Complete Guide to Repairing Your Honda GC160 Engine

In the world of small engines, understanding their functionality and upkeep is essential for optimal performance and longevity. This guide aims to provide a thorough overview of essential maintenance techniques, troubleshooting strategies, and common issues that can arise in these compact power sources.

Effective maintenance can significantly enhance the efficiency and reliability of your equipment. Whether you’re a seasoned technician or a novice user, knowing the intricacies of your engine’s design will empower you to handle various challenges with confidence. Regular care not only prevents costly repairs but also ensures your machine operates smoothly throughout its lifespan.

Throughout this resource, you’ll discover valuable insights into common problems and their solutions, as well as step-by-step procedures for performing essential tasks. By familiarizing yourself with these practices, you can extend the life of your engine and maintain its peak performance, ultimately saving time and resources in the long run.

Overview of Honda GC160 Engine

The engine in question is a versatile power unit commonly utilized in various outdoor equipment and tools. Known for its reliability and efficient performance, it serves as a dependable choice for both commercial and residential applications.

Featuring a robust design, this engine combines a compact structure with powerful output. Its four-stroke cycle enhances fuel efficiency while minimizing emissions, making it an environmentally conscious option. Additionally, the unit is equipped with a recoil starter, allowing for easy ignition and operation.

Maintenance is straightforward, with accessible components that facilitate routine checks and servicing. The engine’s durability is further supported by high-quality materials, ensuring longevity under diverse operating conditions. Overall, this power unit stands out for its balance of performance, ease of use, and maintenance simplicity.

Common Issues with GC160 Engines

Engines of this type often encounter several prevalent problems that can hinder performance and efficiency. Understanding these issues can help users maintain optimal functionality and extend the lifespan of their equipment.

Typical Problems

- Starting Difficulties: Many users report challenges when attempting to start the engine. This can be due to a faulty spark plug, old fuel, or issues with the ignition system.

- Overheating: Excessive heat can lead to significant damage. This is frequently caused by insufficient oil levels, clogged air filters, or malfunctioning cooling systems.

- Power Loss: A noticeable decrease in power may result from fuel line blockages, dirty carburetors, or worn-out components.

- Unusual Noises: Strange sounds during operation often indicate mechanical issues. This could be due to loose parts or worn bearings.

Preventive Measures

- Regularly check and change the oil to ensure proper lubrication.

- Inspect and clean the air filter to maintain airflow.

- Replace spark plugs according to the manufacturer’s schedule.

- Use high-quality fuel to prevent build-up in the fuel system.

By being aware of these common concerns and taking proactive steps, users can significantly enhance the reliability and efficiency of their engines.

Tools Needed for Repairs

When tackling maintenance tasks for small engines, having the right equipment is essential for efficiency and safety. This section outlines the necessary tools to ensure you can effectively address any issues that may arise during servicing. Each tool serves a specific purpose, aiding in the disassembly, inspection, and reassembly processes.

Essential Tools

Below is a list of fundamental tools that will facilitate your work:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Wrenches | To grip and turn fasteners of various sizes. |

| Screwdrivers | For removing and securing screws. |

| Pliers | To grasp, twist, or cut wire and other materials. |

| Torque Wrench | To apply a specific torque to fasteners. |

| Feeler Gauge | To measure gap widths for precision adjustments. |

Additional Equipment

In addition to the basic tools, consider having the following items on hand:

| Tool | Purpose |

|---|---|

| Fuel Container | For safely storing and transporting fuel. |

| Oil Filter Wrench | To easily remove and replace oil filters. |

| Multimeter | For testing electrical systems and components. |

| Cleaning Supplies | To ensure components are free from debris and buildup. |

Step-by-Step Maintenance Procedures

Regular upkeep of small engines is essential for optimal performance and longevity. Following a structured approach ensures that all components are in good condition, minimizing the risk of unexpected failures. This guide outlines key procedures to maintain engine efficiency and reliability.

Begin by checking the oil level and quality. Clean oil lubricates moving parts and prevents wear. If the oil appears dark or gritty, it’s time for a change. Replace it according to the manufacturer’s recommendations to keep the engine running smoothly.

Next, inspect the air filter. A clean filter promotes proper airflow, enhancing combustion and efficiency. If the filter is clogged with dirt and debris, clean or replace it as necessary to maintain optimal performance.

Fuel system maintenance is also crucial. Use fresh fuel and check for any signs of contamination. Regularly inspect fuel lines for leaks or cracks, replacing any damaged components to avoid fuel loss and ensure proper engine function.

Lastly, pay attention to spark plug condition. A worn or fouled spark plug can lead to poor starting and reduced performance. Remove the spark plug, clean it, and replace it if it shows signs of wear. Ensuring a strong spark will help the engine start easily and run efficiently.

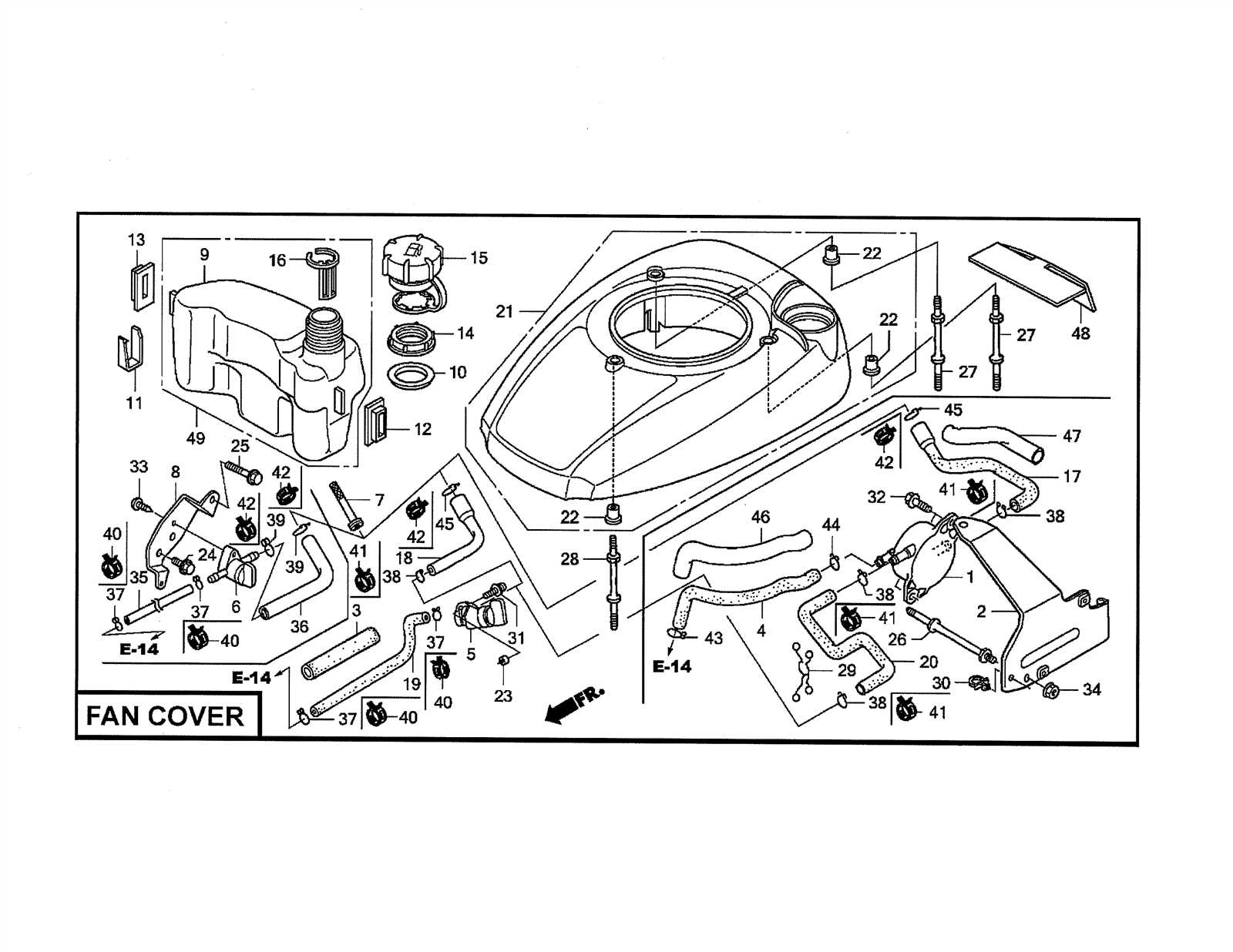

Replacing the Air Filter

Maintaining optimal performance of your engine requires regular attention to various components, including the air filtration system. A clean air filter ensures that the engine receives adequate airflow, which is essential for efficient combustion. Over time, the filter can become clogged with dirt and debris, leading to reduced power and increased fuel consumption. Regular replacement is crucial for preserving the longevity and efficiency of your machinery.

Tools and Materials Needed

To successfully replace the air filter, you will need a few basic tools and materials. Gather a new air filter that is compatible with your engine model, a screwdriver, and possibly a wrench to remove any securing screws or bolts. Having a clean workspace will also help in efficiently completing the task.

Steps for Replacement

Begin by locating the air filter housing, which is typically found near the engine. Use a screwdriver or wrench to remove any fasteners holding the cover in place. Once the cover is removed, carefully take out the old filter. Before inserting the new filter, inspect the housing for any dirt or debris and clean it if necessary. Finally, place the new filter into the housing, secure the cover back in place, and ensure that all fasteners are tightened properly. Regularly checking and replacing the air filter will help maintain your engine’s performance and efficiency.

Changing the Oil Effectively

Properly replacing the lubricant in your small engine is essential for maintaining performance and longevity. Regular oil changes help to ensure that your equipment runs smoothly and efficiently. This section outlines the steps needed to perform this task effectively, ensuring you achieve the best results.

Before starting the process, gather the necessary tools and materials:

- New oil

- Oil pan

- Funnel

- Wrench or socket set

- Clean rags or paper towels

Follow these steps to change the oil:

- Prepare the Engine: Start the engine and let it run for a few minutes to warm up. This helps the oil drain out more easily.

- Turn Off the Engine: After warming up, turn off the engine and allow it to cool for a short period.

- Drain the Old Oil: Locate the oil drain plug and remove it carefully. Allow the used oil to flow into the oil pan completely.

- Replace the Oil Filter: If your engine has an oil filter, remove it and replace it with a new one. Make sure to apply a small amount of new oil to the gasket of the new filter for a better seal.

- Refill with New Oil: Once the old oil has drained completely, replace the drain plug securely. Using a funnel, pour the new lubricant into the fill neck until it reaches the recommended level.

- Check the Level: After filling, wait a moment and then use the dipstick to check the oil level, adding more if necessary.

- Clean Up: Wipe any spills and properly dispose of the old oil and filter according to local regulations.

Regularly changing the lubricant will not only enhance the efficiency of your engine but also prolong its lifespan. Make this task a part of your maintenance routine for optimal performance.

Fuel System Troubleshooting Tips

Ensuring optimal performance of any engine relies heavily on a well-functioning fuel system. Issues in this area can lead to various operational problems, affecting efficiency and reliability. Identifying and resolving these challenges can significantly enhance overall functionality.

Here are some essential tips to help diagnose and fix common fuel system issues:

| Problem | Possible Cause | Suggested Action |

|---|---|---|

| Engine won’t start | Empty fuel tank | Refill with the appropriate fuel |

| Engine runs rough | Clogged fuel filter | Replace the fuel filter |

| Poor acceleration | Dirty carburetor | Clean or rebuild the carburetor |

| Fuel leaks | Worn fuel lines | Inspect and replace damaged lines |

| Excessive fuel consumption | Faulty fuel pump | Test and replace if necessary |

Regular maintenance and inspection of the fuel system components can prevent many issues. By following these tips, users can ensure their engines operate smoothly and efficiently.

Diagnosing Electrical Problems

Identifying issues within the electrical system of small engines can often be challenging. Understanding the various components and how they interact is crucial for effective troubleshooting. This section aims to guide you through systematic approaches to uncovering faults, ensuring optimal performance and reliability.

Common Symptoms of Electrical Issues

When electrical components fail, certain indicators can help pinpoint the problem. Look for signs such as difficulty starting, irregular operation, or complete engine shutdowns. Observing these symptoms can guide the diagnostic process.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Faulty ignition system | Check spark plug and wiring |

| Inconsistent power | Loose connections | Tighten or replace connectors |

| Dim lights | Weak battery | Test battery voltage and charge |

| Overheating | Electrical short | Inspect wiring for damage |

Steps to Diagnose Electrical Problems

To effectively diagnose electrical issues, follow a structured approach. Start by inspecting visible components and connections for wear or damage. Use a multimeter to measure voltage and continuity, ensuring each part of the circuit is functioning as intended. Document your findings to help identify patterns that may lead to the root cause of the malfunction.

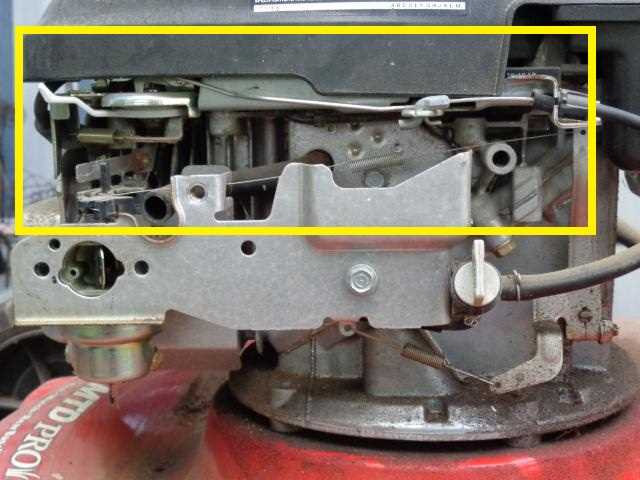

Rebuilding the Carburetor

Restoring the fuel delivery component of small engines is crucial for maintaining optimal performance. A well-functioning carburetor ensures proper air-fuel mixture, leading to smoother operation and enhanced efficiency. This section outlines the essential steps and considerations for a successful rebuild.

Tools and Materials Needed

Before starting the restoration process, gather the necessary tools and materials. A well-equipped workspace will facilitate the procedure and help avoid common pitfalls.

| Tool/Material | Purpose |

|---|---|

| Screwdriver set | For disassembling the carburetor |

| Clean rags | To wipe down surfaces and remove debris |

| Carburetor cleaner | For cleaning internal components |

| Replacement gaskets | To ensure airtight seals during reassembly |

| Wrench set | For securing connections |

Step-by-Step Rebuilding Process

Follow these steps to effectively restore the fuel delivery component:

- Remove the carburetor from the engine, noting the orientation of all parts.

- Disassemble the unit carefully, keeping track of all screws and components.

- Clean all parts thoroughly using the designated cleaner, paying close attention to jets and passages.

- Inspect each component for wear and replace any damaged items with new ones.

- Reassemble the carburetor using fresh gaskets, ensuring all connections are secure.

- Reattach the assembly to the engine and perform a test run to check for proper operation.

Regular maintenance of the fuel delivery system can significantly prolong the life of small engines, making this rebuilding process a worthwhile endeavor.

Understanding Engine Specifications

Engine specifications are essential parameters that define the performance and capabilities of a power unit. These details provide insight into the engine’s design, efficiency, and operational characteristics, enabling users to assess its suitability for various applications. A thorough comprehension of these specifications is crucial for anyone looking to maintain or troubleshoot their machinery effectively.

Key components of engine specifications typically include displacement, power output, torque ratings, and fuel type. Displacement refers to the total volume of the engine’s cylinders and directly influences its power generation potential. Meanwhile, power output is measured in horsepower or kilowatts, indicating the engine’s ability to perform work. Torque ratings, often expressed in foot-pounds or Newton-meters, reflect the twisting force available to turn components like wheels or blades.

Fuel type is another critical aspect, as it determines compatibility with various fuels such as gasoline, diesel, or alternative options. Understanding these specifications allows users to optimize performance, ensure longevity, and align the engine’s capabilities with specific tasks or projects. By familiarizing oneself with these details, one can enhance both efficiency and effectiveness in operation.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Following specific guidelines not only protects the individual working but also safeguards the equipment being serviced. Adopting the right safety measures creates a secure environment for effective and efficient work.

Essential Safety Gear

Wearing appropriate protective equipment can significantly reduce risks. This includes items that shield against mechanical hazards, chemicals, and electrical risks. Ensure you are equipped with the following:

| Gear | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris and chemicals. |

| Gloves | Prevents cuts and chemical exposure. |

| Steel-Toed Boots | Offers protection from heavy objects. |

| Ear Protection | Reduces noise-related damage to hearing. |

Work Environment Considerations

Maintaining a clean and organized workspace minimizes hazards. Ensure tools are properly stored, spills are cleaned up immediately, and sufficient lighting is available. A clutter-free area promotes focus and reduces the likelihood of accidents.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a daunting task. However, with the right approach and resources, you can streamline the process and ensure that you find the necessary items quickly and efficiently. This section will guide you through effective strategies to simplify your search for replacements, whether for routine maintenance or urgent repairs.

Utilizing Online Resources

The internet is a treasure trove of information and tools for identifying and purchasing parts. Numerous websites specialize in components, offering search filters by model, type, and brand. Utilizing these platforms allows you to compare prices and availability, ensuring you get the best deal. Additionally, community forums can provide insights and recommendations from other users who have faced similar challenges.

Local Dealers and Distributors

In many cases, local retailers or authorized distributors can be invaluable resources for sourcing components. Visiting these establishments allows you to physically inspect parts and discuss your needs with knowledgeable staff. Furthermore, building a rapport with local suppliers can lead to better service and quicker access to the parts you require in the future.

Tips for Long-Term Care

Ensuring the longevity and optimal performance of your equipment requires consistent maintenance and attention to detail. By following a few essential practices, you can significantly extend the life of your machinery and enhance its efficiency over time.

Regular Maintenance Checks

- Schedule routine inspections to identify any wear and tear early.

- Change oil and filters as recommended to keep internal components lubricated and clean.

- Examine belts and hoses for signs of cracking or fraying, replacing them as necessary.

Proper Storage Practices

- Store equipment in a dry, covered area to protect it from the elements.

- Ensure that all moving parts are clean and free of debris before storage.

- Consider using protective covers to shield against dust and moisture.

By implementing these strategies, you can foster a reliable and durable machine that meets your needs for years to come.