John Deere Gator 6×4 Repair Guide

Maintaining a utility vehicle is essential for optimal performance and longevity. Understanding how to address common issues and execute regular upkeep can greatly enhance the functionality of this versatile equipment. This section aims to provide detailed insights into the various aspects of caring for your vehicle, ensuring that it remains in peak condition.

Through systematic guidance, owners can navigate challenges efficiently. Whether it’s routine inspections or more complex adjustments, having access to reliable information empowers users to manage their machines effectively. Proper knowledge not only facilitates smoother operations but also fosters confidence in handling repairs and modifications.

By embracing a proactive approach to maintenance, operators can minimize downtime and extend the service life of their equipment. This guide serves as a valuable resource, equipping users with the necessary tools and understanding to keep their vehicles performing at their best.

John Deere Gator 6×4 Overview

This section provides an insightful look into a versatile utility vehicle designed for rugged outdoor tasks. Its robust construction and practical features make it a reliable companion for both work and recreation.

Key Features

- Powerful engine for efficient performance

- Ample cargo capacity for transporting materials

- All-terrain capabilities for diverse environments

- Ergonomic design for user comfort

Applications

The vehicle is well-suited for various tasks, including:

- Agricultural work

- Landscaping and maintenance

- Construction site operations

- Recreational activities

With its reliable functionality, this model stands out in its category, ensuring both efficiency and durability for everyday tasks.

Essential Maintenance Procedures

Regular upkeep is crucial for ensuring optimal performance and longevity of utility vehicles. Implementing a structured maintenance routine helps prevent unexpected breakdowns and promotes safety during operation.

Routine Inspections

Conducting frequent assessments of key components is essential. Check the fluid levels, tire pressure, and battery condition. Inspect belts and hoses for any signs of wear or damage, and ensure that all connections are secure. Documenting findings allows for timely interventions and informed decisions regarding replacements.

Cleaning and Lubrication

Maintaining cleanliness is vital to the functionality of moving parts. Regularly clean the vehicle’s exterior and undercarriage to remove debris that may affect performance. Additionally, applying appropriate lubricants to joints and pivot points minimizes friction and reduces wear. Proper lubrication extends the lifespan of mechanical components and enhances overall efficiency.

Troubleshooting Common Issues

Addressing typical problems that may arise with utility vehicles is essential for maintaining optimal performance. Understanding the common symptoms and potential solutions can save time and enhance reliability.

Below are frequent issues along with their possible causes and remedies:

- Starting Difficulties:

- Check the battery connections for corrosion or looseness.

- Inspect the ignition system for faults.

- Ensure the fuel tank has sufficient fuel.

- Poor Engine Performance:

- Examine the air filter for blockages.

- Verify fuel quality and supply.

- Check for any leaks in the fuel system.

- Transmission Issues:

- Inspect the fluid levels and condition.

- Look for any unusual noises during operation.

- Examine the gear shifting mechanism for proper function.

By systematically evaluating these common issues, users can effectively troubleshoot and maintain their vehicles.

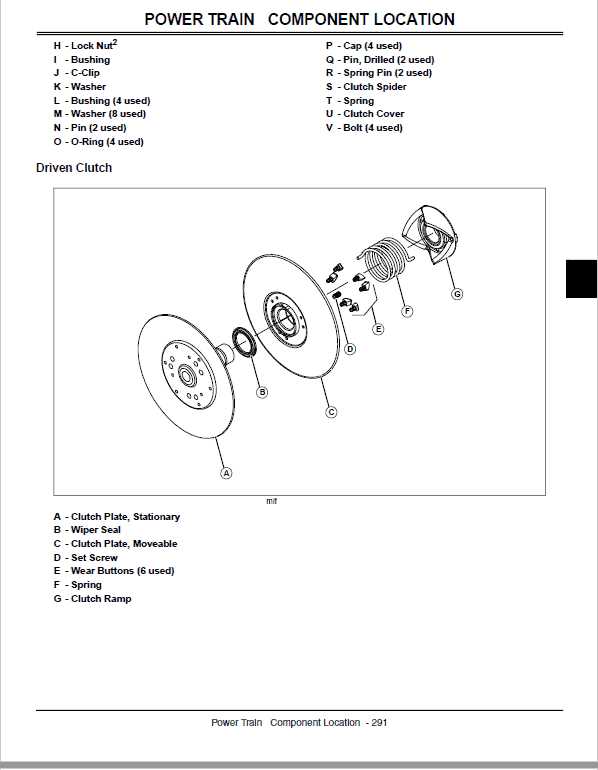

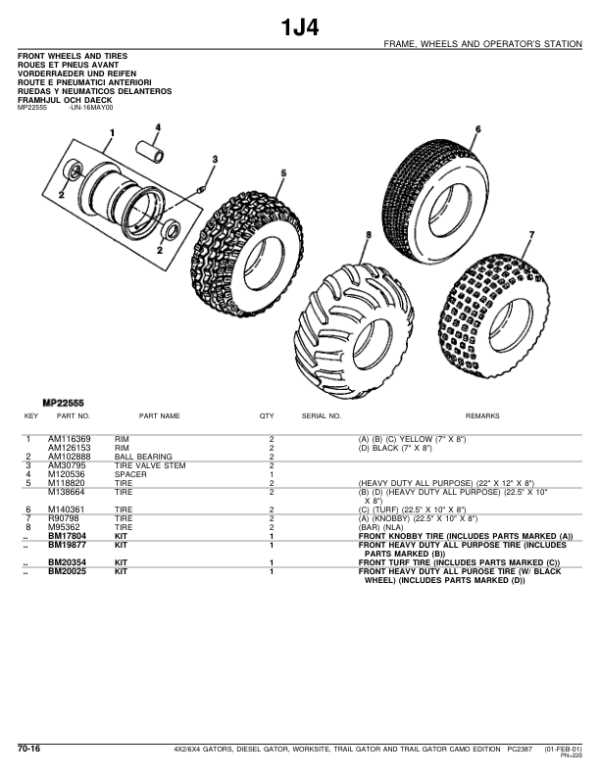

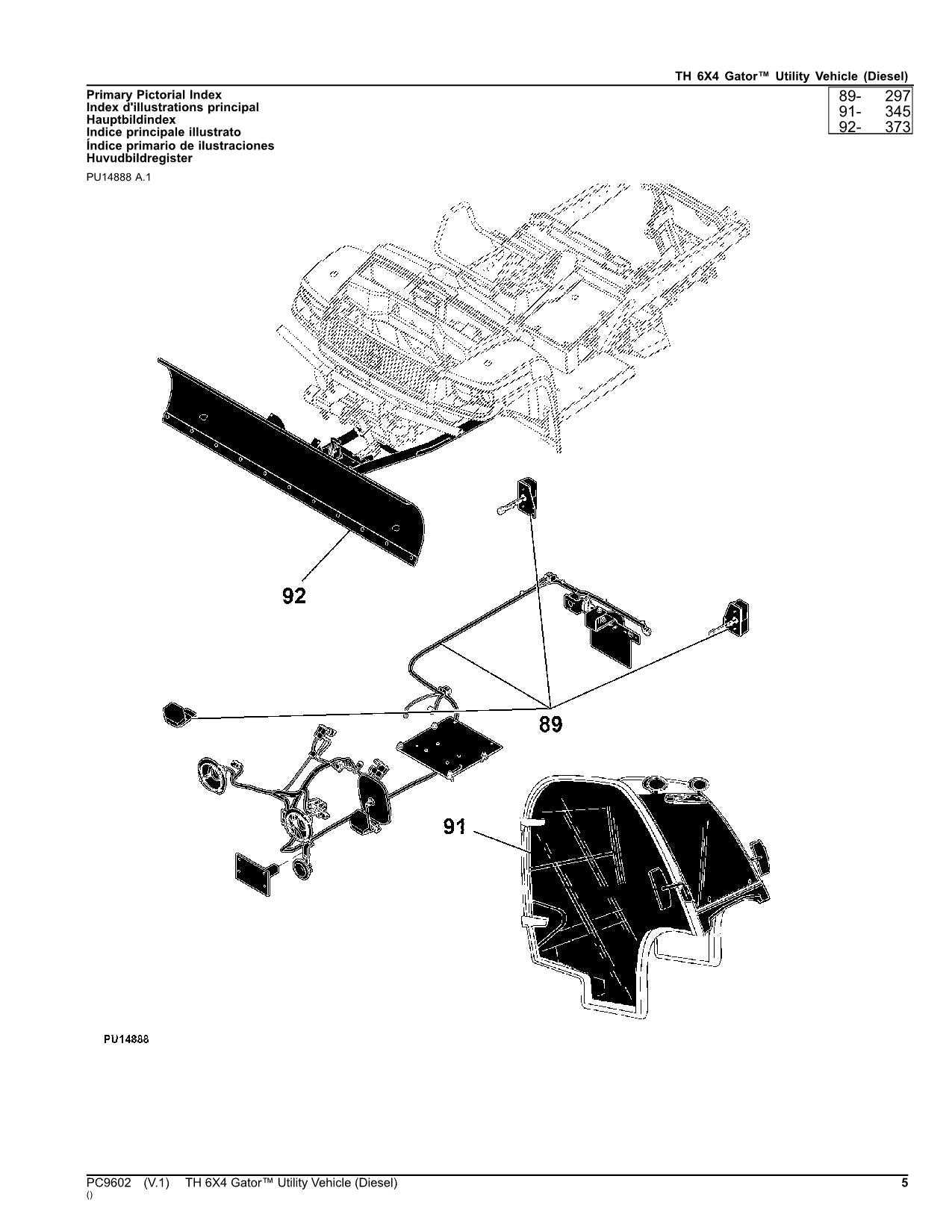

Parts and Components Guide

This section provides an overview of essential elements and assemblies for effective maintenance and functionality. Understanding these components is crucial for ensuring optimal performance and longevity.

Engine and Transmission: The heart of any utility vehicle lies in its power unit and drivetrain. Regular checks and maintenance of these parts are vital to avoid operational issues.

Suspension System: A robust suspension system contributes to a smooth ride and stability. Inspecting the shocks and springs regularly can prevent discomfort and enhance handling.

Electrical System: Proper functioning of the electrical system is necessary for starting and operating various features. Ensure that all wiring and connections are secure and free from corrosion.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential for preventing accidents and injuries. By adhering to basic guidelines, individuals can create a secure environment that facilitates effective work. Proper precautions not only protect the person performing the work but also safeguard the equipment involved.

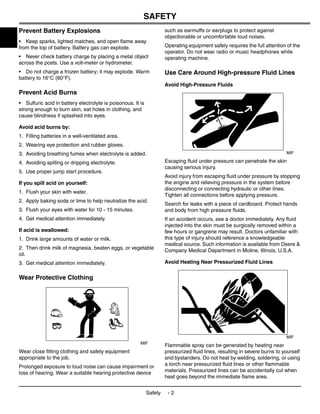

Essential Protective Gear

Before commencing any maintenance activity, it is crucial to wear appropriate protective equipment. This includes items such as gloves, goggles, and steel-toed boots. Wearing the right gear can significantly reduce the risk of injuries from sharp objects, chemicals, or heavy components.

Work Environment Considerations

Maintaining a tidy workspace is vital for safety. Ensure that the area is free from clutter and hazards that could lead to trips or falls. Proper lighting also plays a critical role in enhancing visibility, allowing for more precise work and reducing the likelihood of accidents.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to addressing common issues encountered with utility vehicles. By following systematic procedures, operators can ensure their machines remain in optimal condition. Clear steps facilitate the troubleshooting process, making it easier to identify and resolve problems effectively.

Identifying Common Issues

Begin by assessing the vehicle’s performance. Look for signs such as unusual noises, reduced power, or erratic behavior. These indicators can help pinpoint the underlying cause. Once issues are identified, gather the necessary tools and replacement parts to proceed.

Executing the Repair Process

Follow the outlined steps carefully. Start with safety precautions, ensuring the vehicle is off and secured. Proceed to dismantle the affected components as needed, documenting each step for reference. After replacing faulty parts, reassemble the unit, checking for any loose connections. Finally, conduct a test run to verify that the problem has been resolved.

Tools Required for Repairs

When undertaking maintenance on your utility vehicle, having the right equipment is essential for effective and efficient work. This section outlines the necessary tools that will help facilitate various tasks, ensuring a smooth process and optimal results.

Essential Hand Tools

Basic hand tools are fundamental for any maintenance project. These include wrenches, screwdrivers, and pliers. Each tool serves a specific purpose, allowing for the adjustment and removal of various components with ease. Additionally, investing in a toolbox can help keep your workspace organized and tools easily accessible.

Power Equipment

In more extensive projects, power tools may be necessary to enhance efficiency. Items such as drills and impact wrenches can significantly reduce the time required for certain tasks. When using power equipment, always prioritize safety by employing proper protective gear and following guidelines to avoid accidents.

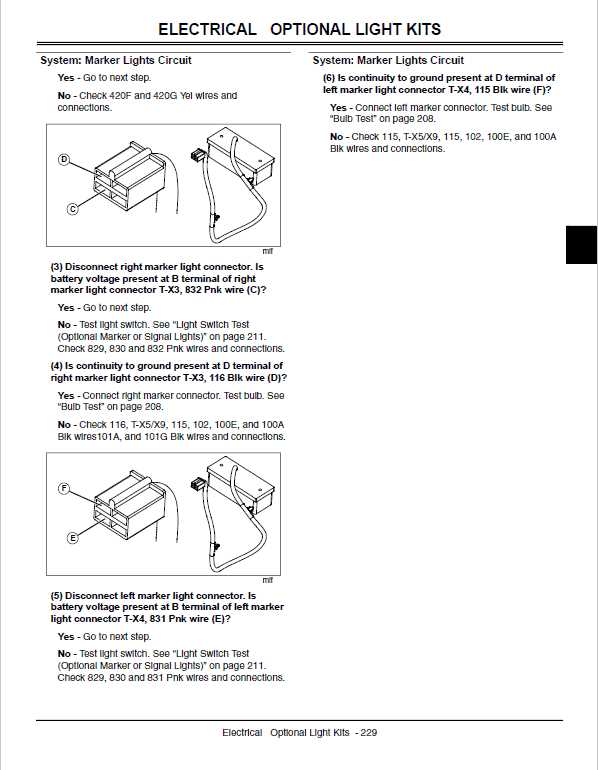

Electrical System Diagnostics

Understanding the intricacies of the electrical system is crucial for ensuring optimal performance and longevity of your vehicle. This section focuses on effective strategies for identifying and resolving electrical issues, which can often lead to significant operational challenges. Accurate diagnostics can help pinpoint faults, streamline repairs, and enhance overall functionality.

Common Electrical Issues

- Battery failure

- Faulty wiring connections

- Defective switches and relays

- Malfunctioning sensors

- Alternator problems

Diagnostic Tools and Techniques

Utilizing the right tools and techniques is essential for effective troubleshooting. Here are some recommended methods:

- Multimeter: Measure voltage, current, and resistance.

- Visual Inspection: Check for damaged wires and loose connections.

- Wiring Diagrams: Refer to schematics for accurate tracing of circuits.

- Diagnostic Software: Use specialized applications for in-depth analysis.

By employing these methods, you can effectively diagnose and rectify electrical system problems, ensuring smooth operation and reducing downtime.

Fluid Replacement Guidelines

Ensuring optimal performance and longevity of your vehicle requires regular maintenance, particularly in the area of fluid management. Proper fluid replacement is crucial for the smooth operation of various systems, preventing wear and tear while enhancing reliability.

Types of Fluids

There are several essential fluids that must be routinely replaced. Each fluid serves a specific purpose, contributing to the overall functionality of the machine.

| Fluid Type | Replacement Interval | Recommended Specifications |

|---|---|---|

| Engine Oil | Every 100 hours of operation | SAE 10W-30 or equivalent |

| Transmission Fluid | Every 200 hours of operation | OEM approved fluid |

| Coolant | Every 2 years | 50/50 mix of antifreeze and water |

Replacement Procedure

To ensure proper fluid replacement, follow the manufacturer’s guidelines closely. Begin by draining the old fluid completely to prevent contamination. After that, refill with the recommended type, ensuring that levels are within specified ranges.

Upgrading Your Gator’s Performance

Enhancing the efficiency and capability of your utility vehicle can significantly improve its functionality and longevity. By implementing various modifications and upgrades, you can ensure that your vehicle meets your specific needs, whether for work or recreation. This section explores several strategies to elevate your vehicle’s overall performance.

Key Performance Enhancements

When looking to boost your vehicle’s performance, consider the following enhancements:

- Improved suspension systems for better handling

- Upgraded engine components for increased power

- High-performance tires for enhanced traction

Performance Upgrade Options

The following table outlines popular options for upgrading your vehicle:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Suspension Kits | Upgrades to shock absorbers and springs | Better stability and ride quality |

| Engine Tuners | ECU modifications to optimize performance | Increased horsepower and torque |

| Exhaust Systems | Aftermarket exhaust for improved airflow | Enhanced sound and performance efficiency |

Investing in these performance enhancements can transform your vehicle into a more capable machine, ready to tackle any challenge.

Understanding the Engine Specifications

This section delves into the essential characteristics of the power unit used in the vehicle. A comprehensive understanding of these specifications is crucial for optimal performance, maintenance, and troubleshooting.

Key Engine Features

- Displacement: Refers to the total volume of all cylinders, affecting power output.

- Cylinder Count: Indicates the number of combustion chambers, impacting efficiency and performance.

- Fuel Type: Specifies the kind of fuel required for operation, influencing energy efficiency.

- Cooling System: Describes the method used to regulate engine temperature, crucial for longevity.

Performance Metrics

- Horsepower: A measure of the engine’s power, determining acceleration and towing capacity.

- Torque: Indicates the twisting force available, essential for handling heavy loads.

- Fuel Efficiency: Evaluates the distance traveled per unit of fuel, important for operational costs.

Familiarity with these specifications will aid in informed decisions regarding maintenance and upgrades, ensuring reliable operation and enhanced performance.

Finding Replacement Parts

When it comes to maintaining and restoring utility vehicles, sourcing the right components is crucial for optimal performance. Locating suitable parts ensures that your machine operates efficiently and reliably over time.

Authorized Dealers are often the best starting point for acquiring authentic components. These vendors provide original equipment and can offer advice on compatibility with your specific model.

For those seeking alternative options, aftermarket suppliers can be a valuable resource. Many of these companies produce high-quality replicas at a lower cost, which can be an appealing choice for budget-conscious users. However, it’s essential to verify the quality and fit of these components to avoid potential issues down the line.

Additionally, online marketplaces and forums dedicated to vehicle enthusiasts can be helpful. Here, you can connect with other owners who may have recommendations or even spare parts for sale. Networking within these communities can lead to great finds and valuable tips on maintenance.