Repair Manual for Deep Carpet Cleaner Parts Diagram

Effective maintenance of cleaning devices is crucial for optimal performance and longevity. A thorough understanding of their various elements enables users to address issues and ensure that the machinery operates smoothly. This knowledge not only enhances efficiency but also prolongs the lifespan of the equipment.

By familiarizing oneself with the layout and function of each component, operators can swiftly identify potential problems and take appropriate action. This insight empowers users to troubleshoot effectively, ultimately saving time and resources in the cleaning process.

Additionally, recognizing the intricacies of the device can enhance the overall cleaning experience, making it more efficient and less time-consuming. Whether you’re seeking to replace a worn-out element or simply wishing to understand your equipment better, a detailed exploration of its features is invaluable.

Repair Manual for Carpet Cleaner

The following section provides guidance on maintaining and restoring your cleaning equipment. It aims to assist users in understanding common issues and troubleshooting techniques to ensure optimal performance.

To begin, it’s essential to familiarize yourself with the main components of your device. Understanding how each part functions can greatly aid in identifying problems when they arise. Regular checks and maintenance routines can prevent many issues from escalating.

Common Issues

Devices may encounter several typical challenges, such as loss of suction, inadequate cleaning results, or unusual noises. Each of these symptoms can often be traced back to a specific component malfunctioning or needing adjustment.

Troubleshooting Steps

Start by examining the filters and hoses for blockages. Cleaning or replacing these elements can often resolve suction problems. Additionally, inspect any moving parts for signs of wear and tear, as this can affect overall functionality.

Maintenance Tips

To prolong the lifespan of your equipment, establish a routine that includes cleaning filters, checking connections, and ensuring all parts are securely fitted. Regular upkeep not only enhances performance but also prevents the need for extensive repairs down the line.

Understanding the Device’s Components

Grasping the various elements of this appliance is essential for effective operation and maintenance. Each part plays a crucial role in ensuring optimal functionality, contributing to the overall performance of the unit.

The primary structure encompasses a housing that encases the internal mechanisms, providing both support and protection. Within this framework, you’ll find an array of components designed to facilitate the desired outcomes, including a motor, which drives the necessary functions, and a fluid reservoir that stores cleaning solutions.

Additionally, various attachments enhance versatility, allowing users to tackle different cleaning scenarios with ease. Understanding how these components interact can significantly improve the efficiency of the appliance, leading to better results.

Common Issues and Troubleshooting Tips

When using a cleaning device, it’s not uncommon to encounter various challenges that can affect performance. Understanding these common problems and knowing how to address them can significantly enhance your cleaning experience. Below are some typical issues users face, along with practical solutions to resolve them.

Inadequate Cleaning Performance

If the appliance is not effectively removing dirt and stains, consider checking the water levels and ensuring the cleaning solution is correctly mixed. Clogged hoses or filters can also hinder performance, so it’s advisable to inspect these components regularly. Additionally, using the right cleaning solution can greatly impact the overall effectiveness of the device.

Device Not Turning On

If you find that the equipment fails to power up, first verify that it is properly plugged in. Inspect the power cord for any visible damage. A tripped circuit breaker may also be a factor; resetting it could resolve the issue. If the problem persists, consider checking internal connections or seeking professional assistance.

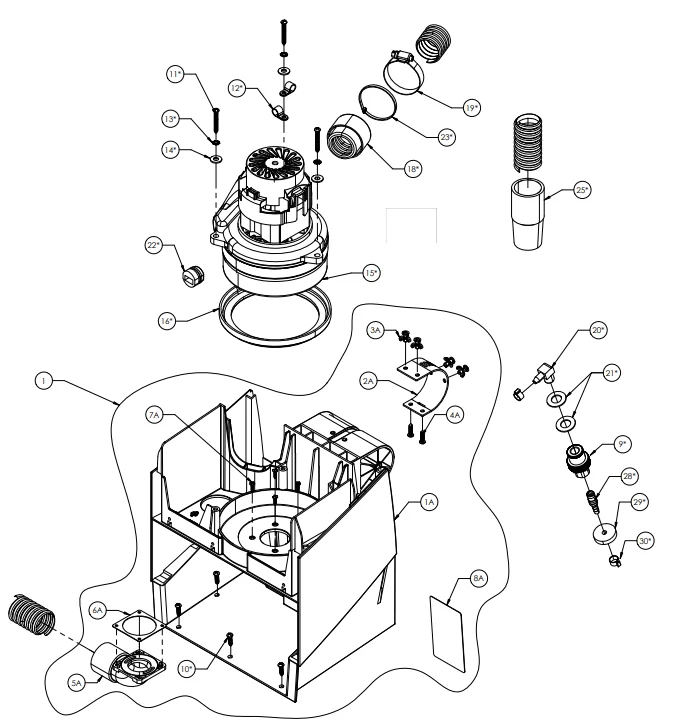

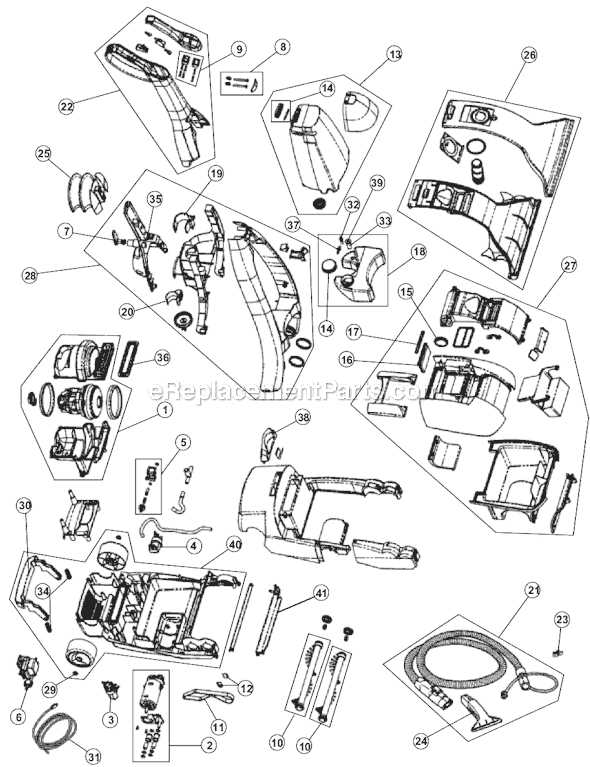

Parts Identification Guide

This section provides a comprehensive overview for recognizing and understanding the various components of your cleaning device. Familiarizing yourself with these elements can enhance your operational efficiency and maintenance practices.

To begin, it is essential to categorize the different sections of the equipment. Each component plays a vital role in ensuring optimal performance. For instance, the motor assembly is crucial for generating the necessary power, while the housing protects the internal mechanisms.

Identifying Components: Start by examining the exterior of the unit. Key features such as the handle, control panel, and water tanks should be easily recognizable. Next, focus on the internal mechanisms, where you will find parts such as the suction fan and filtration system.

Maintenance Tips: Regular inspection of these components not only prolongs the lifespan of your equipment but also improves its overall effectiveness. Look out for signs of wear and ensure that all connections are secure.

Maintenance Procedures for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention. Implementing a structured maintenance routine can significantly extend the lifespan of your device, preventing potential issues and enhancing performance.

To achieve optimal results, consider the following essential practices:

- Regular Cleaning: Routinely remove dirt and debris from the exterior and interior components to prevent buildup that can lead to malfunctions.

- Check and Replace Filters: Monitor filters for clogs or wear, and replace them as necessary to maintain airflow and efficiency.

- Inspect Hoses and Connections: Regularly examine hoses for leaks or damage, ensuring all connections are secure and intact.

- Monitor Performance: Keep an eye on the overall functionality; any changes in operation may indicate the need for further inspection.

- Store Properly: After use, store the equipment in a cool, dry place, protecting it from extreme temperatures and moisture.

By adhering to these maintenance strategies, you can safeguard your investment and ensure that your equipment remains in peak condition for years to come.

How to Disassemble the Cleaner

Taking apart your appliance can be a straightforward process if approached methodically. Understanding the various components and their connections is essential for effective disassembly. Follow these steps to ensure a smooth experience while maintaining the integrity of the unit.

Preparation Steps

- Gather necessary tools, such as a screwdriver and pliers.

- Ensure the device is unplugged to avoid any electrical hazards.

- Find a clean, spacious area to work, minimizing the risk of losing small parts.

Disassembly Process

- Start by removing any removable sections, such as tanks or covers.

- Locate the screws holding the main body together and carefully unscrew them.

- Gently separate the outer casing from the inner components, being mindful of any clips or fasteners.

- Take note of the arrangement of parts for easier reassembly.

By following these guidelines, you will be able to effectively take apart your device for maintenance or inspection. Ensure to handle each component with care to avoid damage.

Replacing Worn-Out Parts

Over time, certain components of your cleaning device may experience wear and tear, leading to decreased efficiency and performance. Regularly assessing and updating these elements is crucial for maintaining optimal functionality. Identifying which components require attention and understanding how to replace them can significantly enhance your equipment’s longevity.

Common Components Needing Replacement

Several components are frequently subject to wear. It is essential to recognize which parts typically need replacing and to address them promptly to ensure seamless operation.

| Component | Signs of Wear | Replacement Frequency |

|---|---|---|

| Belt | Fraying or cracking | Every 6-12 months |

| Brush Roll | Reduced agitation | Every 1-2 years |

| Filter | Clogging or discoloration | Every 3-6 months |

Steps for Replacement

To replace worn components, follow these straightforward steps: first, ensure the equipment is unplugged. Next, consult your specifications to locate the component in question. Carefully remove the old part and install the new one, making sure it is secured properly. Finally, reconnect your device and perform a test run to verify functionality.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. It is essential to adopt proper practices and follow guidelines that minimize risks associated with the process.

Before beginning any work, make sure to gather all necessary tools and materials. This preparation helps to avoid distractions and reduces the likelihood of accidents. Always work in a well-ventilated area to prevent inhalation of harmful substances.

| Safety Tip | Description |

|---|---|

| Disconnect Power | Always unplug the device before starting any task to eliminate the risk of electrical shock. |

| Wear Protective Gear | Use appropriate safety equipment, such as gloves and goggles, to protect yourself from potential hazards. |

| Read Instructions | Familiarize yourself with the guidelines and safety information relevant to the task at hand. |

| Keep Workspace Organized | A tidy work area reduces the risk of tripping and helps maintain focus. |

By adhering to these precautions, you can create a safer environment that allows for effective and efficient maintenance activities.

Tools Required for Repairs

When addressing maintenance tasks for a cleaning device, having the right instruments is essential for efficient execution. This section outlines the necessary tools that facilitate the upkeep and restoration process, ensuring optimal functionality.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and secure various screws during disassembly and assembly. |

| Pliers | To grip, twist, and cut wires or small components as needed. |

| Wrench Set | To loosen or tighten bolts and nuts that may be part of the assembly. |

| Replacement Parts | To replace worn or damaged components ensuring optimal performance. |

| Cleaning Supplies | To clean internal parts for better performance and longevity. |

Detailed Parts Diagram Overview

This section provides an in-depth look at the various components of the equipment, showcasing how each element contributes to its overall functionality. Understanding the arrangement and purpose of these elements is crucial for effective operation and maintenance.

Component Breakdown

Each segment of the apparatus serves a unique role, enhancing performance and user experience. Familiarity with these sections allows for more informed handling and troubleshooting.

Visual Representation

| Component | Description |

|---|---|

| Housing | Protective outer shell ensuring durability and safety. |

| Motor | Power source driving the operational elements. |

| Tank | Container for the fluid used in the cleaning process. |

| Brush | Rotating element that agitates dirt and debris. |

Cleaning Techniques for Optimal Performance

To achieve the best results in maintaining and refreshing textiles, employing effective methods is essential. By understanding various approaches, one can enhance efficiency and prolong the lifespan of cleaning equipment.

Here are some recommended techniques to ensure optimal operation:

| Technique | Description |

|---|---|

| Pre-Treatment | Applying a suitable solution to loosen dirt and stains before the main process can significantly improve effectiveness. |

| Regular Maintenance | Consistently checking and cleaning filters and brushes ensures that the apparatus functions smoothly and efficiently. |

| Water Temperature | Using warm water can enhance the cleaning solution’s ability to break down grime and debris, leading to better outcomes. |

| Slow Passes | Taking your time while operating the machine allows the solution to penetrate deeper into fibers, yielding superior results. |

By incorporating these techniques into your routine, you can significantly improve the effectiveness of your cleaning endeavors.

Assembly Instructions After Repairs

After completing the maintenance tasks, it’s essential to properly reassemble the unit to ensure optimal functionality. Following a systematic approach will facilitate a smooth assembly process, minimizing the risk of errors.

Begin by gathering all components that need to be reattached. Make sure each part is clean and free from debris, as this will enhance performance. Refer to the following table for guidance on the assembly sequence:

| Step | Description |

|---|---|

| 1 | Attach the base to the main body, ensuring all clips are securely fastened. |

| 2 | Reconnect the hoses, making sure they are seated properly to prevent leaks. |

| 3 | Install the filtration components, ensuring they are oriented correctly. |

| 4 | Affix the handle, verifying that it locks into place for stability during operation. |

| 5 | Final checks: inspect all connections and ensure that no parts are loose. |

Once assembly is complete, conduct a brief test to confirm that everything operates as intended. This ensures longevity and reliability for future use.

Where to Find Replacement Parts

Locating suitable components for maintenance or upgrading your equipment can greatly enhance its performance and longevity. Whether you’re seeking original or compatible alternatives, several avenues can provide access to the necessary items.

Online Retailers

Numerous websites specialize in selling various components. Here are some popular options:

- Manufacturer’s official website

- Dedicated appliance parts retailers

- General e-commerce platforms

Local Stores

Visiting local shops can also yield results. Consider checking:

- Home improvement centers

- Specialized appliance repair shops

- General hardware stores

Before purchasing, it’s advisable to compare prices and check the compatibility of the components to ensure optimal functionality.