Comprehensive Guide to Repairing 2019 Chevy Colorado

In the world of automotive care, understanding your vehicle’s systems and components is essential for ensuring optimal performance. This guide aims to provide valuable insights into maintaining and troubleshooting various aspects of a popular mid-size truck. Whether you are a seasoned mechanic or a novice enthusiast, having access to detailed information can empower you to take control of your vehicle’s upkeep.

Every vehicle requires specific attention to maintain its efficiency and longevity. This section will delve into common issues, maintenance procedures, and troubleshooting tips. By familiarizing yourself with the essential practices and techniques, you can enhance your knowledge and skills in automotive maintenance.

Equipped with the right tools and information, you will be better prepared to tackle repairs and enhancements. Understanding the intricacies of your truck not only saves time and money but also enriches your overall driving experience. Let’s explore the essential elements that will keep your vehicle in top condition.

This section provides a comprehensive overview of a versatile mid-size pickup truck, known for its robust performance and practicality. It is designed to cater to various driving needs, combining utility with comfort, making it a popular choice among truck enthusiasts.

Key Features

- Powerful engine options that deliver impressive towing capacity.

- Modern technology integrations for enhanced safety and convenience.

- Spacious interior with flexible seating configurations.

- All-terrain capabilities for off-road adventures.

Target Audience

This vehicle appeals to a diverse group of individuals, including:

- Outdoor enthusiasts seeking reliable transportation for recreational activities.

- Professionals needing a dependable work vehicle.

- Families requiring a versatile vehicle for daily commutes and trips.

Common Issues with Chevy Colorado

The vehicle in question often experiences a range of challenges that can affect its performance and reliability. Understanding these common problems can help owners identify potential issues before they escalate.

One frequent concern is related to the electrical system. Many users report intermittent issues with lights and power accessories, which may indicate a failing battery or faulty wiring.

Another notable area is the transmission. Owners have sometimes noted irregular shifting or delays, which could point to low fluid levels or the need for a software update.

Additionally, suspension components can wear over time, leading to unusual noises or a rough ride. Regular inspections can help address these concerns early.

Finally, engine performance issues are not uncommon, including rough idling or decreased fuel efficiency. Routine maintenance and timely diagnostics can prevent these problems from becoming severe.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to routine upkeep for your vehicle, ensuring optimal performance and longevity. By following these detailed procedures, you can enhance reliability and prevent potential issues.

Routine Inspections

Begin with a thorough examination of essential components. Check fluid levels, including oil, coolant, and brake fluid, and inspect the condition of belts and hoses. Regular assessments help identify wear and tear before they lead to significant problems.

Regular Fluid Changes

Maintaining proper fluid quality is crucial. Schedule timely changes for engine oil, transmission fluid, and brake fluid. Always use high-quality products suited for your vehicle’s specifications to ensure efficiency and safety.

Note: Consistency in these practices is key to extending the lifespan of your vehicle and ensuring a smooth driving experience.

Engine Specifications and Performance

This section provides an overview of the key attributes and capabilities of the vehicle’s powertrain. Understanding these specifications is essential for evaluating overall efficiency, capability, and responsiveness on the road.

The engine is designed to deliver a balance of power and fuel economy. With a displacement of approximately 3.6 liters, it generates impressive horsepower and torque, ensuring robust acceleration and performance in various driving conditions. The engine features advanced technologies, such as variable valve timing and direct fuel injection, which enhance efficiency and reduce emissions.

Performance metrics indicate a commendable towing capacity, making it suitable for various tasks. With a refined transmission system, gear shifts are smooth, contributing to a pleasant driving experience. The combination of engine specifications and performance characteristics makes this vehicle a reliable choice for both daily commutes and adventurous outings.

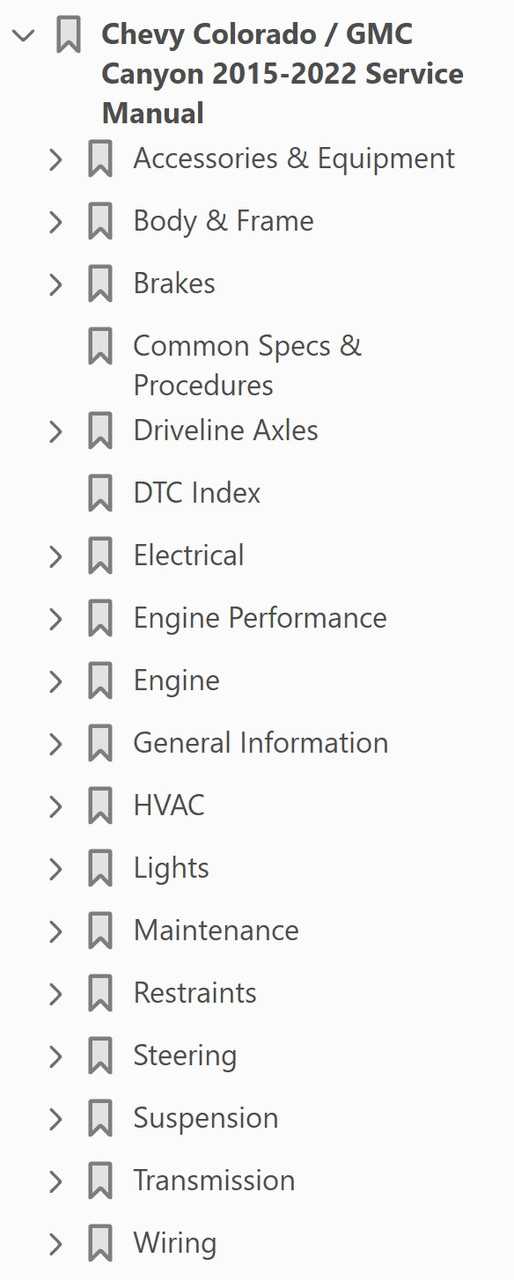

Transmission Troubleshooting Techniques

Understanding and resolving issues related to gear systems can be challenging. Employing systematic approaches helps identify the root causes of malfunctions and ensures effective solutions. This section outlines various techniques to diagnose transmission-related problems, enabling smoother operation and enhanced performance.

Identifying Common Symptoms

Recognizing early warning signs is crucial for timely intervention. Common indicators may include unusual noises, slipping gears, or delayed engagement. By paying attention to these symptoms, one can initiate a more thorough inspection and take appropriate action.

Utilizing Diagnostic Tools

Implementing specialized diagnostic instruments can significantly streamline the troubleshooting process. Tools such as code readers and pressure gauges assist in pinpointing specific issues. These devices provide valuable data, allowing for informed decisions and targeted repairs.

Electrical System Insights and Repairs

The electrical system in modern vehicles plays a crucial role in their overall performance and functionality. Understanding its components and common issues can help in diagnosing and addressing problems effectively. This section delves into various aspects of the electrical framework, emphasizing essential maintenance and troubleshooting techniques.

Key Components of the Electrical Framework

- Battery: Supplies power to the entire system.

- Alternator: Charges the battery and powers electrical systems when the engine is running.

- Fuses: Protect circuits from overload by breaking the connection when necessary.

- Wiring Harness: Connects all electrical components and facilitates communication.

Troubleshooting Common Electrical Issues

- Check the battery voltage and connections for corrosion or looseness.

- Inspect fuses for any that may be blown and replace as needed.

- Examine wiring for damage, fraying, or wear that could lead to short circuits.

- Test the alternator output to ensure it is charging the battery adequately.

Brake System Inspection Procedures

Regular examination of the braking system is crucial for ensuring safe operation and optimal performance of the vehicle. This section outlines essential steps to evaluate the integrity and functionality of the braking components.

Visual Assessment: Begin by performing a thorough visual inspection of the brake components. Check for any signs of wear, damage, or leaks in the brake lines, calipers, and pads. Ensure that all components are securely attached and free from corrosion.

Pad Thickness Measurement: Measure the thickness of the brake pads. If they are below the manufacturer’s specified minimum thickness, they should be replaced immediately to maintain effective stopping power.

Fluid Level Check: Inspect the brake fluid reservoir to ensure the fluid level is within the recommended range. Low fluid levels may indicate a leak in the system, which requires prompt attention.

Brake Performance Test: Conduct a performance test by engaging the brakes at various speeds. Listen for unusual noises, such as grinding or squeaking, which may indicate issues that need addressing.

Final Inspection: After completing the assessment, recheck all components and ensure everything is properly secured. Document any findings and necessary actions for future reference.

Suspension and Steering Adjustments

The proper alignment and calibration of the suspension and steering systems are crucial for optimal vehicle handling and ride quality. Ensuring that these components are accurately set up not only enhances driving comfort but also extends the lifespan of critical parts.

Importance of Proper Alignment

Accurate alignment of the wheels is essential for maintaining even tire wear and stability. Misalignment can lead to pulling to one side, uneven tire wear, and compromised safety. Regular checks and adjustments are recommended to keep the vehicle’s performance at its best.

Adjusting Steering Components

Fine-tuning the steering components is vital for responsiveness and control. This includes ensuring the steering gear is properly adjusted and checking for any play in the steering linkage. Regular maintenance of these elements contributes significantly to the overall driving experience.

Cooling System Maintenance Practices

Maintaining the cooling system is crucial for ensuring optimal performance and longevity of the vehicle. Regular attention to this system can prevent overheating and related issues, ultimately enhancing the driving experience. This section outlines essential practices for effective maintenance.

Regular Inspection and Cleaning

Frequent checks of the cooling components, including the radiator and hoses, help identify potential leaks or blockages. Cleaning the radiator fins and ensuring proper airflow can significantly improve efficiency. It’s also advisable to examine coolant levels regularly to avoid any discrepancies.

Coolant Replacement

Replacing the coolant at recommended intervals is vital for maintaining the system’s effectiveness. Using the appropriate type of coolant ensures compatibility with the engine materials and helps prevent corrosion. Consult the vehicle guidelines for the recommended coolant specifications and replacement schedule.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hoses and connections | Every 3 months | Look for signs of wear or leaks |

| Flush cooling system | Every 2 years | Helps remove debris and contaminants |

| Check coolant level | Monthly | Maintain optimal levels to prevent overheating |

Body and Frame Repair Guidelines

This section focuses on the essential practices for addressing issues related to the vehicle’s outer shell and structural framework. Proper techniques and attention to detail are crucial to maintain the integrity and safety of the automobile.

Common Issues and Solutions

Identifying typical problems is the first step in effective maintenance. Damage may arise from collisions or environmental factors, necessitating specific strategies for resolution.

| Issue | Recommended Action |

|---|---|

| Dents and Scratches | Use a suitable filler and repaint the affected area. |

| Rust and Corrosion | Remove rust, apply a protective coating, and repaint. |

| Misalignment | Realign the frame using specialized tools. |

Safety Considerations

Ensuring safety during bodywork is paramount. Always wear appropriate protective gear and follow safety protocols to mitigate risks associated with the repair process.

Safety Features and Enhancements

This section discusses various protective elements and improvements designed to enhance the safety of the vehicle. Modern advancements in automotive technology contribute significantly to both driver and passenger security, ensuring a more confident driving experience.

Key Protective Elements

- Airbags: Strategically placed to minimize injury during collisions.

- Anti-lock Braking System: Prevents wheel lockup during emergency braking, allowing for better steering control.

- Traction Control: Helps maintain traction on slippery surfaces by adjusting engine power and applying brakes.

- Electronic Stability Control: Assists in maintaining vehicle stability during sharp turns or sudden maneuvers.

Advanced Safety Technologies

- Rearview Camera: Provides a clear view of the area behind the vehicle when reversing.

- Lane Departure Warning: Alerts the driver if the vehicle unintentionally drifts out of its lane.

- Blind Spot Monitoring: Detects vehicles in adjacent lanes that may not be visible to the driver.

- Forward Collision Alert: Warns of potential collisions with vehicles ahead, allowing for timely action.

Tools Required for DIY Repairs

Undertaking maintenance tasks on your vehicle can be a rewarding experience, provided you have the right instruments at your disposal. Having a well-stocked toolkit can significantly enhance the efficiency and effectiveness of your efforts, making the process smoother and more enjoyable.

Essential Hand Tools

Basic hand tools are the backbone of any repair project. A reliable set of wrenches, screwdrivers, and pliers will allow you to tackle a variety of tasks. Socket sets are particularly useful for accessing tight spaces and ensuring proper torque on bolts. Additionally, a torque wrench is critical for applications where precise fastening is essential.

Power Tools and Accessories

For more complex jobs, power tools can save time and effort. A cordless drill is invaluable for both drilling and driving screws. Furthermore, incorporating air tools such as impact wrenches can greatly enhance your capabilities, especially when dealing with rusted or stubborn fasteners.