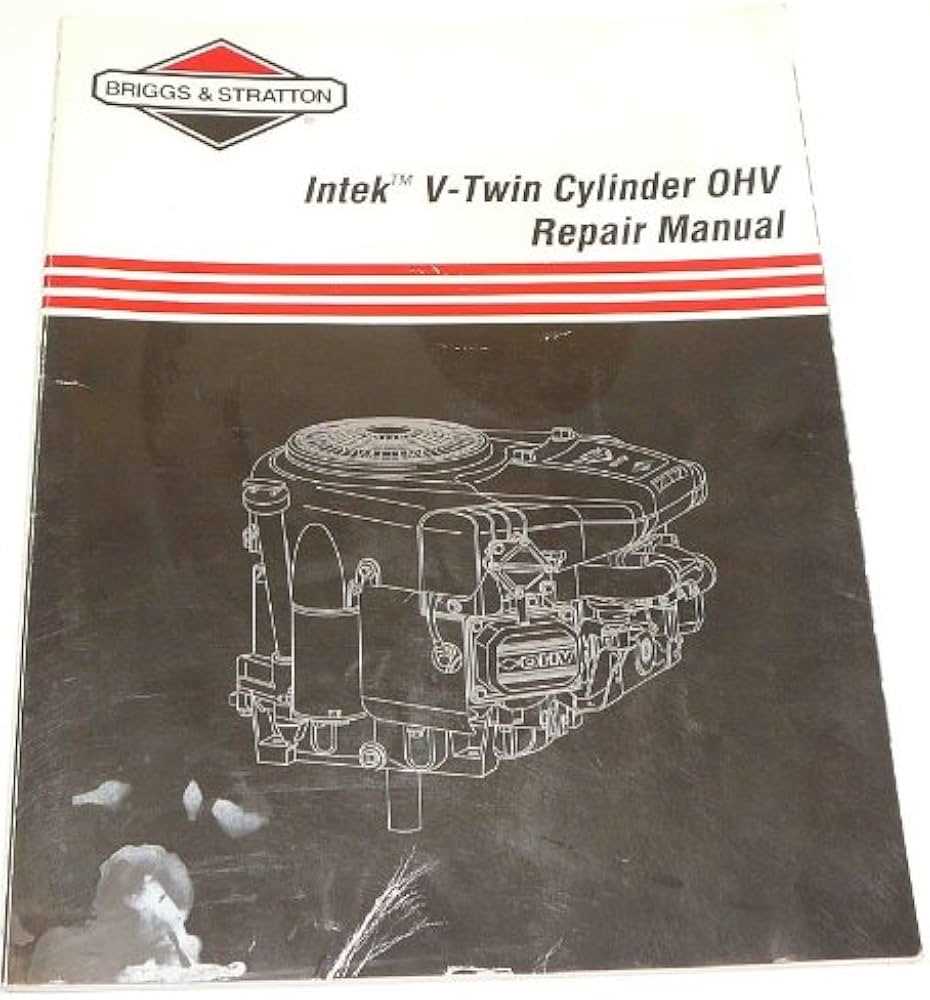

Comprehensive Guide to Repairing the Briggs & Stratton 1330 Engine

Ensuring the longevity and performance of your outdoor power equipment is crucial for optimal functionality. Whether you are a seasoned professional or a weekend warrior, having access to comprehensive information can make all the difference in addressing common challenges and enhancing your machinery’s efficiency. This guide serves as a valuable resource, equipping you with the necessary insights for troubleshooting and upkeep.

In this section, we delve into the specifics of maintaining small engines, focusing on practical techniques and expert tips. From understanding basic components to executing essential tasks, we aim to empower you with knowledge that fosters confidence in handling maintenance procedures. Proper care not only maximizes performance but also extends the life of your equipment.

With a focus on step-by-step instructions and straightforward explanations, this guide offers clarity on various aspects of engine management. Whether you’re dealing with routine checks or more complex issues, the information provided will help demystify the process and facilitate effective solutions. Prepare to enhance your skills and ensure that your machinery runs smoothly for years to come.

Understanding Briggs & Stratton 1330 Model

This section aims to provide a comprehensive overview of a specific engine type known for its reliability and efficiency in various applications. Understanding the key features, maintenance needs, and operational guidelines can greatly enhance user experience and longevity of the product.

Key characteristics of this engine type include:

- Power Output: Designed to deliver robust performance, ideal for demanding tasks.

- Durability: Built with high-quality materials, ensuring longevity and resistance to wear.

- Ease of Use: Engineered for straightforward operation, making it accessible for users of all skill levels.

To maximize the performance and lifespan of the engine, consider the following maintenance tips:

- Regularly check and change the oil to keep the engine running smoothly.

- Inspect air filters frequently and replace them as needed to maintain airflow.

- Keep the spark plug in good condition for optimal ignition and efficiency.

- Clean the cooling fins and check for debris to prevent overheating.

In summary, understanding the specific features and maintenance requirements of this engine type will not only improve its efficiency but also extend its operational life. With proper care and attention, users can expect reliable performance for various tasks.

Common Issues with the 1330 Engine

The performance of small engines can be compromised by various factors, leading to operational difficulties. Understanding the typical problems that may arise can help in troubleshooting and ensuring optimal functionality.

Fuel-Related Problems

One of the most frequent issues involves fuel quality. Stale or contaminated gasoline can cause starting difficulties and poor engine performance. Regularly replacing fuel and using appropriate additives can mitigate this issue. Clogged fuel filters and lines are also common, restricting the flow of fuel and resulting in erratic operation. Checking and cleaning these components is essential for maintaining performance.

Ignition System Failures

Another area to inspect is the ignition system. Problems with the spark plug, such as wear or fouling, can lead to misfires and starting problems. Regular inspection and replacement of spark plugs can enhance reliability. Additionally, faulty ignition coils may contribute to inconsistent engine operation. Ensuring that all ignition components are in good condition is critical for smooth performance.

Tools Needed for Effective Repairs

Having the right instruments is essential for successful maintenance tasks. A well-equipped workspace can significantly enhance efficiency and accuracy during the process. Understanding the necessary items can help streamline efforts and ensure quality outcomes.

Basic Hand Tools: A good set of hand tools is fundamental. This includes screwdrivers of various sizes, wrenches, and pliers. Each tool serves a specific purpose, making it easier to tackle different components.

Power Tools: Incorporating power tools can save time and reduce physical strain. Drills and impact wrenches can facilitate tasks that require more strength or speed, particularly when dealing with stubborn fasteners.

Diagnostic Equipment: To identify issues accurately, having access to diagnostic devices is invaluable. Tools such as multimeters and compression testers can provide insights into the operational status and help pinpoint malfunctions.

Safety Gear: Protecting oneself during maintenance is paramount. Always utilize safety glasses, gloves, and ear protection to mitigate risks associated with mechanical work.

Organizational Tools: Keeping the workspace tidy can improve focus and efficiency. Toolboxes and trays help organize equipment, making it easier to locate items when needed.

In conclusion, a well-chosen assortment of tools not only enhances the effectiveness of maintenance activities but also promotes a safer and more enjoyable experience overall.

Step-by-Step Repair Process Overview

This section outlines a comprehensive approach to addressing mechanical issues effectively. By following a structured method, users can efficiently diagnose and fix common problems, ensuring optimal performance and longevity of the equipment.

- Preparation

- Gather necessary tools and materials.

- Read through relevant documentation for guidance.

- Ensure a clean workspace to avoid contamination.

- Initial Inspection

- Check for visible signs of wear or damage.

- Test the unit to identify performance issues.

- Note any unusual sounds or vibrations during operation.

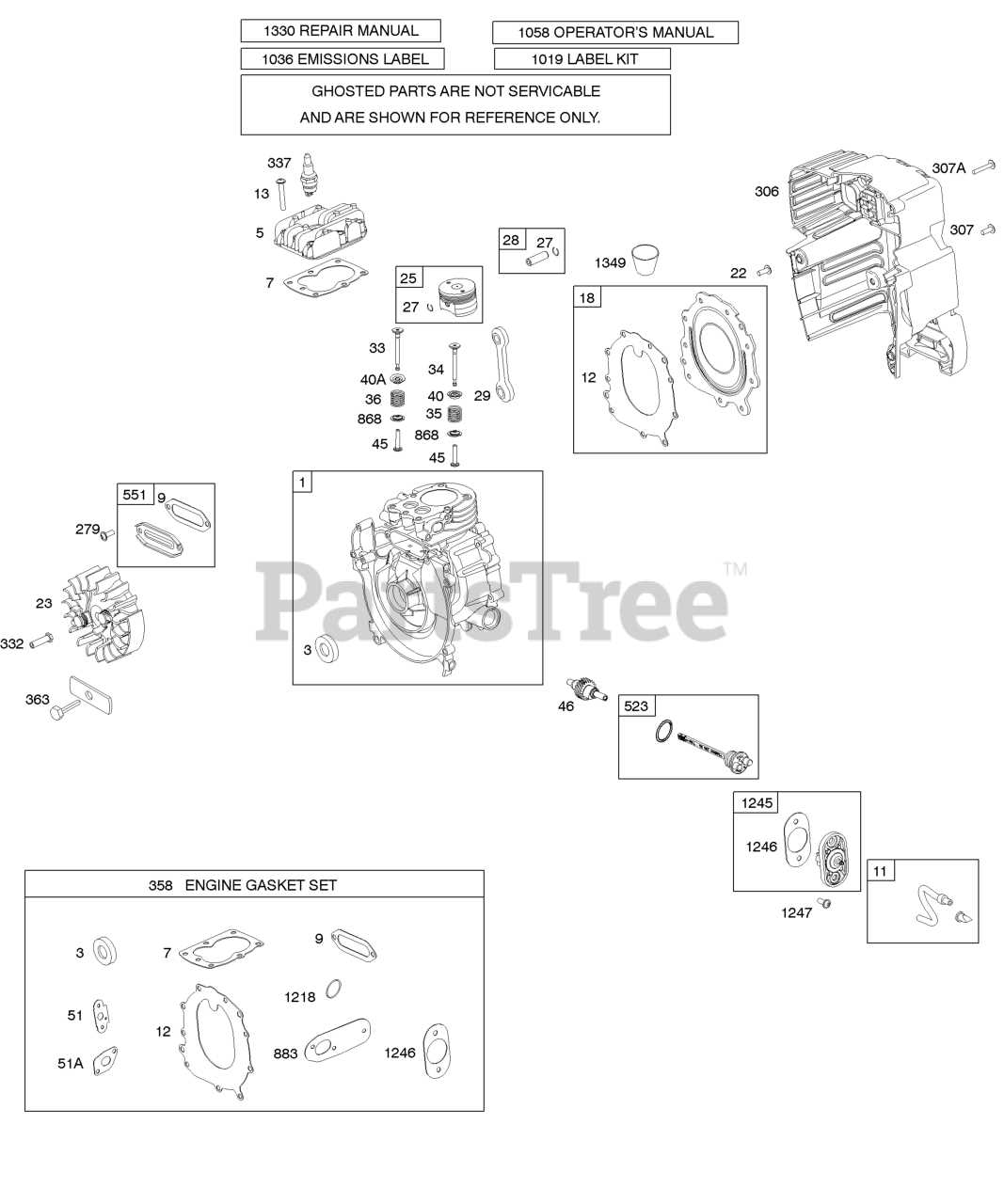

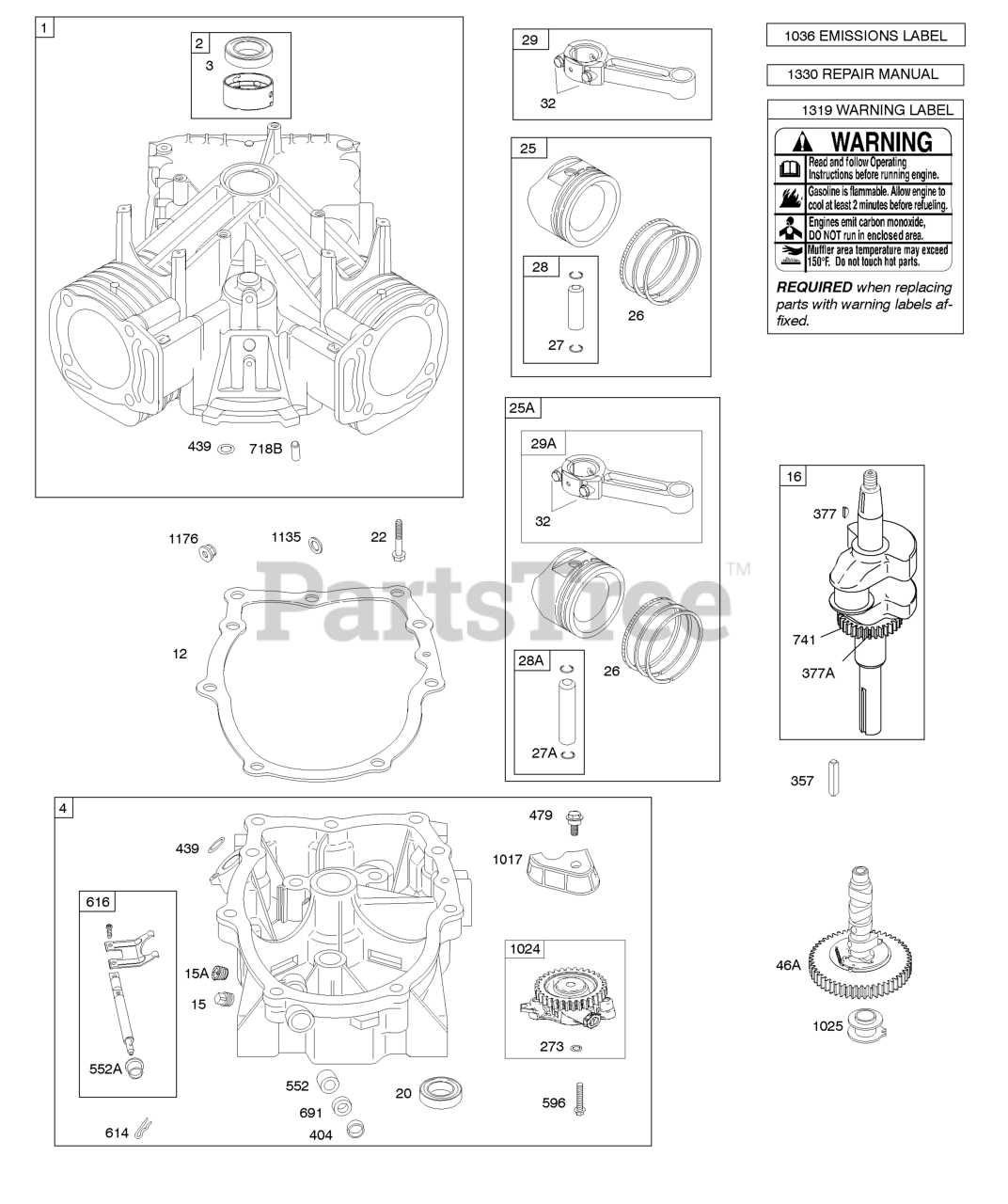

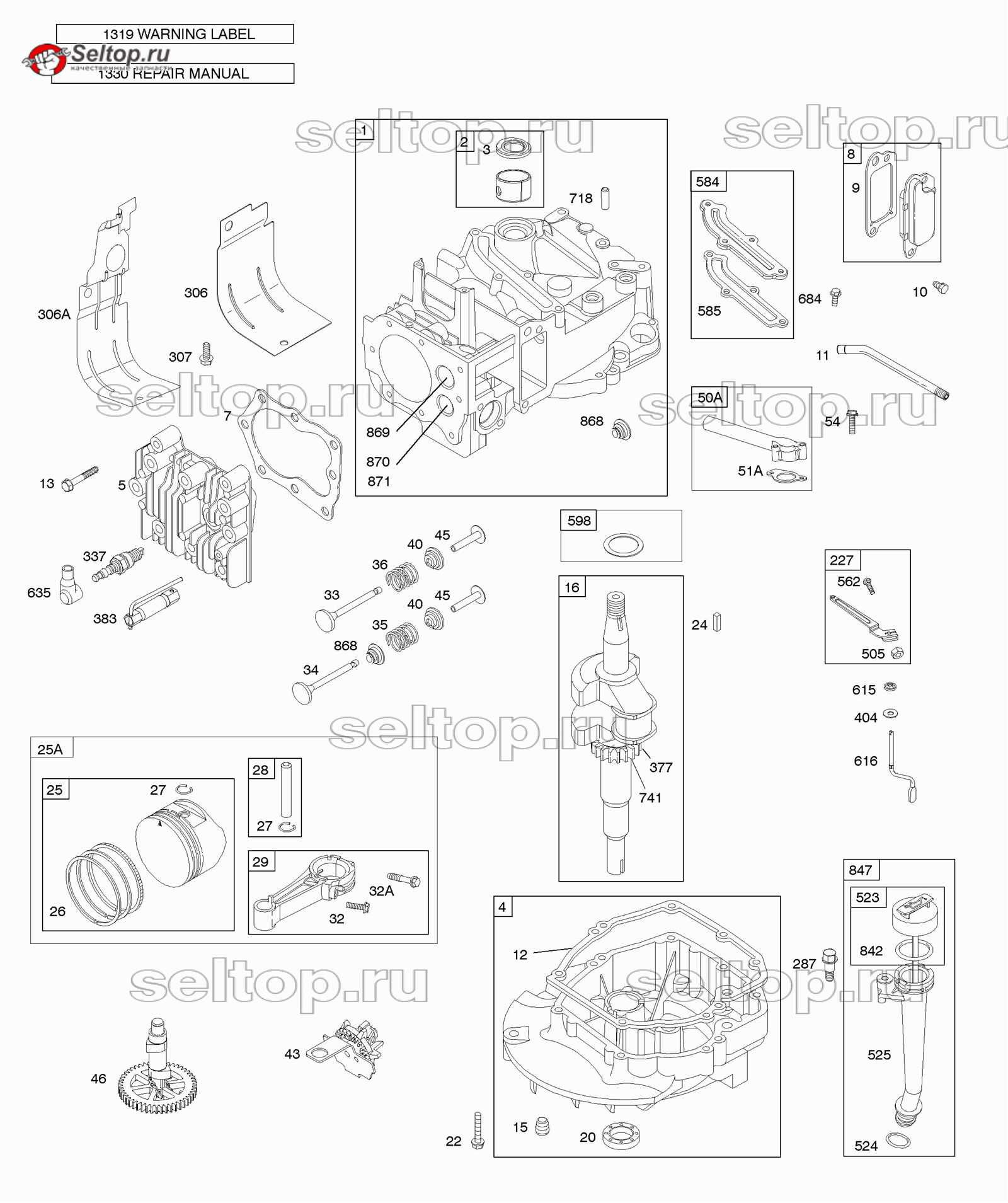

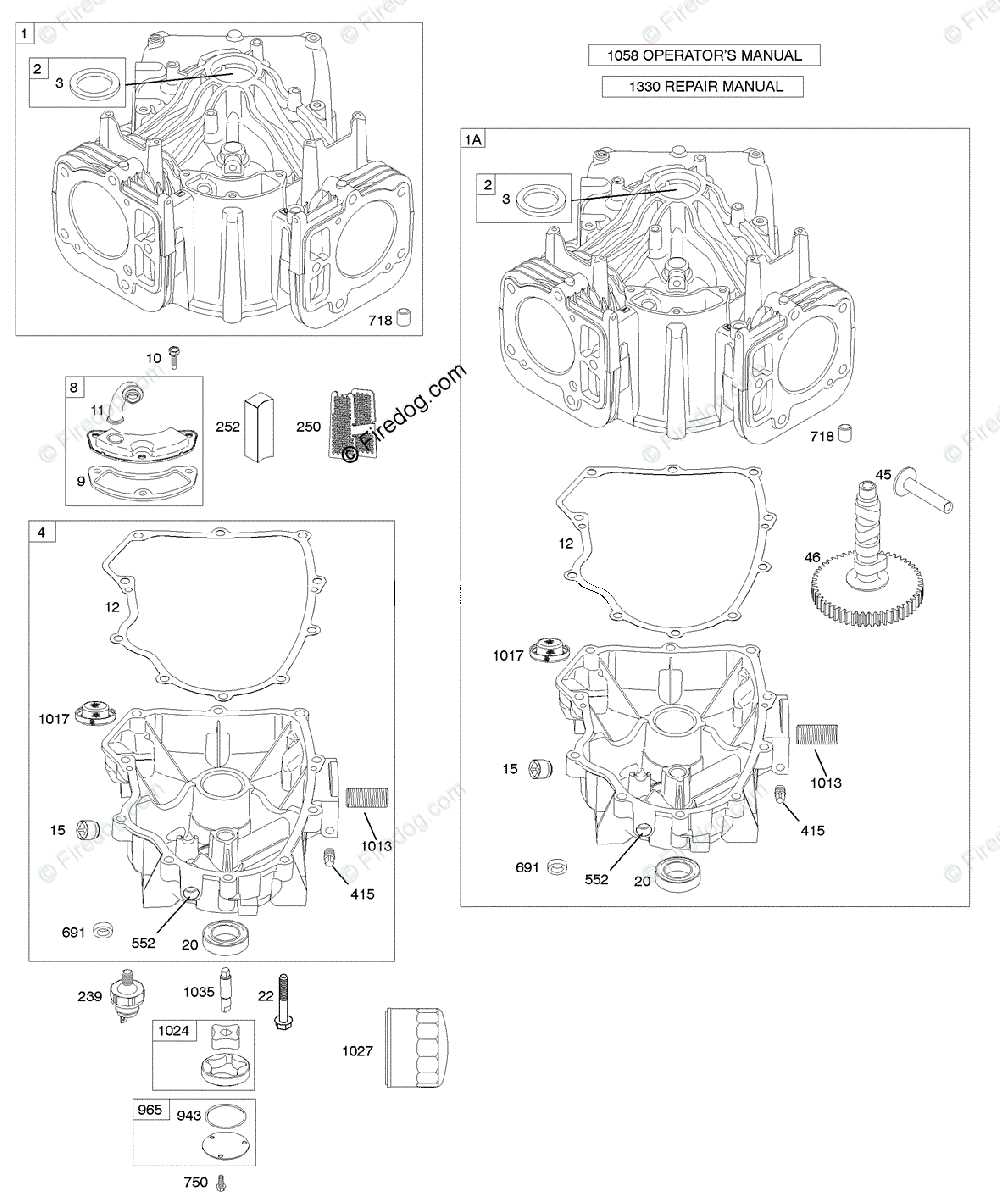

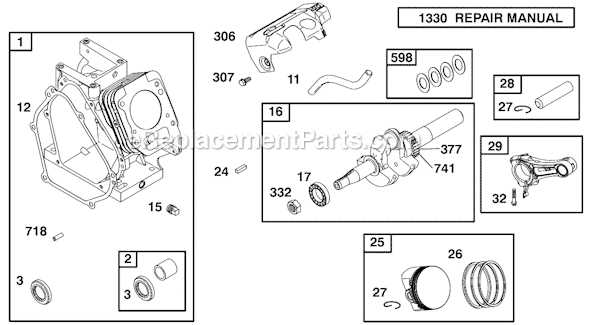

- Disassembly

- Carefully remove exterior panels to access internal components.

- Label parts as they are removed to facilitate reassembly.

- Handle all components with care to prevent damage.

- Diagnosis

- Inspect individual components for faults or obstructions.

- Use diagnostic tools to assess electrical issues if applicable.

- Cross-reference findings with troubleshooting guides.

- Replacement and Repair

- Replace any faulty components with new or refurbished parts.

- Perform necessary adjustments to ensure proper alignment.

- Apply lubricants where needed to reduce friction.

- Reassembly

- Follow the labels and instructions to reassemble the unit.

- Ensure all screws and fasteners are tightened securely.

- Double-check that all components are correctly positioned.

- Final Testing

- Power on the unit and observe its operation.

- Look for any persistent issues or new problems.

- Perform a thorough check to confirm successful resolution of the initial issues.

By adhering to these steps, users can systematically tackle mechanical challenges, restoring functionality and enhancing the performance of their equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor power equipment. By adhering to a few fundamental practices, you can significantly extend the lifespan of your machinery and maintain optimal performance. These tips will guide you in keeping your equipment in prime condition, preventing costly repairs and enhancing reliability.

Routine Checks

Performing consistent inspections allows you to identify potential issues before they escalate. Here are key components to monitor:

| Component | Frequency | Action |

|---|---|---|

| Oil Level | Every Use | Check and top off as needed |

| Air Filter | Every 25 Hours | Clean or replace as necessary |

| Spark Plug | Every 50 Hours | Inspect and replace if worn |

| Fuel System | Seasonally | Inspect for leaks and clean |

Proper Storage

Storing your equipment correctly can prevent deterioration and ensure it is ready for use when needed. Consider the following tips:

- Store in a dry, sheltered location to avoid rust and corrosion.

- Empty the fuel tank if the equipment will not be used for an extended period.

- Cover the machine with a protective tarp to keep dust and debris away.

Troubleshooting Electrical Problems

Electrical issues can be daunting for any equipment owner, often leading to unexpected failures. Identifying and resolving these challenges requires a systematic approach to pinpoint the underlying causes. This section aims to guide users through the process of diagnosing common electrical faults, ensuring efficient operation and longevity of their machinery.

1. Check the Power Supply: Ensure that the device is receiving adequate voltage. Inspect the power cord for any visible damage, and verify that the outlet is functioning correctly. Utilize a multimeter to measure the voltage at the outlet.

2. Inspect Connections: Loose or corroded connections can lead to intermittent power issues. Carefully examine all electrical connections, including terminals and plugs, ensuring they are secure and free of corrosion.

3. Test the Battery: A failing battery can cause starting problems. Check the battery voltage and connections. If the battery appears weak or does not hold a charge, consider replacing it.

4. Examine Fuses and Circuit Breakers: Blown fuses or tripped circuit breakers can interrupt power flow. Inspect these components and replace fuses as necessary. Reset any tripped breakers to restore functionality.

5. Diagnose Internal Components: If issues persist, internal components such as the ignition system or starter motor may be at fault. Test each component systematically, starting with the ignition coil and working towards the starter to identify any malfunctioning parts.

By following these steps, users can effectively troubleshoot and resolve electrical issues, ensuring their equipment operates smoothly and reliably.

Replacing the Fuel System Components

Maintaining the fuel system is essential for optimal performance and longevity of your engine. Over time, various parts may wear out or become clogged, affecting fuel delivery and efficiency. This section outlines the steps necessary for replacing key components to ensure smooth operation.

Begin by disconnecting the fuel lines and removing any existing filters or pumps. Inspect each component for signs of damage or degradation. It’s crucial to use high-quality replacements that are compatible with your engine’s specifications. When installing new parts, ensure all connections are secure to prevent leaks.

After replacing the components, it’s advisable to check for proper functionality by running the engine and observing its performance. Regular maintenance of the fuel system not only enhances efficiency but also contributes to the overall reliability of your equipment.

Essential Safety Precautions to Follow

When working with any type of machinery, it is crucial to prioritize safety to prevent accidents and ensure a smooth operation. Adhering to specific guidelines can significantly reduce the risk of injury and damage to equipment. This section outlines key safety measures that should always be observed.

Pre-Operation Safety Checks

- Inspect the equipment for any visible damage or wear.

- Ensure all safety guards and shields are in place.

- Check fuel levels and ensure there are no leaks.

- Verify that all tools and accessories are in good condition.

- Review the owner’s manual for specific safety recommendations.

Operational Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Keep the work area clean and free of obstructions to avoid tripping hazards.

- Never operate machinery while under the influence of alcohol or drugs.

- Maintain a safe distance from moving parts and rotating components.

- Be aware of your surroundings and watch for other workers or obstacles.

How to Clean and Adjust Carburetors

Maintaining optimal performance of small engines often hinges on the proper care of their fuel delivery systems. Regular cleaning and adjustment of these components ensure efficient operation, prevent stalling, and enhance overall functionality. This guide outlines essential steps to effectively service these vital parts.

Cleaning the Carburetor

Start by gathering the necessary tools and materials. A clean working area is crucial for a successful procedure. Follow these steps to clean the carburetor:

- Disconnect the fuel supply and remove the carburetor from the engine.

- Disassemble the carburetor carefully, taking note of the order of components.

- Soak parts in a carburetor cleaner solution for optimal dirt and grime removal.

- Use a soft brush to scrub hard-to-reach areas.

- Rinse and dry all components thoroughly before reassembling.

Adjusting the Carburetor

Once cleaned, it’s important to adjust the carburetor for the best performance. Follow these steps:

| Adjustment Step | Action |

|---|---|

| Idle Speed | Turn the idle screw clockwise to increase speed, counterclockwise to decrease. |

| Air-Fuel Mixture | Adjust the mixture screw to achieve a smooth engine run at idle. |

| Throttle Response | Check responsiveness and make minor adjustments as needed for optimal acceleration. |

Following these steps will enhance engine efficiency and prolong its lifespan. Regular maintenance is key to keeping small engines in peak condition.

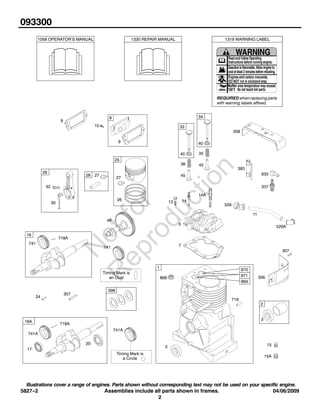

Locating Replacement Parts Efficiently

Finding the right components for your outdoor power equipment can be a straightforward process if approached methodically. By utilizing the right resources and techniques, you can save time and ensure you obtain the necessary items for optimal performance.

Here are some effective strategies to help you locate replacement parts:

- Consult the Owner’s Manual: This document typically contains a parts list and diagrams, aiding in identifying specific components.

- Visit Authorized Dealers: Local dealerships often carry a wide range of original parts and can provide expert advice.

- Utilize Online Retailers: Websites dedicated to outdoor equipment offer searchable databases for components, often with customer reviews and compatibility information.

- Join Online Forums: Engaging with communities focused on outdoor machinery can provide insights into sourcing hard-to-find parts.

- Check Salvage Yards: These locations can be treasure troves for used parts at reduced prices.

By following these steps, you can streamline the process of finding necessary replacements and keep your equipment running smoothly.

Resources for Further Assistance

When tackling maintenance or troubleshooting challenges, having access to the right resources can significantly enhance your understanding and skills. Numerous platforms provide valuable information, ranging from expert forums to instructional videos, all aimed at helping users resolve issues efficiently.

Online Communities: Engaging with online forums can be an excellent way to connect with fellow enthusiasts and professionals. These platforms often feature discussions about common problems, solutions, and shared experiences that can guide you through your tasks.

Video Tutorials: Many content creators share step-by-step visual guides on various platforms. These tutorials can be particularly helpful for visual learners, offering practical demonstrations that make complex procedures easier to grasp.

Manufacturer Resources: Always check the official website for technical documents, FAQs, and contact information for customer support. These resources are tailored to provide accurate information directly from the source.

Local Workshops: Consider attending workshops or classes offered by local repair shops or community colleges. These hands-on sessions can deepen your knowledge and provide personal guidance from experienced technicians.

By utilizing these resources, you can enhance your troubleshooting skills and ensure that your equipment remains in optimal condition.