Comprehensive Guide to Repairing the GM 4L60E Transmission

Understanding the complexities of automotive systems is essential for any vehicle owner or enthusiast. This guide aims to provide an in-depth overview of the intricacies involved in maintaining and restoring one of General Motors’ most popular automatic gear-shifting units. Whether you’re facing common issues or simply looking to enhance your knowledge, this resource will equip you with valuable insights.

Throughout this exploration, we will delve into the components and functions that ensure smooth operation and performance. From identifying symptoms of malfunction to troubleshooting techniques, the following sections will illuminate the various aspects of care and restoration. Knowledge of these elements can significantly extend the lifespan of your vehicle’s drivetrain.

Moreover, we will highlight best practices and tips to facilitate effective intervention and promote a deeper understanding of the mechanisms at play. By mastering these principles, you will be better prepared to tackle any challenges that arise, ensuring your automobile remains in optimal condition for years to come.

Understanding the 4L60E Transmission

The system in focus plays a crucial role in the operation of many vehicles, providing seamless power delivery from the engine to the wheels. Its design incorporates advanced features that enhance performance and efficiency, making it a popular choice among manufacturers and enthusiasts alike.

Key characteristics include:

- Hydraulic control mechanisms that facilitate smooth gear shifts.

- A modular design that allows for easier servicing and part replacement.

- Electronic controls that improve responsiveness and adaptability to driving conditions.

Understanding the components of this system can help in diagnosing issues and maintaining optimal performance:

- Torque Converter: Engages and disengages the engine from the drivetrain, enhancing efficiency.

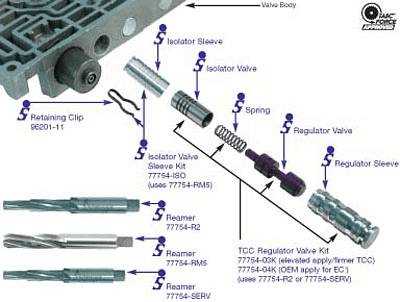

- Valve Body: Acts as the brain, directing fluid flow to various parts of the unit for shifting.

- Clutch Packs: Responsible for the actual engagement of gears, ensuring power is transmitted smoothly.

Regular maintenance and awareness of common problems can significantly extend the lifespan of this essential automotive component. Knowledge of how each part functions together is vital for anyone looking to optimize their vehicle’s performance.

Common Issues with 4L60E Transmissions

The automatic gear-shifting system in many vehicles is prone to various challenges that can affect performance and reliability. Understanding these common problems can help owners recognize symptoms early and take appropriate action to maintain optimal functionality.

Fluid Leaks

One of the most prevalent concerns involves fluid escaping from the assembly. This can lead to insufficient lubrication and overheating, resulting in significant damage. Regular checks for puddles beneath the vehicle or a low fluid level in the reservoir can help identify leaks early.

Shifting Problems

Difficulty in changing gears can indicate several underlying issues. Drivers may experience harsh shifts, delayed engagement, or slipping between gears. These symptoms can stem from worn components or electronic malfunctions. Addressing these concerns promptly is crucial to avoid further complications.

Maintaining vigilance regarding these common issues can prolong the lifespan of the gear system and enhance overall vehicle performance. Regular maintenance and prompt attention to symptoms can save time and resources in the long run.

Essential Tools for Transmission Repair

When working on the intricate systems that ensure smooth vehicle operation, having the right equipment is crucial. A well-equipped workspace not only enhances efficiency but also increases the likelihood of achieving successful outcomes. This section highlights the fundamental instruments necessary for anyone looking to delve into this complex field.

Basic Hand Tools

Having a collection of reliable hand tools is essential for any mechanical work. These tools allow for precise adjustments and facilitate the disassembly and reassembly of components. Key items include:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening various fasteners. |

| Torque Wrench | Ensures bolts are tightened to specified settings. |

| Screwdriver Set | For adjusting and removing screws in different sizes. |

| Pliers | For gripping, twisting, and cutting wires and components. |

| Hammer | For gentle persuasion of parts without damage. |

Specialized Equipment

In addition to hand tools, certain specialized equipment can make complex tasks more manageable. These tools are designed to address specific challenges that arise during the process:

| Tool | Purpose |

|---|---|

| Lift or Jack | To elevate the vehicle for easier access to the undercarriage. |

| Fluid Transfer Pump | For transferring lubricants and fluids safely and cleanly. |

| Diagnostic Scanner | To read error codes and assess electronic systems. |

| Clutch Alignment Tool | To ensure proper alignment during reassembly. |

Step-by-Step Disassembly Process

This section outlines the methodical approach required for the disassembly of a complex assembly. Carefully following each step ensures that all components are removed in a systematic manner, minimizing the risk of damage and allowing for thorough inspection and maintenance.

Preparation

Begin by gathering all necessary tools and workspace materials. Ensure that the area is clean and organized. Disconnect all electrical connections and fluid lines, and remove any external components that may obstruct access to the main assembly. It’s advisable to document the arrangement of parts as they are removed.

Disassembly Steps

Start with the outer casing, carefully unfastening bolts and screws. Work your way inward, noting the order and orientation of each component as it is taken out. Utilize appropriate methods to avoid damaging any seals or gaskets. Once the outer parts are removed, proceed to extract internal components systematically, ensuring to keep track of all small pieces, springs, and clips. Following this structured approach will facilitate a smoother reassembly process.

Inspecting Internal Components Thoroughly

Performing a detailed examination of internal parts is crucial for ensuring optimal performance and longevity of any complex machinery. This process allows for the identification of wear, damage, or malfunctions that could lead to inefficiencies or complete failure. A thorough inspection can save time and resources in the long run by addressing potential issues before they escalate.

Key steps in the inspection process include:

- Disassembling the unit carefully to avoid damaging any components.

- Cleaning all parts to remove debris and contaminants that may obscure signs of wear.

- Checking for visible damage such as cracks, warping, or excessive wear.

When assessing internal elements, pay attention to the following components:

- Gears: Look for signs of chipping or uneven wear patterns.

- Bearings: Inspect for smooth operation and signs of scoring or pitting.

- Seals: Check for any cracks or deformities that could lead to leaks.

- Valves: Ensure they move freely and are not stuck or damaged.

Documentation of findings is essential. Keeping a detailed log of any issues discovered and any corrective actions taken will facilitate future assessments and maintenance tasks.

By adhering to a meticulous inspection routine, you enhance the reliability and efficiency of the system, ultimately prolonging its operational lifespan.

Replacing Worn Gaskets and Seals

When maintaining the efficiency of your vehicle’s components, addressing worn gaskets and seals is crucial. These parts play a significant role in preventing fluid leaks and ensuring optimal performance. Over time, exposure to heat, pressure, and contaminants can degrade these materials, leading to potential issues that may affect the entire system’s operation.

Identifying Signs of Wear

Common indicators of deteriorating gaskets and seals include visible leaks, changes in fluid levels, and unusual noises during operation. Regular inspections can help identify these issues early, allowing for timely intervention. Look for signs such as fluid stains on the ground or around the unit, as well as any abnormal pressure readings.

Steps for Replacement

To replace these components effectively, begin by gathering the necessary tools and materials. Carefully remove the old gaskets and seals, ensuring that the surfaces are clean and free of debris before installation. Apply the new gaskets with precision, following manufacturer guidelines for torque specifications and placement. Once installed, monitor the system closely for any signs of leakage or irregular behavior, as this will help confirm a successful replacement.

Reassembling the 4L60E Transmission

Putting the components back together is a critical phase in restoring the functionality of your unit. This process requires precision and attention to detail to ensure optimal performance.

Follow these essential steps to achieve a successful reassembly:

- Start by cleaning all parts thoroughly to remove any debris or old lubricant.

- Inspect each component for wear or damage before proceeding.

- Carefully align the main housing and begin inserting internal parts in the correct order.

- Ensure that all seals and gaskets are replaced to prevent leaks.

- Apply appropriate lubricants to moving parts to facilitate smooth operation.

After completing the assembly, perform a detailed check to confirm that everything is securely in place before installation.

Fluid Types and Maintenance Tips

Proper fluid selection and regular upkeep are essential for ensuring optimal performance and longevity of your vehicle’s powertrain. Understanding the various types of fluids available, along with best practices for maintenance, can significantly enhance the overall efficiency and reliability of your system.

When it comes to fluid types, it is crucial to choose products specifically designed for your vehicle’s requirements. Most vehicles utilize a synthetic or conventional fluid, each with unique properties suited for different conditions. Synthetic options often provide better protection at extreme temperatures and extended intervals between changes, while conventional fluids may be more cost-effective for regular use.

Regular checks and changes of the fluid are vital. It’s advisable to inspect fluid levels periodically and top them off as needed. Additionally, following a schedule for complete fluid changes can help prevent contamination and maintain the system’s integrity. Pay attention to any signs of discoloration or unusual odors, as these can indicate degradation and the need for replacement.

Furthermore, ensuring that the cooling system is functioning effectively can help manage fluid temperatures, which is critical for performance. Clean filters and proper sealing also contribute to the health of the entire system, minimizing the risk of leaks and maintaining pressure.

By selecting the right fluids and adhering to a diligent maintenance routine, you can significantly improve the reliability and efficiency of your vehicle’s components, leading to a smoother driving experience.

Upgrading Components for Performance

Enhancing vehicle efficiency and power often requires a closer look at the internal mechanisms. By focusing on specific parts, drivers can achieve noticeable improvements in performance and responsiveness. This section delves into key components that can be upgraded to elevate overall functionality.

- Valves: Upgrading to high-performance valves can improve airflow and enhance responsiveness, leading to better acceleration.

- Gears: Installing gears with a lower ratio can increase torque, allowing for quicker acceleration and improved power delivery.

- Clutches: High-performance clutches provide better grip and heat resistance, making them essential for high-torque applications.

- Bearings: Using high-quality bearings reduces friction and improves longevity, ensuring smoother operation.

- Fluid Coolers: Adding an external cooler helps maintain optimal operating temperatures, extending component life and performance under stress.

By selecting the right upgrades, enthusiasts can transform their vehicle’s dynamics, ensuring not only enhanced speed but also improved reliability. Prioritizing these components is key to achieving a balance between performance and durability.

Troubleshooting After Reassembly

After putting everything back together, it’s crucial to ensure that the system operates smoothly. Issues may arise due to various factors during the reassembly process. Identifying and resolving these problems early can save time and prevent further complications.

1. Fluid Leaks: One of the most common issues encountered is fluid leakage. Check all seals and gaskets for proper seating. If leaks are detected, inspect the connections and replace any damaged components.

2. Shifting Issues: If the shifting feels rough or inconsistent, examine the linkage and adjustments. Make sure everything is aligned correctly and that the necessary components are functioning as intended.

3. Noises: Unusual sounds can indicate potential problems. Listen for grinding or whining noises, which may suggest improper assembly or wear on internal parts. Conduct a thorough inspection to pinpoint the source.

4. Overheating: Monitor the temperature closely. If the unit runs hot, it might be due to insufficient fluid levels or a malfunctioning cooling system. Address these factors promptly to avoid severe damage.

5. Diagnostic Tools: Utilizing diagnostic tools can help identify electronic issues that may not be visible. Scanning for error codes can provide insights into potential faults and guide corrective actions.

Systematic evaluation after reassembly is essential for ensuring optimal performance. Taking the time to troubleshoot effectively can lead to a more reliable and efficient operation.

Preventive Measures for Longevity

Ensuring the durability of essential vehicle components is crucial for maintaining optimal performance and reducing the risk of costly repairs. By implementing a series of proactive strategies, vehicle owners can significantly extend the lifespan of their systems and enhance overall driving experience.

Regular Maintenance Practices

Routine upkeep plays a vital role in preserving the functionality of crucial components. Regular checks and timely servicing can help identify potential issues before they escalate. Key practices include:

| Maintenance Task | Frequency |

|---|---|

| Fluid Level Checks | Every 3,000 miles |

| Filter Replacement | Every 15,000 miles |

| Seal Inspections | Annually |

| Component Cleaning | Every 20,000 miles |

Driving Habits for Enhanced Performance

Adopting mindful driving behaviors can also contribute to longevity. Avoiding aggressive acceleration and sudden stops can reduce strain on vital parts. Additionally, ensuring proper loading and adhering to weight limits can prevent unnecessary wear and tear, ultimately leading to a smoother and longer-lasting operation.

When to Seek Professional Help

Understanding when to call in an expert can be crucial for maintaining the functionality and longevity of your vehicle’s components. While some issues can be resolved with basic knowledge and tools, others require specialized skills and equipment. Recognizing the signs that professional assistance is needed can save you time, money, and further complications.

Here are some indicators that it’s time to seek help from a qualified technician:

- Persistent Problems: If issues continue after you’ve attempted basic troubleshooting, it’s a sign that a deeper problem may exist.

- Unusual Noises: Hearing strange sounds, such as grinding or clunking, can indicate serious underlying issues that need expert attention.

- Fluid Leaks: Any visible leaks, especially if they’re oily or colored, warrant immediate professional inspection.

- Warning Lights: Activation of dashboard indicators suggests that something is amiss and should be checked by a professional.

- Performance Issues: Sluggishness, stalling, or difficulty shifting can point to complications that require skilled intervention.

When in doubt, seeking assistance from a professional can ensure that the work is done correctly and safely, preserving the integrity of your vehicle.