Complete Guide to Inglis Dryer Repair and Troubleshooting

Maintaining household equipment is essential for ensuring longevity and optimal performance. Understanding the intricacies of these machines can save time and money while preventing unnecessary inconvenience. This section delves into common issues that may arise and offers insights into troubleshooting techniques and practical solutions.

Whether facing minor hiccups or more complex challenges, being equipped with the right knowledge can empower users to tackle problems effectively. This guide presents a comprehensive overview of common malfunctions, allowing individuals to navigate their equipment with confidence. Through a blend of step-by-step instructions and helpful tips, users will find themselves better prepared to handle various situations.

Moreover, familiarizing oneself with the components and functioning of these devices is crucial for any homeowner. With a little patience and the right approach, many issues can be resolved without the need for professional assistance. Emphasizing a proactive attitude towards maintenance not only enhances appliance efficiency but also contributes to a smoother household experience.

Understanding Your Inglis Dryer

Familiarizing yourself with your appliance is essential for optimal performance and longevity. This section aims to provide insights into its features, functionality, and common considerations that enhance efficiency.

Components play a crucial role in how the unit operates. Key elements include the control panel, drum, and ventilation system, each contributing to the overall drying process.

It’s important to recognize the signs of potential issues. Familiarity with normal sounds and behaviors can help you detect irregularities early, preventing larger problems down the line.

Lastly, regular maintenance is vital. Keeping the lint trap clean and ensuring proper airflow will not only improve performance but also extend the life of your appliance.

Common Dryer Problems and Solutions

When it comes to household appliances, issues can arise that hinder their performance. Identifying these problems promptly can save time and resources. Below are some frequent malfunctions along with effective resolutions to ensure smooth operation.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Not Starting | Power supply issue, door not closed properly, faulty start switch | Check outlet, ensure door is secure, test or replace start switch |

| Poor Drying Performance | Blocked vent, overloaded drum, incorrect settings | Clear lint from vent, reduce load size, verify settings |

| Unusual Noises | Loose components, worn drum rollers, foreign objects | Inspect for loose parts, replace rollers, remove any debris |

| Overheating | Blocked venting, faulty thermostat, lint buildup | Clean vents, check thermostat function, clear lint from filter |

| Burning Smell | Lint accumulation, electrical issues, worn belt | Inspect for lint clogs, check wiring, replace any damaged belts |

Tools Needed for Repairs

When tackling maintenance tasks on your appliance, having the right equipment is crucial for efficiency and effectiveness. This section outlines essential instruments that will assist in diagnosing issues and performing necessary fixes, ensuring that your unit operates smoothly.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws of various sizes. |

| Wrench | Useful for loosening and tightening nuts and bolts. |

| Multimeter | To check electrical components and ensure proper functionality. |

| Pliers | For gripping and bending wires or small parts. |

| Flashlight | Helps illuminate dark areas while working. |

| Vacuum Cleaner | To clean dust and debris from internal components. |

| Protective Gloves | To safeguard hands from sharp objects and chemicals. |

Equipping yourself with these tools not only facilitates a smoother process but also enhances safety and precision during your tasks. Proper preparation is key to achieving successful outcomes in any maintenance endeavor.

Step-by-Step Troubleshooting Guide

This section provides a structured approach to identifying and resolving common issues that may arise with your appliance. By following these systematic steps, you can efficiently diagnose problems and apply effective solutions, ultimately ensuring optimal performance.

Identify the Problem

- Observe any unusual sounds or smells.

- Check for error codes on the display, if applicable.

- Consider any recent changes in usage or maintenance.

Common Issues and Solutions

-

No Power:

- Ensure the unit is plugged in securely.

- Check the circuit breaker or fuse box for any tripped breakers or blown fuses.

-

Overheating:

- Clean the lint filter to improve airflow.

- Inspect the venting system for obstructions.

-

Poor Performance:

- Examine the load size and distribution.

- Verify that the settings are appropriate for the fabric type.

By following these guidelines, you can troubleshoot effectively and restore functionality to your appliance with confidence.

Replacing a Broken Heating Element

When a crucial component fails, it can disrupt the entire functioning of your appliance, leading to inadequate performance. Addressing this issue promptly ensures optimal efficiency and extends the lifespan of your unit. This guide will walk you through the steps to replace the faulty element, restoring the necessary heat for effective operation.

Identifying the Problem

Before proceeding with the replacement, it’s essential to confirm that the heating element is indeed the source of the malfunction. Common signs include insufficient warmth or no heat at all during operation. Conducting a simple diagnostic test can help isolate the issue, allowing you to take the next steps confidently.

Step-by-Step Replacement Process

To successfully install a new heating element, begin by disconnecting the appliance from its power source for safety. Once unplugged, remove the necessary panels to access the element. Carefully detach the old component, noting the connections for the new installation. Finally, secure the new part in place, reassemble the panels, and restore power to check for proper functionality.

Cleaning the Lint Filter Effectively

Maintaining optimal performance of your appliance is essential for efficiency and safety. One crucial aspect of upkeep is ensuring the lint trap is free from debris. Regular cleaning helps prevent potential hazards and improves the longevity of your equipment.

Here are some effective steps to clean the lint filter:

- Remove the Filter: Carefully take out the lint trap from its designated slot.

- Inspect for Residue: Check the filter for any build-up or damage that may hinder airflow.

- Gently Clean: Use your fingers or a soft brush to remove loose lint. For stubborn residue, rinse with warm water.

- Dry Thoroughly: Ensure the filter is completely dry before reinserting it to avoid moisture issues.

- Replace Securely: Return the lint trap to its original position, making sure it fits snugly.

By following these steps, you can effectively maintain the efficiency of your appliance and ensure a safer environment in your home.

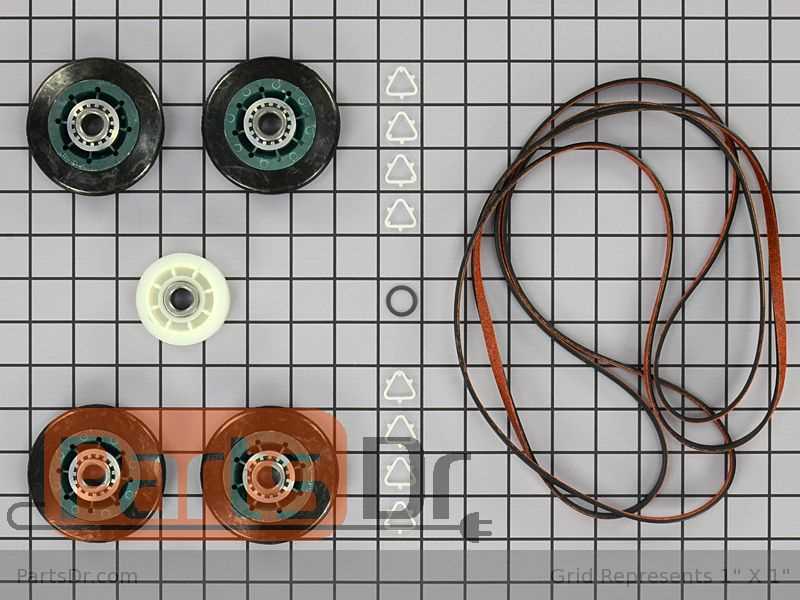

Adjusting Drum Tension and Alignment

Ensuring proper tension and alignment of the drum is crucial for optimal performance and longevity of your appliance. Misalignment or inadequate tension can lead to noise, uneven wear, and inefficient operation. This section outlines the essential steps to achieve the correct setup, enhancing both functionality and durability.

Assessing Tension: Begin by checking the tension of the drum. A well-adjusted drum should rotate smoothly without excessive resistance. If you notice tightness or slack, adjustments may be necessary. Use appropriate tools to modify the tension mechanism, ensuring it is neither too loose nor too tight.

Checking Alignment: Next, examine the alignment of the drum within its housing. An aligned drum will sit evenly, allowing for optimal rotation. If it appears skewed, inspect the support rollers and bearings for wear. Realigning these components can often resolve any issues. Adjust the positioning by loosening the mounting screws and repositioning the drum until it sits correctly.

Final Testing: After making the necessary adjustments, run a short cycle to test the setup. Listen for any unusual sounds and observe the drum’s movement. If everything functions smoothly, your adjustments have been successful. Regular maintenance checks can prevent future issues, ensuring consistent performance.

Checking Electrical Connections

Ensuring reliable electrical connections is crucial for the efficient operation of any appliance. Poor or faulty connections can lead to performance issues or even pose safety risks. By systematically examining the wiring and connections, one can identify potential problems that might hinder functionality.

Start by disconnecting the power supply to eliminate any hazards. Inspect all visible wires for signs of wear, fraying, or corrosion. Make sure that terminals are secure and that there are no loose connections. Using a multimeter, check for continuity and voltage at various points to ensure proper flow of electricity throughout the system.

If any irregularities are found, it may be necessary to replace damaged components or tighten loose connections. After making adjustments, reconnect the power and monitor the appliance to confirm that it operates correctly. Regular checks of electrical connections can prevent future complications and extend the lifespan of the equipment.

Replacing Faulty Thermostats

When the temperature regulation system malfunctions, it can lead to inefficient performance and potential damage. Addressing these issues promptly is crucial for maintaining optimal functionality. This section provides a step-by-step guide to identifying and substituting malfunctioning temperature control devices.

Identifying the Issue

The first step in addressing temperature inconsistencies is diagnosing the problem. Common symptoms include overheating, inadequate heating, or frequent cycling. Utilizing a multimeter can help verify whether the temperature regulator is functioning within the specified range. If readings indicate failure, replacement becomes necessary.

Replacement Process

Begin by disconnecting the appliance from the power source to ensure safety. Access the compartment housing the temperature control device, typically located at the rear or side. Carefully detach the faulty component, noting the wiring configuration for reference. Install the new device, ensuring secure connections, and reassemble the unit. Finally, restore power and conduct a test cycle to confirm proper operation.

Maintaining Your Dryer for Longevity

Proper care and regular upkeep are essential for extending the lifespan of your appliance. By implementing a few simple practices, you can ensure optimal performance and reduce the likelihood of unexpected breakdowns. Regular attention not only enhances efficiency but also saves you money on energy bills and repairs.

Begin by routinely cleaning the lint trap after each use. This small step prevents buildup, which can lead to overheating and decreased effectiveness. Additionally, consider inspecting and cleaning the venting system periodically to avoid clogs that could impair airflow and increase drying times.

Next, keep the exterior and interior of the unit clean. Wipe down surfaces and remove any debris that may accumulate around the door seals and vents. This not only maintains hygiene but also supports proper functioning.

Finally, be mindful of the load sizes. Overloading can strain components and lead to premature wear. Adhering to recommended load capacities will help your appliance operate smoothly and efficiently for years to come.

Identifying Error Codes and Meanings

Understanding the various signals that indicate issues can significantly simplify the troubleshooting process. Each code corresponds to a specific problem, allowing users to diagnose faults effectively. Familiarizing oneself with these indicators empowers users to address concerns promptly, ensuring optimal performance.

Common Error Codes

Below is a table that outlines some frequently encountered error codes along with their meanings:

| Error Code | Meaning |

|---|---|

| E01 | System malfunction detected |

| E02 | Heating element failure |

| E03 | Door latch issue |

| E04 | Blockage in airflow |

| E05 | Power supply irregularity |

Interpreting the Codes

Each code provides critical information that can guide users in determining the necessary steps to resolve issues. Understanding the context of these signals can help in deciding whether to attempt a fix or seek professional assistance. Accurate identification of the problem is the first step toward restoring functionality.

When to Call a Professional Technician

Knowing when to seek the assistance of a skilled expert can save time, money, and further complications. While many minor issues can be resolved independently, certain situations require the expertise of a trained technician.

Here are some scenarios where professional help is essential:

- Unusual Noises: If your appliance starts making strange sounds that were not present before, this may indicate a serious issue that needs attention.

- Inconsistent Performance: When the equipment fails to operate at expected levels, such as not heating or cooling properly, it’s time to call an expert.

- Frequent Breakdowns: Repeated malfunctions can signal underlying problems that require a professional diagnosis.

- Electrical Issues: If you notice sparks, burning smells, or frequent tripping of circuit breakers, immediate professional intervention is necessary.

- Complex Repairs: Tasks involving intricate components or those requiring specialized tools should always be handled by a technician.

Seeking assistance at the right time not only ensures safety but also prolongs the lifespan of your appliance. When in doubt, consulting with a qualified professional is the best course of action.