Comprehensive Guide to Ford 6610 Tractor Repair Manual

In the world of agriculture, ensuring the efficiency and longevity of essential machinery is paramount. Understanding the intricacies of maintenance can significantly enhance the performance of your equipment, preventing costly downtime and extending its operational life. This guide aims to provide valuable insights into the various aspects of caring for your heavy-duty vehicles.

Proper upkeep involves a comprehensive approach that includes regular inspections, timely servicing, and the use of quality components. Familiarity with the specific features and requirements of your machine is crucial for effective management. This knowledge empowers operators to address potential issues proactively, ensuring seamless functionality in demanding environments.

By delving into systematic procedures and troubleshooting techniques, this resource equips users with the tools necessary to tackle common challenges. From basic maintenance tasks to more complex repairs, mastering these skills can lead to improved reliability and efficiency. Embrace the journey of understanding your machinery better and unlock its full potential.

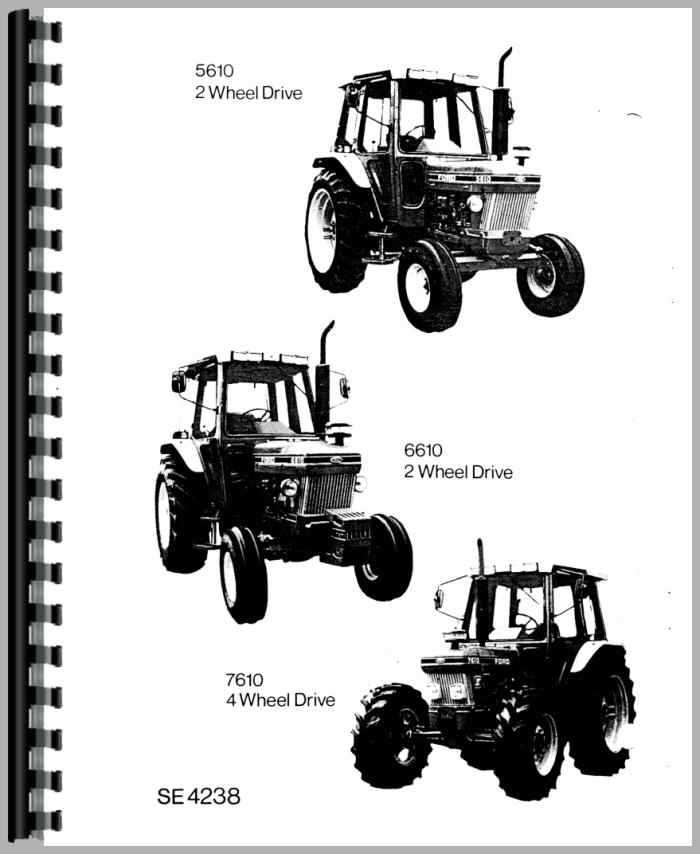

Overview of Ford 6610 Tractor

This section provides an insight into a robust agricultural machine known for its versatility and efficiency. Designed to meet the needs of modern farming, it boasts a range of features that enhance performance in various tasks. Understanding its capabilities and specifications is essential for operators looking to maximize productivity.

Key Features

The model is equipped with a powerful engine that delivers impressive horsepower, making it suitable for heavy-duty applications. Its advanced transmission system allows for smooth gear changes, enhancing control over different terrains. Additionally, the design prioritizes operator comfort, ensuring that users can work for extended periods without fatigue.

Applications

This machine excels in multiple roles, from plowing and tilling to hauling and transporting goods. Its adaptability to different attachments makes it a valuable asset on any farm. Whether tackling large fields or smaller plots, this model provides reliability and efficiency that farmers depend on.

Common Issues with Ford 6610

Maintenance and functionality challenges can arise with agricultural machinery over time. Understanding frequent problems can help in timely diagnosis and effective solutions, ensuring optimal performance and longevity.

- Electrical System Failures:

- Battery issues, including poor charging or faulty connections.

- Wiring harness wear leading to short circuits.

- Malfunctioning alternators affecting power supply.

- Hydraulic System Problems:

- Leaks in hoses or connections, causing pressure loss.

- Faulty pumps resulting in inadequate fluid movement.

- Filter blockages impacting overall hydraulic efficiency.

- Engine Performance Issues:

- Overheating due to coolant leaks or blocked radiators.

- Difficulty starting, often linked to fuel system problems.

- Loss of power attributed to air filter restrictions.

- Transmission Complications:

- Difficulty shifting gears, which may indicate low fluid levels.

- Strange noises when engaging gears suggesting wear.

- Slipping issues that can arise from clutch wear or damage.

By being aware of these common issues, operators can take proactive steps to maintain their equipment, ensuring efficient operation and reducing downtime.

Essential Tools for Repair

Having the right instruments at hand is crucial for effective maintenance and troubleshooting of machinery. A well-equipped workspace ensures that you can tackle any issue efficiently, enhancing both safety and productivity. Below is a list of indispensable tools that will aid in various tasks.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening nuts and bolts. |

| Wrenches | To provide leverage for turning fasteners. |

| Screwdrivers | Essential for assembling and disassembling components. |

| Pliers | Useful for gripping and bending wires or small parts. |

| Torque Wrench | To apply a specific torque to fasteners, ensuring proper tightness. |

| Multimeter | For diagnosing electrical issues and measuring voltage, current, and resistance. |

| Impact Gun | For quickly loosening stubborn bolts. |

| Oil Filter Wrench | To easily remove and install oil filters. |

By equipping yourself with these essential tools, you will be better prepared to address any challenges that arise during maintenance tasks. Investing in quality instruments will not only streamline your workflow but also prolong the lifespan of your equipment.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of agricultural machinery. By adhering to systematic procedures, operators can prevent breakdowns and enhance efficiency. This guide outlines fundamental practices to maintain equipment effectively.

Daily Maintenance Tasks

- Inspect fluid levels: Check oil, coolant, and fuel to ensure they are within the recommended ranges.

- Examine filters: Review air and fuel filters for clogs and replace as necessary.

- Clean external components: Remove dirt and debris from the exterior, especially around vents and radiators.

- Check tire pressure: Ensure that all tires are inflated to the specified levels for safe operation.

Weekly Maintenance Procedures

- Lubricate moving parts: Apply grease to joints and bearings to minimize wear and tear.

- Inspect belts and hoses: Look for signs of wear, cracking, or fraying, and replace any damaged components.

- Test battery: Check the charge level and clean terminals to prevent corrosion.

- Examine lights and signals: Ensure all lights are functioning properly for safe operation in low visibility.

Following these procedures diligently will not only extend the life of the equipment but also enhance its reliability during use. Regular maintenance fosters a safer and more productive working environment.

Engine Troubleshooting Tips

When facing issues with a power unit, identifying the root cause can often feel overwhelming. However, systematic examination and understanding of common symptoms can streamline the process and lead to effective solutions. This section provides practical advice to help diagnose and rectify common engine problems, ensuring optimal performance.

Common Symptoms and Their Causes

One of the first steps in troubleshooting is recognizing typical signs of malfunction. For instance, if the engine is struggling to start, it may indicate a weak battery or faulty ignition system. Excessive smoke can also point to issues such as oil leaks or fuel mixture problems. Always take note of the color and quantity of smoke, as these details are vital for diagnosis.

Steps to Diagnose Issues

Begin by conducting a visual inspection. Look for obvious leaks, damaged components, or loose connections. Check the fluid levels as low oil or coolant can lead to significant issues. Next, utilize diagnostic tools like pressure gauges or code readers to gather more information. Testing electrical systems is also crucial, as many engine problems stem from faulty wiring or sensors. Address each symptom methodically to uncover the underlying cause.

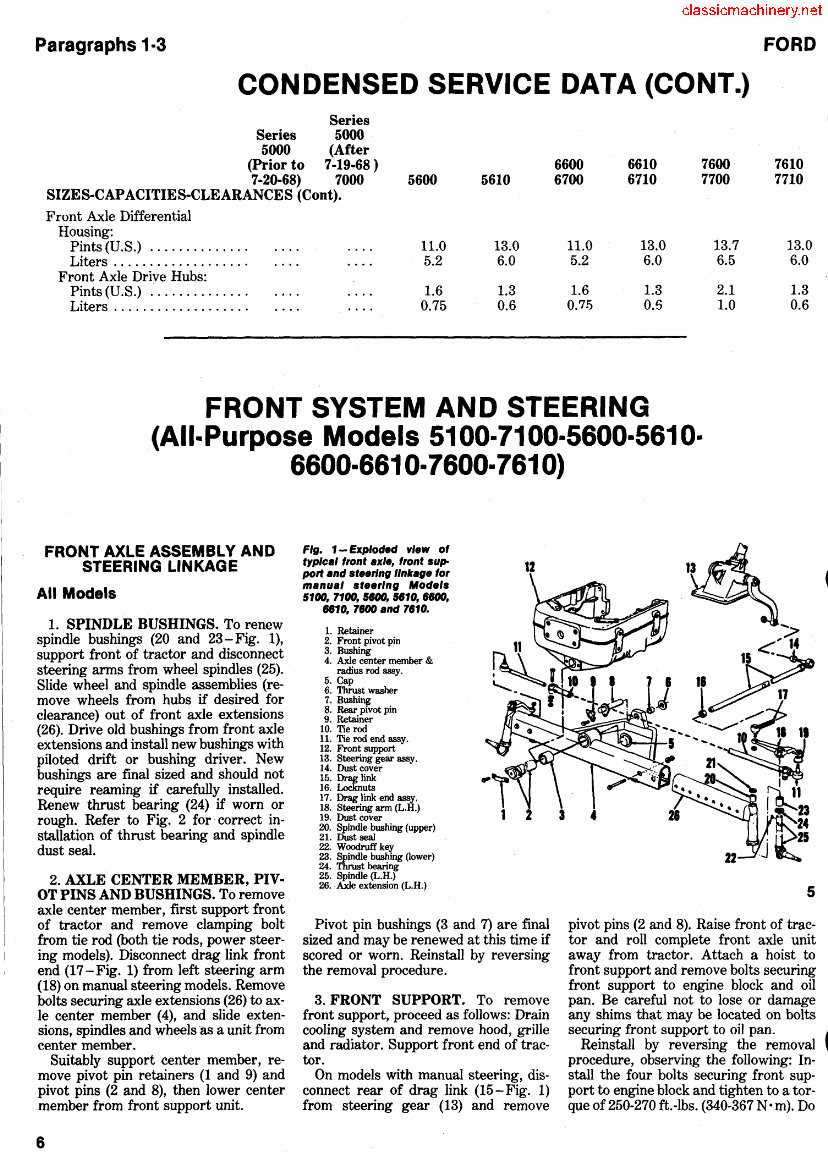

Transmission Repair Techniques

The process of addressing issues within a transmission system is crucial for maintaining optimal performance. Understanding the common problems that can arise, along with the methods to rectify them, can significantly enhance longevity and efficiency.

Identifying Symptoms is the first step in troubleshooting. Unusual noises, slipping gears, or fluid leaks often signal underlying issues. Careful observation can provide valuable insights into the necessary interventions.

Disassembly of the unit requires meticulous attention. Documenting the arrangement of components helps prevent errors during reassembly. Using appropriate tools to carefully remove parts ensures that no damage occurs in the process.

Inspection of each component is vital. Look for wear, cracks, or deformities in gears and bearings. Replacing worn parts with high-quality replacements is essential to restore functionality.

Reassembly demands precision. Following the documented layout, each piece should be placed back correctly, ensuring that all seals and gaskets are intact to prevent future leaks.

Testing the system post-reassembly is crucial. Running the transmission through various speeds and loads will help confirm that all repairs are effective and that the system operates smoothly.

Utilizing these techniques will ensure a thorough approach to addressing transmission issues, ultimately contributing to the reliability and efficiency of the vehicle.

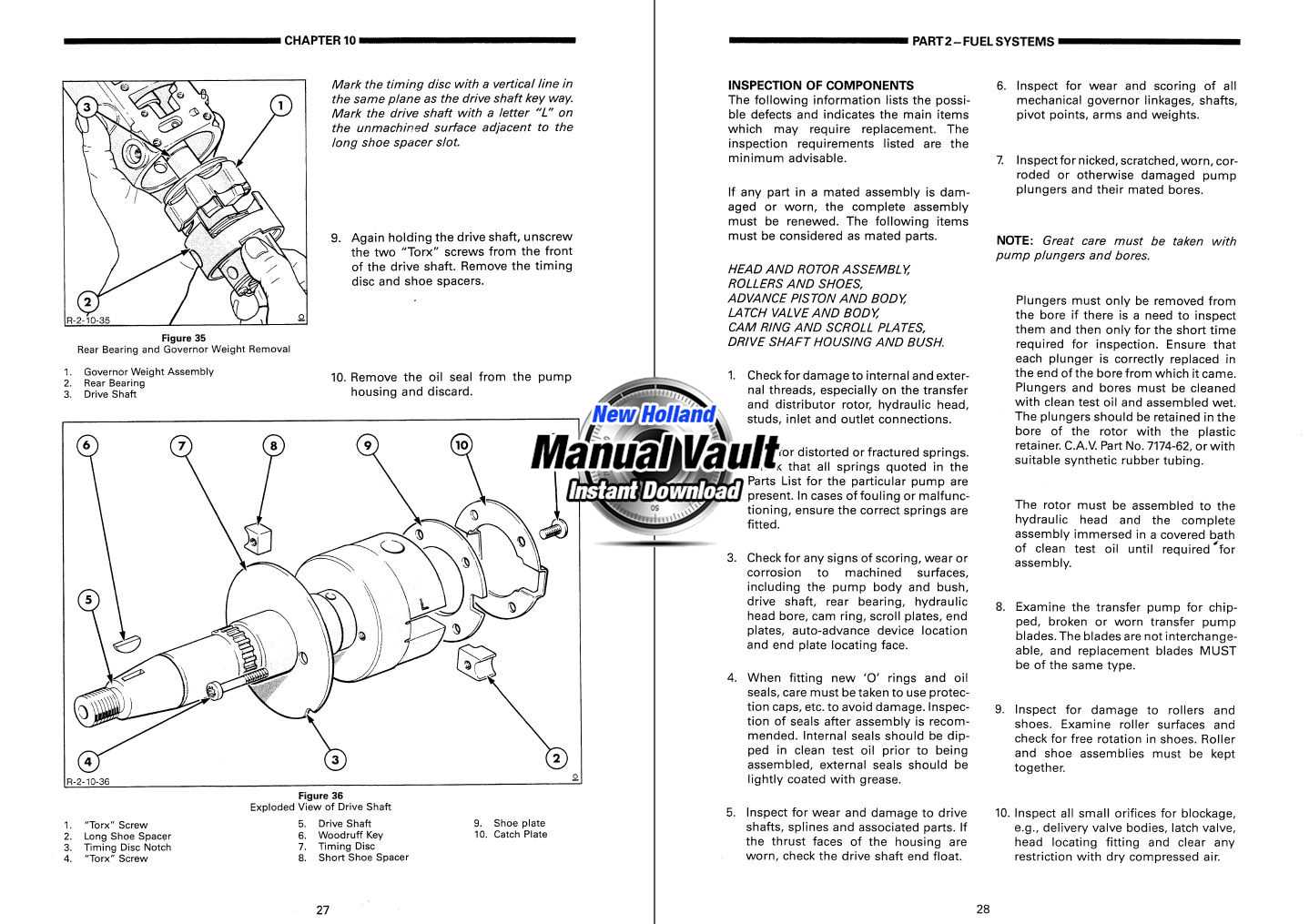

Hydraulic System Diagnostics

The hydraulic system is a critical component in heavy machinery, responsible for powering various functions through fluid pressure. Effective troubleshooting is essential to ensure optimal performance and longevity. This section outlines key diagnostic steps to identify issues within the hydraulic setup, enabling efficient maintenance and repair.

Common Symptoms of Hydraulic Issues

Recognizing early signs of hydraulic system problems can prevent more extensive damage. Below are typical symptoms that indicate potential failures:

| Symptom | Possible Cause |

|---|---|

| Slow or unresponsive movement | Low fluid levels or contaminated fluid |

| Fluid leaks | Worn seals or damaged hoses |

| Overheating | Blocked filters or insufficient cooling |

| Noisy operation | Air in the system or failing pump |

Diagnostic Procedures

To effectively diagnose hydraulic problems, follow these systematic steps:

- Inspect fluid levels and condition regularly.

- Check for visible leaks and wear on hoses and connections.

- Test the pressure at various points in the system using a gauge.

- Evaluate the performance of pumps and cylinders for any irregularities.

By methodically addressing these aspects, one can ensure the hydraulic system operates efficiently, minimizing downtime and costly repairs.

Electrical Components Maintenance

Proper upkeep of electrical systems is crucial for optimal performance and longevity of machinery. This section outlines essential practices to ensure that the electrical components function efficiently and reliably over time.

Regular inspections and maintenance can prevent costly failures and downtime. It’s important to check connections, clean terminals, and replace any worn or damaged parts promptly. Below is a summary of key electrical components and their maintenance tasks:

| Component | Maintenance Task | Frequency |

|---|---|---|

| Batteries | Check charge level and clean terminals | Monthly |

| Wiring | Inspect for fraying and ensure secure connections | Quarterly |

| Fuses | Test for functionality and replace if blown | As needed |

| Relays | Inspect for corrosion and test operation | Annually |

| Switches | Ensure proper operation and clean contacts | As needed |

By adhering to these maintenance guidelines, you can enhance the reliability and efficiency of electrical systems, contributing to the overall functionality of the equipment.

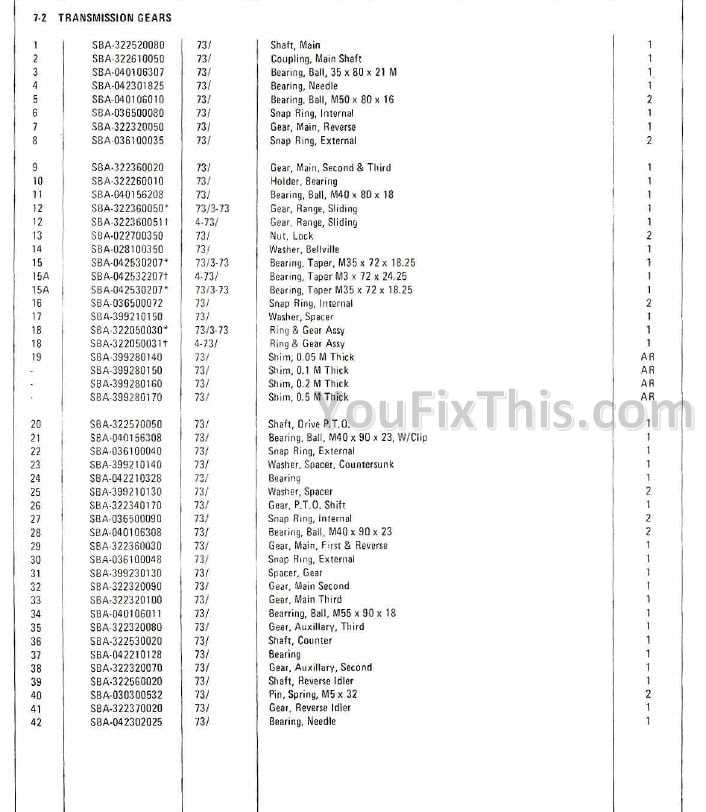

Parts Replacement Guide

This section provides essential information for maintaining and restoring the functionality of your agricultural machinery. Understanding when and how to replace components is crucial for optimal performance and longevity.

Identifying Worn Parts: Regular inspections are vital for detecting signs of wear and tear. Look for unusual noises, vibrations, or performance issues that may indicate that a part needs replacement. Components such as belts, filters, and seals should be examined routinely.

Replacement Process: Before starting any replacement, ensure you have the correct tools and components ready. Follow a systematic approach: disconnect the power source, remove any necessary coverings, and carefully replace the faulty part. Always consult a reference guide for specific procedures related to each component.

Testing After Replacement: Once the new part is installed, it’s important to test the machinery to ensure everything functions smoothly. Run the equipment at a low speed initially to confirm that the replacement has been successful and that no additional adjustments are needed.

Maintenance Tips: To prolong the lifespan of newly installed parts, adhere to a regular maintenance schedule. Clean and lubricate moving parts as recommended, and keep an eye out for potential issues before they become significant problems.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on machinery is paramount. Adhering to proper protocols not only protects the individual performing the work but also safeguards the equipment itself. Awareness of potential hazards and employing preventive measures can significantly reduce the risk of accidents.

Wear Appropriate Personal Protective Equipment (PPE)

Utilizing suitable PPE is essential when engaging in maintenance tasks. This includes items such as safety glasses, gloves, and steel-toed boots. Protective gear shields against flying debris and potential injuries, creating a safer work environment.

Work in a Well-Ventilated Area

When performing tasks that may release harmful fumes or dust, ensuring adequate ventilation is critical. Working outdoors or in a space with good airflow minimizes the risk of inhalation of hazardous substances, promoting overall health.

Disconnect Power Sources

Before starting any service work, always disconnect the power sources. This includes batteries and electrical connections. De-energizing the equipment prevents unintended start-ups, reducing the likelihood of injury.

Keep the Workspace Organized

A cluttered work area can lead to accidents and injuries. Keeping tools and materials organized not only enhances efficiency but also minimizes the risk of trips and falls. Ensure that all items are stored properly when not in use.

Follow Manufacturer Guidelines

Consulting the specific guidelines provided by the manufacturer is crucial. These instructions often contain important safety information and procedures that should be strictly followed to prevent accidents and ensure optimal functioning.

Service Intervals and Schedules

Regular maintenance is crucial for ensuring optimal performance and longevity of your machinery. Establishing a well-defined schedule for servicing not only helps in preventing unexpected breakdowns but also enhances efficiency and reliability in operations. Adhering to recommended intervals can significantly reduce wear and tear, ultimately saving time and resources.

Routine Maintenance Tasks

Routine checks should include an inspection of vital components such as the engine, transmission, and hydraulic systems. Fluid levels should be monitored consistently, and any signs of leakage must be addressed immediately. It is also important to replace filters and conduct thorough cleaning of parts to prevent dirt and debris from causing issues.

Seasonal and Annual Servicing

In addition to routine tasks, specific seasonal and annual services are necessary. Seasonal adjustments may involve changing lubricants to suit varying temperatures, while annual servicing should encompass a comprehensive evaluation of the entire system. Following these schedules will ensure that your equipment operates at its peak efficiency throughout its lifespan.

Resources for Further Assistance

When tackling maintenance and troubleshooting challenges, having access to reliable information and support can make a significant difference. This section highlights various avenues where individuals can seek additional guidance and resources to enhance their knowledge and skills.

Online Forums and Communities: Engaging with fellow enthusiasts and professionals in online discussion boards can provide valuable insights. Platforms dedicated to machinery and equipment often feature sections for specific models, where users share experiences and solutions.

Instructional Videos: Many creators on video-sharing platforms offer step-by-step demonstrations. These visual resources can be particularly helpful for understanding complex procedures and seeing them executed in real-time.

Local Dealerships and Service Centers: Authorized dealerships typically have access to official documentation and trained technicians who can provide expert advice. Visiting or contacting these establishments can yield practical tips and parts availability.

Books and Literature: A variety of publications are available that cover maintenance techniques and common issues. Local libraries or online bookstores often have a selection that can aid in deepening one’s understanding.

Manufacturer’s Website: The official website often hosts a wealth of information, including troubleshooting guides, FAQs, and technical bulletins. Regularly checking these resources can keep users updated on the latest developments and practices.

Utilizing these resources can empower individuals to effectively address challenges and improve their proficiency in managing equipment, ensuring optimal performance and longevity.