Comprehensive Guide to Bosch CP3 Injection Pump Repair

Maintaining optimal performance of your vehicle’s fuel distribution mechanism is crucial for ensuring efficiency and longevity. Understanding the intricacies of this vital component can significantly enhance your knowledge and enable you to address issues that may arise over time. This guide provides essential insights into the processes involved in diagnosing and resolving common complications associated with this particular technology.

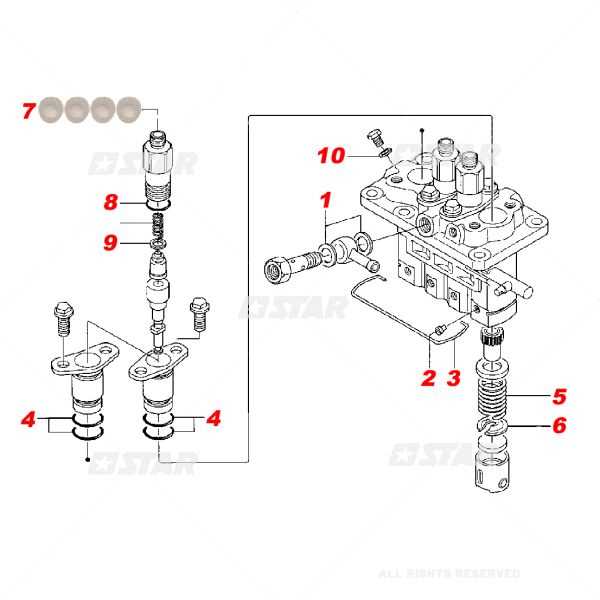

Step-by-step procedures and detailed illustrations will assist both novice and seasoned enthusiasts in navigating the complexities of this system. From identifying symptoms of malfunction to executing the necessary adjustments, every aspect is covered to facilitate a thorough understanding of the operation. By following the outlined protocols, you can ensure that your vehicle operates at its best, minimizing downtime and maximizing reliability.

Whether you’re embarking on a DIY project or simply seeking to expand your automotive knowledge, this resource is designed to empower you with the skills required for effective maintenance. Embrace the challenge and equip yourself with the tools to tackle fuel delivery issues confidently.

Understanding Bosch CP3 Injection Pumps

This section provides insight into a crucial component of modern fuel delivery systems. These devices are essential for ensuring optimal performance and efficiency in diesel engines. A thorough understanding of their functionality, components, and maintenance is vital for any technician or enthusiast involved in engine management and diagnostics.

The mechanism operates by precisely controlling fuel flow under high pressure, which is necessary for effective combustion. This ensures that engines run smoothly and efficiently, reducing emissions and enhancing power output. Below is a summary of key features and components:

| Feature | Description |

|---|---|

| Fuel Delivery | Ensures precise metering of fuel to the engine cylinders. |

| Pressure Regulation | Maintains optimal pressure levels for efficient combustion. |

| Durability | Designed to withstand harsh operating conditions and extend service life. |

| Performance Optimization | Enhances engine responsiveness and power across various loads. |

Understanding these elements aids in troubleshooting and enhances the overall effectiveness of engine management systems. This knowledge is essential for achieving optimal operational standards and ensuring the longevity of the engine.

Common Issues with CP3 Pumps

Understanding the frequent challenges encountered with fuel delivery systems is essential for effective troubleshooting and maintenance. These issues can lead to performance degradation and may necessitate intervention to restore functionality.

- Fuel Leakage: This is a prevalent problem, often arising from worn seals or faulty connections. Identifying the source of leakage is crucial to prevent further damage.

- Insufficient Pressure: Low pressure can affect the engine’s performance. This might be caused by blockages, damaged components, or improper calibration.

- Contamination: The presence of debris or impurities in the fuel can lead to clogging and operational failures. Regular filtration and system checks can mitigate this issue.

- Noise and Vibration: Unusual sounds during operation may indicate internal wear or misalignment. This can affect efficiency and should be addressed promptly.

- Electrical Failures: Issues with sensors or wiring can disrupt the system’s functionality. Regular inspections can help in early detection.

lessCopy code

Addressing these common problems with proper diagnostics and maintenance practices can significantly enhance the lifespan and efficiency of the fuel delivery system.

Essential Tools for Repairing CP3

Having the right equipment is crucial for ensuring the success of any maintenance task. Each tool serves a unique purpose, contributing to the efficiency and effectiveness of the entire process. This section highlights the fundamental implements needed for optimal outcomes.

Wrenches are vital for loosening and tightening various components. An adjustable wrench is particularly useful for handling different sizes of fittings.

Screwdrivers are essential for manipulating fasteners, with a variety of types, such as flathead and Phillips, needed for different applications.

Torque wrench ensures that connections are secured to the manufacturer’s specifications, preventing future issues caused by over or under-tightening.

Diagnostic tools are also important, allowing for precise identification of issues before disassembly. These can include electronic testers and pressure gauges.

Cleaning supplies help maintain a tidy workspace, which is critical for avoiding contamination during assembly. This includes brushes, solvents, and lint-free cloths.

Lastly, a workbench with adequate lighting and storage solutions creates an organized environment, enhancing both safety and productivity.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring your fuel delivery mechanism. Following a systematic method ensures that each component is properly assessed and reinstated, enhancing the efficiency and longevity of the system.

Preparation and Disassembly

Begin by gathering the necessary tools and materials. Ensure your workspace is clean and organized. Disconnect all relevant connections and remove the assembly from its mounting. Take care to document the arrangement of parts as you disassemble, using photographs or notes if necessary.

Inspection and Replacement

Once disassembled, inspect each component for signs of wear or damage. Look for cracks, corrosion, or other issues that may impair functionality. Replace any defective parts with high-quality alternatives to ensure optimal performance. After replacement, reassemble the unit, reversing the disassembly process, and tighten all connections securely.

Finally, conduct thorough tests to verify that the system operates smoothly and efficiently, ensuring a reliable performance for your vehicle.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard equipment and surrounding areas. Understanding and implementing these guidelines is essential for a successful and safe experience.

Personal Protective Equipment

- Wear safety glasses to protect your eyes from debris.

- Use gloves to avoid skin contact with hazardous materials.

- Ensure appropriate footwear is worn to prevent slips and falls.

- Utilize hearing protection if working in a noisy environment.

Work Area Preparation

- Clear the workspace of any unnecessary items to minimize distractions.

- Ensure adequate lighting to clearly see all components.

- Keep fire extinguishers accessible in case of emergencies.

- Verify that all tools and equipment are in good condition before use.

By following these essential safety measures, individuals can significantly reduce risks and enhance the effectiveness of their work processes.

Troubleshooting CP3 Pump Problems

Identifying and resolving issues with fuel delivery systems is essential for optimal engine performance. Various symptoms can indicate underlying problems, and understanding these can help diagnose and address the situation effectively.

Common Symptoms

- Engine stalling or failure to start

- Unusual noises during operation

- Decreased power output

- Excessive smoke from the exhaust

- Increased fuel consumption

Diagnostic Steps

- Check for error codes using an appropriate diagnostic tool.

- Inspect fuel lines for leaks or blockages.

- Examine electrical connections for corrosion or damage.

- Assess fuel quality and ensure it meets specifications.

- Verify that the system is primed and free of air.

By following these guidelines, you can systematically address potential issues, ensuring reliable operation and longevity of your system.

Preventative Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your mechanical systems. By implementing routine checks and adhering to best practices, you can avoid potential issues and enhance performance. Below are some key strategies to help maintain optimal function.

| Maintenance Activity | Frequency | Description |

|---|---|---|

| Fluid Level Check | Monthly | Ensure that all necessary fluids are at appropriate levels to prevent overheating and component wear. |

| Filter Replacement | Every 6 months | Change filters regularly to maintain cleanliness and prevent contaminants from affecting system performance. |

| Visual Inspection | Monthly | Look for signs of leaks, wear, or damage to components to address issues before they escalate. |

| System Calibration | Annually | Calibrate settings to ensure accurate operation and efficiency of the system. |

| Component Lubrication | Quarterly | Apply lubricant to moving parts to reduce friction and wear, enhancing performance. |

By following these suggestions, you can significantly reduce the risk of failure and prolong the life of your equipment. Consistency is key to effective maintenance and ensuring reliable operation.

When to Replace Your CP3 Pump

Recognizing the right moment for a component replacement is crucial for maintaining optimal performance in any vehicle. Certain signs and symptoms can indicate that your fuel delivery system may be failing, leading to potential complications if not addressed promptly. Understanding these indicators can save you time and money in the long run.

Common Symptoms of Failure

Engine misfires, rough idling, or decreased acceleration are often the first noticeable signs of a failing component. If you experience unexpected power loss or an increase in fuel consumption, it may be time to assess the health of your system. Unusual noises, such as whining or grinding, should also prompt further investigation.

Performance Issues

Inconsistent engine performance or difficulty starting the vehicle can be indicative of an underlying issue. Additionally, frequent error codes related to fuel delivery may suggest that replacement is necessary. Addressing these problems early can help avoid more severe engine damage and ensure your vehicle operates smoothly.

Upgrading CP3 Components for Efficiency

Improving the efficiency of your fuel delivery system can lead to enhanced performance and reduced emissions. By focusing on key components, you can achieve significant gains in power output and fuel economy. This section outlines various strategies and components that can be upgraded to optimize functionality.

Key Areas for Improvement

- Fuel Injectors: Upgrading to high-flow injectors can improve atomization and combustion, resulting in better engine response.

- Fuel Lines: Installing larger diameter lines reduces pressure drop and enhances fuel flow, contributing to overall system efficiency.

- Filter Systems: Utilizing advanced filtration options minimizes contaminants, ensuring cleaner fuel delivery to the engine.

Performance Enhancements

- Tuning: Custom tuning can optimize engine performance parameters, aligning them with upgraded components for maximum output.

- Boost Control: Implementing better boost control mechanisms can improve the air-fuel mixture, leading to more efficient combustion.

- Heat Management: Upgrading cooling systems helps maintain optimal operating temperatures, preventing performance loss due to overheating.

By systematically addressing these components, you can significantly enhance the overall efficiency of your system, leading to better performance and longevity.

Understanding Pump Calibration Techniques

Calibration is a crucial process that ensures optimal performance and accuracy of fuel delivery systems. Proper adjustment of these systems guarantees efficient operation and reduced emissions, making it vital for mechanics and technicians to master various techniques. This section delves into the methods employed for achieving precise calibration in fuel delivery systems.

Importance of Calibration

Accurate calibration is essential for several reasons:

- Enhances engine performance by ensuring proper fuel-air mixture.

- Reduces harmful emissions, contributing to environmental sustainability.

- Improves fuel efficiency, saving costs in the long run.

- Extends the lifespan of engine components by preventing wear and tear.

Calibration Techniques

There are various techniques utilized for calibrating fuel delivery systems. Some of the most common methods include:

- Static Calibration: Involves testing the system while it is not in operation to ensure correct settings.

- Dynamic Calibration: Performed while the system is running, allowing for real-time adjustments and observations.

- Pressure Testing: Measures the pressure levels to ensure they meet the specified standards.

- Flow Rate Analysis: Evaluates the volume of fuel delivered over a specific period to confirm efficiency.

By understanding and applying these calibration techniques, technicians can enhance the performance and reliability of fuel systems, leading to improved overall engine function.

Resources for Further Learning

For those looking to deepen their understanding of automotive systems and their components, a wealth of resources is available. Engaging with various materials can enhance both theoretical knowledge and practical skills. Whether you are a novice or an experienced technician, exploring additional literature, online courses, and community forums can provide valuable insights.

Books and Guides: Numerous publications cover topics related to automotive mechanics and component functioning. Seek out detailed guides that break down complex systems and offer troubleshooting tips. These resources can serve as excellent references for hands-on projects.

Online Courses: Various platforms offer structured learning experiences through video lectures and interactive modules. Enrolling in specialized courses can provide a more in-depth understanding of system operations, allowing learners to grasp the intricacies of performance and maintenance.

Forums and Communities: Participating in online discussion groups can foster connections with fellow enthusiasts and professionals. Engaging in these platforms allows for the exchange of ideas, troubleshooting advice, and practical experiences that can enrich one’s knowledge base.

YouTube Channels: Many channels focus on automotive repair and maintenance, providing visual guidance that complements written materials. Tutorials and demonstrations can illustrate techniques and processes effectively, aiding in practical learning.

Utilizing these resources can significantly enhance one’s expertise and confidence in handling automotive systems. Continuous learning is essential in a field that evolves rapidly with new technologies and methodologies.