Comprehensive Guide to Repairing the Stihl 044 Chainsaw

When it comes to maintaining high-performance outdoor power equipment, understanding the intricacies of its operation is essential. This section delves into the key aspects of upkeep and problem-solving techniques that can enhance the longevity and efficiency of your tools. Proper attention to detail can make a significant difference in performance and reliability.

Having a solid grasp of the inner workings allows users to identify potential issues before they escalate. This guide emphasizes practical steps for regular upkeep and essential repairs that ensure optimal functionality. By familiarizing yourself with the components and mechanics, you can approach any challenges with confidence.

Equipping yourself with the right knowledge not only empowers you to tackle common malfunctions but also cultivates a deeper appreciation for your equipment. Embracing this hands-on approach transforms the maintenance experience, turning it into an opportunity for growth and understanding rather than a daunting task.

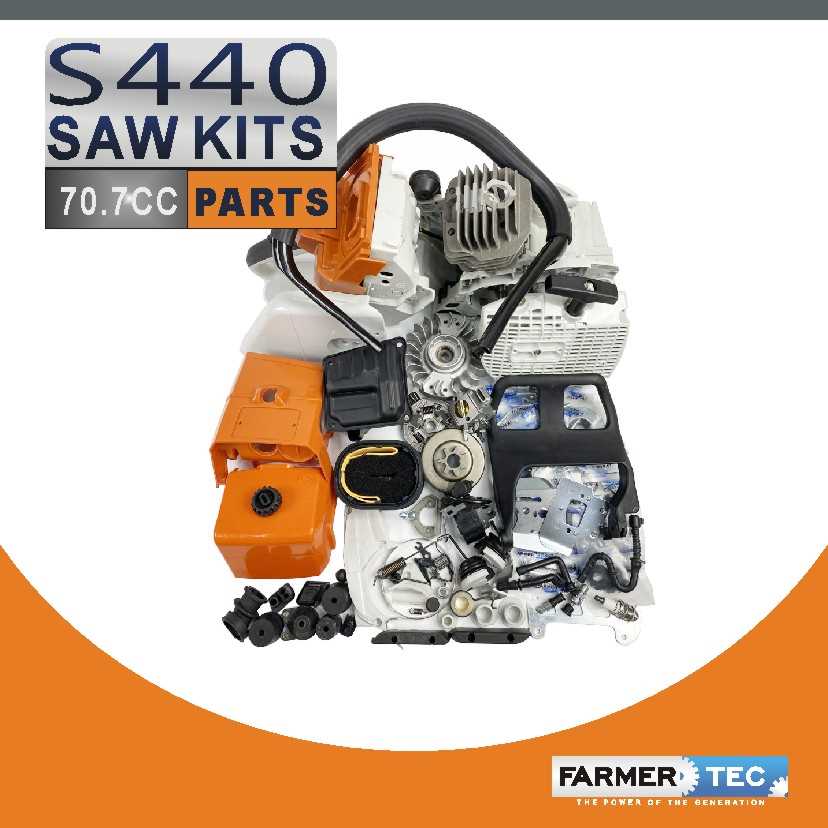

Overview of Stihl 044 Chainsaw

This section provides a comprehensive look at a powerful and versatile tool designed for various cutting tasks. Known for its robust performance and reliability, this chainsaw has become a favored choice among both professionals and enthusiasts in the forestry and landscaping industries.

Key Features

- High-performance engine

- Lightweight design for improved maneuverability

- Easy start mechanism for user convenience

- Durable construction to withstand tough conditions

Applications

- Tree felling and limbing

- Firewood cutting

- Land clearing projects

- Tree pruning and trimming

With its impressive capabilities, this chainsaw is suitable for a wide range of applications, making it an essential tool for those in need of efficiency and power in their cutting tasks.

Common Issues with Stihl 044

When operating high-performance chainsaws, users may encounter several frequent problems that can hinder functionality and efficiency. Understanding these common complications is crucial for maintaining optimal performance and extending the life of the equipment.

Typical Problems Encountered

- Poor starting

- Inconsistent power output

- Excessive vibration during operation

- Fuel leakage

- Chain lubrication issues

Root Causes

- Fuel mixture may be incorrect, leading to combustion issues.

- Air filter could be clogged, restricting airflow and affecting performance.

- Spark plug may be dirty or worn, resulting in weak ignition.

- Chain tension might be improperly adjusted, causing operational inefficiencies.

- Seals and gaskets may be damaged, leading to leaks and reduced performance.

Essential Tools for Repairs

When it comes to maintaining outdoor power equipment, having the right instruments is crucial for ensuring optimal performance and longevity. A well-equipped toolkit not only simplifies the process but also enhances the overall effectiveness of your work. Understanding which items are essential can save time and prevent unnecessary frustrations during maintenance tasks.

Basic Hand Tools: A set of quality hand tools is fundamental. This includes screwdrivers of various sizes, pliers, and wrenches. These items will assist in loosening or tightening components, making adjustments, and handling small repairs.

Specialized Equipment: Depending on the machine, certain specialized tools may be necessary. For instance, a spark plug socket or a chain sharpening tool can significantly ease the upkeep of specific parts. Investing in these tools can lead to more precise adjustments and repairs.

Safety Gear: Always prioritize safety. Protective goggles, gloves, and hearing protection are essential to shield yourself from potential hazards during maintenance work. Proper gear can prevent injuries and ensure a safer working environment.

Cleaning Supplies: Keeping your equipment clean is vital for its performance. Brushes, rags, and appropriate cleaning solutions help remove debris and prevent buildup that can lead to malfunctions.

In summary, equipping yourself with a well-rounded set of tools and safety equipment not only makes the maintenance process smoother but also enhances the reliability of your outdoor machinery. Taking the time to gather these essentials will ultimately contribute to a more efficient and enjoyable experience.

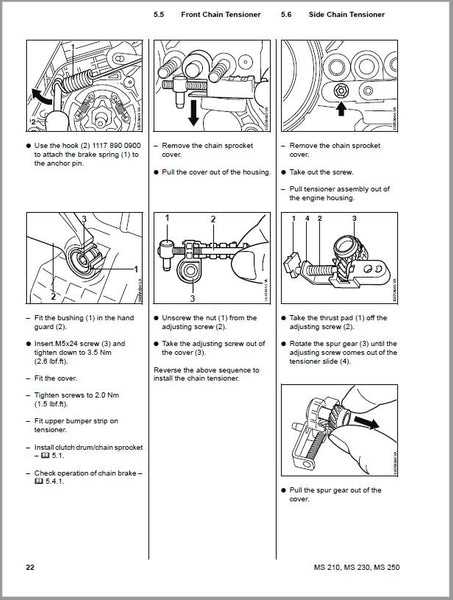

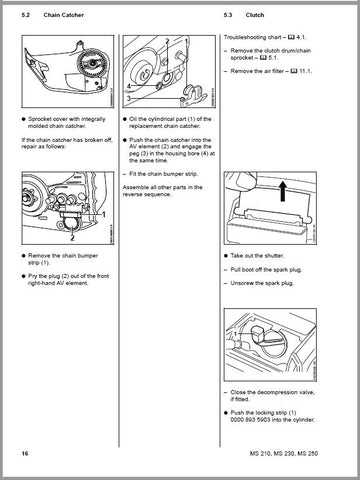

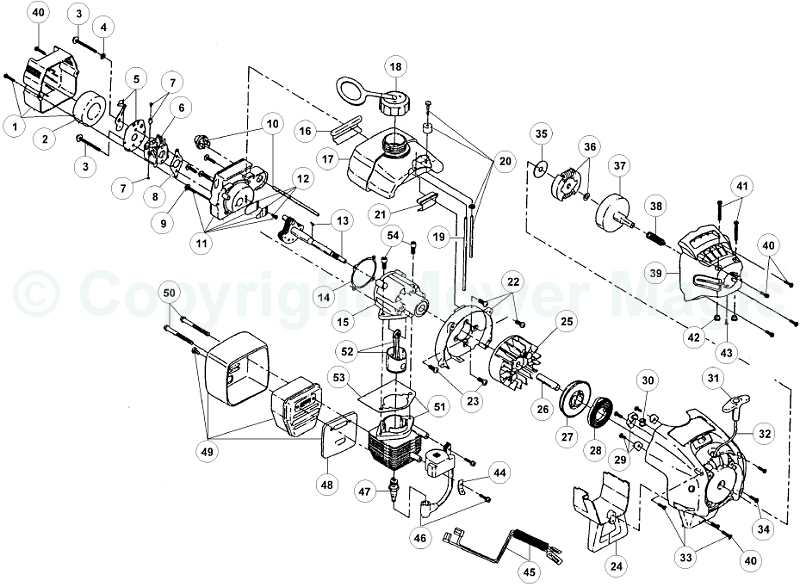

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to dismantling your equipment effectively and safely. Following these guidelines will ensure that each component is handled properly, minimizing the risk of damage and facilitating smooth reassembly.

Preparation for Disassembly

Before you begin, gather all necessary tools and ensure your workspace is clean and organized. Disconnect the power source to prevent any accidents. It is essential to document the assembly order and placement of each part for easier reassembly later. Taking photos during the process can be particularly helpful.

Disassembly Process

Start with the outer casing, removing screws and fasteners carefully. Keep them in a designated container to avoid losing any small pieces. Once the casing is removed, proceed to detach internal components such as the fuel tank, air filter, and ignition system. Always handle delicate parts with care, using appropriate tools to prevent damage. For any stubborn components, gentle tapping or the application of a lubricant may assist in loosening them.

As you continue, maintain a systematic approach, ensuring that each step is performed with precision. Upon completion, you will have access to the internal mechanisms, allowing for thorough cleaning or replacement as needed.

Diagnosing Engine Problems

Identifying issues within a power unit is essential for maintaining optimal performance and longevity. A systematic approach can help uncover underlying faults that may affect functionality. Understanding common symptoms and their potential causes is the first step toward effective troubleshooting.

1. Unusual Noises: If the engine produces unexpected sounds such as knocking or rattling, this may indicate loose components or internal damage. Carefully inspect for any signs of wear or misalignment.

2. Starting Difficulties: Struggles with ignition can stem from several factors, including fuel delivery problems, ignition system failures, or air intake issues. Ensure that the fuel is fresh, and check the spark plug for signs of wear.

3. Overheating: Excessive temperatures can lead to severe damage. Monitor the cooling system and verify that the airflow is not obstructed. Low oil levels or old oil can also contribute to overheating.

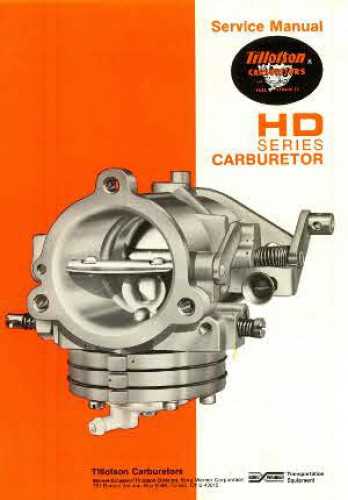

4. Poor Performance: A noticeable drop in power or efficiency often points to fuel blockages, air filter issues, or carburetor malfunctions. Inspect fuel lines for clogs and ensure that air filters are clean and unobstructed.

5. Excessive Smoke: Smoke emitted from the exhaust can indicate various problems, such as oil leaks or combustion issues. Blue smoke often suggests oil burning, while black smoke may indicate an overly rich fuel mixture.

By methodically assessing these indicators, one can effectively diagnose and address engine issues, ensuring reliable operation and extending the lifespan of the equipment.

Replacing the Fuel System Components

Maintaining optimal performance of your equipment often involves addressing issues within the fuel delivery system. Over time, various parts may wear out or become clogged, necessitating their replacement. This process ensures efficient fuel flow and helps prevent operational problems.

Before beginning, gather the necessary tools and components to facilitate a smooth replacement. Follow safety precautions to protect yourself and the equipment. Below is a summary of the key components involved:

| Component | Description |

|---|---|

| Fuel Filter | Prevents debris from entering the fuel line, ensuring clean fuel delivery. |

| Fuel Line | Transports fuel from the tank to the carburetor; should be checked for cracks or leaks. |

| Primer Bulb | Helps to draw fuel into the system for easier starting; may require replacement if damaged. |

| Carburetor Gasket | Seals the carburetor to prevent air leaks, ensuring proper fuel mixing. |

By carefully replacing these components, you can enhance the functionality and longevity of your equipment, ultimately leading to improved performance during use.

Chain and Bar Maintenance Tips

Proper upkeep of your cutting equipment is essential for optimal performance and longevity. Regular attention to the chain and guide bar can significantly enhance cutting efficiency and reduce wear. Below are key practices to ensure your tools remain in peak condition.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Inspect Chain Tension | Before Each Use | Ensure the chain is snug but can still be rotated by hand. |

| Sharpen Chain Blades | Every 3-5 Uses | Use a proper file or sharpener; maintain the correct angle for effective cutting. |

| Clean the Bar Groove | After Each Use | Remove debris to prevent binding and ensure smooth operation. |

| Lubricate the Chain | Before Each Use | Use high-quality bar oil for optimal lubrication and reduced friction. |

| Check for Wear | Monthly | Inspect for damage or excessive wear; replace as necessary to avoid accidents. |

By following these guidelines, you can extend the life of your cutting gear, ensuring reliable and efficient performance for all your projects.

Electrical System Troubleshooting

This section focuses on diagnosing issues related to the electrical components of the equipment. Proper identification of electrical malfunctions is crucial for ensuring optimal performance and longevity of the machine. By systematically evaluating the various elements of the electrical system, users can effectively resolve issues and maintain functionality.

Common symptoms of electrical problems include difficulty starting, intermittent operation, or complete failure of the ignition system. The following table outlines potential causes and corresponding troubleshooting steps to assist in diagnosing and rectifying these issues.

| Symptom | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Engine won’t start | Faulty ignition coil | Test the coil with a multimeter; replace if necessary. |

| Intermittent operation | Loose connections | Inspect all wiring connections; tighten or replace as needed. |

| No spark | Defective spark plug | Remove the plug; check for wear and replace if damaged. |

| Dim or flickering lights | Weak battery | Test the battery voltage; recharge or replace if low. |

Regular maintenance and inspections of the electrical components can prevent many common issues. If problems persist after following the troubleshooting steps, consulting a professional for further assistance is advisable.

Lubrication Techniques for Longevity

Proper lubrication is essential for ensuring the durability and efficiency of mechanical equipment. Implementing effective lubrication practices can significantly extend the life of your tools and minimize wear and tear. Understanding the various techniques and their importance is crucial for maintaining optimal performance.

Types of Lubricants

Choosing the right lubricant is key to effective maintenance. Different types of lubricants serve various purposes:

- Oil-based lubricants: Ideal for reducing friction and heat in moving parts.

- Grease: Provides a thicker consistency, suitable for high-load applications.

- Synthetic lubricants: Offer superior performance in extreme conditions.

Application Techniques

Effective application of lubricants can make a significant difference:

- Regular intervals: Schedule consistent lubrication to prevent dry conditions.

- Clean surfaces: Ensure that all surfaces are free of dirt and debris before applying any lubricant.

- Correct quantity: Apply the appropriate amount to avoid over-lubrication, which can attract dirt.

By adhering to these lubrication techniques, you can enhance the longevity and performance of your equipment, ensuring it operates smoothly for years to come.

Reassembly: Best Practices

Successfully putting components back together requires careful attention to detail and adherence to specific techniques. Proper reassembly not only ensures the longevity of the equipment but also enhances its performance. Following best practices during this process minimizes the risk of future issues and helps maintain optimal functionality.

Preparation Steps

- Gather all necessary tools and components before starting.

- Clean all parts thoroughly to remove any debris or old lubricant.

- Organize components in a logical order to simplify the assembly process.

Assembly Techniques

- Refer to documentation or diagrams to ensure accurate placement of parts.

- Apply lubricant to moving parts as specified to prevent wear.

- Use appropriate torque settings for fasteners to avoid damage.

- Double-check alignment of components before finalizing connections.

By following these guidelines, you can enhance the efficiency and reliability of your machinery, ensuring it operates at its best after reassembly.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks on machinery. Proper precautions not only protect the individual performing the work but also enhance the efficiency of the process. Following established safety protocols can prevent accidents and injuries.

Here are essential safety measures to keep in mind:

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and ear protection.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep your workspace organized and free of clutter to minimize the risk of accidents.

Before starting any task, take the time to:

- Disconnect the power source to prevent unintentional activation.

- Ensure all tools are in good condition and appropriate for the job.

- Review safety instructions specific to the equipment being serviced.

By adhering to these guidelines, individuals can create a safer environment and reduce the likelihood of mishaps during maintenance activities.

Resources for Further Assistance

When seeking guidance for maintenance and troubleshooting, a variety of resources can provide valuable support. Engaging with community forums, online tutorials, and expert articles can enhance your understanding and skills.

Consider visiting community forums where enthusiasts and professionals share their experiences and solutions. These platforms often feature discussions on common issues, offering practical tips and tricks from individuals who have faced similar challenges.

Another excellent option is to explore video tutorials on platforms such as YouTube. Visual demonstrations can simplify complex processes, allowing you to follow along step-by-step. Look for channels dedicated to outdoor equipment maintenance to ensure quality content.

Additionally, manufacturer websites may provide downloadable resources, including technical specifications and troubleshooting guides. These documents can serve as a reliable reference for understanding your equipment’s features and requirements.

Lastly, consider connecting with local repair shops or authorized service centers. Professionals in these establishments can offer expert advice and assistance, ensuring that your equipment receives the best care possible.