Essential Guide to Ford 9N Tractor Repair Manual

Understanding the intricacies of agricultural machinery is crucial for anyone engaged in farming activities. Effective maintenance ensures optimal performance, longevity, and reliability of equipment, which ultimately enhances productivity on the field. This section will delve into the necessary knowledge and techniques required for proper upkeep.

Maintenance tasks can often seem daunting, but with the right approach, they become manageable and straightforward. Familiarity with the various components and their functions can significantly ease the process. Emphasis will be placed on systematic checks and adjustments that can prevent costly breakdowns.

Moreover, adopting a proactive stance towards upkeep not only saves time and resources but also contributes to a safer working environment. Through this guide, readers will gain insights into troubleshooting common issues, performing routine inspections, and ensuring that their machinery operates at peak efficiency.

Understanding the Ford 9N Tractor

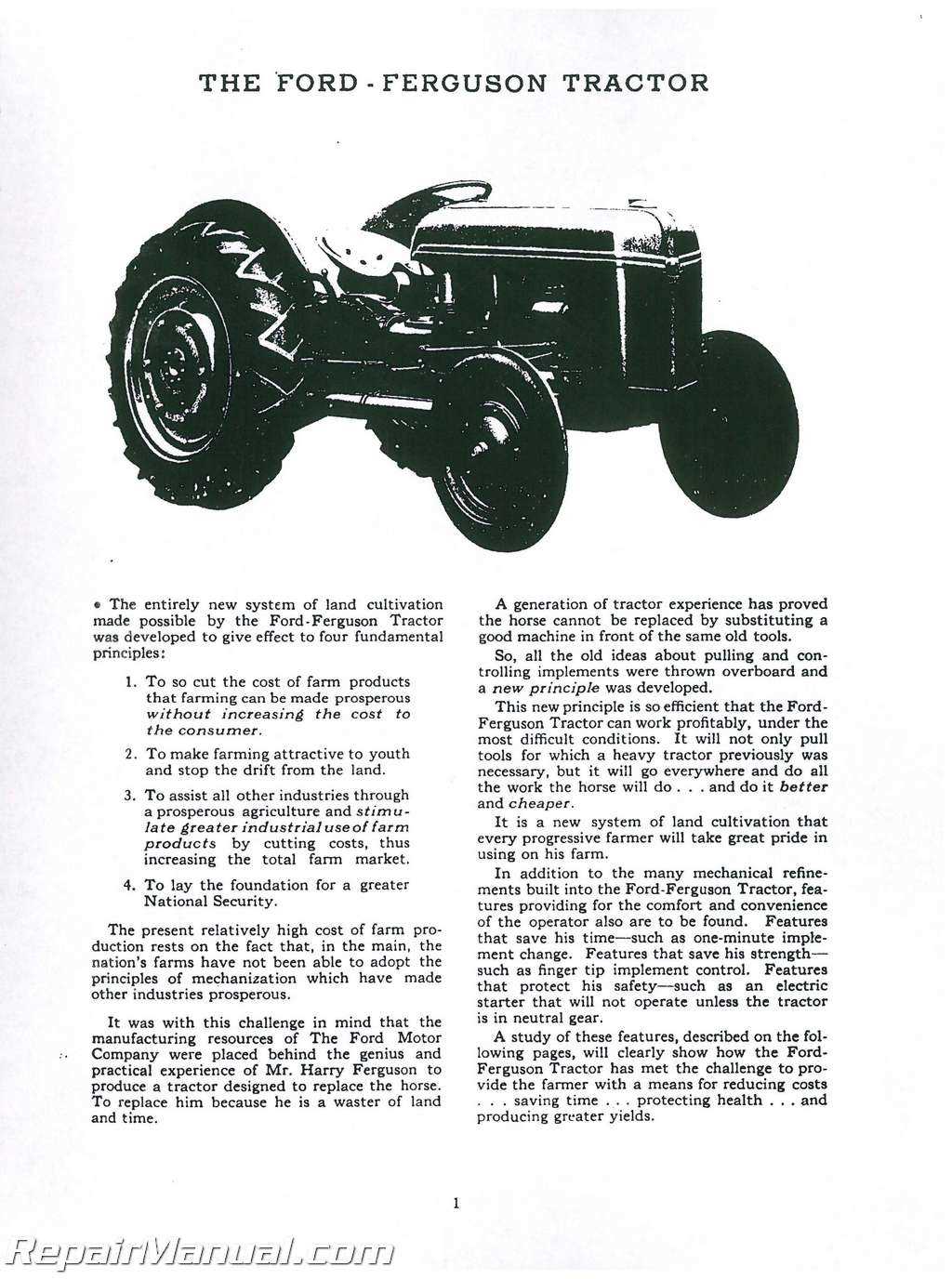

This section delves into the nuances of a historic agricultural machine that has left a significant mark on farming practices. Recognized for its innovative design and functionality, it became a staple for many who relied on its capabilities. Exploring its features and operations provides insight into its enduring legacy and utility in various agricultural tasks.

Historical Context

The inception of this model occurred during a pivotal era in agricultural technology, where the shift from animal power to mechanization was rapidly transforming farming. Introduced in the early 20th century, this machine embodied the spirit of innovation, offering farmers greater efficiency and ease in their daily tasks. Its design reflects a response to the needs of the time, addressing both productivity and reliability.

Key Features

Among its notable characteristics are a robust engine, user-friendly controls, and a durable frame, making it suitable for a range of applications. The engine, often praised for its performance, delivers consistent power, while the simplicity of its design allows for straightforward operation and maintenance. Understanding these features is crucial for appreciating its role in modern agriculture.

In conclusion, examining this remarkable piece of machinery reveals much about the evolution of farming equipment and its lasting impact on agricultural practices.

Common Issues with Ford 9N Tractors

Operating classic machinery often presents unique challenges that owners must navigate. A particular model, known for its vintage design and functionality, can encounter several frequent problems that may impede its performance. Understanding these common issues can help enthusiasts maintain their equipment effectively.

Mechanical Failures

One of the primary concerns involves the mechanical components that are essential for smooth operation. Wear and tear over time can lead to various failures, impacting efficiency and reliability.

| Issue | Description |

|---|---|

| Engine Misfire | Irregular firing can cause power loss and increased fuel consumption. |

| Hydraulic Leaks | Fluid loss can result in reduced lifting capability and performance. |

| Transmission Problems | Difficulty in shifting gears can hinder operation and maneuverability. |

Electrical Issues

Another area that often requires attention is the electrical system. Faulty wiring or components can lead to a host of problems that disrupt normal function.

| Issue | Description |

|---|---|

| Battery Drain | Excessive discharge can leave the system inoperable and cause starting issues. |

| Faulty Ignition | Problems in the ignition system can lead to starting failures and erratic engine behavior. |

| Lighting Failures | Burned-out bulbs or faulty wiring can impair visibility during operation. |

Tools Needed for Repairs

When it comes to maintaining machinery, having the right instruments at your disposal is crucial for efficient and effective work. Whether you’re tackling minor adjustments or significant overhauls, the correct tools can make all the difference in achieving optimal performance.

Essential Instruments

- Wrenches: Various sizes to accommodate different fasteners.

- Screwdrivers: A mix of flathead and Phillips for versatility.

- Socket Set: Ideal for reaching tight spots and ensuring a secure fit.

- Pliers: Useful for gripping, twisting, and cutting.

- Hammer: For driving nails and adjusting parts.

Additional Equipment

- Torque Wrench: Ensures bolts are tightened to the proper specifications.

- Jack Stands: Essential for safely lifting and supporting the equipment.

- Grease Gun: Helps in maintaining lubrication in moving parts.

- Multimeter: A must-have for electrical diagnostics.

- Diagnostic Tools: For troubleshooting and identifying issues.

Having these instruments on hand will not only streamline the maintenance process but also enhance the longevity and reliability of your machinery.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your equipment in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of your machinery. Following these detailed steps ensures that everything operates smoothly and efficiently.

Essential Tools and Supplies

- Wrenches and sockets

- Screwdrivers

- Oil and lubricants

- Filters

- Cleaning supplies

- Safety gear (gloves, goggles)

Maintenance Steps

- Inspect fluid levels and top up as necessary.

- Change the oil and replace the oil filter regularly.

- Check and replace air and fuel filters when needed.

- Examine belts and hoses for signs of wear or damage.

- Grease all moving parts to reduce friction and wear.

- Clean the exterior to prevent corrosion and dirt buildup.

- Test the battery and clean terminals to ensure proper connectivity.

- Inspect tires for pressure and tread wear, and adjust accordingly.

By adhering to these steps, you will help ensure that your equipment remains reliable and efficient for years to come. Regular attention to maintenance will pay off in enhanced performance and fewer unexpected issues.

Engine Troubleshooting Techniques

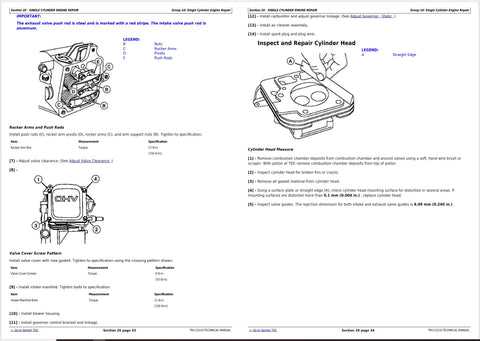

Diagnosing issues within an engine requires a systematic approach to identify the root cause of performance problems. Understanding common symptoms and their potential sources is essential for effective resolution. By employing various assessment methods, operators can streamline the troubleshooting process, ensuring that issues are addressed efficiently.

Begin by observing the engine’s behavior during operation. Pay attention to unusual sounds, vibrations, or changes in power delivery. These indicators can reveal underlying mechanical or electrical faults. Additionally, monitoring fluid levels and checking for leaks can provide valuable insights into the engine’s health.

Next, utilize diagnostic tools such as compression gauges and multimeters to gather quantitative data. Compression tests help assess the integrity of internal components, while electrical diagnostics can pinpoint issues with wiring or sensors. Analyzing this information allows for a more focused investigation into specific areas of concern.

Consulting manufacturer specifications is vital when evaluating performance parameters. Comparing observed data against recommended values can highlight deviations that may indicate faults. Moreover, performing routine maintenance and inspections helps prevent issues before they escalate, promoting longevity and reliability.

In summary, a thorough understanding of symptoms combined with appropriate diagnostic techniques can significantly enhance the troubleshooting process. By methodically assessing and analyzing various aspects of engine performance, operators can effectively identify and resolve issues, ensuring optimal functionality.

Transmission Repair Tips and Tricks

When it comes to maintaining and fixing the power delivery system of your equipment, understanding the intricacies can save both time and resources. Proper attention to detail and knowledge of common issues can significantly enhance performance and longevity. This section provides practical insights and strategies to effectively troubleshoot and resolve transmission challenges.

Common Issues and Solutions

Recognizing frequent problems can expedite the diagnostic process. Here are some typical symptoms and their potential fixes:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Difficulty shifting gears | Low fluid levels | Check and refill transmission fluid |

| Slipping transmission | Worn clutch components | Inspect and replace clutch if necessary |

| Unusual noises | Faulty bearings | Examine and replace damaged bearings |

Maintenance Best Practices

Regular upkeep can prevent many transmission issues from arising. Consider these best practices to maintain optimal functionality:

- Check fluid levels routinely and replace fluid according to the schedule.

- Inspect components for wear and tear, addressing any signs of damage promptly.

- Keep the system clean to avoid debris build-up that can lead to malfunction.

Electrical System Diagnostics

The efficiency of any agricultural machine heavily relies on its electrical components. Diagnosing issues within the electrical framework is crucial for maintaining optimal performance and preventing breakdowns. This section aims to provide a systematic approach to identifying and resolving common electrical problems.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical malfunctions is the first step in troubleshooting. Below are typical symptoms that may indicate underlying issues:

| Symptom | Possible Cause |

|---|---|

| No Start | Dead battery, faulty ignition switch |

| Dim Lights | Weak battery, poor connections |

| Intermittent Power | Worn wiring, loose connections |

| Blown Fuses | Overloaded circuit, short circuit |

Troubleshooting Steps

To effectively address electrical issues, follow these steps:

- Inspect the battery for charge and corrosion.

- Check all connections for tightness and cleanliness.

- Test individual components using a multimeter.

- Replace any faulty fuses and monitor for recurrence.

Systematic diagnostics can significantly reduce downtime and enhance the longevity of equipment. Ensuring the electrical system functions correctly is essential for peak operational performance.

Hydraulic System Maintenance Overview

The hydraulic system plays a crucial role in the overall performance of agricultural machinery, providing the necessary power for various functions. Regular upkeep is essential to ensure optimal functionality, prevent breakdowns, and extend the lifespan of the components. This section outlines key maintenance practices to keep the hydraulic system operating smoothly.

Routine checks and timely interventions can prevent minor issues from escalating into major repairs. Focus on monitoring fluid levels, inspecting hoses and connections, and ensuring that filters are clean. Maintaining these elements will help ensure that the hydraulic system remains efficient and reliable.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Level Check | Monthly | Ensure hydraulic fluid is at the recommended level to maintain pressure and performance. |

| Filter Inspection | Every 500 hours | Check and replace filters to prevent contaminants from entering the system. |

| Hose Condition Check | Quarterly | Inspect hoses for cracks, leaks, or wear to avoid failures during operation. |

| Connection Tightness | Every 100 hours | Ensure all connections are tight to prevent fluid loss and maintain system integrity. |

By adhering to these maintenance guidelines, operators can significantly enhance the performance and reliability of the hydraulic system, ensuring seamless operation during critical tasks.

Restoration Tips for Vintage Models

Restoring classic machinery is a rewarding endeavor that combines skill, patience, and a passion for history. Each project presents unique challenges and opportunities to breathe new life into timeworn equipment. Proper planning and technique can transform these treasures into fully functional pieces that honor their heritage.

Begin with thorough research to understand the specific model’s history and common issues faced during restoration. Gathering original documents and images can provide insight into authentic parts and finishes. Establish a detailed plan that outlines the steps necessary for the revival, including budgeting for parts and tools.

When disassembling components, label and organize each part to ensure an efficient reassembly process. Clean all surfaces meticulously, removing decades of grime and rust. Utilize appropriate solvents and tools to avoid damaging delicate elements. For any repairs, consider using original specifications to maintain authenticity.

While sourcing replacement parts, prioritize quality and compatibility. Seek out reputable suppliers who specialize in vintage components. Joining online forums or local clubs can connect you with other enthusiasts who may have valuable insights or spare parts.

Finally, document each stage of the process through photographs and notes. This not only helps in future maintenance but also provides a fascinating chronicle of your restoration journey. Embrace the challenges, and let the passion for preserving history guide your efforts.

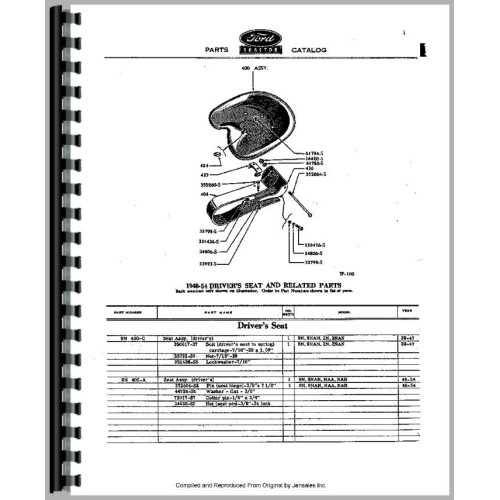

Finding Replacement Parts Easily

Locating suitable components for your machinery can often feel overwhelming. However, with the right strategies and resources, the process can be streamlined significantly. This section aims to provide you with effective methods to identify and acquire the necessary parts swiftly.

Online Marketplaces are invaluable when searching for components. Websites dedicated to machinery supplies often have extensive inventories, allowing you to compare prices and availability. Utilize search filters to narrow down your options based on specifications and compatibility.

Local Dealerships and specialized shops can also be a reliable source. Establishing a relationship with these vendors may provide access to exclusive offers or expert advice. Always inquire about any upcoming promotions or discounts that could aid in your search.

Community Forums and online groups can be treasure troves of information. Engaging with fellow enthusiasts can lead to recommendations for suppliers or even tips on sourcing hard-to-find items. Don’t hesitate to share your own experiences as well.

Salvage Yards are another option worth considering. These places often house a variety of used components at a fraction of the cost of new ones. Although it may require some digging, the savings can be substantial, and you might find quality parts in good condition.

By utilizing these avenues, you can enhance your chances of finding the components you need, ensuring that your equipment remains in optimal working condition.