Kubota Diesel 3 Cylinder Repair Guide

Maintaining the efficiency and longevity of your agricultural engine is crucial for optimal performance. This section aims to provide insights into essential upkeep practices that can enhance functionality and reliability.

Understanding the components of the engine will enable you to identify potential issues early on. By recognizing the signs of wear or malfunction, you can take proactive steps to ensure smooth operation.

Proper care not only extends the life of the machinery but also contributes to better fuel efficiency and reduced operational costs. Adopting a systematic approach to maintenance will help you maximize productivity.

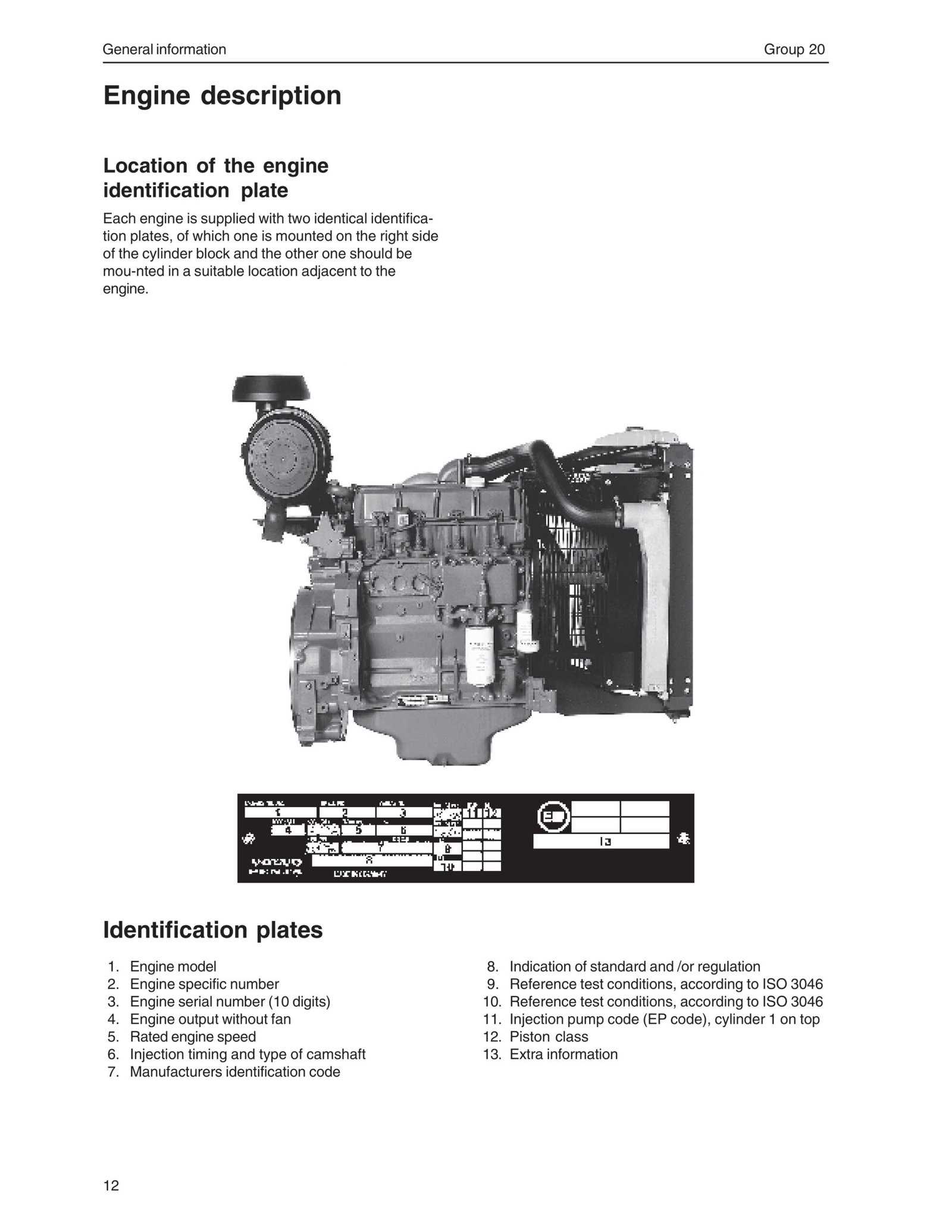

Understanding the 3 Cylinder Design

The architecture of a three-chamber engine is a marvel of engineering, allowing for enhanced efficiency and power delivery. This configuration optimally balances performance with compactness, making it a popular choice in various applications.

In essence, the three-chamber setup promotes smooth operation through its inherent balance. Each chamber contributes to the overall cycle, ensuring that the forces are evenly distributed. This design minimizes vibrations, leading to a more stable performance under load.

Efficiency is a critical factor in this configuration. By maximizing the combustion process within each chamber, these engines achieve impressive fuel consumption rates. The streamlined design facilitates better airflow, promoting effective mixing of air and fuel.

Furthermore, maintenance considerations are simplified due to the compact layout. With fewer components than larger configurations, troubleshooting and servicing become more manageable, ensuring longevity and reliability in operation.

Common Issues and Troubleshooting Tips

When dealing with machinery, several challenges may arise that require attention. Identifying these common problems early can prevent further complications and ensure optimal performance. Below are some frequent issues encountered and practical advice for addressing them.

Typical Problems

- Overheating

- Unusual noises during operation

- Difficulty starting

- Loss of power or efficiency

Troubleshooting Suggestions

- Check Cooling System: Ensure that the coolant levels are adequate and that there are no leaks in the system.

- Inspect Fuel Quality: Use clean, uncontaminated fuel to prevent starting issues.

- Listen for Irregular Sounds: If strange noises are present, investigate the source and check for loose or damaged components.

- Regular Maintenance: Conduct routine checks and servicing to keep the equipment in peak condition.

By being aware of these typical issues and implementing the suggested solutions, operators can maintain smoother functionality and enhance the longevity of their equipment.

Maintenance Procedures for Optimal Performance

To ensure the highest efficiency and longevity of your engine, regular upkeep is essential. Following a systematic approach to care will help maintain optimal functionality and prevent unforeseen issues. Understanding the necessary steps can significantly enhance performance and reliability.

Start by regularly checking and replacing fluids, including engine oil and coolant, to ensure they meet the required specifications. Consistent oil changes are crucial for reducing wear and tear on internal components. Additionally, inspecting and cleaning air and fuel filters will help maintain proper airflow and fuel delivery, leading to improved combustion and efficiency.

Routine examination of belts and hoses for signs of wear is vital. Replacing any damaged or worn parts promptly will prevent further complications. Furthermore, ensuring the proper calibration of the engine’s timing and fuel injection systems will enhance responsiveness and fuel economy.

Lastly, maintaining clean electrical connections and inspecting the battery will ensure reliable starting and operation. Regular maintenance not only contributes to performance but also extends the lifespan of the engine, making it a worthwhile investment in your equipment.

Essential Tools for Repairs

When maintaining machinery, having the right set of instruments is crucial for effective performance and longevity. This section highlights the fundamental tools necessary for conducting various tasks efficiently.

Commonly Used Instruments

A diverse range of instruments facilitates effective maintenance. Below is a selection of commonly utilized tools that can enhance your workflow:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To fasten or remove screws with various head types. |

| Pliers | Useful for gripping, twisting, and cutting wire. |

| Socket Set | For applying torque to nuts and bolts in tight spaces. |

Safety Equipment

Prioritizing safety is paramount during maintenance tasks. Essential protective gear includes gloves, goggles, and ear protection to ensure a safe working environment.

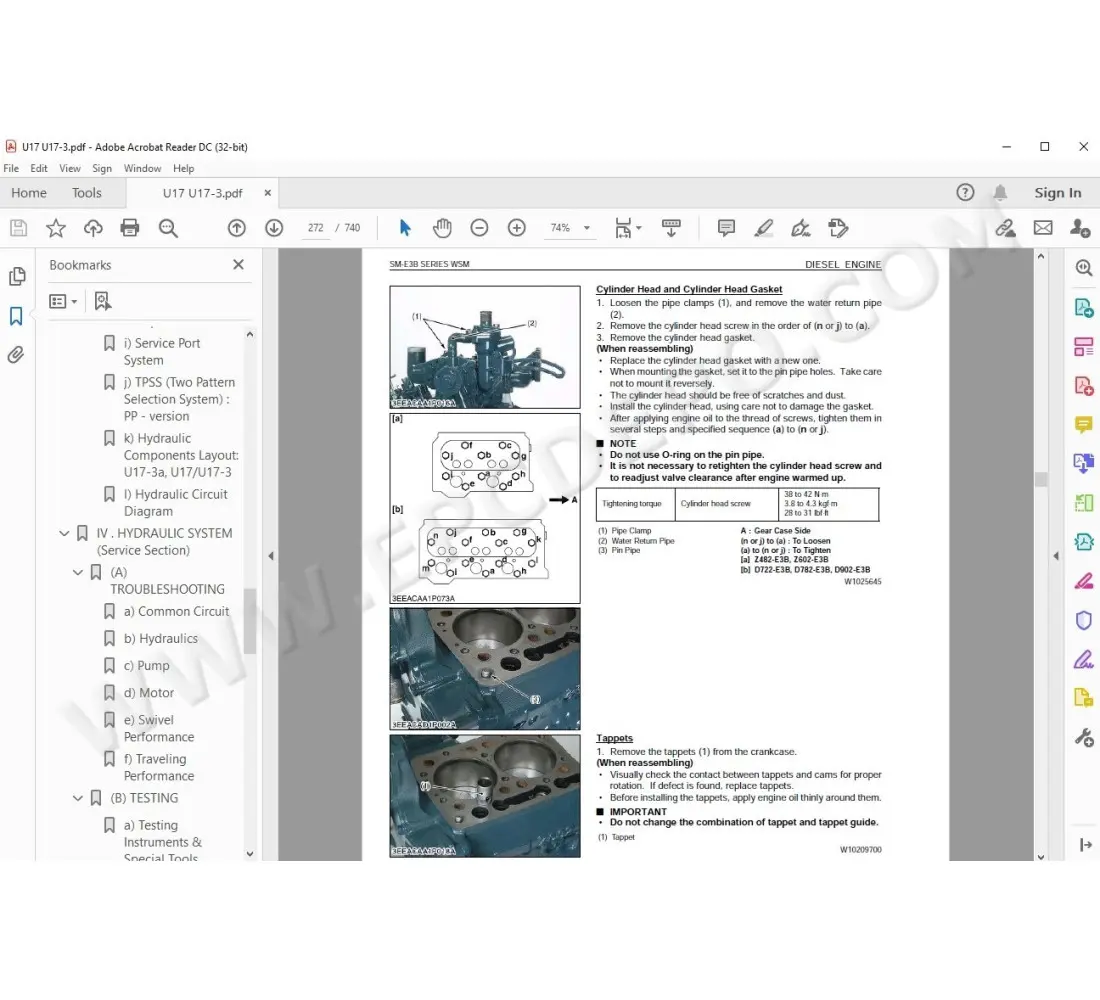

Step-by-Step Repair Guidelines

This section provides a comprehensive approach to troubleshooting and servicing your engine system. By following these detailed instructions, you can effectively address common issues and ensure optimal performance.

1. Initial Assessment: Begin with a thorough examination of the engine. Check for any visible signs of wear, leaks, or damage. Understanding the current state will help in formulating a strategy for the upcoming tasks.

2. Gather Necessary Tools: Before diving into the procedures, assemble all required tools and replacement parts. Having everything at hand will streamline the process and minimize interruptions.

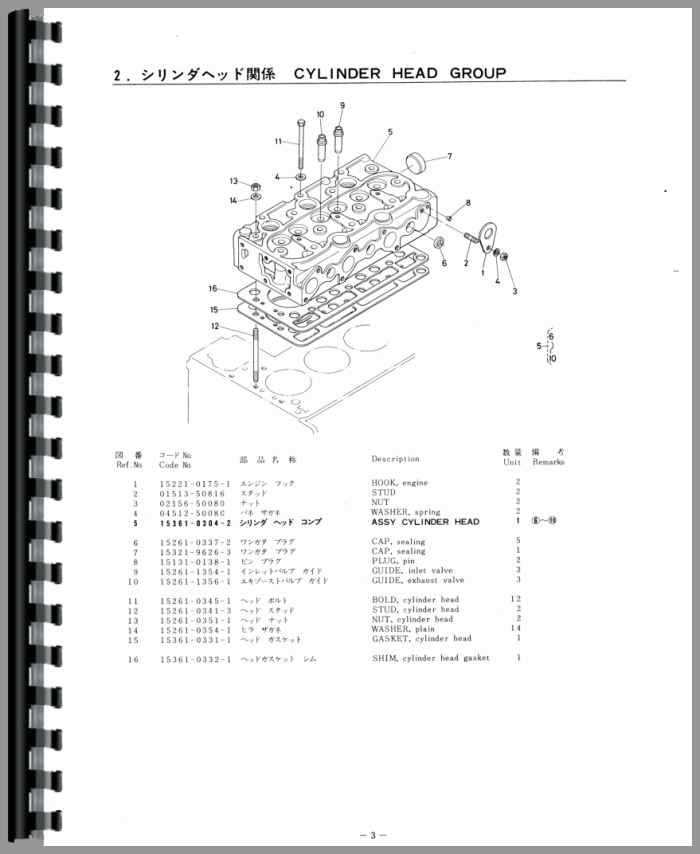

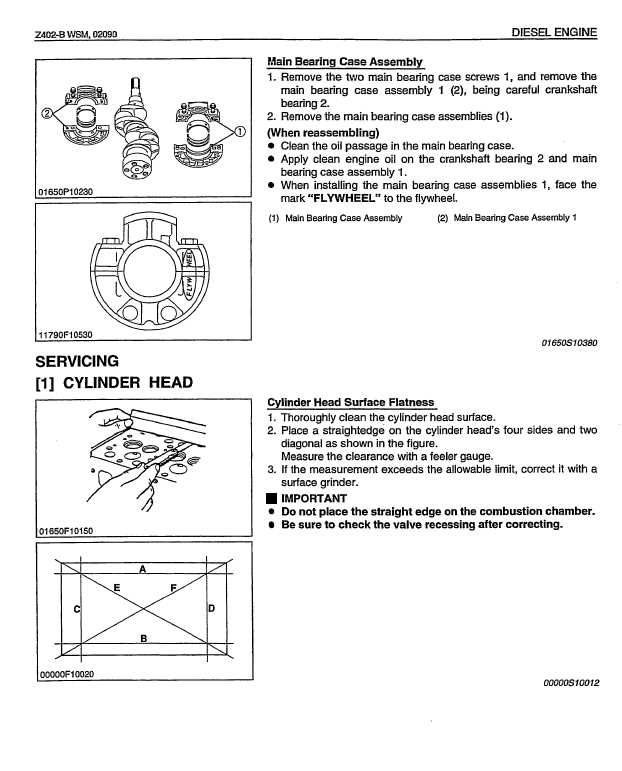

3. Disassembly Process: Carefully remove any components that need attention. Document each step to avoid confusion during reassembly. Take note of the order and orientation of parts.

4. Component Inspection: Once disassembled, inspect each part for defects or excessive wear. Clean components as necessary to maintain functionality and longevity.

5. Replacement and Reassembly: Replace any faulty components with new ones. Follow the documented order from disassembly to ensure everything fits correctly upon reassembly.

6. Final Testing: After reassembly, conduct a series of tests to confirm the system operates as intended. Pay attention to any irregular sounds or performance issues that may arise.

Following these structured guidelines will facilitate a successful service experience, enhancing the reliability of your machinery.

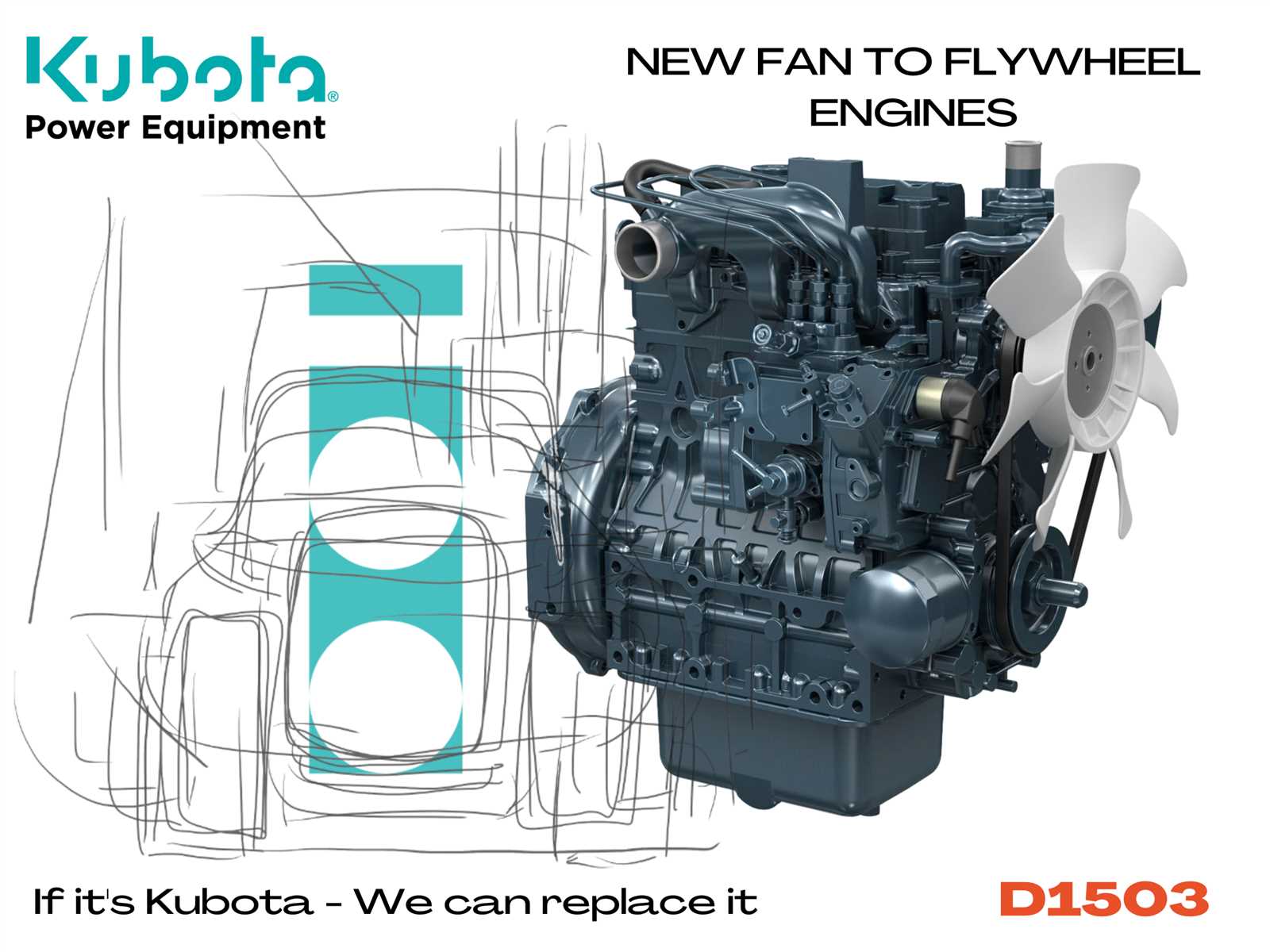

Parts Replacement and Upgrades

Maintaining optimal performance in machinery often involves the timely exchange of components and enhancements. Ensuring that each part is functioning at its best not only prolongs the lifespan of the equipment but also boosts efficiency and reliability.

Identifying Worn Components

Regular inspections are essential for spotting parts that require attention. Look for signs of wear such as leaks, unusual noises, or reduced efficiency. Promptly replacing these elements can prevent more significant issues down the line.

Enhancing Performance

Upgrading specific parts can lead to improved power and fuel efficiency. Consider modern alternatives that offer better durability and performance. Investing in high-quality upgrades can significantly enhance the overall functionality of the machine.

Preventative Measures to Extend Lifespan

To ensure the longevity of machinery, implementing effective strategies is essential. These practices not only enhance performance but also minimize the likelihood of unexpected failures.

Regular Maintenance: Consistent upkeep is crucial. This includes routine checks and timely replacement of worn components. By adhering to a maintenance schedule, potential issues can be identified early, preventing costly breakdowns.

Quality Fluids: Utilizing high-quality lubricants and coolants is vital for optimal operation. These fluids reduce friction and prevent overheating, thereby safeguarding the internal parts from excessive wear.

Operational Awareness: Understanding the limits of the equipment is key. Avoiding overloading and adhering to recommended operational guidelines helps prevent strain, prolonging the life of the machine.

Environment Control: Protecting machinery from harsh environmental conditions can significantly impact its lifespan. Storing equipment in a sheltered area and ensuring proper ventilation can mitigate the effects of moisture and temperature extremes.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, adhering to safety measures is essential to ensure a secure working environment. These guidelines are designed to protect the individual performing the work as well as the equipment itself. Proper preparation and awareness can prevent accidents and enhance the efficiency of the process.

Essential Safety Gear

Before beginning any task, it is vital to equip oneself with the necessary protective equipment. This includes items such as gloves, goggles, and appropriate footwear, which can shield against potential hazards. Ensuring that all gear is in good condition contributes to overall safety.

Work Environment Considerations

A well-organized workspace minimizes risks and enhances productivity. Keeping tools and materials neatly arranged helps avoid accidents. Additionally, ensuring adequate ventilation is crucial when working with substances that may release harmful fumes.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from chemicals and sharp objects |

| Goggles | Shield eyes from debris and harmful substances |

| Steel-toed Boots | Provide foot protection against heavy items |

| Respirator | Filter harmful airborne particles and gases |

Fuel System Management Techniques

Effective administration of fuel systems is crucial for optimal performance and longevity of machinery. By implementing sound practices, operators can enhance efficiency and minimize potential issues related to fuel delivery and consumption.

Key Strategies for Efficiency

Adopting several strategies can significantly impact the functionality of the fuel system. Regular monitoring of fuel quality, timely maintenance, and proper calibration of components are essential practices that help maintain system integrity.

Importance of Quality Control

Ensuring the quality of fuel is vital for preventing contamination and maximizing engine efficiency. Using filtration systems and conducting regular inspections can mitigate the risks associated with impurities in the fuel.

| Technique | Description | Benefits |

|---|---|---|

| Regular Monitoring | Consistent checks on fuel levels and quality. | Improves reliability and performance. |

| Component Calibration | Adjusting components for optimal operation. | Enhances efficiency and reduces waste. |

| Filtration Systems | Using filters to remove impurities. | Prevents damage and extends lifespan. |

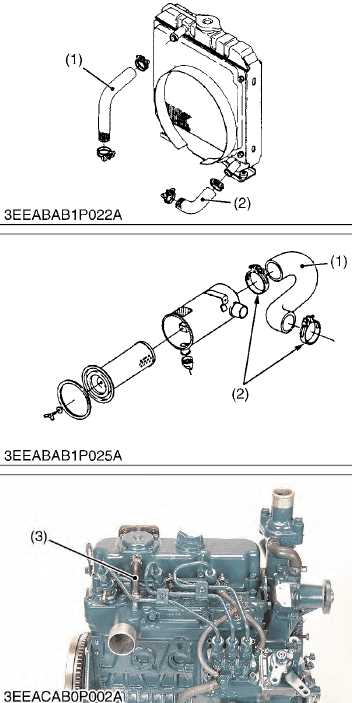

Cooling System Maintenance Essentials

Maintaining the cooling system is crucial for the optimal performance and longevity of an engine. Regular attention to this component helps prevent overheating and ensures efficient operation. Understanding the fundamental aspects of upkeep can significantly enhance reliability and efficiency.

Key maintenance practices include regular checks of coolant levels, inspecting for leaks, and ensuring the radiator is free from obstructions. Each of these steps plays a vital role in the overall health of the cooling system.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Coolant Level | Weekly | Ensure that the coolant is at the recommended level to prevent overheating. |

| Inspect for Leaks | Monthly | Look for any signs of leakage around hoses, connections, and the radiator. |

| Clean Radiator | Seasonally | Remove dirt and debris from the radiator to enhance airflow and cooling efficiency. |

By following these essential practices, one can ensure that the cooling system operates smoothly and effectively, preventing potential engine issues down the line.

Final Thoughts on Engine Care

Maintaining the longevity and efficiency of your power unit is crucial for optimal performance. Regular attention to various components can prevent potential issues and ensure smooth operation. A proactive approach to maintenance not only extends the lifespan of your machinery but also enhances its reliability in demanding conditions.

Key Maintenance Practices

Implementing a structured maintenance routine is essential. Below are fundamental practices to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil to ensure proper lubrication and prevent wear. |

| Filter Inspection | Every 50 hours | Check and replace air and fuel filters as needed to maintain efficiency. |

| Coolant Levels | Monthly | Ensure coolant levels are adequate to prevent overheating. |

Importance of Regular Checks

Consistent monitoring of these practices not only safeguards your equipment but also optimizes its performance. Addressing minor concerns promptly can prevent them from escalating into significant problems, saving time and resources in the long run.