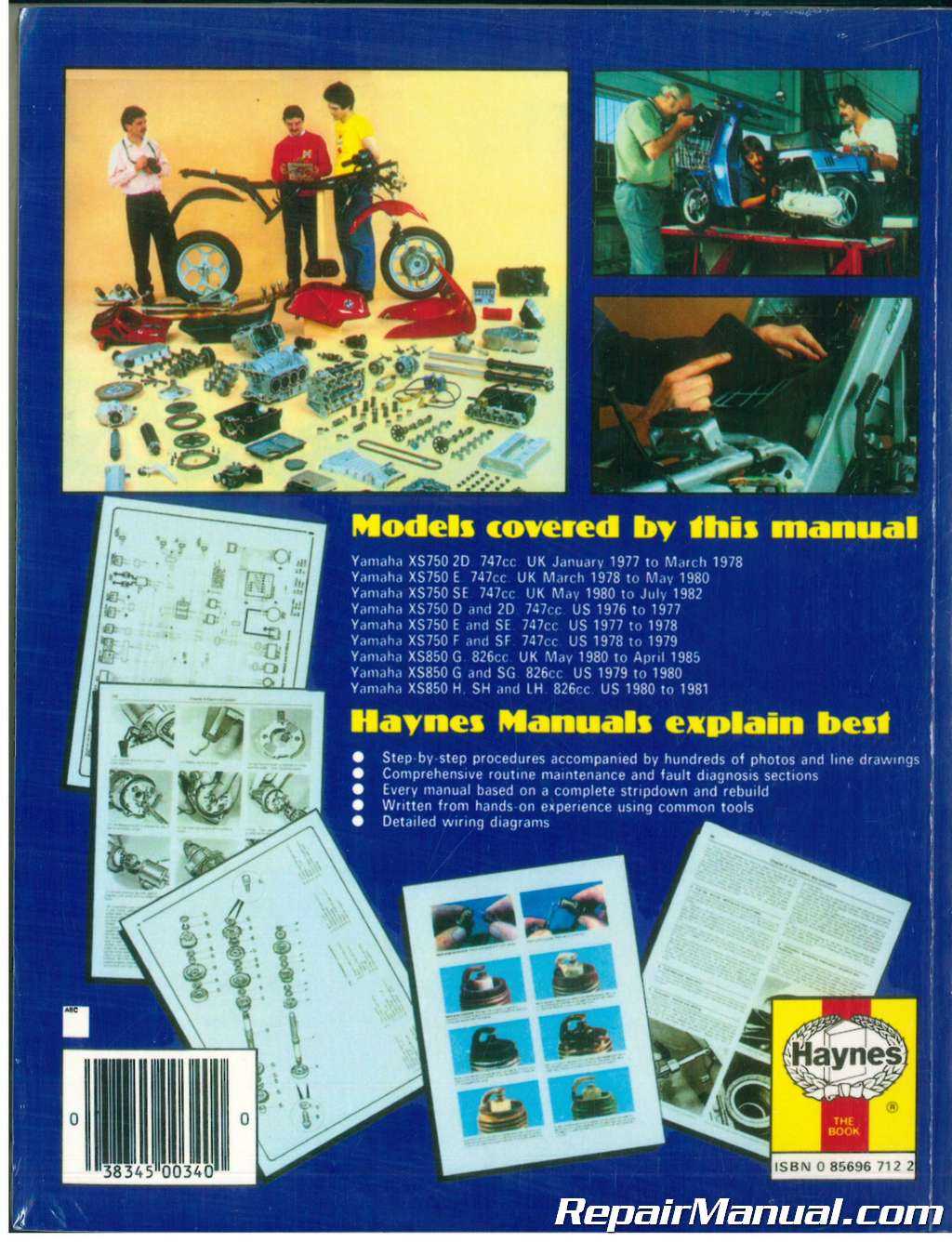

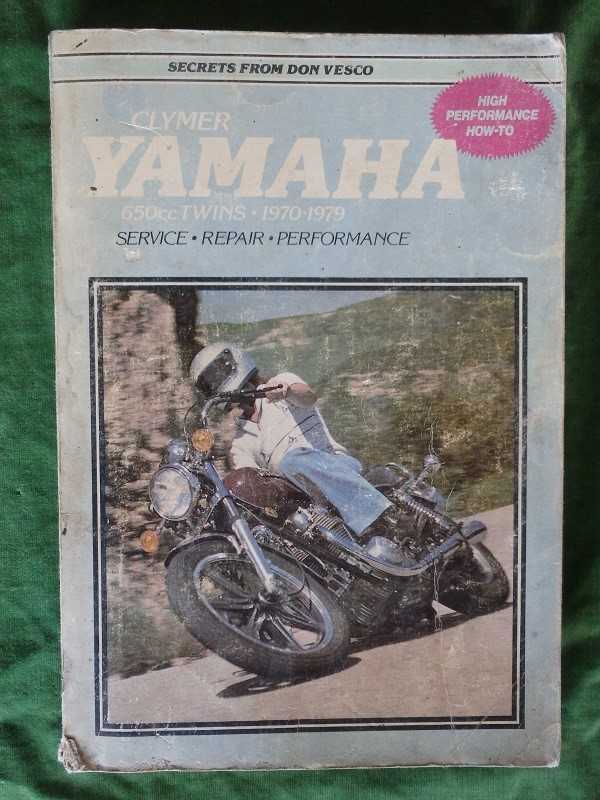

Complete Guide to 79 Yamaha XS750 Repair Manual

Maintaining a classic two-wheeled machine requires not only passion but also a wealth of knowledge. Enthusiasts often seek detailed resources that provide insights into the intricacies of their beloved vehicles. Such information empowers owners to address common issues and enhance the longevity of their machines.

For those venturing into the realm of restoration and upkeep, having access to structured documentation can make all the difference. It equips riders with the necessary skills to tackle everything from routine maintenance to more complex repairs. A well-organized source of information serves as a companion on the journey towards ensuring optimal performance and reliability.

Whether you’re a seasoned mechanic or a novice looking to deepen your understanding, embracing the wisdom contained in a thorough guide can transform your experience. With careful attention to detail, you can navigate the unique challenges posed by these timeless machines, keeping them running smoothly for years to come.

Understanding the Yamaha XS750

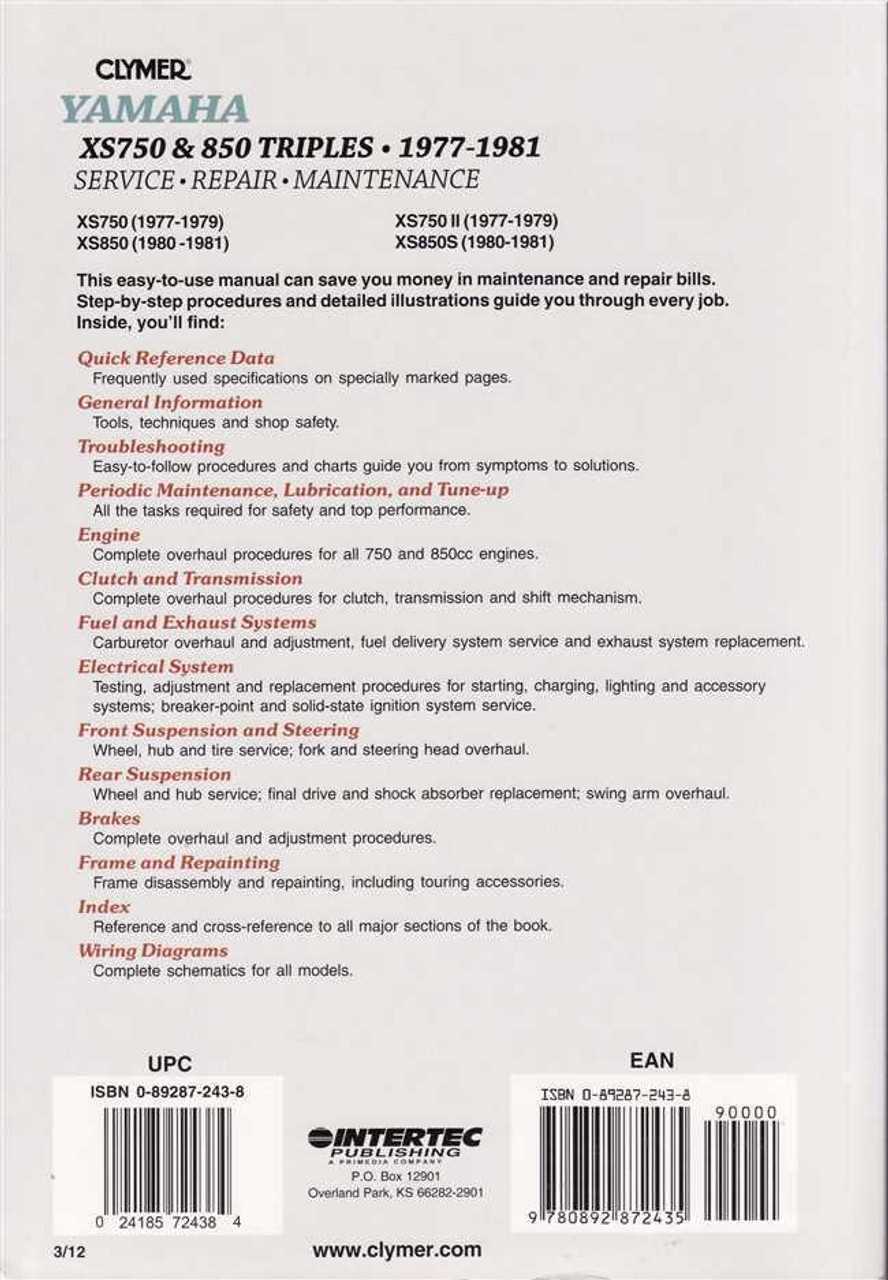

This section explores the intricacies of a classic motorcycle that has captured the hearts of enthusiasts. Known for its distinctive engineering and design, this model combines performance with reliability, making it a popular choice among riders seeking both adventure and comfort.

With its unique three-cylinder engine, the machine delivers a harmonious blend of power and smooth operation. Riders appreciate the balance it offers, allowing for an enjoyable experience whether navigating city streets or cruising along open highways.

| Feature | Description |

|---|---|

| Engine Type | Three-cylinder, air-cooled, four-stroke |

| Displacement | 748 cc |

| Power Output | Approximately 65 hp |

| Transmission | 5-speed, constant mesh |

| Weight | Approximately 485 lbs (220 kg) |

Understanding the nuances of this motorcycle requires familiarity with its maintenance needs and performance characteristics. Proper care ensures longevity, while attention to detail enhances the riding experience. For those who appreciate vintage engineering, this model represents a significant chapter in motorcycle history.

Common Issues with the XS750

This section discusses frequent problems encountered by owners of this classic motorcycle model. Understanding these issues can help in maintaining performance and ensuring a smoother riding experience. Regular checks and maintenance can mitigate many of these common concerns.

Electrical System Troubles

One of the prevalent challenges involves the electrical system. Symptoms may include flickering lights or difficulty starting the engine. Often, these issues stem from worn connections or aging components. Regular inspection of wiring harnesses and ensuring a secure battery connection can prevent many electrical failures.

Engine Performance Problems

Another area of concern is engine performance. Riders may notice rough idling or a lack of power during acceleration. These symptoms can be caused by several factors, such as clogged fuel lines or dirty air filters. Keeping the fuel system clean and replacing filters as needed can significantly enhance engine reliability and performance.

Essential Tools for Repairs

To effectively maintain and restore mechanical equipment, having the right instruments is crucial. These tools not only facilitate the process but also ensure that tasks are completed efficiently and safely. Whether you are a novice or an experienced mechanic, understanding which items are essential can significantly impact your success.

| Tool | Description |

|---|---|

| Socket Set | Includes various sizes to fit different fasteners, making it ideal for loosening and tightening bolts. |

| Wrenches | Both adjustable and fixed wrenches are necessary for gripping and turning nuts and bolts. |

| Screwdrivers | A variety of Phillips and flathead screwdrivers to handle different types of screws. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage. |

| Pliers | Useful for gripping, twisting, and cutting wires or other small components. |

| Impact Driver | Helps in loosening stubborn screws and bolts with minimal effort. |

| Multimeter | Essential for diagnosing electrical issues by measuring voltage, current, and resistance. |

| Oil Filter Wrench | Specialized tool for removing and installing oil filters easily. |

Equipping yourself with these basic instruments will enhance your ability to tackle various tasks with confidence and precision. Each tool plays a vital role in ensuring that work is performed effectively and safely, contributing to the longevity of the machinery in question.

Step-by-Step Maintenance Guide

Proper upkeep of your motorcycle is essential for ensuring its longevity and optimal performance. This guide outlines the necessary steps to effectively maintain your vehicle, helping you to prevent issues before they arise and ensuring a smooth riding experience. Each section will cover different aspects of care, from routine checks to specific tasks, making it easy to follow along.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 3,000 miles | Replace old oil with fresh lubricant to ensure engine efficiency. |

| Chain Inspection | Monthly | Check for wear and proper tension; lubricate if necessary. |

| Brake Pads Check | Every 5,000 miles | Inspect brake pads for thickness and replace if worn. |

| Coolant Level | Monthly | Verify the coolant level and top off if low to prevent overheating. |

| Tire Pressure | Weekly | Check and adjust tire pressure to manufacturer specifications. |

| Battery Maintenance | Every 6 months | Inspect battery terminals for corrosion and ensure proper charge. |

By following this guide, you can maintain your machine effectively, ensuring reliability and safety on the road. Regular attention to these tasks will lead to a more enjoyable riding experience and potentially save on costly repairs in the long run.

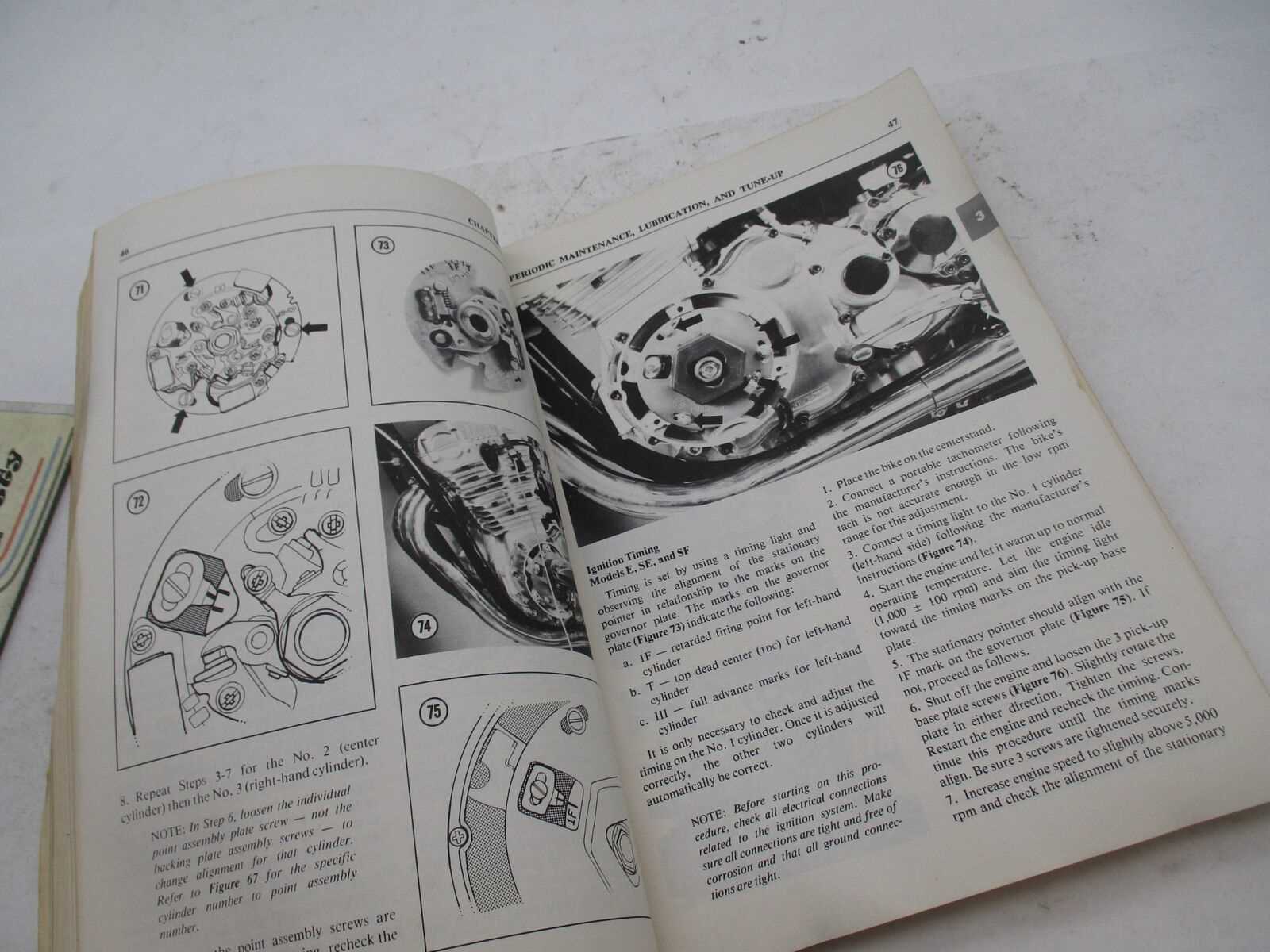

Electrical System Troubleshooting

Diagnosing issues within an electrical framework is crucial for maintaining optimal performance and ensuring safety. Understanding the various components involved can aid in identifying faults effectively. This section provides guidance on addressing common electrical problems that may arise.

Step 1: Visual Inspection

Begin with a thorough visual examination of the wiring and connectors. Look for signs of wear, corrosion, or damage. Ensure that all connections are secure and free from dirt or moisture, as these can lead to poor conductivity.

Step 2: Testing Voltage

Utilize a multimeter to measure voltage at key points in the system. Compare the readings with the specified values to determine if there are any discrepancies. Low voltage can indicate issues such as a failing battery or faulty wiring.

Step 3: Continuity Check

Perform a continuity test to confirm that current can flow through the circuit. Disconnect power sources before testing. A lack of continuity may point to broken wires or malfunctioning components that need replacement.

Step 4: Component Inspection

Examine individual parts such as fuses, relays, and switches for functionality. Replace any components that show signs of failure. Ensure that fuses are rated appropriately for the circuit to prevent future issues.

Step 5: Grounding Issues

Check grounding connections, as poor grounds can cause erratic behavior in the system. Clean and tighten grounding points to ensure a solid connection, which is essential for the overall integrity of the electrical system.

By systematically addressing these areas, one can efficiently diagnose and rectify electrical problems, leading to improved performance and reliability.

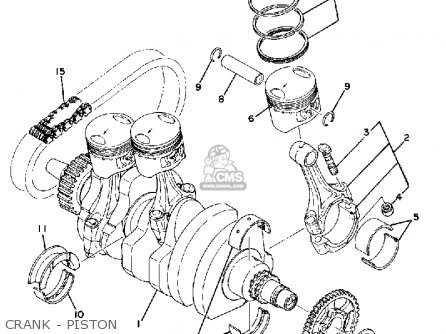

Engine Overhaul Procedures Explained

Undertaking a comprehensive refurbishment of an engine involves a series of meticulous steps designed to restore performance and longevity. This process is crucial for ensuring that the power unit operates efficiently and reliably, particularly after years of use. Understanding the essential phases can make the task less daunting and more manageable for enthusiasts and technicians alike.

Initial Assessment and Preparation

Before diving into the refurbishment, it’s important to conduct a thorough evaluation of the engine’s current condition. This initial assessment will guide the entire process. Key steps include:

- Checking for visible damage or wear.

- Gathering necessary tools and parts.

- Reviewing specifications for the specific engine model.

Preparing a clean and organized workspace is also vital to facilitate a smooth overhaul process.

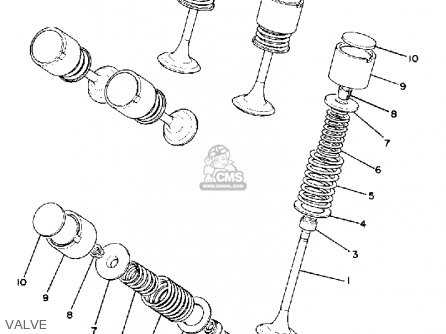

Disassembly and Inspection

The next phase involves careful disassembly of the engine components. This stage requires attention to detail to prevent damage and ensure proper reassembly. Important tasks include:

- Removing external components, such as the exhaust and intake systems.

- Taking apart the engine block and associated parts.

- Inspecting each component for signs of wear, such as cracks or excessive corrosion.

Documentation of the condition of each part will aid in reassembly and any necessary replacements.

By following these procedures, the overall performance of the engine can be significantly enhanced, leading to improved reliability and efficiency.

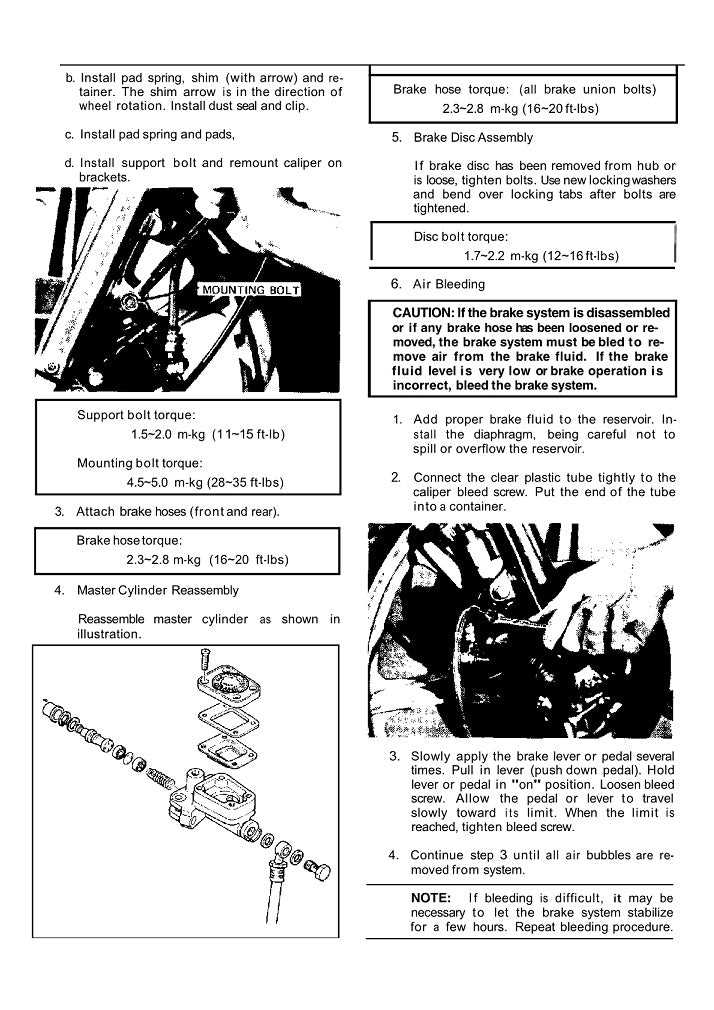

Replacing Tires and Brakes

Maintaining optimal performance and safety of your two-wheeled vehicle requires periodic replacement of essential components such as tires and braking systems. This section will guide you through the fundamental processes involved, ensuring that your ride remains smooth and secure on the road.

Changing Tires

Proper tire condition is vital for traction, stability, and overall handling. Begin by lifting the bike using a suitable stand, then remove the wheel by loosening the axle nut. Ensure you have the correct replacement tires ready, matching the specifications recommended for your model. After placing the new tire onto the rim, inflate it to the recommended pressure and reattach the wheel securely.

Replacing Brake Pads

Brake pads are crucial for effective stopping power. Start by removing the wheel to access the brake assembly. Detach the caliper and take out the old pads. Clean the caliper and inspect for wear or damage. Insert the new pads, ensuring they fit snugly, and reassemble the caliper. Finally, test the brake lever to confirm proper function before taking your bike back on the road.

Regular maintenance of these components not only enhances performance but also extends the lifespan of your vehicle, ensuring a safe and enjoyable ride.

Adjusting the Suspension System

Proper adjustment of the suspension system is crucial for optimal performance and comfort while riding. A well-tuned setup enhances stability, control, and overall handling, allowing for a more enjoyable experience on the road. This section will guide you through the essential steps to achieve the perfect balance for your machine.

Before starting the adjustment process, it’s important to consider the following factors:

- Rider weight and gear

- Type of riding (commuting, touring, or sport)

- Road conditions and terrain

Follow these steps to adjust your suspension effectively:

- Assess Current Settings: Check the existing preload, compression, and rebound settings to determine if they need adjustment.

- Adjust Preload: This setting influences the initial height and sag of the suspension. Increase or decrease preload based on rider weight and gear.

- Modify Compression: Adjust the compression damping to control how quickly the suspension compresses when encountering bumps. Softer settings provide more comfort, while firmer settings enhance control.

- Tweak Rebound: Set the rebound damping to ensure the suspension returns to its original position at the right speed, preventing excessive bouncing or sluggishness.

- Test Ride: After adjustments, take a test ride to evaluate the changes. Pay attention to handling and comfort.

- Fine-Tune: Based on your test ride, make further adjustments as necessary to achieve the desired performance.

Regularly revisiting these settings, especially after changes in load or riding style, ensures that your suspension system remains responsive and effective.

Restoration Tips for Vintage Models

Restoring classic two-wheeled vehicles requires a blend of passion, patience, and attention to detail. Whether you are a seasoned enthusiast or a newcomer, certain guidelines can help ensure a successful revival of these timeless machines. Below are key considerations to keep in mind during your restoration journey.

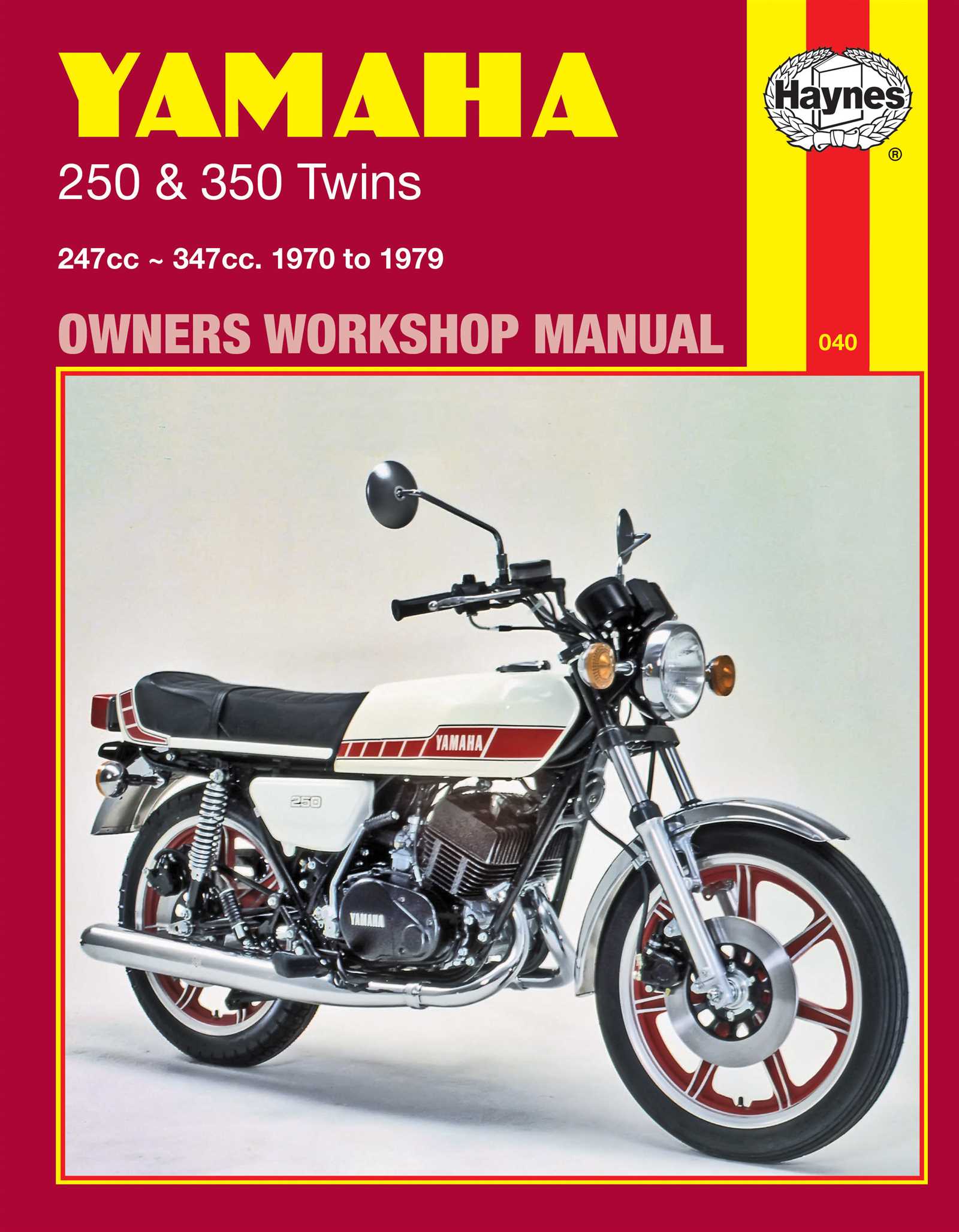

- Research Thoroughly: Gather as much information as possible about the specific model you are working on. Online forums, enthusiast groups, and vintage publications can provide invaluable insights.

- Document the Process: Keep a detailed record of your restoration steps. This can help you track progress and serves as a useful reference for future projects.

- Source Quality Parts: Look for authentic components or high-quality reproductions. Original parts can enhance the vehicle’s value and authenticity.

In addition to the above tips, consider the following aspects to ensure a thorough and effective restoration:

- Assess the Condition: Before diving in, evaluate the overall state of the vehicle. Identify critical areas that require immediate attention.

- Set a Budget: Establish a realistic financial plan to avoid overspending. Include costs for parts, tools, and any professional services you may need.

- Take Your Time: Rushing the restoration can lead to mistakes. Allow yourself ample time to complete each stage carefully.

- Join a Community: Engaging with fellow restorers can provide support, advice, and motivation throughout the project.

With dedication and the right approach, restoring vintage two-wheeled models can be a rewarding experience that preserves their legacy for future generations.

Finding Replacement Parts Easily

Locating suitable components for your vehicle can often be a daunting task, yet it is crucial for ensuring optimal performance and longevity. Fortunately, there are various strategies to simplify this process, allowing enthusiasts and mechanics alike to source what they need with minimal hassle.

One effective approach is to explore both online and offline resources. Utilizing specialized websites, local dealerships, and automotive supply stores can yield a wide array of options. Additionally, networking with fellow enthusiasts can provide valuable insights and recommendations.

| Resource Type | Description | Advantages |

|---|---|---|

| Online Marketplaces | Websites dedicated to selling automotive parts. | Convenience and extensive selection. |

| Local Dealerships | Official retailers for brand-specific components. | Access to original parts and expert advice. |

| Automotive Forums | Online communities where enthusiasts share information. | Networking and firsthand recommendations. |

| Junkyards | Salvage yards with used parts. | Cost-effective solutions for rare items. |

By leveraging these resources, you can significantly enhance your ability to find the necessary parts, ultimately leading to a smoother restoration or maintenance experience.