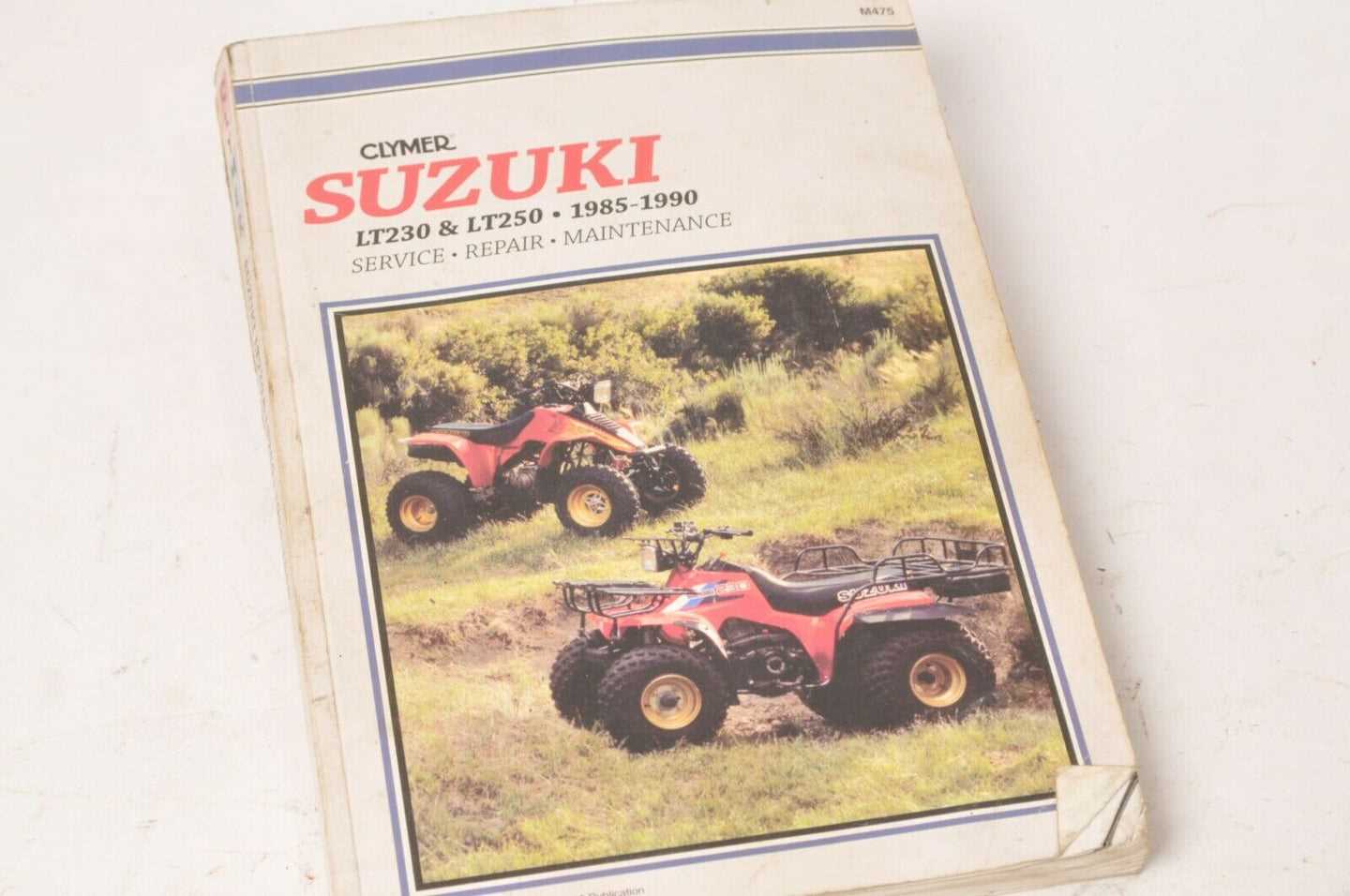

Suzuki LT230 Repair Guide

Proper upkeep of your off-road vehicle is essential for ensuring optimal performance and longevity. This section provides insights into the essential practices and procedures that will help maintain your vehicle’s functionality and reliability.

Understanding the intricacies of your machine can enhance your ability to troubleshoot and resolve common issues. By following comprehensive guidelines and utilizing appropriate resources, you can ensure that your vehicle remains in excellent condition, ready for any adventure.

Whether you’re a seasoned enthusiast or a newcomer to the world of all-terrain vehicles, familiarizing yourself with essential care techniques can significantly improve your experience. Engaging with well-structured information allows for informed decisions and effective actions in maintaining your machine.

Essential Tools for Repairs

To effectively maintain and restore your all-terrain vehicle, having the right equipment is crucial. This section focuses on the fundamental tools necessary for servicing and troubleshooting, ensuring that you are well-prepared for any task at hand.

Wrenches are essential for loosening and tightening various components, while screwdrivers allow for easy access to intricate parts. It’s advisable to have a complete set that includes both flathead and Phillips options.

Another important item is a socket set, which provides versatility in dealing with different bolt sizes. Additionally, pliers can be invaluable for gripping and twisting various elements during maintenance.

Don’t overlook the need for jacks or stands, which help elevate the vehicle safely, making it easier to work underneath. Furthermore, a reliable multimeter is necessary for diagnosing electrical issues, ensuring everything is functioning correctly.

Having a well-stocked toolbox is not just about convenience; it significantly enhances your ability to perform quality upkeep on your machine, allowing for a smooth and efficient experience.

Common Issues and Solutions

This section addresses frequent problems encountered by users and provides practical remedies. Understanding these challenges can enhance the overall experience and performance of your vehicle.

Electrical Failures

One of the typical issues is electrical malfunctions, which can lead to starting difficulties or lighting problems. Here are some solutions:

- Check the battery for corrosion or loose connections.

- Inspect the wiring for any signs of wear or damage.

- Replace faulty fuses that may be affecting electrical components.

Engine Performance

Engine performance may decline due to various factors. Consider the following solutions:

- Ensure that the air filter is clean and free of debris.

- Change the oil and replace the oil filter regularly.

- Examine the fuel system for clogs or leaks.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your all-terrain vehicle remains in optimal condition. Regular upkeep is essential for performance and longevity, and following this structured guide will help you navigate through the necessary tasks with ease.

Essential Maintenance Tasks

To keep your vehicle running smoothly, certain tasks should be performed regularly. Below is a table outlining these essential activities along with their recommended frequency:

| Task | Frequency |

|---|---|

| Oil Change | Every 1,000 miles or 3 months |

| Air Filter Inspection | Every 500 miles |

| Tire Pressure Check | Monthly |

| Brake System Inspection | Every 2,000 miles |

Detailed Steps for Each Task

Following these detailed steps for each maintenance task will ensure effective upkeep:

- For oil changes, start by warming up the engine, then drain the old oil and replace it with fresh lubricant.

- Inspect the air filter for debris and replace it if necessary to maintain airflow.

- Check the tire pressure using a gauge and inflate as needed to recommended levels.

- Examine the brake components for wear and replace any parts that show signs of damage.

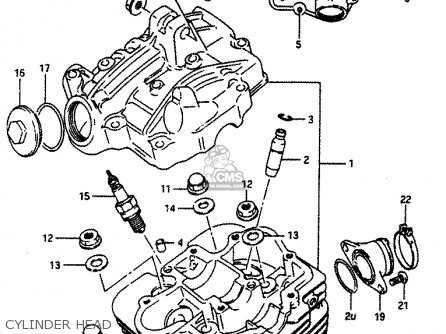

Engine Troubleshooting Techniques

Diagnosing issues within an engine can be a complex task, requiring a systematic approach to identify and resolve various problems. Employing effective techniques can help in pinpointing the source of malfunctions, ensuring optimal performance and longevity.

Here are some key methods to assist in the troubleshooting process:

- Visual Inspection: Begin with a thorough examination of the engine components. Look for signs of wear, damage, or leaks that may indicate underlying issues.

- Check Fluid Levels: Regularly monitor oil and coolant levels. Low levels can lead to overheating and increased wear.

- Listen for Unusual Noises: Pay attention to any strange sounds during operation. Knocking or grinding noises can signify serious problems.

- Examine Spark Plugs: Remove and inspect spark plugs for signs of fouling or wear. This can provide insight into combustion efficiency and engine health.

Additionally, utilizing diagnostic tools can enhance the troubleshooting process:

- Use an engine analyzer to check for error codes.

- Perform a compression test to evaluate the internal condition.

- Inspect fuel delivery systems for blockages or malfunctions.

By following these techniques, you can effectively address engine-related issues and maintain peak performance.

Transmission Repair Overview

This section focuses on the essential aspects of addressing issues related to the power transfer system in an all-terrain vehicle. Proper understanding and maintenance of this component are crucial for optimal performance and longevity.

Common Issues

Transmission problems can arise from various factors, including wear and tear, improper lubrication, or external damage. Identifying these concerns early can prevent more significant failures and costly repairs.

Maintenance Tips

Regular inspections and fluid changes are vital for maintaining the functionality of the transmission. Ensuring that the system is free from debris and contaminants will help extend its lifespan. Always refer to the manufacturer’s guidelines for specific recommendations regarding service intervals.

Electrical System Diagnostics

This section focuses on evaluating the electrical framework of your vehicle, ensuring optimal functionality. Understanding the various components and their interactions is crucial for identifying issues and maintaining performance.

Component Inspection

Begin by examining each element within the electrical system, such as the battery, wiring, and connections. Look for signs of wear, corrosion, or damage. A thorough inspection can reveal potential problems that might affect overall operation.

Testing Procedures

Employ diagnostic tools to assess the voltage and continuity across circuits. Utilize a multimeter to measure electrical values accurately. Regular testing can help pinpoint malfunctioning parts, enabling timely repairs and preventing further complications.

Suspension System Adjustments

Ensuring optimal performance of the suspension framework is crucial for maintaining stability and comfort during operation. Proper adjustments can significantly enhance the handling characteristics and overall ride quality.

To achieve the desired setup, begin by assessing the current condition of the suspension components. Inspect for any signs of wear or damage, as this may affect the system’s functionality. Adjustments should focus on spring tension and damping settings to cater to various riding conditions.

When altering the suspension settings, take into account the weight of the rider and any additional loads. This will help in fine-tuning the suspension for improved responsiveness and safety. Regularly checking and adjusting the system not only prolongs its lifespan but also enhances the riding experience.

Brake System Inspection Tips

Ensuring the proper functioning of the braking mechanism is crucial for safety and performance. Regular assessments can help identify issues before they escalate, allowing for timely maintenance and improved reliability.

Visual Check for Wear and Damage

Begin by examining the braking components for any visible signs of wear, such as cracks, fraying, or excessive corrosion. Inspect the pads and discs to ensure they are within acceptable thickness limits and free from any foreign debris that could affect their effectiveness.

Fluid Condition and Levels

Check the hydraulic fluid levels in the reservoir and inspect the fluid’s condition. Look for discoloration or contamination, which may indicate the need for a fluid change. Ensure that all hoses and connections are secure and free from leaks.

Parts Replacement Guide

This section provides essential information on how to effectively swap out components in your all-terrain vehicle. Regular maintenance and timely part replacements are crucial for optimal performance and longevity.

When it comes to upgrading or replacing parts, it’s vital to consult reliable resources and use compatible items. Begin by identifying the specific parts that require attention, whether due to wear, damage, or performance issues. Keeping an inventory of common replacements can simplify the process.

For best results, follow these guidelines:

- Ensure you have the right tools and equipment for the job.

- Refer to detailed specifications for each component before removal.

- Maintain cleanliness during the replacement process to prevent contamination.

- Carefully test the vehicle after replacements to verify functionality.

By adhering to these principles, you can ensure a smoother replacement experience and enhance the overall efficiency of your vehicle.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe working environment is crucial. Proper precautions help minimize risks and protect both the individual performing the work and the equipment involved.

Always wear appropriate protective gear, such as gloves, goggles, and sturdy footwear. This equipment is essential to guard against potential hazards, including sharp objects and chemical exposure.

Before starting any task, make sure the area is well-ventilated and free of clutter. An organized workspace reduces the likelihood of accidents and enables efficient work flow.

Disconnect power sources and secure any moving parts before conducting inspections or modifications. This prevents unintended activation and safeguards the technician from injury.

Lastly, always refer to relevant documentation for guidance on specific safety measures. Following these protocols ensures a safer, more effective maintenance experience.