Comprehensive Guide to the 1970 Motors Auto Repair Manual

The realm of automotive craftsmanship has long captivated enthusiasts and professionals alike. Understanding the intricacies of these mechanical marvels is essential for anyone looking to delve into the world of vehicle enhancement and upkeep. This guide serves as a valuable resource, shedding light on fundamental techniques and insights that empower individuals to nurture and rejuvenate their beloved machines.

As we explore the historical context and technical specifics of vehicle maintenance, it becomes clear that a profound appreciation for engineering and design is necessary. By mastering the essential practices, one can ensure that every component operates harmoniously, resulting in an optimized driving experience. This guide aims to provide not just information, but a roadmap for cultivating a deeper connection with the art of automotive care.

Throughout the sections, we will delve into the critical elements of vehicle upkeep, from troubleshooting common issues to executing advanced enhancements. Whether you are a novice eager to learn or a seasoned aficionado seeking to refine your skills, this resource will equip you with the knowledge to tackle various challenges and celebrate the joy of restoration.

Overview of 1970 Motors Auto Repair

This section provides insights into the maintenance and servicing practices for vehicles produced in the early 1970s. Understanding the techniques and common issues faced by these machines can enhance your ability to keep them running smoothly and efficiently. Key aspects include troubleshooting methods, essential tools, and recommended procedures tailored for this era of automotive engineering.

Key Characteristics

- Simple mechanical systems

- Accessible engine compartments

- Standardized components for easier sourcing

Common Issues and Solutions

- Electrical system failures

- Check battery connections

- Inspect wiring for wear and corrosion

- Cooling system inefficiencies

- Monitor coolant levels regularly

- Flush the radiator as needed

- Brake system performance

- Inspect brake pads for wear

- Ensure proper fluid levels

Essential Tools for Auto Repair

Having the right instruments at your disposal is crucial for successfully handling vehicle maintenance tasks. A well-equipped workspace can significantly enhance efficiency and ensure safety during the process. Understanding the fundamental tools required for various jobs can empower enthusiasts and professionals alike to tackle any challenge that arises.

Basic hand tools such as wrenches, pliers, and screwdrivers are indispensable for performing a wide range of tasks. These instruments allow for easy tightening and loosening of fasteners, making them essential for assembly and disassembly. Additionally, a quality socket set can provide the versatility needed to work with different sizes and types of bolts.

Power tools can further streamline tasks, especially when dealing with stubborn components. An electric drill, for instance, can save time when installing or removing parts. Furthermore, specialized tools like torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, preventing damage and ensuring longevity.

Safety equipment should also be prioritized. Items such as gloves, goggles, and protective clothing are essential to safeguard against potential hazards. A good set of creepers and ramps can facilitate comfortable access to the undercarriage, making difficult tasks more manageable.

Ultimately, investing in a comprehensive collection of tools not only enhances your ability to maintain and improve vehicles but also fosters a deeper understanding of their mechanics. Being well-prepared is key to achieving successful outcomes in any automotive endeavor.

Common Issues in 1970 Motors

Vehicles from this era often faced a variety of challenges that owners should be aware of. Understanding these prevalent problems can aid in maintenance and ensure longevity. Below are some typical concerns associated with these classic machines.

Electrical System Problems

The electrical systems in vehicles from this time period were not as advanced as today’s technology, leading to several common issues:

- Poor connections and corroded terminals

- Fading or malfunctioning headlights

- Faulty ignition systems

- Weak batteries, especially in colder climates

Engine Performance Issues

Another frequent category of problems relates to engine efficiency and reliability:

- Fuel leaks from worn lines

- Overheating due to inadequate cooling systems

- Carburetor malfunctions leading to poor fuel-air mixtures

- Excessive smoke due to worn piston rings

Step-by-Step Repair Procedures

This section provides a comprehensive guide to executing various maintenance tasks effectively. Following structured methodologies ensures precision and minimizes errors, leading to successful outcomes for your vehicle’s upkeep.

Preparation for Maintenance

- Gather necessary tools and materials.

- Ensure the workspace is clean and well-lit.

- Review safety precautions before starting any task.

Executing the Repair

- Identify the specific issue to address.

- Follow the outlined steps for disassembly, if required.

- Replace or fix the faulty components as needed.

- Reassemble all parts in the correct order.

- Conduct a thorough inspection to confirm everything is secure.

By adhering to these systematic procedures, you can effectively manage various tasks and ensure longevity for your vehicle.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your vehicle involves consistent care and attention. By following a few essential practices, you can significantly enhance the lifespan and reliability of your machine.

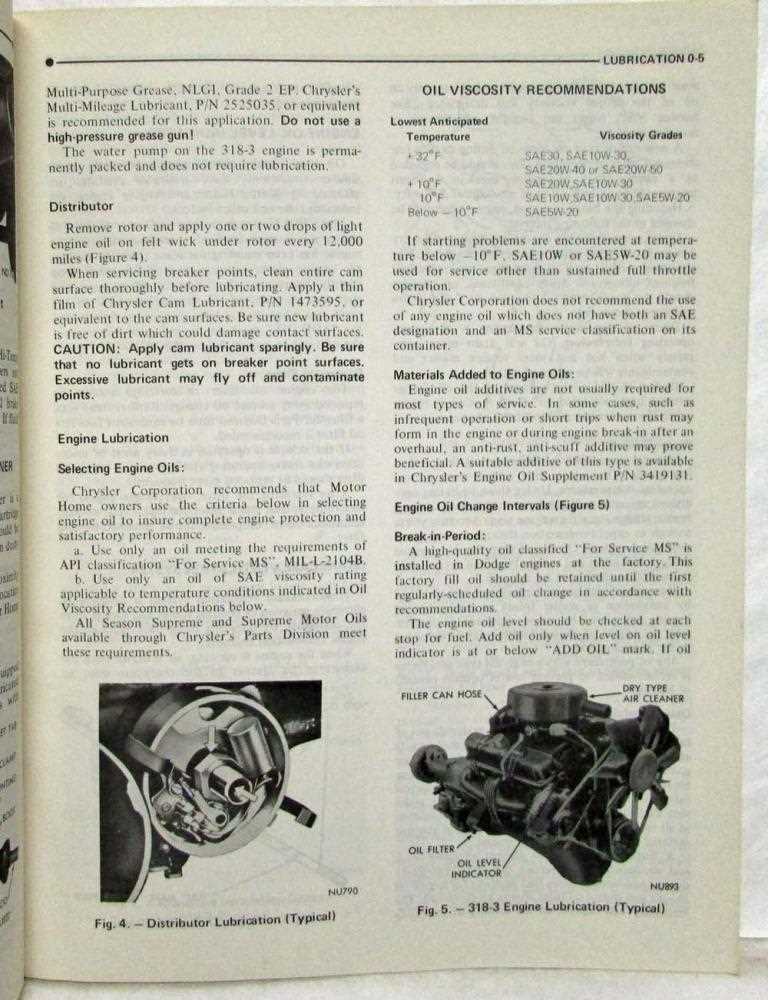

- Regular Oil Changes: Keep the engine lubricated by changing the oil at recommended intervals. Fresh oil helps reduce wear and keeps components functioning smoothly.

- Check Fluid Levels: Regularly inspect and top off essential fluids, including coolant, brake fluid, and transmission fluid, to prevent overheating and system failures.

- Tire Maintenance: Monitor tire pressure and tread depth. Properly inflated tires improve fuel efficiency and handling, while good tread ensures safety.

- Brake Inspections: Have the braking system checked periodically. Worn pads or damaged rotors can lead to unsafe conditions.

- Belt and Hose Checks: Inspect belts and hoses for cracks or wear. Replacing them as needed can prevent breakdowns and costly repairs.

Implementing these practices can help maintain optimal performance and prevent potential issues, ensuring that your vehicle serves you well for years to come.

Understanding Engine Components

The heart of any vehicle lies within its power unit, where various parts work in harmony to convert fuel into motion. Gaining insight into these elements is crucial for anyone interested in how performance and efficiency are achieved. Each component plays a significant role, contributing to the overall functionality of the system.

Key Elements of the Power Unit

Among the essential components are the cylinder block, where combustion occurs, and the cylinder head, which houses vital elements like valves and spark plugs. Together, they create a sealed environment that allows for the ignition of fuel. Additionally, the crankshaft transforms the linear motion of the pistons into rotational movement, driving the vehicle forward.

Supporting Systems

Complementing these main parts are systems such as the fuel injection system, which ensures an optimal mix of air and fuel enters the combustion chamber, and the exhaust system, responsible for expelling gases safely. Understanding these components and their interactions is fundamental for comprehending how the entire mechanism operates efficiently.

Transmission Troubleshooting Techniques

Identifying issues within the gearbox can be a complex task, yet understanding the common symptoms and applying systematic approaches can greatly enhance the diagnosis process. This section will explore various methods to effectively pinpoint problems that may arise within the transmission system.

Observation and Testing

Begin by observing the behavior of the vehicle during operation. Pay attention to any unusual noises, vibrations, or performance issues. Conducting a series of tests, such as checking fluid levels and inspecting for leaks, can provide essential insights. Fluid quality is particularly crucial; burnt or contaminated fluid often indicates deeper issues.

Check for Codes

Utilizing diagnostic tools to retrieve error codes can simplify the troubleshooting process. These codes can guide technicians toward specific faults, allowing for a more focused approach in addressing the underlying problem.

Manual Inspection

Performing a thorough manual inspection of the transmission components is vital. Look for signs of wear, damage, or misalignment in parts such as the gears, clutches, and linkage systems. Visual assessments can often reveal critical problems that may not be apparent through other methods.

Test Drives

Conducting controlled test drives can help replicate issues under varying conditions. Monitoring shifts, acceleration, and responsiveness during these tests provides valuable data. Documenting these observations allows for a more comprehensive understanding of the transmission’s performance.

Consult Resources

When in doubt, refer to technical resources and databases specific to the vehicle in question. These resources can offer additional troubleshooting steps and solutions that may not be immediately apparent. Staying informed about updates and common issues can further enhance diagnostic accuracy.

By employing these techniques, one can systematically approach transmission problems, ultimately leading to effective solutions and improved vehicle performance.

Electrical Systems Diagnostics

Understanding the functionality and issues within a vehicle’s electrical framework is crucial for effective maintenance and troubleshooting. This segment focuses on identifying faults and ensuring that the various components operate harmoniously, enabling optimal performance and reliability.

Key areas to examine include power distribution, component interaction, and the integrity of connections. Proper diagnostics can prevent minor issues from escalating into significant problems, ensuring the longevity of the system.

| Component | Common Issues | Diagnostic Steps |

|---|---|---|

| Battery | Weak charge, corrosion | Check voltage, clean terminals |

| Alternator | Insufficient charging, noise | Test output voltage, listen for sounds |

| Starter | Failure to engage, clicking sound | Inspect connections, test solenoid |

| Fuses | Blown fuses, intermittent issues | Check for continuity, replace as needed |

| Wiring | Fraying, poor connections | Visual inspection, test with multimeter |

By following a systematic approach to diagnosing electrical issues, one can enhance both safety and functionality. Regular checks and prompt attention to problems can greatly improve the overall efficacy of the system.

Suspension and Steering Repairs

The proper functioning of the suspension and steering systems is vital for a vehicle’s safety and performance. Addressing issues in these areas not only enhances driving comfort but also ensures optimal handling and stability. This section focuses on common challenges and solutions associated with these crucial components.

Common Issues

- Worn shock absorbers

- Loose steering components

- Misaligned wheels

- Damaged bushings

- Leaking struts

Repair Procedures

- Inspecting Components: Regularly check all parts for wear and damage.

- Replacing Worn Parts: Swap out any deteriorated elements, including shocks, struts, and bushings.

- Wheel Alignment: Adjust angles to ensure proper handling and tire wear.

- Checking Fluid Levels: Maintain adequate levels in power steering systems to avoid failures.

- Test Driving: After repairs, take the vehicle for a test drive to confirm improvements.

Bodywork and Paint Restoration

Restoring the exterior of a vehicle involves a meticulous approach to rejuvenating its appearance and integrity. This process not only enhances the aesthetic value but also protects the underlying materials from deterioration. Achieving a flawless finish requires a combination of skilled craftsmanship and an understanding of the materials involved.

Surface Preparation

Before any finishing touches can be applied, proper surface preparation is essential. This includes removing rust, dents, and any old paint layers. Cleanliness is crucial; ensuring the surface is free from debris and contaminants lays the foundation for a successful application of paint and protective coatings. Techniques such as sanding and using chemical strippers can be employed to achieve a smooth, ready-to-paint surface.

Painting Techniques

Once the surface is prepared, the next step is the application of the paint. Various methods exist, including spray painting and brush application, each offering different benefits. Layering the paint allows for a deeper, more vibrant finish. Additionally, sealing the paint with a clear coat not only adds shine but also protects against environmental elements. Regular maintenance of the paintwork ensures longevity and sustained visual appeal.

Finding Quality Replacement Parts

When it comes to maintaining your vehicle, sourcing reliable components is crucial for ensuring longevity and performance. High-quality parts not only enhance functionality but also contribute to overall safety. This section explores effective strategies for locating the best replacements to keep your vehicle in optimal condition.

Where to Look for Parts

- Authorized Dealers: These establishments often provide original equipment manufacturer (OEM) parts, ensuring compatibility and quality.

- Specialty Stores: Stores that focus on specific vehicle brands or types can offer a wider selection of both OEM and aftermarket components.

- Online Retailers: Websites dedicated to automotive supplies often have user reviews, making it easier to gauge the reliability of a part.

- Salvage Yards: For cost-effective options, consider used parts from reputable salvage yards, ensuring they are inspected for quality.

Evaluating Quality

- Check Reviews: Always look for feedback from previous customers to assess the reliability of a part.

- Compare Prices: While lower prices can be tempting, they may indicate lower quality. Look for parts that strike a balance between cost and durability.

- Ask for Warranties: Quality components often come with warranties, providing peace of mind regarding their performance.

- Inspect Before Purchase: If buying in person, always examine the part for signs of wear or damage.

Safety Precautions During Repairs

Ensuring safety is paramount when engaging in any form of mechanical work. Adhering to certain guidelines can significantly reduce the risk of accidents and injuries. Proper preparation and awareness are key components in creating a secure environment for both the individual and the equipment involved.

Essential Guidelines

- Always wear appropriate protective gear, including gloves and safety glasses.

- Ensure that the work area is well-ventilated to avoid inhalation of harmful fumes.

- Keep tools organized and within reach to prevent unnecessary movement around the workspace.

- Be aware of your surroundings and any potential hazards that may arise during the task.

Handling Tools and Equipment

- Inspect tools regularly for wear or damage before use.

- Use tools only for their intended purpose to prevent accidents.

- Disconnect power sources before performing any work on electrical components.

- Follow manufacturer instructions carefully when using machinery.