Comprehensive Repair Guide for 2008 KTM 50 SX

Maintaining a high-performance mini motorcycle requires a solid understanding of its components and the intricacies involved in its upkeep. This guide serves as a comprehensive resource for enthusiasts and riders, providing essential insights into troubleshooting, part replacement, and general care. With the right knowledge, you can ensure your machine operates at peak efficiency and longevity.

Within this section, you’ll discover valuable tips and detailed instructions aimed at empowering riders to tackle common issues with confidence. Whether you’re a seasoned mechanic or a novice eager to learn, this compilation of information is designed to make the process straightforward and accessible. By familiarizing yourself with the inner workings of your vehicle, you can enhance both its performance and your riding experience.

Furthermore, understanding the various systems of your mini motorcycle not only aids in effective maintenance but also fosters a deeper connection between the rider and the machine. Engaging with the mechanical aspects can be both rewarding and enlightening, turning routine upkeep into an opportunity for growth and learning. Embrace the journey of mastering your vehicle and unlock the full potential of your riding adventures.

KTM 50 SX Overview

The 50 SX represents a pinnacle of engineering in the realm of youth motocross machines. Designed specifically for young riders, it combines performance with safety, making it an ideal choice for those entering the world of off-road racing.

This model features a lightweight chassis, providing excellent maneuverability and control. The powertrain is crafted to deliver a smooth yet thrilling riding experience, ensuring that budding racers can develop their skills effectively. Key components such as the suspension system and braking mechanisms are tailored to enhance stability and responsiveness, allowing riders to tackle various terrains with confidence.

Moreover, the 50 SX is equipped with user-friendly adjustments, enabling parents to customize the bike’s settings as their child progresses. This adaptability is crucial for fostering growth in a sport that demands both skill and courage. Overall, the 50 SX stands as a testament to innovation, making it a top contender in its class.

Key Specifications of the 2008 Model

This section highlights the essential features and technical attributes that define this particular off-road machine. Understanding these specifications is crucial for enthusiasts and riders alike, ensuring optimal performance and maintenance.

Engine Specifications

- Type: Single-cylinder, 2-stroke

- Displacement: 49 cc

- Cooling System: Liquid-cooled

- Bore x Stroke: 40 mm x 39.2 mm

- Compression Ratio: 13.5:1

Chassis and Dimensions

- Frame Type: Steel frame

- Seat Height: 28.3 inches (720 mm)

- Wheelbase: 43.3 inches (1100 mm)

- Weight (Dry): Approximately 55 lbs (25 kg)

- Front Suspension: Inverted fork, 35 mm

- Rear Suspension: Monoshock, adjustable

Common Issues with KTM 50 SX

When it comes to performance machines designed for young riders, certain challenges can frequently arise. Understanding these potential problems is crucial for maintaining optimal functionality and ensuring a safe riding experience. Below are some of the typical concerns owners may encounter with this specific model.

Engine Performance

One common issue involves the engine’s ability to start and run smoothly. Riders may experience difficulties with ignition, leading to unreliable performance. Additionally, issues such as improper fuel mixture or carburetor malfunctions can affect acceleration and overall power output.

Suspension and Handling

Another area that often requires attention is the suspension system. Problems such as leaks in the fork seals or inadequate damping can lead to poor handling characteristics, making it challenging for riders to control their machine effectively. Regular inspection and maintenance of the suspension components are vital to ensure a smooth and safe ride.

Step-by-Step Repair Techniques

This section provides a structured approach to addressing common issues that may arise with your two-wheeled companion. By following detailed steps, you can ensure effective solutions and maintain optimal performance.

Tools and Materials Required

| Tool/Material | Purpose |

|---|---|

| Socket Wrench Set | For loosening and tightening bolts |

| Screwdriver Set | For removing and adjusting screws |

| Oil | To lubricate moving parts |

| Cleaning Supplies | For maintaining cleanliness |

Basic Troubleshooting Steps

Begin by identifying the symptoms of the issue. Conduct a visual inspection to pinpoint any obvious damage or wear. After that, follow systematic steps to test each component, ensuring that you address the root cause rather than just the symptoms.

Tools Required for Repairs

Ensuring optimal performance of your vehicle necessitates a set of essential instruments. These tools facilitate effective troubleshooting and maintenance, allowing for a seamless restoration process. Whether you’re addressing minor adjustments or significant overhauls, having the right equipment is crucial for achieving desired outcomes.

Basic Tool Kit

A well-rounded tool kit is the foundation for any maintenance task. Here are some fundamental items you’ll need:

| Tool | Purpose |

|---|---|

| Socket Set | To fasten and loosen bolts and nuts |

| Wrenches | For gripping and turning fasteners |

| Phillips and Flathead Screwdrivers | To drive screws of various types |

| Torque Wrench | To ensure proper fastening according to specifications |

| Pliers | For gripping, twisting, and cutting wires |

Specialized Tools

In addition to basic tools, certain specialized instruments may be necessary for specific tasks. These tools enhance precision and efficiency in more intricate repair procedures.

| Tool | Purpose |

|---|---|

| Chain Breaker | To remove and install chains |

| Compression Tester | To measure engine cylinder compression |

| Leak Down Tester | To assess the integrity of engine seals |

| Oil Filter Wrench | To easily remove oil filters |

Understanding the Maintenance Schedule

Maintaining your vehicle is essential for ensuring its longevity and optimal performance. A well-structured plan outlines the necessary tasks to keep the machine running smoothly, preventing breakdowns and enhancing safety. Following a consistent schedule helps you stay on top of essential services, making it easier to identify and address potential issues before they escalate.

Regular upkeep not only prolongs the life of your vehicle but also improves its efficiency and reliability. By adhering to a maintenance timetable, you can maximize your riding experience while minimizing unexpected repairs. Below is a table that summarizes key maintenance tasks and their recommended intervals:

| Maintenance Task | Frequency |

|---|---|

| Engine Oil Change | Every 10 hours of operation |

| Air Filter Cleaning | Every 5 hours of operation |

| Brake Inspection | Every 10 hours of operation |

| Chain Lubrication | Every ride |

| Tire Pressure Check | Before each ride |

| Spark Plug Replacement | Every 20 hours of operation |

By following these guidelines, you can ensure that your vehicle remains in peak condition, ready to provide an exhilarating riding experience whenever you need it.

Electrical System Troubleshooting

This section focuses on diagnosing and resolving issues related to the electrical components of a small motocross bike. Understanding the intricacies of the electrical system is crucial for ensuring optimal performance and reliability. By following systematic procedures, you can identify malfunctions, replace faulty parts, and restore proper functionality.

Common Electrical Issues

Several problems may arise within the electrical framework, ranging from simple connection failures to more complex component breakdowns. Familiarity with the symptoms of these issues can facilitate quicker troubleshooting.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| No Spark | Engine won’t start | Faulty ignition coil, poor wiring connections |

| Flickering Lights | Inconsistent lighting | Loose bulb, failing regulator |

| Battery Drain | Battery discharges quickly | Short circuit, parasitic draw |

| Overheating | Components getting excessively hot | Overloaded circuits, defective parts |

Troubleshooting Steps

To effectively address electrical concerns, follow these organized steps:

- Inspect wiring for any visible damage or loose connections.

- Test components individually using a multimeter to verify their functionality.

- Check the battery charge and connections to ensure proper power supply.

- Refer to the electrical schematic for your model to trace circuits.

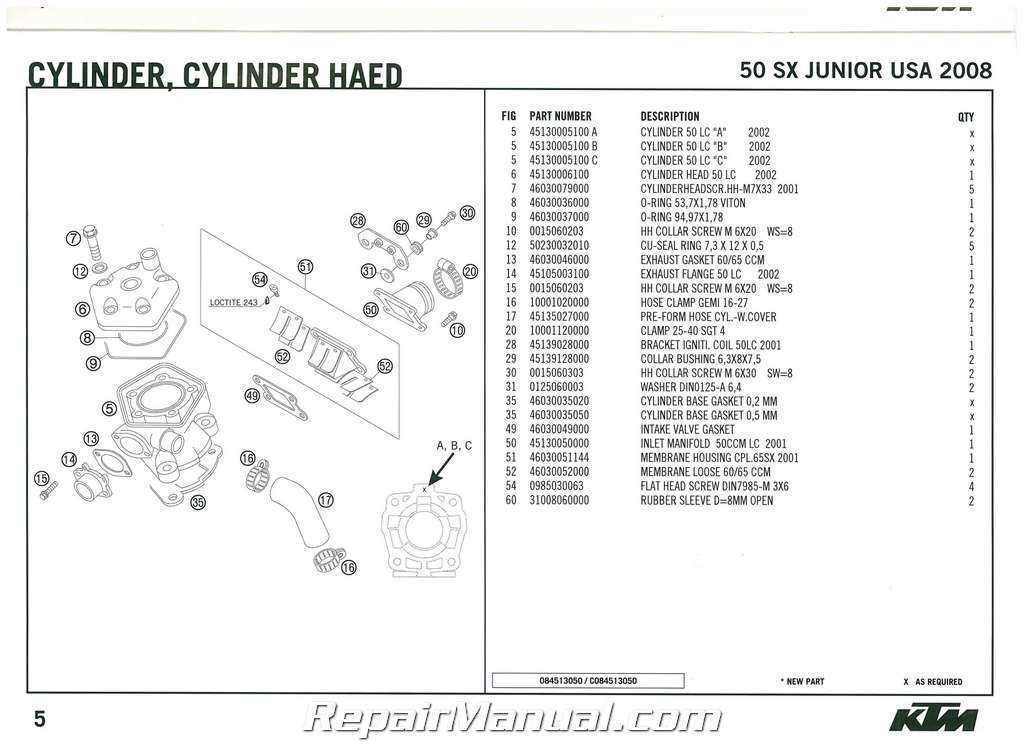

Engine Rebuild Guide

Rebuilding a small engine requires careful attention to detail and a thorough understanding of its components. This process can significantly enhance performance and prolong the life of the machine. In this section, we will outline the essential steps and considerations for a successful engine overhaul.

| Step | Description |

|---|---|

| 1 | Disassembly: Begin by removing the engine from the frame, ensuring all connections and cables are disconnected safely. |

| 2 | Inspection: Examine each component for wear and damage, focusing on the piston, cylinder, and crankshaft. |

| 3 | Cleansing: Clean all parts using appropriate solvents to eliminate dirt and debris, ensuring a smooth rebuilding process. |

| 4 | Replacement: Identify any worn parts that require replacement and source quality components to ensure durability. |

| 5 | Reassembly: Carefully reassemble the engine, following the manufacturer’s specifications for torque settings and assembly sequences. |

| 6 | Testing: Once reassembled, conduct a series of tests to verify performance and make adjustments as necessary. |

Following these steps will not only improve engine efficiency but also enhance overall reliability. Remember to document your process for future reference and continuous improvement.

Suspension Adjustments and Repairs

The proper functioning of a bike’s suspension system is crucial for optimal performance and rider comfort. Fine-tuning this system can significantly enhance handling and stability, especially when tackling various terrains. Understanding how to adjust and maintain the suspension components ensures a smoother ride and prolongs the lifespan of the machine.

Adjustments to the suspension typically involve modifying settings such as preload, compression, and rebound. Preload affects the initial tension on the springs, impacting how the bike responds to weight changes. Compression adjustments determine how quickly the suspension absorbs impacts, while rebound controls the speed at which it returns to its original position. Each of these settings should be tailored to suit the rider’s weight and riding style.

Regular maintenance is essential for keeping the suspension in top shape. This includes checking for leaks in the seals, inspecting the fork and shock body for any signs of wear, and ensuring that the fluid levels are appropriate. Replacing worn components and ensuring proper lubrication can prevent more significant issues down the line.

For those encountering persistent issues, it may be beneficial to consult with a professional technician. They can provide insight into more advanced modifications or repairs, ensuring that the suspension performs at its best. Regularly reviewing and adjusting these systems can make a noticeable difference in the overall riding experience.

Brake System Maintenance Tips

Ensuring the reliability of your stopping mechanism is crucial for safety and performance. Regular upkeep not only prolongs the lifespan of components but also enhances overall effectiveness. Here are essential practices to maintain your braking system effectively.

- Inspect Brake Pads: Regularly check the condition of your brake pads. Look for signs of wear and replace them if they appear thin or damaged.

- Monitor Brake Fluid Levels: Keep an eye on brake fluid levels and top up if necessary. Low fluid can lead to reduced braking efficiency.

- Check for Leaks: Inspect the entire system for any signs of fluid leakage. Address leaks promptly to avoid potential failures.

- Clean Brake Components: Dust and debris can accumulate on brake parts. Clean them periodically to ensure optimal function.

Following these tips will help maintain the effectiveness of your braking system, ensuring a safe and enjoyable riding experience.

Owner’s Tips for Longevity

Ensuring the long-lasting performance of your machine requires attention to detail and consistent maintenance practices. By following some straightforward guidelines, you can significantly enhance the durability and reliability of your vehicle. These tips are designed to help you preserve its condition and enjoy many years of trouble-free operation.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct frequent checks on vital components to catch potential issues early. |

| Fluid Maintenance | Change oil and coolant regularly to prevent overheating and wear. |

| Cleanliness | Keep the machine clean to avoid dirt accumulation, which can lead to damage. |

| Tire Care | Monitor tire pressure and tread to ensure safe handling and performance. |

| Storage | Store in a dry, sheltered environment to protect against weather-related deterioration. |

| Professional Servicing | Schedule regular professional check-ups to address any complex issues. |