

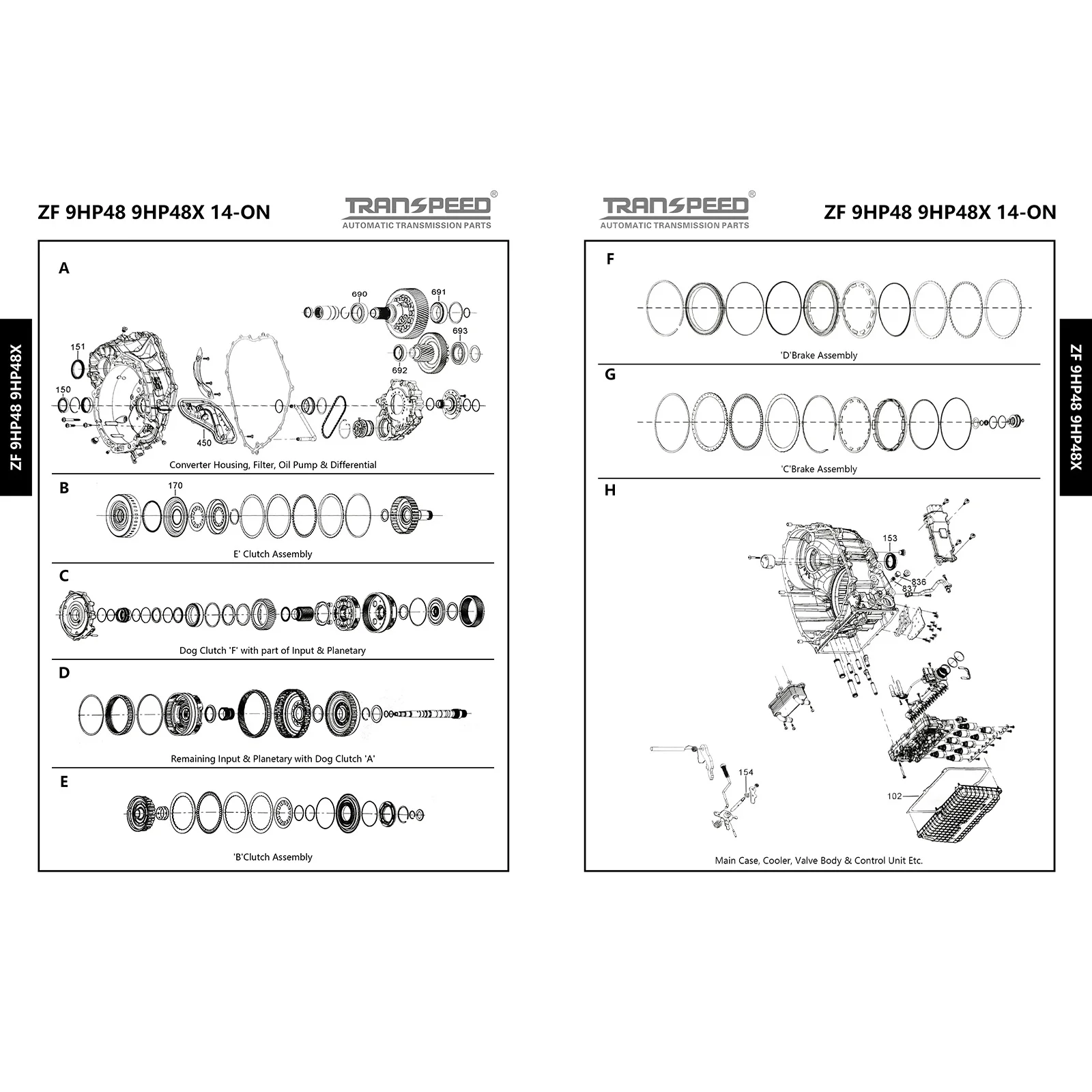

Understanding Manual Transmission Components

Exploring the intricate elements that enable the seamless operation of a vehicle’s gear-shifting mechanism provides valuable insight into its functionality. Each part plays a crucial role in ensuring efficient power transfer from the engine to the wheels, allowing for enhanced control and performance.

- Clutch: Engages and disengages the engine from the drivetrain, facilitating smooth gear changes.

- Gear Set: Comprises various gears that determine the vehicle’s speed and torque, each designed for specific functions.

- Shift Forks: Guide the gear selector into the desired position, ensuring accurate engagement of gears.

- Synchronizers: Help match the speeds of gears during shifting, preventing grinding and ensuring smooth transitions.

- Input Shaft: Connects the engine to the gear set, transmitting power for movement.

- Output Shaft: Transfers power from the gear set to the drive axles, ultimately driving the wheels.

- Housing: Encases all components, providing protection and structural integrity to the entire assembly.

Understanding these vital components enables better comprehension of the mechanisms at play, highlighting the importance of each in achieving optimal vehicle performance.

Common Issues in Manual Transmissions

Many drivers experience a range of challenges related to their vehicles’ gear-shifting systems. Identifying and understanding these problems can lead to more efficient handling and enhanced vehicle longevity.

1. Slipping Gears: This issue manifests when the vehicle unexpectedly changes gears or loses power during acceleration. It can be caused by worn components or insufficient fluid levels, leading to a frustrating driving experience.

2. Stiff Shifting: Difficulty in changing gears is often reported, particularly when the lever feels resistant. This may be attributed to low lubricant levels or the need for component replacement, affecting overall ease of use.

3. Unusual Noises: Strange sounds, such as grinding or clunking, can indicate underlying problems. These noises often arise from damaged gears or insufficient lubrication, signaling a need for further investigation.

4. Fluid Leaks: Observing fluid spots under the vehicle can be a clear sign of leakage. This not only impacts performance but also poses a risk of further damage if not addressed promptly.

5. Warning Lights: Illumination of dashboard indicators can alert drivers to issues within the gear-shifting mechanism. These alerts serve as crucial reminders to seek assistance before the situation escalates.

Tools Needed for Transmission Repair

To effectively address issues within a vehicle’s shifting system, it’s essential to have the right instruments at hand. Proper equipment ensures not only efficiency but also accuracy throughout the process. A well-organized toolkit can significantly enhance the experience, making it smoother and more productive.

Essential Hand Tools

Start with a basic set of hand tools, which includes wrenches, screwdrivers, and pliers. These items are crucial for loosening and tightening various components. Additionally, a ratchet and socket set will allow for easier access to bolts in tight spaces, making the job less cumbersome.

Specialized Equipment

For more complex tasks, specialized gear becomes necessary. A gear puller is vital for removing certain parts without damage. Furthermore, a torque wrench is indispensable for ensuring that fasteners are tightened to the manufacturer’s specifications, which is critical for the longevity of the components.

Preparing Your Vehicle for Repair

Before starting any maintenance work on your automobile, it is essential to ensure that the environment is conducive and all necessary preparations are made. This includes organizing your workspace and gathering the right tools and equipment needed for the task. Taking these preliminary steps can significantly enhance efficiency and safety during the procedure.

Begin by parking the vehicle on a flat, stable surface, and engage the parking brake to prevent any unintended movement. Ensure that you have adequate lighting in the workspace, which will help in identifying components and avoiding potential hazards. Additionally, it is advisable to disconnect the battery to eliminate any risk of electrical shocks while working.

Next, consult the vehicle’s documentation for specific guidelines and recommended practices. This can provide valuable insights into the intricacies of the automobile, making the process smoother. Lastly, wearing appropriate safety gear, such as gloves and goggles, will protect you from possible injuries and contaminants throughout the undertaking.

Draining Transmission Fluid Safely

Properly removing fluid from a vehicle’s shifting system is essential to ensure optimal performance and longevity. This process requires attention to detail and adherence to safety measures to prevent accidents and damage.

Gathering Necessary Tools

Before starting, collect all required tools and materials. A suitable container for collecting the old liquid, a funnel, and appropriate wrenches are essential. Additionally, having safety gloves and goggles will protect against spills and splashes.

Executing the Drainage Process

Begin by positioning the vehicle on a level surface and securing it with wheel chocks. Locate the drain plug, typically found on the underside of the system. Carefully remove the plug using the appropriate tool, allowing the fluid to flow into the collection container. Ensure that the area is well-ventilated, as fumes may be present.

Once the fluid has completely drained, replace the drain plug securely. Dispose of the old fluid according to local regulations to ensure environmental safety.

Removing the Transmission Assembly

In this segment, we will discuss the procedure for detaching the gear system from the vehicle. This critical task requires careful planning and attention to detail to ensure all components are handled correctly and safely.

Preparation Steps

Before commencing the detachment, gather all necessary tools and equipment. It’s essential to create a clean and organized workspace, as this will facilitate the process and minimize the risk of losing parts. Ensure that the vehicle is securely lifted and supported to provide adequate access to the assembly.

Detachment Process

Start by disconnecting all relevant connections, such as electrical and hydraulic lines. Pay close attention to the mounting bolts; these often require specific tools to remove. Once all connections are cleared, carefully lower the assembly from its position, taking care to avoid damaging surrounding components. Ensure that you follow safety protocols throughout this process to protect yourself and the vehicle.

Inspecting Gears and Synchros

Evaluating the internal components of a vehicle’s power transfer system is essential for ensuring optimal performance. This process involves examining various parts for signs of wear, damage, or misalignment. Attention to detail during this stage can help identify issues that may lead to operational failures.

Visual Examination

Start with a thorough visual assessment of the gears and synchronizers. Look for any visible wear patterns, such as scoring or pitting. Damaged teeth on the gears can cause shifting difficulties and should be noted. Additionally, check for any unusual discoloration, which might indicate overheating.

Functional Testing

Next, perform a functional test of the synchronizers. Ensure they engage smoothly when shifting. Any grinding or excessive resistance could suggest that these components are not functioning correctly. Proper synchronization is crucial for seamless gear changes, and any irregularities should be addressed promptly to maintain efficiency.

Replacing Worn Components Effectively

Ensuring optimal performance of mechanical systems often requires timely replacement of deteriorated parts. This process not only enhances efficiency but also prolongs the lifespan of the entire assembly. Addressing wear issues can prevent more severe complications down the line.

To achieve effective replacement, consider the following steps:

- Assessment: Begin with a thorough evaluation of the components to identify those that exhibit signs of wear or damage.

- Selection of Parts: Source high-quality replacements that meet or exceed the original specifications. This ensures compatibility and durability.

- Preparation: Gather necessary tools and workspace. A clean and organized area can facilitate a smoother process.

- Removal: Carefully extract the worn components, taking note of their arrangement for accurate reinstallation.

- Installation: Position the new parts precisely, following the manufacturer’s guidelines to avoid misalignment.

- Testing: After installation, conduct tests to verify that the system operates as intended and that all components function harmoniously.

By adhering to these steps, individuals can effectively manage the replacement of degraded components, ensuring improved functionality and reliability.

Reassembling the Transmission Unit

Reassembling the mechanical assembly requires careful attention to detail and a methodical approach. Each component must be aligned properly to ensure optimal functionality and longevity of the system. It is essential to follow a structured sequence during the assembly process to prevent any mishaps or misalignment.

Begin by gathering all necessary parts and tools, ensuring everything is clean and free of debris. This will facilitate a smoother assembly and help avoid contamination. Start with the main casing, placing it in an appropriate position for easy access. Gradually introduce internal components, such as gears and shafts, making certain each piece fits snugly and securely.

As you progress, pay close attention to the installation of seals and gaskets, as these are crucial for maintaining pressure and preventing leaks. Once all parts are in place, double-check the alignment and fit of each component. This final inspection is vital to catch any potential issues before completing the assembly.

Finally, securely fasten all covers and housings, ensuring that everything is tightened according to the manufacturer’s specifications. This step is critical to achieving the desired performance and reliability of the system. With everything in position, the assembly is complete, and the unit is ready for reinstallation.

Refilling Transmission Fluid Properly

Maintaining the appropriate level of fluid is essential for ensuring optimal performance in your vehicle’s gearbox system. This process involves careful attention to detail and adherence to specific procedures to guarantee efficiency and prevent potential issues.

Gather Necessary Tools

Before starting, ensure you have all required tools and materials on hand. This includes a funnel, the correct type of fluid recommended by the manufacturer, and a clean cloth to catch any spills. Proper preparation will make the process smoother and more effective.

Follow the Correct Procedure

Begin by locating the fill plug and removing it carefully. Use the funnel to add the fluid gradually, checking the level regularly to avoid overfilling. Once you achieve the recommended level, securely replace the plug. Clean up any spills to maintain a tidy workspace and ensure safety.

Testing Your Repair Work

After completing the necessary adjustments, it’s essential to verify the effectiveness of your efforts. This phase ensures that everything is functioning as intended, helping to prevent future issues.

Begin by engaging the vehicle in a safe environment, ideally on a level surface. Start the engine and allow it to warm up. Pay attention to any unusual sounds or vibrations that may indicate underlying problems.

Next, test the gear shifting. Move through each gear slowly and deliberately, ensuring smooth transitions. If you experience any resistance or grinding noises, it may suggest that further investigation is needed.

Additionally, monitor the response during acceleration. A well-functioning system should provide seamless power delivery without hesitation. If there are any noticeable delays or stuttering, it may be a sign of improper adjustments.

Lastly, perform a brief road test. This practical examination allows you to assess the overall performance under real driving conditions. Note how the vehicle behaves when navigating turns and inclines, ensuring it meets expected standards.

In conclusion, diligent testing not only confirms the quality of your work but also enhances safety and reliability for future use.