Complete Guide to Repairing Your Admiral Washer

Maintaining the functionality of your household appliance is crucial for efficient daily chores. Understanding common issues and their solutions can save time, effort, and money. This section will guide you through essential strategies to address frequent malfunctions and restore optimal performance.

Whether you’re facing issues with draining, spinning, or general operation, knowing how to approach these challenges can empower you to tackle them confidently. With a combination of practical steps and insights, you’ll be equipped to diagnose problems effectively.

In the following paragraphs, we will delve into specific symptoms and offer detailed suggestions to help you navigate through various situations. By familiarizing yourself with these approaches, you’ll enhance your ability to maintain your appliance in peak condition.

Common Issues with Admiral Washers

When it comes to household appliances, certain challenges can frequently arise, causing inconvenience for users. Understanding these typical problems can assist in troubleshooting and maintaining optimal performance. Below, we outline some of the most prevalent complications encountered by users of these laundry machines.

Unusual Noises

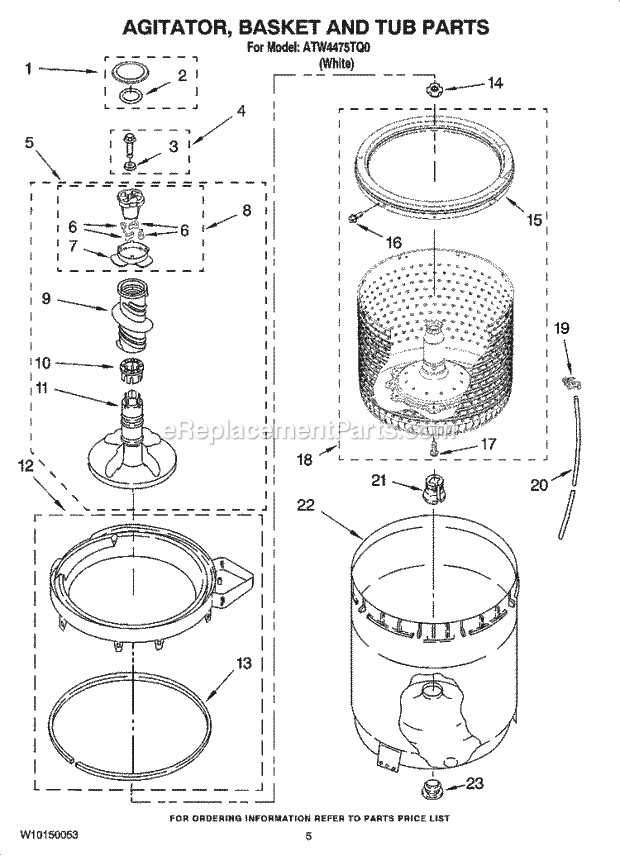

One of the most common concerns involves strange sounds during operation. Rattling, grinding, or banging noises can indicate a variety of issues, such as loose components or foreign objects trapped within the drum. Identifying and addressing the source of these sounds promptly can prevent further damage.

Drainage Problems

Another frequent issue is improper drainage, which can lead to excess water remaining in the drum after a cycle. This might stem from a clogged drain hose or a malfunctioning pump. Ensuring that these parts are clear and functioning properly is essential for efficient operation and to avoid potential water damage.

Essential Tools for Repairs

To effectively address issues with household appliances, having the right set of instruments is crucial. This selection not only facilitates the process but also ensures safety and efficiency during the task. Below is a compilation of essential items that every DIY enthusiast should consider for their toolkit.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are necessary for loosening and tightening screws.

- Socket Wrench Set: Ideal for removing bolts and nuts, a complete set will help tackle various sizes commonly found in appliances.

- Pliers: These versatile tools are useful for gripping, twisting, and cutting wires or other small components.

- Utility Knife: A sharp blade is essential for cutting through insulation, tape, and other materials.

- Multimeter: This device is essential for measuring voltage, current, and resistance, aiding in diagnosing electrical issues.

Equipping your workspace with these instruments will streamline the troubleshooting and fixing process, making it more manageable and effective. By being prepared, you can confidently tackle any challenge that arises.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to identifying and resolving common issues that may arise during the operation of your appliance. By following these steps, you can effectively diagnose problems and implement solutions, ensuring your device operates smoothly and efficiently.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| No power | Disconnected power source | Check the power cord and outlet |

| Leaking water | Damaged hose | Inspect and replace hoses as needed |

| Unusual noises | Foreign objects | Examine the drum for items stuck inside |

| Poor performance | Overloading | Reduce load size for optimal results |

Steps to Follow

Begin with a visual inspection of your appliance, ensuring all connections are secure and free from damage. Next, assess any error codes displayed on the control panel, referring to the device’s specifications for clarification. Proceed to test various functions, such as filling and draining, to isolate the issue. Document each step taken to maintain clarity in your troubleshooting process.

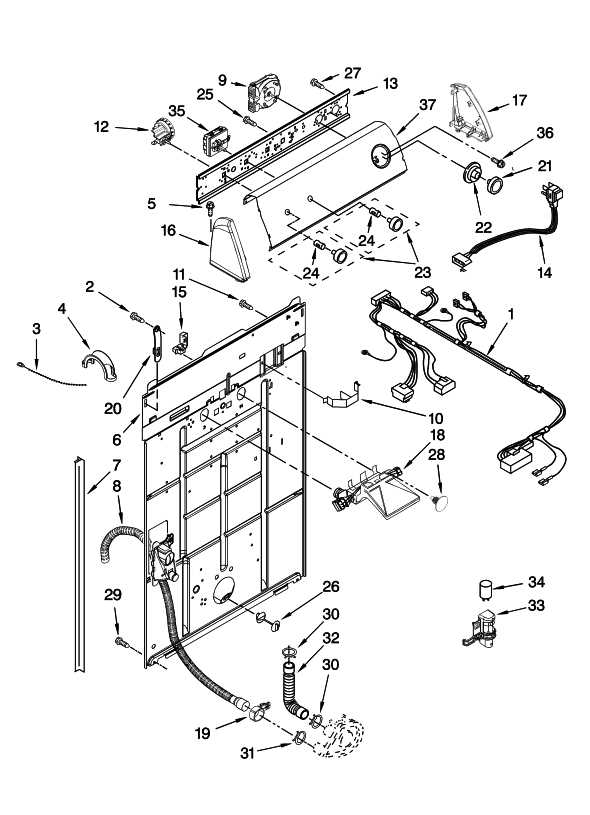

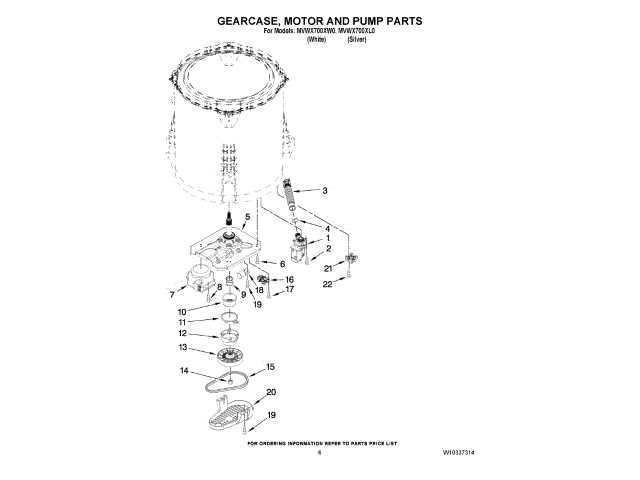

How to Replace the Drive Belt

Replacing the drive belt is a crucial task that ensures the efficient functioning of your appliance. This component is responsible for transferring motion from the motor to the drum, enabling smooth operation. Over time, wear and tear may cause the belt to fray or break, leading to performance issues. In this guide, you will learn the steps to successfully replace this vital part.

Required Tools and Materials

Before starting the process, gather the necessary tools and materials. You will need:

- Screwdriver – for removing the panels

- Socket wrench – for securing any bolts

- Replacement drive belt – ensure it is compatible with your model

- Towel – to catch any drips if applicable

Step-by-Step Instructions

Follow these steps to replace the drive belt:

- Unplug the appliance to ensure safety before you begin any work.

- Remove the outer panels to access the interior components. Use the screwdriver to take out screws and carefully detach the panels.

- Locate the drive belt around the motor and drum assembly. Take note of its routing for proper installation of the new belt.

- Remove the old belt by gently sliding it off the pulleys.

- Install the new drive belt following the same routing as the old one. Make sure it is seated properly on all pulleys.

- Reassemble the panels and secure them with the screws you removed earlier.

- Plug the appliance back in and run a test cycle to ensure everything is functioning correctly.

By following these straightforward steps, you can successfully replace the drive belt and restore the performance of your appliance.

Cleaning the Filter: A Quick Guide

Maintaining optimal performance of your appliance often involves a simple yet essential task: cleaning the filter. This component plays a crucial role in ensuring efficient operation and preventing potential issues. Regular maintenance can enhance the lifespan of your unit and improve its effectiveness.

Step 1: Locate the Filter

Step 2: Prepare for Cleaning

Before beginning the cleaning process, ensure that the device is unplugged to avoid any accidents. Place a towel or shallow container underneath to catch any water that may spill during removal.

Step 3: Remove the Filter

Gently twist or pull out the filter, being cautious not to damage any surrounding components. Take a moment to inspect it for any visible debris or buildup.

Step 4: Clean the Filter

Rinse the filter under warm running water to eliminate dirt and lint. For stubborn residues, use a soft brush or cloth. Ensure it is thoroughly cleaned before proceeding.

Step 5: Reinstall the Filter

Once the filter is dry and free from obstructions, carefully reinsert it into its designated slot. Make sure it is securely in place to avoid any operational issues.

Step 6: Test the Appliance

After reinstalling the filter, plug the device back in and run a short cycle to verify that everything is functioning properly. Watch for any unusual noises or leaks.

By following these straightforward steps, you can ensure your machine operates smoothly and efficiently, prolonging its life and enhancing its performance.

Electrical Problems: Diagnosis and Fixes

Identifying and resolving electrical issues is crucial for maintaining the functionality of home appliances. These complications can arise from various sources, including faulty components, poor connections, or external factors. Understanding the symptoms and following a systematic approach can lead to effective solutions.

Common electrical problems include:

- Appliance not turning on

- Inconsistent performance or unexpected shut-offs

- Unusual noises during operation

- Burning smell or visible smoke

To diagnose these issues, consider the following steps:

- Check Power Supply: Ensure the appliance is plugged in and the outlet is functioning. Test with another device if necessary.

- Inspect Cords and Connections: Look for any signs of wear, fraying, or loose connections that may interrupt power flow.

- Examine Circuit Breaker: Ensure that the circuit breaker has not tripped. Reset it if needed.

- Test Internal Components: Use a multimeter to check the integrity of internal parts such as fuses, motors, and wiring.

Once the issue is identified, potential fixes might include:

- Replacing damaged cords or plugs

- Reconnecting loose wires

- Swapping out faulty components

- Consulting a professional for complex issues

By following these guidelines, you can efficiently address electrical malfunctions and ensure your appliance operates smoothly.

Maintaining Your Washer for Longevity

Proper upkeep is essential for extending the lifespan of your laundry appliance. By following a few straightforward practices, you can ensure that it operates efficiently and remains in excellent condition for years to come. Regular attention not only enhances performance but also minimizes the risk of unexpected breakdowns.

Regular Cleaning is vital. Ensure that you clean the drum and dispensers periodically to prevent the buildup of detergent residue and mildew. A mixture of vinegar and baking soda can work wonders in removing odors and stains.

Check Hoses frequently for any signs of wear or damage. Cracks or leaks can lead to significant issues. Replace any compromised hoses to avoid potential flooding or other water-related problems.

Level the Appliance to prevent excessive vibrations during cycles. An unbalanced setup can lead to unnecessary wear on internal components, impacting both performance and lifespan.

Use the Right Detergent and adhere to the manufacturer’s recommendations for dosage. Overuse can lead to suds buildup, while underuse may result in poor cleaning performance.

Run Regular Maintenance Cycles with hot water and a cleaning solution to keep the inner workings in optimal condition. This simple step helps eliminate buildup and keeps everything running smoothly.

By implementing these maintenance tips, you will not only enhance the efficiency of your appliance but also contribute to its longevity, ensuring reliable service for many years ahead.

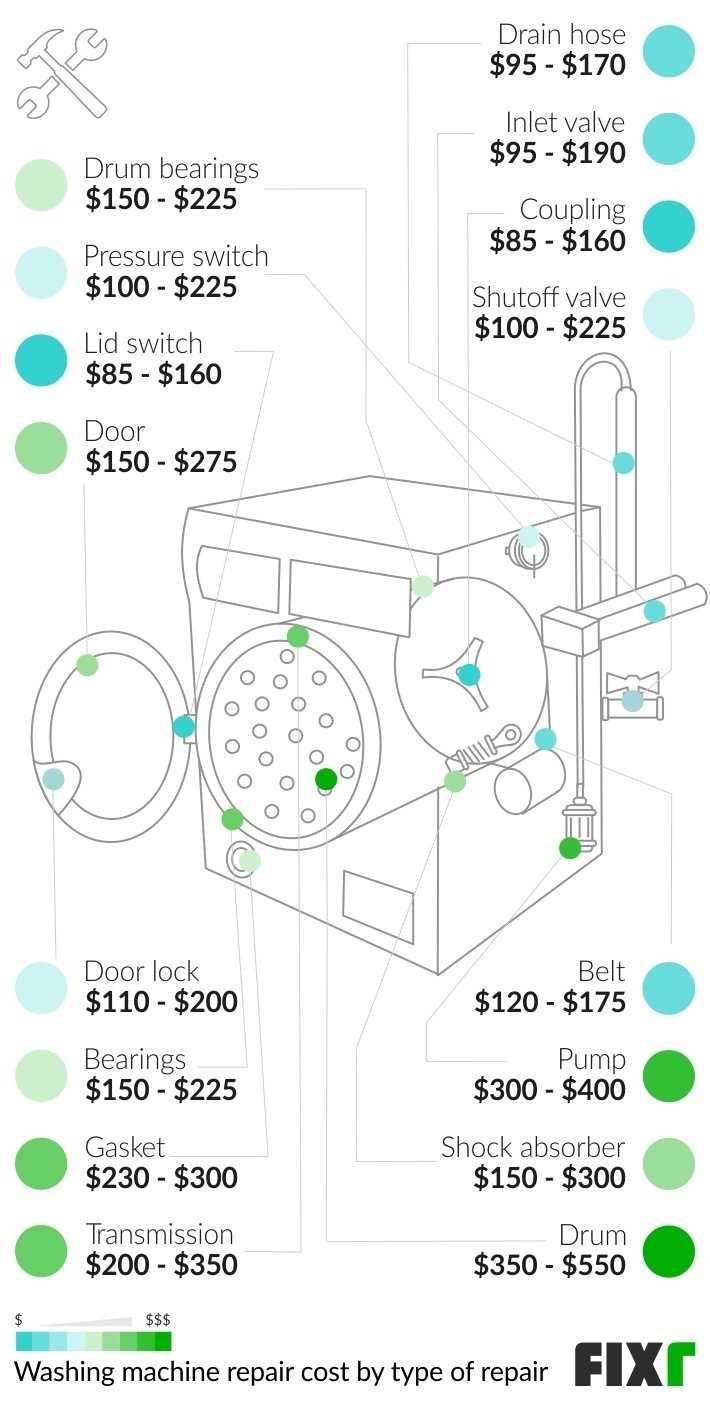

Parts Replacement: Where to Find Them

When it comes to maintaining your appliance, sourcing the right components is crucial. Whether you’re dealing with a malfunction or performing routine upkeep, knowing where to find high-quality parts can save you time and effort.

Here are several reliable options for locating the necessary items:

- Online Retailers: Numerous websites specialize in appliance parts, offering a wide selection at competitive prices. Some popular options include:

- Amazon

- eBay

- PartSelect

- Manufacturer’s Website: Check the official site of the brand for direct access to genuine components and helpful resources.

- Local Appliance Stores: Many brick-and-mortar shops stock essential parts. It’s often beneficial to call ahead to confirm availability.

- Salvage Yards: For older models, consider visiting appliance salvage yards. You may find hard-to-locate items at a fraction of the new price.

- Repair Forums and Communities: Engaging with online forums can provide recommendations for trustworthy suppliers and tips from fellow users.

lessCopy code

By exploring these avenues, you can efficiently track down the parts you need, ensuring your appliance continues to function optimally.

Understanding Washer Error Codes

Error codes are vital indicators that communicate issues within your laundry appliance. Recognizing these codes can significantly simplify troubleshooting, enabling users to identify and address problems effectively. By interpreting these signals, you can enhance the longevity and performance of your equipment.

Common Error Codes and Their Meanings

Different brands and models may present unique codes, but many share common signals. Here are some frequent error codes you might encounter:

- E01: Indicates a door lock malfunction.

- E02: Signifies an issue with water supply.

- E03: Represents a drainage problem.

- E04: Warns of an unbalanced load.

Troubleshooting Steps

When faced with an error code, follow these steps to troubleshoot:

- Consult your device’s documentation for a complete list of error codes.

- Verify connections and ensure water supply is adequate.

- Inspect the drainage system for blockages.

- Redistribute the load to achieve balance.

By systematically addressing these codes, you can maintain optimal functionality and extend the lifespan of your laundry equipment.

DIY Repair vs. Professional Help

When faced with a malfunctioning appliance, individuals often grapple with the choice between tackling the issue themselves or enlisting the expertise of a technician. Each approach carries its own set of advantages and disadvantages, making it essential to weigh the options carefully.

Advantages of DIY

- Cost savings: Performing tasks on your own can significantly reduce expenses.

- Flexibility: You can work at your own pace and schedule.

- Satisfaction: Successfully fixing an issue can provide a sense of accomplishment.

Benefits of Professional Assistance

- Expertise: Professionals possess specialized knowledge and experience.

- Time efficiency: Technicians can often complete repairs more quickly.

- Warranty protection: Using a qualified service may preserve any existing warranties.

Ultimately, the decision hinges on your comfort level, skillset, and the complexity of the situation at hand.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Adhering to specific guidelines helps to mitigate risks and protect both the individual and the equipment. A thorough understanding of safety measures is essential to achieve a secure and effective working environment.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects, and sturdy footwear to prevent injuries from falling items. Ensuring that the workspace is free from hazards also contributes significantly to safety.

Power Sources and Tools

Before beginning any task, it is important to disconnect power sources to prevent electrical shock. Utilize the correct tools for each job, as improper equipment can lead to accidents. Regularly inspecting tools for wear and tear ensures that they function safely and effectively, reducing the risk of malfunctions during use.