Comprehensive Guide to 2005 Dodge Durango Repair Manual

Owning a robust SUV comes with the responsibility of keeping it in optimal condition. Regular upkeep not only ensures longevity but also enhances performance and safety. For enthusiasts and everyday drivers alike, having a thorough understanding of maintenance procedures is essential.

In this guide, we delve into the intricacies of servicing this particular model. By exploring detailed procedures, troubleshooting tips, and essential guidelines, readers will be equipped with the knowledge necessary to tackle various mechanical challenges. This resource aims to empower owners, providing clarity and confidence in their maintenance endeavors.

From routine inspections to complex repairs, understanding the underlying mechanics of your vehicle can lead to significant benefits. Whether you’re a seasoned mechanic or a novice, this comprehensive resource will support your journey in maintaining a reliable and efficient machine.

Overview of the 2005 Dodge Durango

This section provides a comprehensive look at a versatile sport utility vehicle that has made a significant mark in the automotive world. Known for its robust design and practicality, this model appeals to those seeking a blend of comfort and functionality.

Key Features

- Spacious interior accommodating up to seven passengers

- Powerful engine options providing impressive towing capacity

- All-wheel drive availability enhancing traction and stability

- Advanced safety features ensuring passenger protection

- Ample cargo space catering to diverse storage needs

Performance and Handling

This vehicle is engineered for both on-road comfort and off-road capability. With a sturdy chassis and responsive steering, it delivers a driving experience that is both enjoyable and secure.

- Engine choices ranging from V6 to V8 configurations

- Transmission options designed for smooth shifting

- Suspension system offering a balanced ride

Overall, this SUV combines style, utility, and performance, making it a compelling option for families and adventurers alike.

Common Issues and Solutions

When it comes to maintaining a vehicle, certain problems tend to arise more frequently than others. Understanding these common challenges and knowing how to address them can greatly enhance the longevity and performance of your automobile. Below are some prevalent issues and their effective solutions.

Engine Performance Issues

One of the most frequent concerns drivers face is related to engine performance. Symptoms such as rough idling, stalling, or decreased power can indicate underlying problems. These may stem from issues like faulty spark plugs, clogged fuel injectors, or air filter blockages. Regularly inspecting and replacing spark plugs and ensuring proper fuel system maintenance can significantly improve engine functionality.

Electrical System Failures

Another common challenge is related to the electrical system. Drivers may experience problems such as dimming headlights, malfunctioning power windows, or a dead battery. Often, these issues can be traced back to a failing alternator or worn-out battery connections. Conducting periodic checks on the battery and its terminals, as well as ensuring that the alternator is functioning correctly, can help mitigate these issues.

Maintenance Tips for Durango Owners

Proper upkeep is essential for ensuring the longevity and optimal performance of your vehicle. Regular attention to various components not only enhances driving safety but also helps maintain its value over time. Adopting a proactive approach can prevent costly repairs down the line.

Regular Fluid Checks

Monitoring fluid levels is crucial. Engine oil should be checked frequently, as it lubricates moving parts and prevents wear. Additionally, ensure that coolant, brake fluid, and transmission fluid are at the appropriate levels, as these are vital for your vehicle’s operation and safety.

Tire Care and Rotation

Tires play a significant role in performance and fuel efficiency. Regularly check tire pressure to prevent uneven wear and enhance handling. It’s also advisable to rotate tires periodically to ensure even tread wear, which contributes to a smoother ride and extends tire life.

Essential Tools for DIY Repairs

Having the right instruments is crucial for any hands-on maintenance tasks. A well-equipped toolkit not only makes the process smoother but also enhances the overall efficiency of your projects. Whether you are tackling minor fixes or more extensive modifications, understanding which tools are essential can greatly simplify your efforts.

Basic Hand Tools

Starting with a selection of fundamental hand tools is vital. Items like wrenches, screwdrivers, and pliers form the backbone of any toolkit. These instruments enable you to manage a variety of tasks, from tightening loose components to replacing worn-out parts.

Power Tools and Accessories

Incorporating power tools can significantly expedite your work. Drills, saws, and impact wrenches allow for quicker execution of demanding jobs. Always remember to include appropriate safety gear when using these devices to ensure a secure working environment.

Understanding the Repair Manual Structure

A comprehensive guide for vehicle maintenance is typically organized in a systematic manner to enhance usability and efficiency. By grasping the layout of such documentation, users can navigate through complex information with ease, ensuring they locate necessary details swiftly. This structure not only aids in identifying specific components but also assists in understanding the overall functionality of the vehicle.

| Section | Description |

|---|---|

| Introduction | Overview of the vehicle and its specifications, providing essential background information. |

| Maintenance Schedule | Detailed timelines and intervals for routine checks and services to keep the vehicle in optimal condition. |

| Troubleshooting | Guidelines for diagnosing common issues, including symptoms and potential causes. |

| Repair Procedures | Step-by-step instructions for performing specific fixes, ensuring clarity and safety. |

| Specifications | Technical data regarding various components, helping users understand the required standards. |

| Glossary | Definitions of technical terms used throughout the guide, aiding comprehension. |

By familiarizing oneself with this structure, one can enhance their proficiency in vehicle care, leading to more effective problem-solving and maintenance practices.

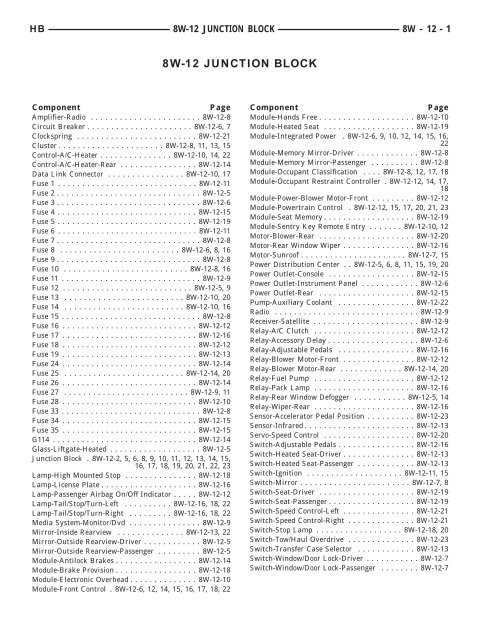

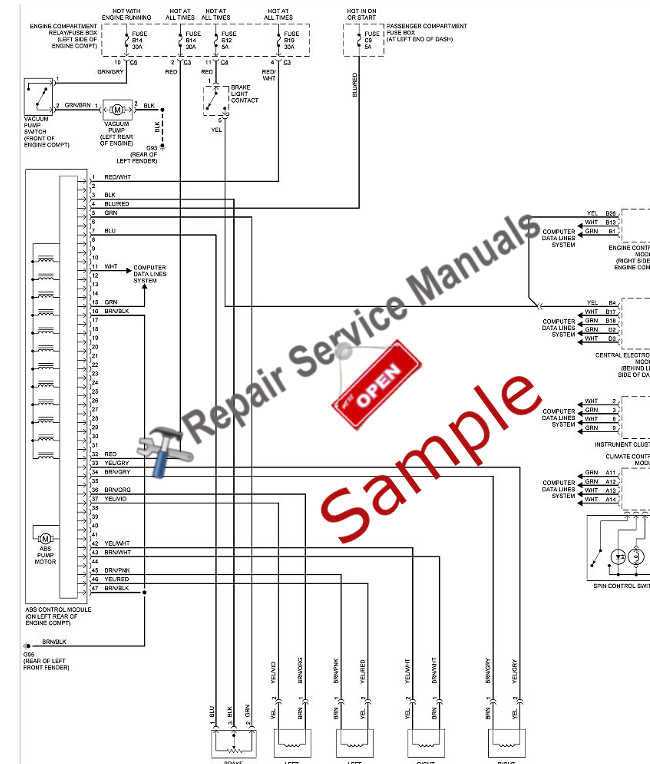

Electrical System Troubleshooting Guide

Diagnosing issues within an automotive electrical system can be challenging but essential for maintaining vehicle functionality. This section provides a structured approach to identifying and resolving common electrical problems. By following systematic steps, you can efficiently pinpoint faults and implement effective solutions.

Key components of the electrical system include the battery, alternator, fuses, wiring, and various sensors. Understanding their roles and interactions is crucial for successful troubleshooting.

-

Initial Inspection

- Check battery voltage and connections.

- Inspect fuses for continuity and damage.

- Examine wiring for signs of wear or corrosion.

-

Battery Assessment

- Measure voltage using a multimeter.

- Ensure terminals are clean and securely connected.

- Test for load capacity if necessary.

-

Alternator Functionality

- Check voltage output while the engine is running.

- Inspect for unusual noises or overheating.

- Test the belt tension and condition.

-

Fuse and Relay Examination

- Identify circuits affected by blown fuses.

- Replace faulty fuses with the correct amperage.

- Test relays for proper operation.

-

Wiring and Connector Checks

- Inspect connectors for tightness and corrosion.

- Follow wiring diagrams to trace problematic circuits.

- Repair or replace damaged wiring as needed.

By methodically assessing each component, you can effectively address electrical issues and restore optimal performance. Regular maintenance and inspections will further enhance system reliability.

Engine Repair and Maintenance Procedures

Proper care and attention to the engine are crucial for ensuring optimal performance and longevity of any vehicle. This section outlines essential practices and techniques for diagnosing issues, performing routine checks, and executing necessary adjustments or replacements. Understanding these processes can greatly enhance the reliability and efficiency of your automotive experience.

Routine Maintenance Checks

Regular inspections play a vital role in identifying potential problems before they escalate. Fluid levels, including oil, coolant, and transmission fluids, should be monitored consistently. Additionally, examining belts and hoses for signs of wear can prevent unexpected breakdowns. It is advisable to adhere to a maintenance schedule that includes these essential checks to maintain engine health.

Diagnostic Procedures

When performance issues arise, systematic diagnostics are necessary to pinpoint the root cause. Utilizing OBD-II scanners can reveal error codes that indicate specific malfunctions. Furthermore, conducting a compression test can assess the engine’s internal condition, helping to identify problems such as valve leaks or cylinder damage. Addressing these concerns promptly can lead to significant improvements in functionality.

Transmission Problems and Fixes

Issues related to the transmission can significantly impact vehicle performance and reliability. Understanding common symptoms and their potential solutions is essential for maintaining a smooth driving experience. Below are prevalent concerns and recommended fixes for those facing transmission challenges.

- Slipping Gears:

This symptom often manifests as unexpected changes in gear while driving. It can lead to reduced power and efficiency. Common causes include low fluid levels, worn components, or electrical faults.

- Check and top off transmission fluid.

- Inspect for leaks or damaged seals.

- Consult a professional for deeper mechanical issues.

- Delayed Engagement:

A noticeable delay when shifting from park to drive or reverse can indicate underlying issues. This may be attributed to low fluid, a malfunctioning solenoid, or other internal problems.

- Examine fluid levels and quality.

- Test the transmission solenoid.

- Consider a full system inspection if problems persist.

- Overheating:

Excessive heat can lead to severe damage if not addressed. Common causes include low fluid levels, towing heavy loads, or a faulty cooler.

- Ensure fluid is at the correct level.

- Monitor the vehicle’s temperature during operation.

- Install an auxiliary cooler if towing is frequent.

- Noisy Operation:

Unusual sounds such as grinding or whining can indicate mechanical failure within the transmission. These noises often suggest worn gears or insufficient lubrication.

- Inspect for fluid leaks and refill as needed.

- Listen for changes in noise when shifting gears.

- Seek expert diagnosis for potential internal damage.

phpCopy code

Addressing transmission issues promptly can prevent further complications and ensure the longevity of the vehicle. Regular maintenance and fluid checks are crucial for optimal performance.

Brake System Inspection and Repair

Ensuring the optimal functioning of the braking mechanism is crucial for vehicle safety. Regular evaluation of the brake components helps identify potential issues before they escalate, promoting a smooth and secure driving experience. This section outlines essential steps for assessing and addressing the brake system.

Inspection Steps

Conducting a thorough examination of the braking system involves several key procedures:

- Check brake fluid levels and quality.

- Inspect brake pads and shoes for wear and tear.

- Examine rotors and drums for damage or warping.

- Assess the condition of brake lines and hoses for leaks or deterioration.

- Evaluate the brake calipers for proper function and responsiveness.

Common Repairs

If any issues are detected during inspection, the following repairs may be necessary:

- Replacing worn brake pads or shoes.

- Resurfacing or replacing rotors and drums.

- Flushing and replenishing brake fluid.

- Fixing or replacing damaged brake lines and hoses.

- Rebuilding or replacing calipers as needed.

Maintaining the braking system in top condition not only enhances safety but also improves overall vehicle performance. Regular inspections and timely repairs are vital for preserving the reliability of this critical component.

Suspension and Steering Adjustments

The performance and handling of a vehicle are significantly influenced by the settings and conditions of its suspension and steering systems. Proper adjustments can enhance ride quality, improve cornering stability, and ensure that the vehicle responds effectively to driver inputs. This section outlines essential considerations for optimizing these critical components.

Alignment and Angles are vital for ensuring that the wheels are positioned correctly relative to each other and the road. Misalignment can lead to uneven tire wear and compromised handling. Regularly checking the camber, caster, and toe angles can help maintain optimal performance.

Suspension Components, such as shocks, struts, and springs, should be inspected for wear and tear. Replacing worn parts is crucial for maintaining ride comfort and vehicle control. Additionally, adjusting the stiffness of these components can tailor the driving experience to specific preferences or conditions.

Steering System Checks are equally important. Inspecting the steering gear, linkages, and fluid levels ensures smooth operation. Any signs of play or resistance can indicate issues that need addressing to maintain precise handling and responsiveness.

Overall, regular maintenance and adjustments of the suspension and steering systems not only prolong the life of these components but also enhance the driving experience, contributing to safety and performance on the road.

Cooling System Maintenance Practices

Proper upkeep of the cooling system is essential for optimal vehicle performance and longevity. Regular maintenance helps prevent overheating and ensures that the engine operates efficiently. Adopting a systematic approach to maintaining this crucial system can significantly enhance the reliability of your vehicle.

Key practices to consider include routine inspections, fluid checks, and timely replacements of essential components. Below are some recommended practices to maintain the cooling system effectively:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Hoses | Every 6 months | Check for signs of wear, leaks, or cracks to prevent coolant loss. |

| Check Coolant Level | Monthly | Ensure that the coolant is at the proper level to avoid overheating. |

| Flush Cooling System | Every 2 years | Remove old coolant and contaminants to maintain optimal thermal performance. |

| Replace Thermostat | Every 5 years | Ensure the thermostat opens and closes properly to regulate engine temperature. |

| Inspect Radiator | Annually | Check for blockages and leaks to ensure effective heat dissipation. |

Implementing these practices not only extends the life of the cooling system but also enhances overall vehicle reliability. Regular attention to this system will lead to improved performance and greater peace of mind during operation.