Guide to Bosch Magneto Repair

This section provides essential insights into the upkeep of vital engine parts, focusing on efficient troubleshooting and restoration techniques. Understanding the functionality and potential issues of these components is crucial for optimal performance.

With detailed instructions and helpful tips, readers will learn how to effectively assess and address common malfunctions. This guide aims to empower enthusiasts and professionals alike to enhance their knowledge and skills in maintaining these essential systems.

Whether you are a seasoned expert or a novice, mastering these practices will not only extend the life of your equipment but also improve its reliability. Engaging with this material will pave the way for successful interventions and informed decision-making.

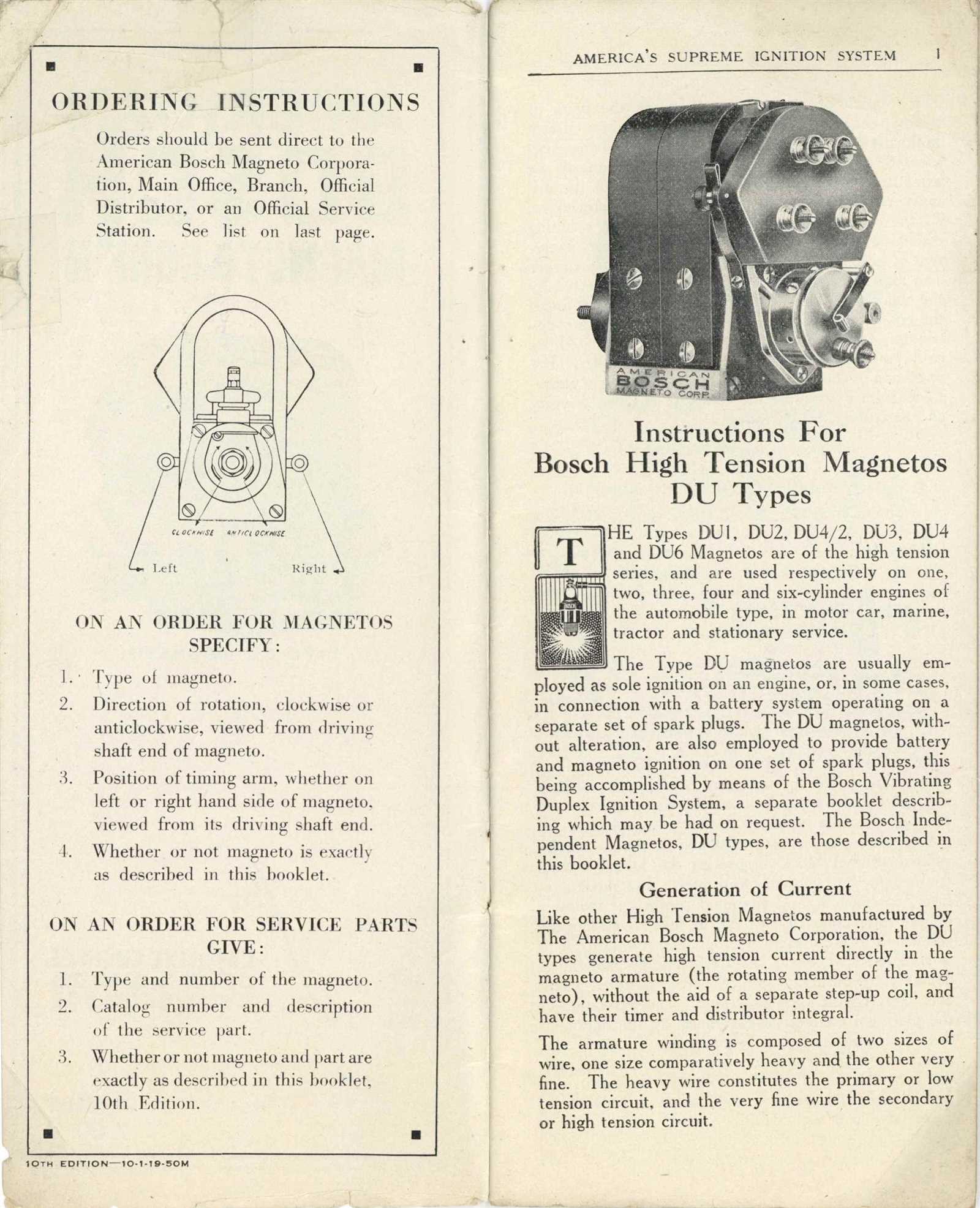

Understanding Magneto Systems

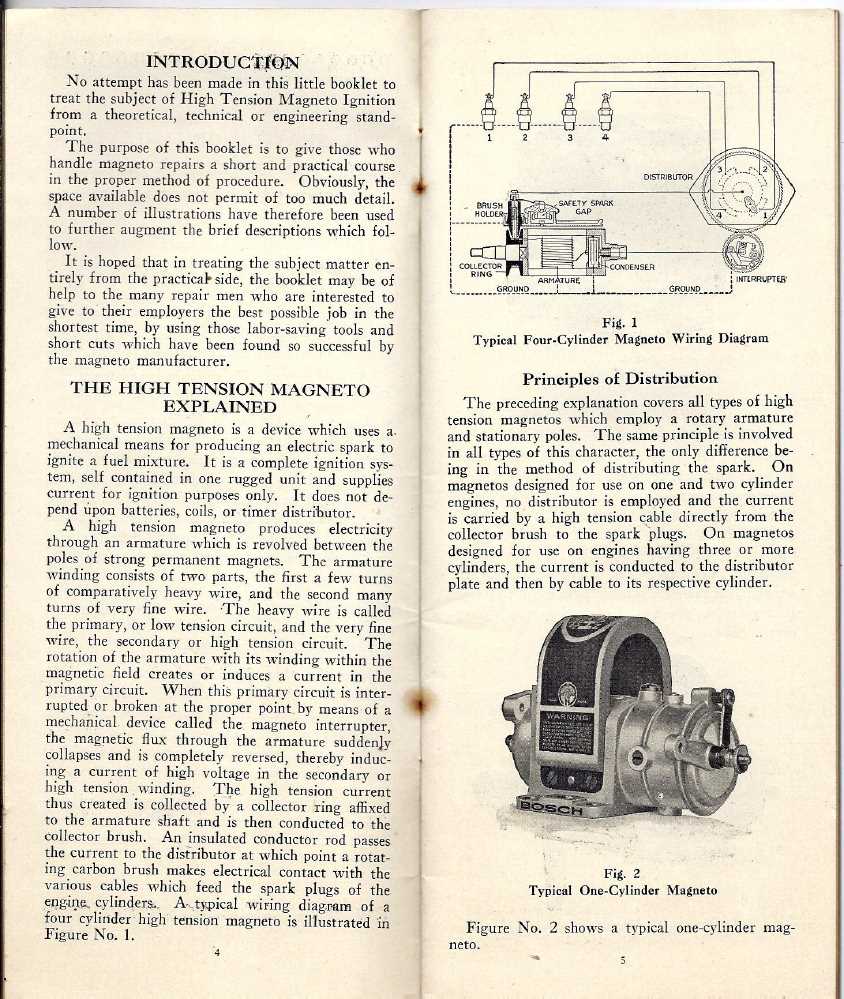

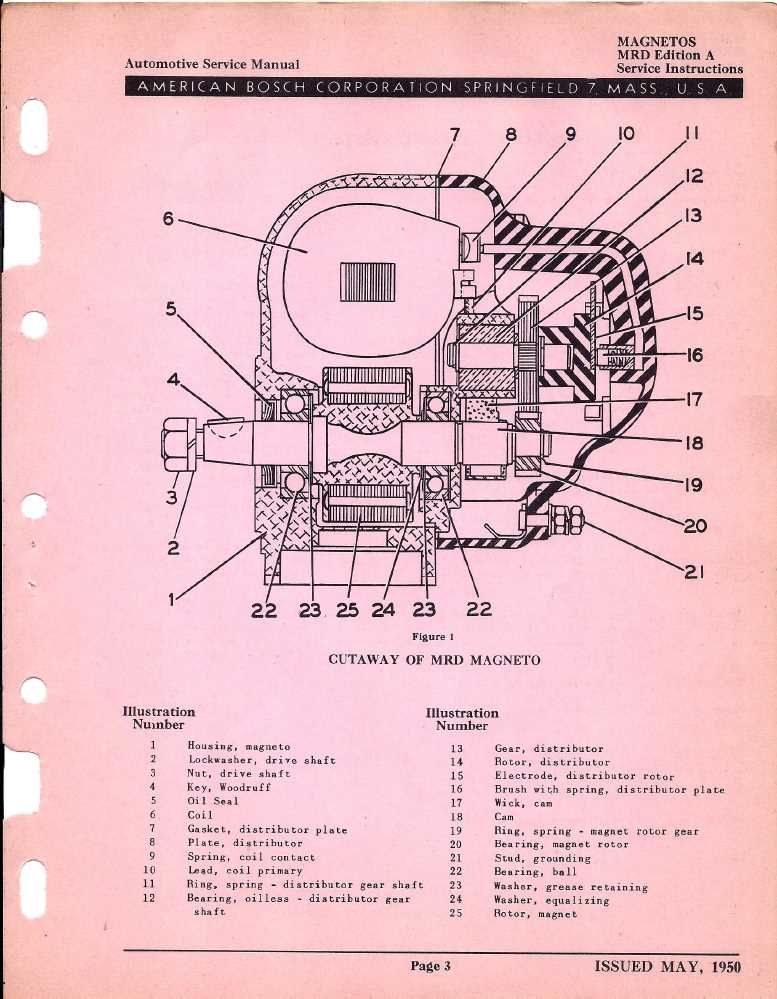

The functionality of ignition systems plays a critical role in the performance of combustion engines. These devices convert mechanical energy into electrical energy, enabling the ignition process. A solid grasp of how these systems operate is essential for effective maintenance and troubleshooting.

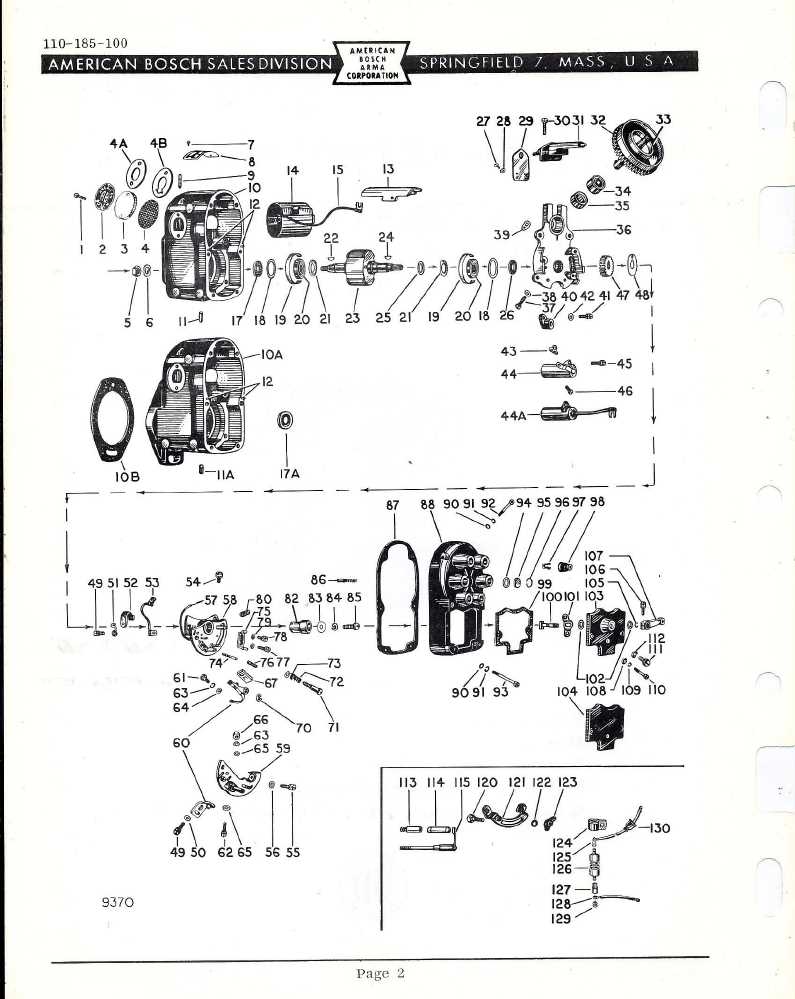

Key components of these systems include:

- Coils: Transform mechanical energy into high-voltage electricity.

- Capacitors: Store and release electrical energy, aiding in the ignition process.

- Contact Points: Control the flow of electricity, ensuring efficient energy transfer.

- Timing Mechanism: Ensures that the ignition spark occurs at the right moment for optimal performance.

Regular inspection and maintenance of these components can enhance reliability and efficiency. Understanding the intricacies of each part allows for informed decisions when addressing issues or performing upgrades.

Common Issues with Magnetos

In the realm of ignition systems, various challenges can arise that affect performance and reliability. Understanding these typical problems is crucial for maintaining efficient operation.

One frequent issue is a lack of spark, which may result from faulty connections or degraded components. Over time, wear and tear can lead to diminished electrical output, causing difficulties in starting the engine.

Another common concern involves the timing of the ignition. If the timing is misaligned, it can cause poor combustion, resulting in reduced power and increased emissions. Regular checks are necessary to ensure proper synchronization.

Additionally, moisture intrusion can create electrical shorts, leading to erratic performance. Protecting the system from water exposure is essential for longevity.

Finally, excessive vibration can cause loose connections and component failure. Ensuring secure mounting and periodic inspections can help mitigate this problem.

Tools Needed for Repairs

When undertaking maintenance on ignition systems, having the right instruments is essential for efficient and effective work. Proper equipment not only facilitates the process but also ensures safety and accuracy during the task.

- Screwdrivers: A variety of sizes is necessary for different screws and fasteners.

- Wrenches: Both adjustable and fixed wrenches will help in loosening and tightening various components.

- Multimeter: This tool is crucial for testing electrical components and connections.

- Pliers: Needle-nose and standard pliers can assist in gripping and manipulating wires.

- Torque Wrench: Ensures that screws and bolts are tightened to the manufacturer’s specifications.

In addition to the basic tools, specific items may enhance your efficiency:

- Wire Strippers: Useful for preparing wires for connections.

- Safety Goggles: Protects your eyes from debris during work.

- Gloves: Keeps hands safe from sharp edges and chemicals.

Gathering these essential tools will help streamline the maintenance process and ensure successful outcomes in your tasks.

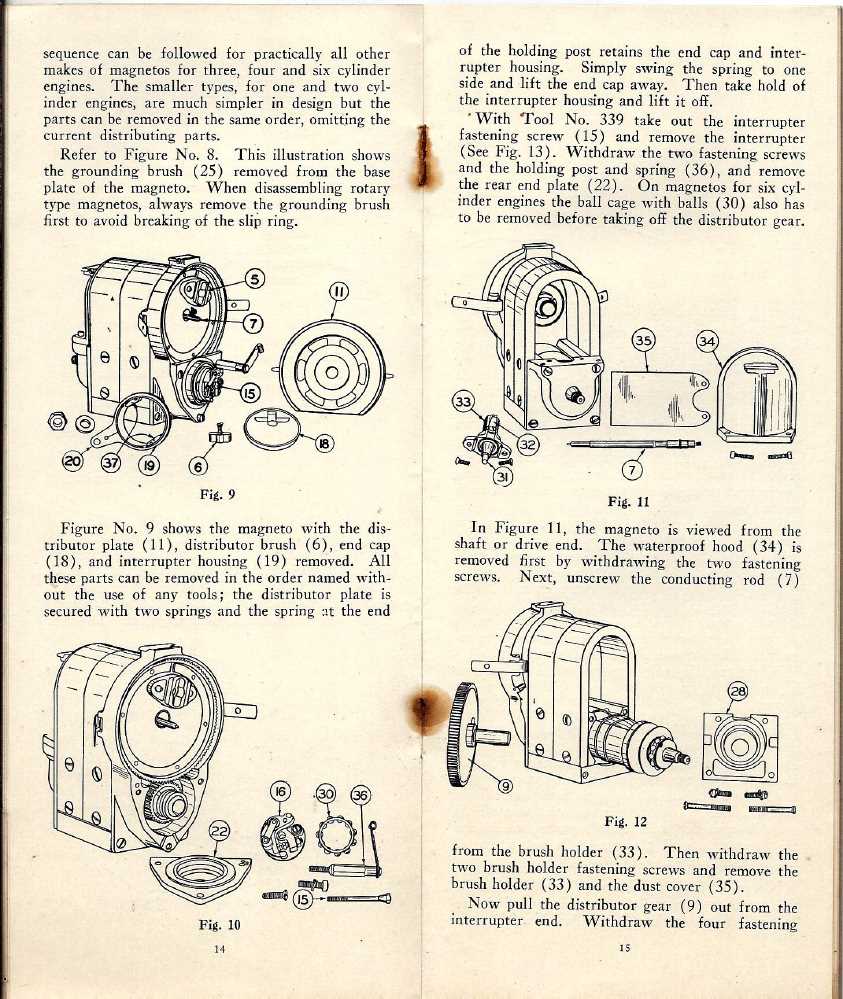

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring functionality to a specific ignition component. Following a systematic method ensures efficiency and effectiveness in addressing common issues.

-

Gather Necessary Tools and Materials:

- Multimeter

- Screwdriver set

- Cleaning solvent

- Replacement parts, if needed

-

Disconnect Power Source:

Ensure safety by disconnecting the electrical supply before beginning any work. This prevents accidental shocks and damage to components.

-

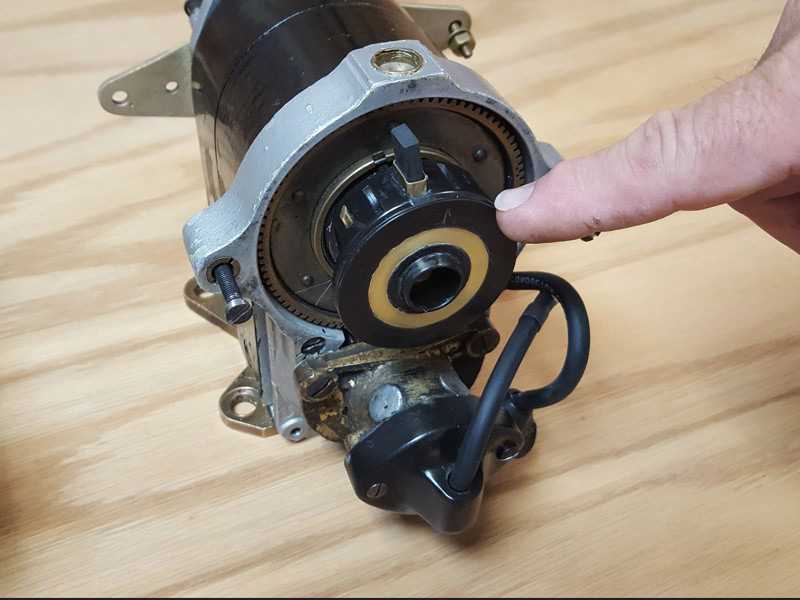

Remove the Unit:

Carefully detach the component from its housing. Take note of the arrangement of wires and connectors for easier reassembly.

-

Inspect for Damage:

Examine the internal parts for wear, corrosion, or other signs of failure. Document any findings for reference.

-

Clean Components:

Utilize a cleaning solvent to remove dirt and debris. Ensure that all parts are thoroughly dried before proceeding.

-

Test Electrical Continuity:

Use a multimeter to check for continuity in the coils and connections. Replace any components that do not pass this test.

-

Reassemble and Secure:

Carefully reattach all components in the original configuration. Ensure that connections are secure to prevent future issues.

-

Reconnect Power and Test:

Reconnect the power source and conduct a test to verify that the unit operates as expected. Monitor for any irregularities.

By adhering to these steps, you can effectively restore the functionality of your ignition component, ensuring reliable performance.

Inspecting Magneto Components

Thorough examination of ignition system parts is essential for ensuring optimal performance and reliability. Each component plays a crucial role in the overall function, and any signs of wear or damage can lead to operational issues. Regular checks can prevent larger problems and extend the lifespan of the system.

Visual Inspection

Start with a visual assessment of all elements. Look for cracks, corrosion, or signs of overheating. Pay special attention to wiring and connections, as these are often prone to deterioration. A careful look can reveal potential problems before they escalate.

Functional Testing

Once the visual check is complete, proceed with functional testing. Utilize appropriate tools to measure electrical output and ensure that each part operates within specified parameters. Consistent testing helps identify any inconsistencies that may indicate malfunctioning components, allowing for timely intervention.

Testing Magneto Functionality

This section outlines essential procedures for evaluating the operational efficiency of an ignition system component. Ensuring that this part functions correctly is crucial for optimal engine performance. Various testing methods can help identify issues and confirm proper operation.

Visual Inspection

Start by conducting a thorough visual examination of the component. Look for signs of wear, corrosion, or damage that might affect functionality. Pay special attention to connections and terminals, as these can influence the overall performance.

Electrical Testing

Utilize a multimeter to assess the electrical output. Set the device to measure voltage and connect it to the appropriate terminals. A strong and consistent reading indicates proper operation, while low or erratic values may signal a problem that requires further investigation.

Cleaning and Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Proper cleaning and maintenance not only enhance functionality but also prevent potential issues that may arise from neglect.

Here are some effective practices to keep in mind:

- Routine Inspection: Regularly check for any signs of wear or damage. Early detection can save time and resources.

- Cleaning Components: Use a soft brush or cloth to remove dust and debris from the surfaces. Ensure all parts are free from contaminants.

- Lubrication: Apply appropriate lubricants to moving parts as needed to ensure smooth operation and reduce friction.

- Storage Conditions: Keep the device in a dry and cool environment to prevent rust and corrosion. Proper storage extends its lifespan.

- Follow Manufacturer Guidelines: Adhere to recommended practices for care and servicing outlined by the manufacturer for best results.

By implementing these suggestions, you can maintain peak performance and extend the life of your device significantly.

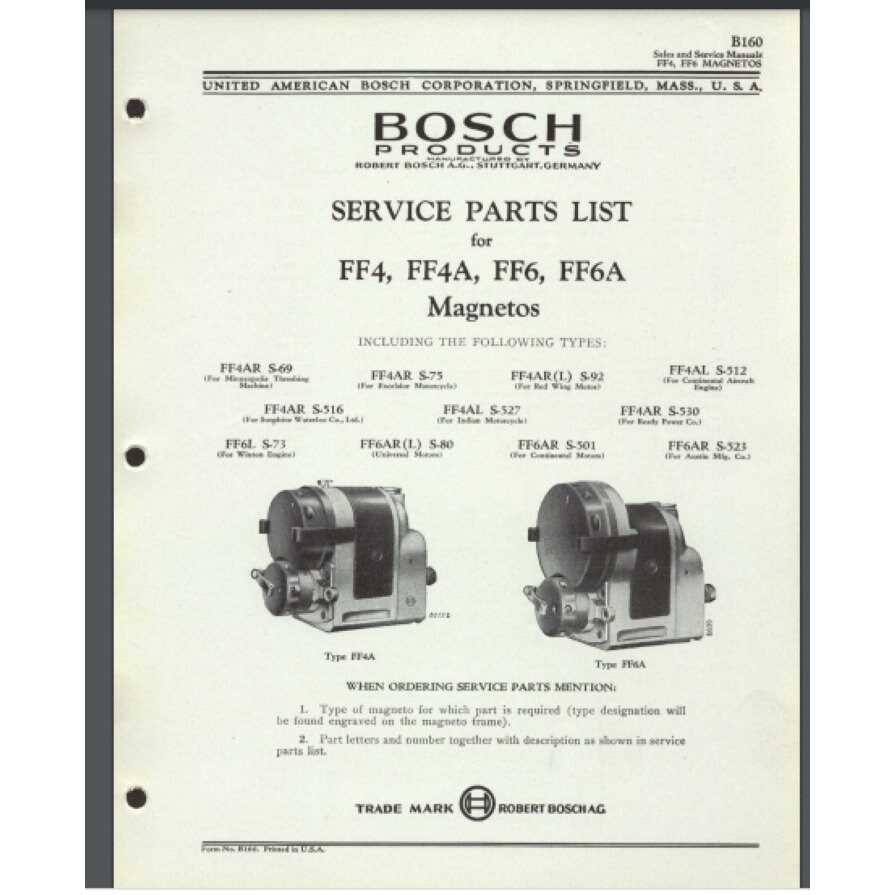

Replacing Faulty Parts

In the process of maintaining and restoring electrical systems, identifying and substituting damaged components is crucial for optimal performance. This section highlights essential steps and considerations for effectively executing this task.

Initial Assessment is the first step in the replacement process. Carefully examine the entire assembly to pinpoint malfunctioning elements. Signs of wear, discoloration, or unusual noises often indicate the need for replacement.

Once the faulty components are identified, it is essential to select suitable replacements. Ensure that new parts meet the specifications required for the system to function correctly. High-quality components contribute significantly to longevity and reliability.

During the installation phase, follow proper procedures and safety measures. Disconnect power sources before starting work, and utilize appropriate tools to prevent damage to surrounding components. Taking these precautions will facilitate a smoother replacement process.

Finally, after the new parts are installed, conduct a thorough functionality test. This verification step ensures that the system operates as intended and that the replacement was successful. Regular maintenance checks following installation can help prolong the lifespan of the newly added components.

Adjusting Ignition Timing

Proper timing alignment is essential for optimal engine performance. This process ensures that the ignition system activates at the right moment, leading to efficient combustion and improved overall function. Adjusting the timing can significantly influence power output and fuel efficiency.

To effectively adjust the ignition timing, follow these steps:

| Step | Description |

|---|---|

| 1 | Locate the timing marks on the engine components. |

| 2 | Use a timing light to check the current timing setting. |

| 3 | Loosen the adjustment bolt for the ignition system. |

| 4 | Rotate the ignition component to set the desired timing. |

| 5 | Tighten the adjustment bolt securely. |

| 6 | Recheck the timing with the timing light to ensure accuracy. |

Following these steps will help maintain the efficiency of the engine and enhance performance capabilities. Regular timing adjustments are recommended as part of routine maintenance.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual but also enhance the effectiveness of the work being done.

Before commencing any work, consider the following essential guidelines:

- Wear appropriate personal protective equipment (PPE) such as gloves and goggles.

- Ensure that the workspace is clean and free from hazards, such as spills or clutter.

- Disconnect power sources to avoid electrical shock.

- Use tools that are in good condition and appropriate for the task.

Additionally, follow these safety measures:

- Read all relevant documentation and familiarize yourself with the equipment.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep a first aid kit nearby in case of emergencies.

- Never rush the process; take your time to ensure everything is done correctly.

By adhering to these practices, you can create a safer environment for yourself and others while undertaking maintenance activities.

Common Mistakes to Avoid

When working with electrical components, it is essential to be aware of potential pitfalls that can lead to inefficiencies or damage. Understanding these common errors can enhance the effectiveness of your maintenance efforts.

Neglecting Proper Safety Measures: Always prioritize safety. Failing to use protective gear or neglecting to disconnect power sources can lead to serious accidents.

Ignoring Manufacturer Guidelines: Each device comes with specific instructions that are crucial for successful handling. Skipping these guidelines may result in improper assembly or malfunction.

Using Incompatible Parts: Replacing components with those that do not match specifications can lead to performance issues. Ensure that all parts are compatible with your system.

Overlooking Regular Maintenance: Regular upkeep is vital for longevity. Neglecting routine checks can lead to more significant issues down the line.

Rushing the Process: Taking your time during repairs is essential. Hasty actions can result in missed steps or errors that compromise functionality.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding and skills in the field. There are various avenues to consider, each offering valuable insights and practical knowledge that can aid in deepening your expertise.

Online Courses and Webinars

Participating in structured online courses or attending webinars can provide a comprehensive overview of essential concepts. These resources often include interactive elements, enabling you to engage with instructors and peers, fostering a collaborative learning environment.

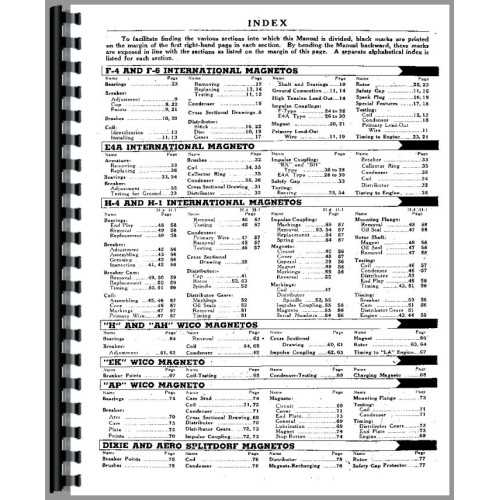

Books and Manuals

Reading specialized literature allows for a deeper dive into specific topics. Look for titles that cover both fundamental principles and advanced techniques, ensuring a well-rounded grasp of the subject matter. Additionally, reference guides can serve as handy tools for quick consultation.

Utilizing these resources can empower you to build a solid foundation and refine your skills effectively.