Coleman Powermate 6250 Repair Manual Guide

In the world of portable energy solutions, the reliability and functionality of power generators are paramount. Understanding the intricacies of these devices can significantly enhance their lifespan and efficiency. This section delves into essential insights that equip users with the knowledge to troubleshoot and maintain their equipment effectively.

Whether you’re facing minor issues or preparing for routine upkeep, having a solid foundation in the operating principles and common challenges can make all the difference. By familiarizing yourself with various components and procedures, you’ll be empowered to tackle repairs with confidence and ensure your generator remains in peak condition.

This guide offers a structured approach to addressing typical problems, including step-by-step instructions and helpful tips. With a focus on practical applications, readers will gain a deeper understanding of their equipment, ultimately leading to smoother operation and enhanced reliability.

Overview

This section provides a comprehensive look at a portable energy solution designed for various applications. Known for its reliability and performance, this device is a popular choice among users who require power in remote locations or during emergencies.

Featuring a robust engine and a sturdy frame, this unit is built to withstand challenging conditions. Its easy portability makes it ideal for outdoor activities such as camping and tailgating, as well as for home backup during power outages.

The device offers a range of output options, allowing users to power multiple appliances simultaneously. With user-friendly controls and an efficient fuel system, it ensures convenience and effectiveness. Whether for recreational use or essential needs, this generator stands out as a practical and dependable power source.

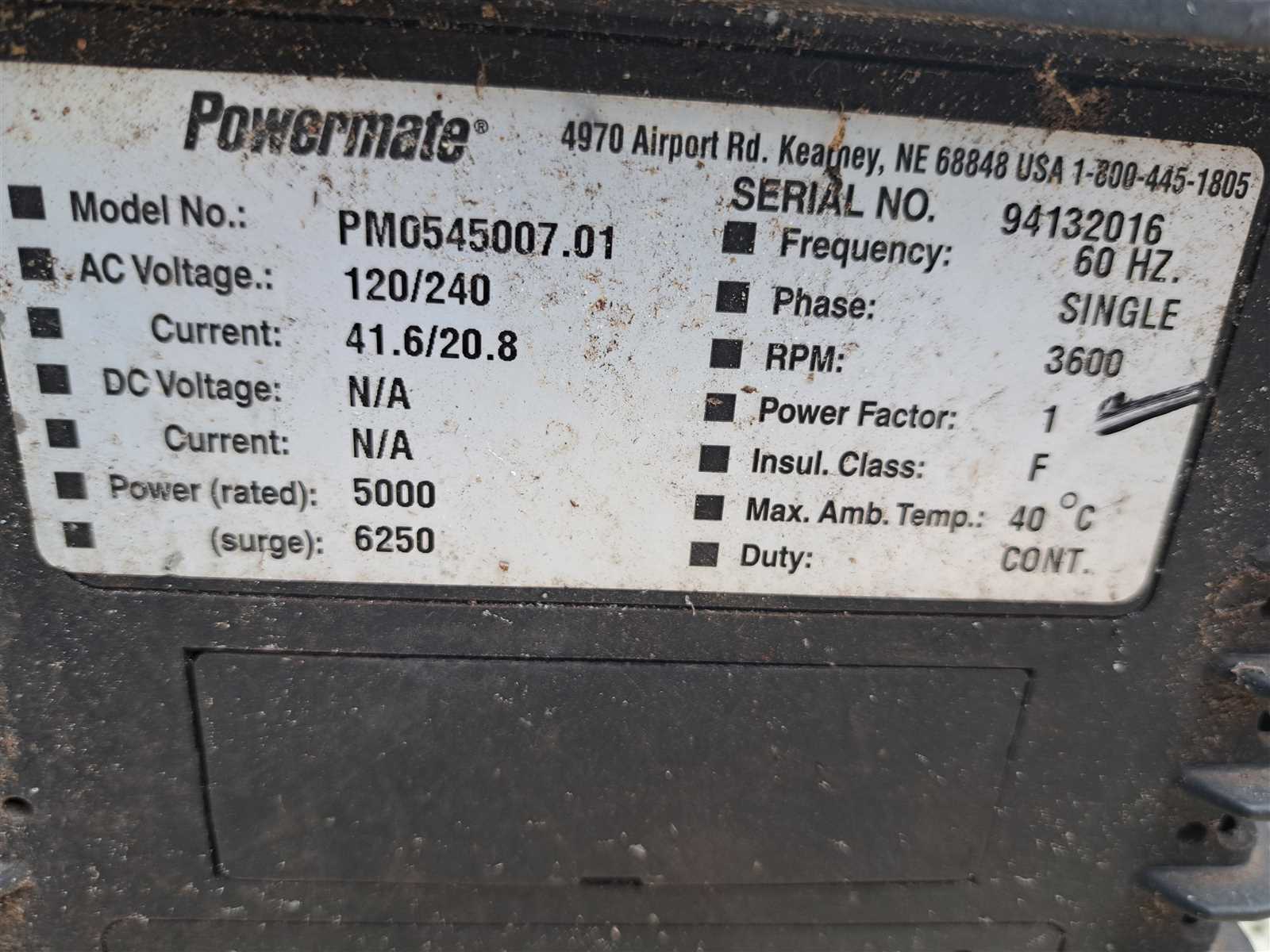

Key Specifications: The generator boasts impressive wattage capabilities, making it suitable for both light and heavy-duty tasks. Its fuel efficiency contributes to longer run times, providing peace of mind for users in need of consistent energy.

Maintenance and Care: Regular upkeep is essential to prolong the life of the equipment. Simple checks and routine servicing can help maintain optimal performance and prevent potential issues.

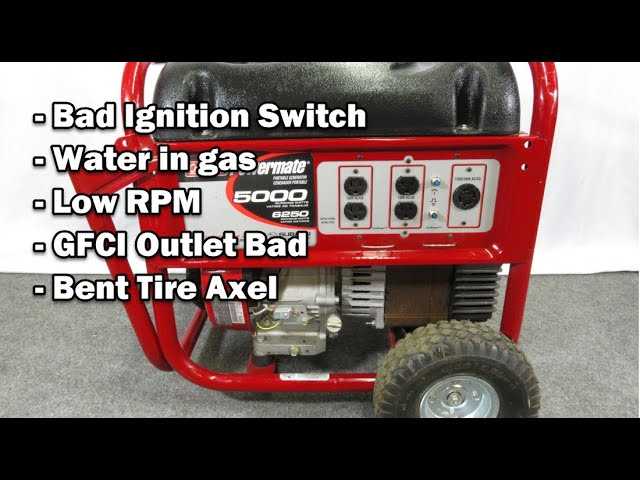

Common Issues with Coleman Powermate

When operating portable power generators, users often encounter several recurring challenges that can hinder performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity. Below are some frequently observed problems that owners should be aware of.

1. Fuel System Problems: A common concern is related to the fuel system, including clogged filters and improper fuel types. These issues can lead to reduced power output and difficulty in starting the unit.

2. Electrical Failures: Users may experience electrical malfunctions such as tripped circuit breakers or inconsistent voltage. These problems can stem from overloaded circuits or faulty wiring connections.

3. Maintenance Neglect: Regular maintenance is essential for any power equipment. Neglecting tasks such as oil changes and air filter replacements can result in decreased performance and increased wear.

4. Noise Levels: Excessive noise during operation can be a concern for many users. This may indicate underlying issues with the engine or muffler, requiring attention to prevent further complications.

5. Starting Difficulties: Difficulty in starting the generator is another prevalent issue, often caused by battery failure, fuel line issues, or a malfunctioning ignition system.

By being aware of these potential challenges, users can take proactive steps to address them and maintain their equipment in optimal working condition.

Essential Tools for Repairs

Having the right equipment is crucial for successfully addressing mechanical issues. Whether tackling minor adjustments or significant overhauls, a well-equipped toolkit can make all the difference. Understanding which instruments are necessary can streamline the process and enhance efficiency.

Basic Toolkit Essentials

- Wrenches: Various sizes are essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: Provides a range of sizes to accommodate different nuts and bolts.

- Hammer: Helpful for driving nails or making minor adjustments.

Specialized Tools

- Multimeter: Essential for diagnosing electrical issues and measuring voltage.

- Torque Wrench: Ensures bolts are tightened to the specified level.

- Jack and Stands: Necessary for lifting equipment safely during maintenance.

- Leak Detector: Useful for identifying fluid leaks in various systems.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues encountered with portable power generators. Following a systematic procedure will help ensure efficient restoration of functionality, allowing you to make informed decisions and tackle repairs with confidence.

Identifying the Problem

The first step in the process is to accurately diagnose the issue at hand. Begin by examining the unit for any visible signs of damage, unusual noises, or performance irregularities. It is crucial to gather as much information as possible regarding the symptoms before proceeding with disassembly or further inspection.

Gathering Tools and Parts

Once the problem is identified, assemble the necessary tools and replacement components. Commonly required items may include wrenches, screwdrivers, and various electrical parts. Ensure you have access to a workspace that is clean and well-lit to facilitate a smooth repair process.

Safety Precautions During Repair

Ensuring a safe environment while addressing equipment issues is crucial for both personal safety and effective maintenance. Adhering to specific guidelines minimizes risks and promotes a successful outcome. Here are essential safety measures to consider before beginning any maintenance task.

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling fumes or dust particles.

- Ensure the equipment is powered off and disconnected from any power source before starting work.

- Keep the workspace organized and free from clutter to prevent accidents.

Before initiating any service, familiarize yourself with the equipment’s specifications and guidelines to enhance safety and efficiency.

- Inspect tools for damage; replace any that are worn or broken.

- Utilize proper lifting techniques to prevent injury when handling heavy components.

- Store flammable materials away from the work area to reduce fire hazards.

- Have a first aid kit readily available in case of minor injuries.

By following these precautions, you can create a safer work environment and effectively address any issues that arise.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your equipment requires regular upkeep and attention. By implementing a few straightforward practices, you can significantly extend the lifespan and performance of your machine.

- Regular Cleaning: Keep the exterior and interior components clean. Dust, dirt, and debris can hinder performance and lead to wear over time.

- Check Fluid Levels: Regularly monitor oil and fuel levels. Maintaining appropriate levels is crucial for optimal function and preventing damage.

- Inspect Components: Periodically examine belts, hoses, and filters for wear and tear. Replace any worn parts promptly to avoid further issues.

- Follow Operating Guidelines: Adhere to the manufacturer’s recommendations regarding usage and maintenance schedules. This ensures you are using the equipment as intended.

- Store Properly: When not in use, store the device in a dry, sheltered location. Protecting it from the elements helps prevent corrosion and damage.

By incorporating these maintenance strategies into your routine, you can enjoy enhanced reliability and performance, ensuring that your equipment serves you well for years to come.

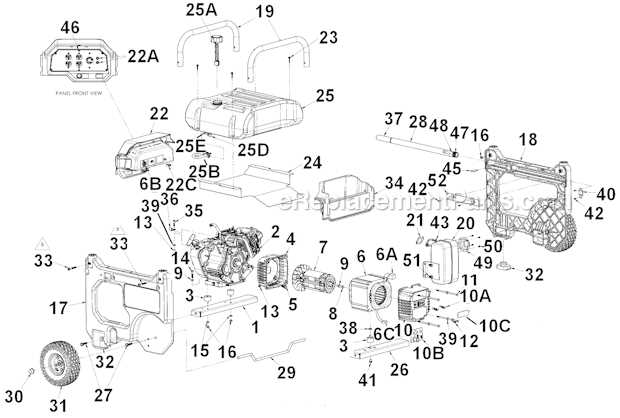

Parts Replacement and Sourcing

Maintaining equipment often requires replacing worn or damaged components to ensure optimal performance. Identifying the right parts and sourcing them effectively is crucial for keeping machinery running smoothly. This section focuses on the strategies for sourcing replacements and the considerations to keep in mind during the process.

When it comes to finding parts, it is essential to know the specifications and compatibility of the components needed. Understanding the model and type of equipment helps streamline the search process. There are various avenues available for obtaining these items, ranging from authorized dealers to aftermarket suppliers.

| Source Type | Description | Pros | Cons |

|---|---|---|---|

| Authorized Dealers | Official sellers of original parts | Guaranteed compatibility, high quality | Usually more expensive |

| Aftermarket Suppliers | Third-party manufacturers providing alternatives | Cost-effective options, wide variety | Quality may vary, potential compatibility issues |

| Online Marketplaces | Platforms for buying and selling various parts | Convenient, often competitive prices | Risk of counterfeit products, variable seller reliability |

| Local Hardware Stores | Physical stores that stock a range of components | Immediate availability, personalized assistance | Limited selection, may not have specific parts |

Regardless of the source chosen, verifying part numbers and reading reviews can help ensure the right fit and quality. By following these guidelines, users can effectively manage parts replacement and maintain the longevity of their equipment.

Troubleshooting Electrical Problems

Electrical issues can arise unexpectedly and often disrupt the smooth operation of your equipment. Identifying the source of these problems is essential for ensuring safety and restoring functionality. This section outlines common electrical issues, diagnostic steps, and potential solutions to help you get back on track.

Here are some typical electrical problems you might encounter:

- Power failures

- Intermittent operation

- Overheating components

- Flickering lights

To effectively troubleshoot these issues, follow these systematic steps:

- Check the Power Source: Ensure that the unit is plugged in and that the outlet is functioning. Use a multimeter to test for voltage if necessary.

- Inspect Cables and Connections: Look for frayed wires, loose connections, or signs of wear. Tighten or replace any damaged components.

- Examine Fuses and Breakers: Inspect fuses for continuity and reset any tripped circuit breakers. Replace blown fuses as needed.

- Test Components: Use a multimeter to check the functionality of key components, such as switches, relays, and circuit boards.

When addressing electrical problems, remember these safety precautions:

- Always disconnect power before inspecting or repairing components.

- Use insulated tools to prevent shock hazards.

- Consult a professional if you’re unsure about any procedures.

By following these guidelines, you can effectively troubleshoot and resolve electrical issues, ensuring the reliable performance of your equipment.

Fuel System Maintenance Explained

Ensuring the optimal performance of an engine heavily relies on the condition of its fuel system. This critical component requires regular attention to prevent issues that could lead to inefficient operation or potential breakdowns. Proper maintenance not only enhances functionality but also extends the lifespan of the machinery.

One of the primary aspects of fuel system care involves regularly inspecting and replacing fuel filters. These filters are essential in trapping impurities that could clog fuel lines or injectors, thus impairing engine performance. Keeping them clean ensures a steady flow of fuel and reduces the risk of damage.

Another important maintenance task is checking for leaks within the system. Fuel leaks can lead to safety hazards and significant performance issues. Periodically examining hoses, connections, and the fuel tank helps in identifying potential problems early on, allowing for timely repairs.

Furthermore, using the appropriate type of fuel is crucial. Different engines are designed to operate with specific fuel grades, and using the wrong type can result in subpar performance and increased wear. It’s advisable to consult the manufacturer’s guidelines to ensure compliance.

Finally, periodically cleaning the fuel injectors can significantly enhance engine efficiency. Over time, deposits can build up, leading to reduced fuel flow and performance. Professional cleaning services or dedicated fuel additives can help maintain injector cleanliness, promoting smoother operation and improved fuel economy.

Customer Support and Resources

Accessing reliable assistance and information is essential for ensuring optimal performance of your equipment. This section provides valuable avenues for obtaining support and resources that can enhance your experience and address any issues that may arise.

Support Channels

- Online Help Center: A comprehensive database of articles and guides.

- Customer Service Hotline: Speak directly with a representative for personalized help.

- Email Support: Send inquiries and receive detailed responses.

Additional Resources

- User Forums: Connect with other users to share experiences and solutions.

- Video Tutorials: Visual guides to assist with common problems and maintenance tips.

- Product Documentation: Access detailed specifications and usage guidelines.