Comprehensive Guide for 1993 Chevy Lumina Repairs

In the realm of automotive care, having access to a detailed resource can significantly enhance the ownership experience. This collection of information serves as an essential companion for enthusiasts and owners alike, aiming to provide clarity and understanding of various components and systems within the vehicle.

By delving into this repository, readers will uncover insights into troubleshooting common issues, performing routine upkeep, and exploring the intricacies of the automobile’s functionality. Such knowledge not only fosters a deeper appreciation for the engineering behind the vehicle but also empowers individuals to take charge of their maintenance tasks.

Equipped with this valuable information, one can confidently approach any challenge that arises, ensuring optimal performance and longevity. Whether you are a seasoned expert or a novice, this guide is designed to assist every step of the way, making the journey of vehicle ownership more rewarding and manageable.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance tasks. A well-equipped workspace enhances efficiency and simplifies the process, making it easier to tackle various challenges that may arise during vehicle upkeep.

Start with a reliable set of hand tools, including wrenches, screwdrivers, and pliers. These basic items form the foundation of any toolkit, allowing for a wide range of adjustments and modifications. Additionally, socket sets provide versatility for tightening or loosening fasteners in hard-to-reach areas.

Investing in diagnostic equipment is also beneficial. Such tools help identify issues promptly, enabling quicker resolutions. A multimeter, for instance, can assess electrical systems, while code readers are invaluable for interpreting trouble codes from the vehicle’s onboard computer.

Safety gear should not be overlooked. Gloves, goggles, and protective clothing ensure personal safety while working on various components. Keeping the workspace organized with storage solutions enhances productivity and prevents misplacement of tools.

Common Issues with Chevy Lumina

This section explores frequent challenges encountered by vehicle owners, highlighting typical problems that may arise over time. Understanding these common issues can assist in proactive maintenance and enhance overall vehicle longevity.

Mechanical Concerns

Several mechanical aspects may lead to complications, impacting the driving experience:

- Engine performance inconsistencies

- Transmission shifting difficulties

- Brake system wear and effectiveness

Electrical Problems

Electrical systems can often be a source of frustration, with common failures including:

- Battery drainage issues

- Faulty lighting systems

- Malfunctioning dashboard indicators

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to vehicle upkeep, ensuring optimal performance and longevity. Regular attention to various systems not only enhances reliability but also prevents costly repairs in the future.

- Begin with an overall inspection of the exterior and interior.

- Check fluid levels, including oil, coolant, and brake fluid.

- Examine tire pressure and tread depth for safety.

- Inspect the battery for corrosion and ensure secure connections.

Following these preliminary checks, proceed with more detailed tasks:

-

Engine Maintenance:

- Change engine oil and replace the oil filter as recommended.

- Inspect air and fuel filters for cleanliness and replace if necessary.

-

Brake System Inspection:

- Check brake pads and rotors for wear.

- Examine brake lines for leaks and damage.

-

Cooling System Care:

- Flush the cooling system and replace coolant as specified.

- Inspect hoses for cracks and ensure clamps are tight.

Regular maintenance tasks not only keep the vehicle running smoothly but also enhance safety and performance. Following this guide can help you manage upkeep efficiently.

Understanding Engine Specifications

Grasping the nuances of powertrain attributes is essential for effective vehicle maintenance and performance optimization. This section delves into key elements that define engine characteristics, influencing both efficiency and functionality. A comprehensive understanding can aid in diagnosing issues and enhancing overall vehicle performance.

Key Attributes of Powertrains

Engine specifications encompass various aspects, including displacement, configuration, and fuel type. Displacement refers to the total volume of all cylinders, impacting power output and efficiency. The configuration of the engine, whether inline, V-shaped, or flat, affects balance and smoothness during operation. Additionally, the choice of fuel type significantly influences combustion efficiency and emissions.

Importance of Performance Metrics

Performance metrics such as horsepower and torque are critical indicators of engine capability. Horsepower signifies the engine’s power to perform work over time, while torque reflects the rotational force available, crucial for acceleration. Understanding these metrics helps in evaluating an engine’s capability to meet driving demands effectively.

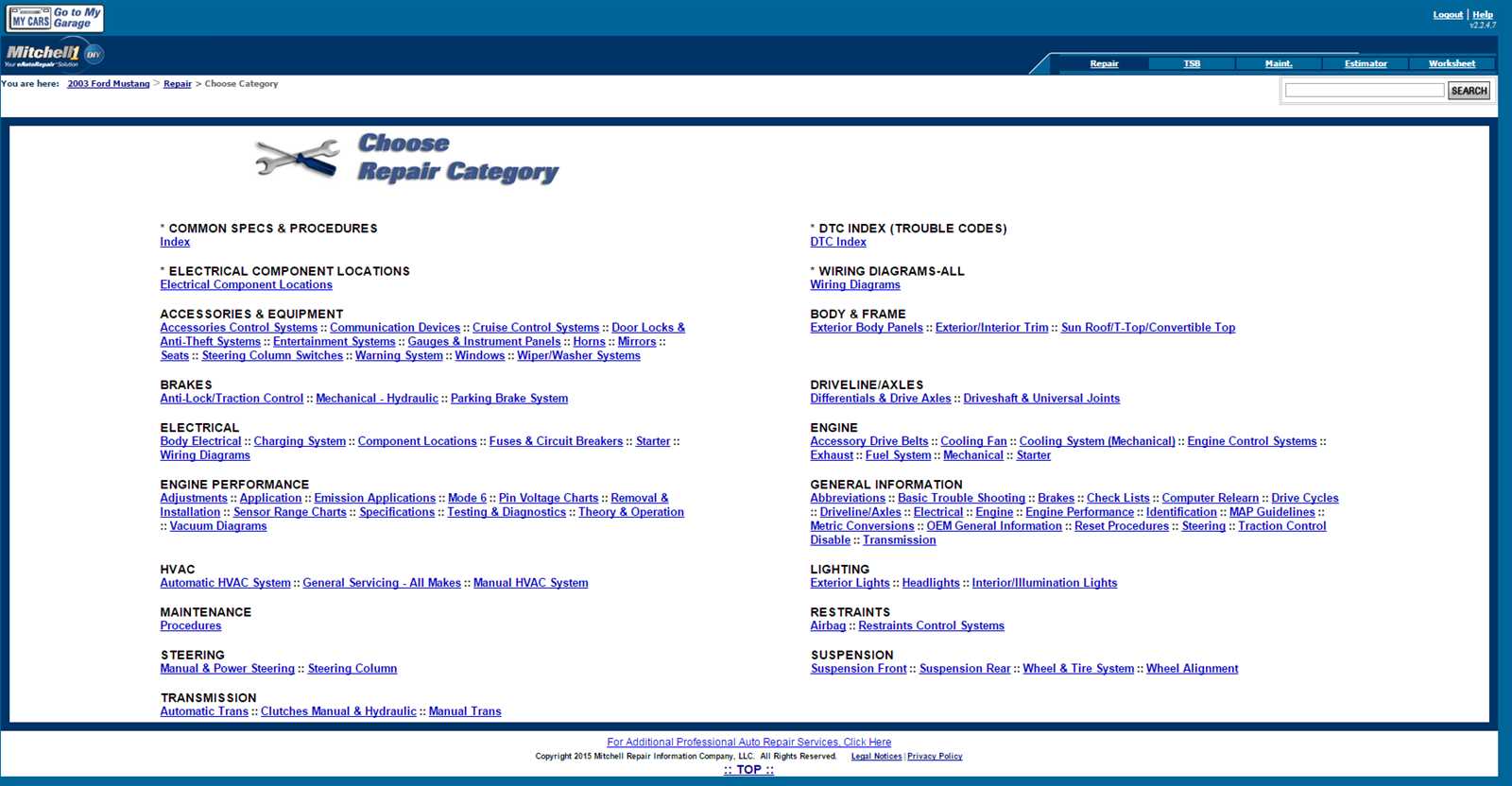

Electrical System Troubleshooting Tips

Addressing issues within the electrical framework of a vehicle requires a systematic approach. Understanding how to identify and rectify common malfunctions can significantly enhance performance and reliability.

1. Check Battery Health: Ensure the battery is functioning properly. Inspect terminals for corrosion and verify connections are secure. A multimeter can help assess voltage levels.

2. Inspect Fuses: Blown fuses can disrupt electrical circuits. Regularly examine the fuse box and replace any damaged components to restore functionality.

3. Examine Wiring Integrity: Look for signs of wear or damage in the wiring harness. Frayed or broken wires can lead to intermittent issues or complete failures.

4. Test Switches: Verify that switches operate correctly. Malfunctions in light switches or ignition systems can create problems that are easily overlooked.

5. Assess Ground Connections: A poor ground can result in erratic behavior of electrical systems. Ensure that ground connections are clean and tightly secured.

6. Utilize Diagnostic Tools: Employing diagnostic equipment can provide valuable insights into the state of the electrical system. Scanners can detect fault codes that assist in pinpointing issues.

By following these troubleshooting tips, vehicle owners can effectively address electrical concerns and maintain optimal operation.

Brake System Inspection Procedures

Ensuring the functionality of the braking mechanism is vital for vehicle safety. Regular assessments can help identify issues before they escalate, contributing to overall performance and reliability.

The following steps outline a comprehensive approach to evaluating the braking system:

- Begin by examining the brake fluid level. Ensure it is within the recommended range.

- Check for any visible leaks around brake lines and components.

- Inspect the brake pads for wear. Replace them if they appear excessively thin.

- Examine the rotors for signs of warping or scoring. Ensure they are smooth and even.

- Test the functionality of the brake calipers. Look for any sticking or uneven movement.

Following these inspection steps regularly can help maintain optimal braking performance and enhance safety on the road.

Suspension and Steering Care

Maintaining the suspension and steering systems is crucial for ensuring a smooth and safe driving experience. Regular attention to these components helps prevent wear and enhances vehicle stability, allowing for better handling and comfort on the road.

Regular Inspections are essential for identifying any potential issues early. Check for signs of wear in components such as shock absorbers and ball joints, as well as ensuring that steering links are properly aligned. Listening for unusual noises while turning can also indicate underlying problems that need addressing.

Fluid Levels should be monitored consistently. Ensure that the power steering fluid is at the appropriate level and free of contaminants. Low fluid levels can lead to increased wear and tear, ultimately affecting the performance of the steering system.

Tire Maintenance plays a vital role in overall suspension health. Keeping tires properly inflated and rotated promotes even wear and helps maintain optimal handling characteristics. Additionally, regular alignment checks can prevent uneven tire wear and improve steering response.

By following these guidelines, drivers can ensure that their vehicle’s suspension and steering systems remain in excellent condition, contributing to a safer and more enjoyable driving experience.

Cooling System Servicing Insights

Maintaining optimal functionality within a vehicle’s thermal management system is crucial for preventing overheating and ensuring efficient performance. This section explores key considerations and best practices for keeping this vital system in peak condition.

Regular inspections and timely interventions can significantly enhance longevity and reliability. Here are some essential aspects to consider during servicing:

| Service Task | Recommended Frequency | Notes |

|---|---|---|

| Coolant Level Check | Monthly | Ensure proper levels for effective heat dissipation. |

| Radiator Flush | Every 2 Years | Removes debris and prevents corrosion. |

| Thermostat Inspection | As Needed | Replace if it fails to regulate temperature. |

| Hoses and Clamps Check | Every 6 Months | Look for wear and replace damaged components. |

By adhering to these guidelines, vehicle owners can ensure their thermal management systems operate efficiently, thus enhancing overall performance and reliability.

Transmission Overhaul Process

This section outlines the essential steps involved in revitalizing a vehicle’s shifting mechanism. Properly executing this procedure can significantly enhance performance and longevity. Following a systematic approach ensures that all components are carefully inspected, cleaned, and reassembled to function optimally.

Disassembly and Inspection

Begin by removing the unit from the vehicle. Carefully document the arrangement of parts to simplify reassembly. Once disassembled, examine each component for wear and damage. Pay particular attention to gears, seals, and bearings, as these elements are critical for smooth operation. Any signs of deterioration should be addressed with replacements.

Reassembly and Testing

After ensuring all parts are in satisfactory condition, proceed with reassembly. Utilize appropriate lubricants to facilitate smooth interactions between components. Once fully assembled, conduct thorough testing to verify functionality. Monitor for any irregularities during operation, as they may indicate further adjustments or repairs are needed.

Safety Precautions During Repairs

Ensuring personal safety while working on vehicles is paramount. Understanding potential hazards and taking proactive measures can significantly reduce the risk of accidents. This section outlines essential practices that should be followed to maintain a secure environment during maintenance tasks.

Protective Gear: Always wear appropriate personal protective equipment, such as gloves and safety glasses. This attire minimizes the risk of injury from sharp objects or harmful substances.

Workspace Organization: Keep the workspace tidy and free from clutter. A well-organized area helps prevent tripping hazards and allows for easier access to tools and components.

Proper Ventilation: Ensure adequate airflow in the workspace, especially when working with chemicals or running the engine. Good ventilation helps reduce exposure to fumes that can be harmful to health.

Tool Safety: Use tools correctly and maintain them in good condition. Regular inspections can prevent malfunction and ensure that equipment operates safely.

Emergency Preparedness: Familiarize yourself with emergency procedures and keep first aid supplies readily available. Knowing how to respond in case of an accident is crucial for ensuring safety.

By adhering to these guidelines, individuals can foster a safer environment while undertaking automotive tasks, ultimately leading to more efficient and secure work.